Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

A Comparative Study on Different Types of Solar Dryers

Authors: Swejal Khemariya

DOI Link: https://doi.org/10.22214/ijraset.2023.55725

Certificate: View Certificate

Abstract

In India, 16 % of the total produce that is being wasted every year is horticultural produce. The underlying cause of post-harvest loss in the country is the lack of infrastructure for short-term storage, particularly at the farm level, concentration of cold storage in some states, lack of trained staff to operate cold storage systems, as well as the lack of intermediate processing in the production catchments. In the country, there is a 90% deficit of cold storage facilities. This shortage is compounded by misallocation. The cold storages are concentrated in a few states while vast expanses of the nation are left underserved. The nation’s 60% cold storages are located in just 4 states – Uttar Pradesh, Gujarat, West Bengal and Punjab. Out of the 30.11 million metric tonnes of cold storage facility provided by the 6,300 cold chain warehouses in the country, Tamil Nadu has access to only 0.0239. In India, milk, meat and poultry are prioritized for cold chain transport because they are highly perishable; meaning a lack of temperature-controlled transit would cause a near absence of these products in the market. Consequently, when horticultural produce is shipped, it is often sent in unrefrigerated, overstocked trucks that either rot the food in transit or damage it severely due to poor packaging. Furthermore, the Indian government estimates that 80-90% of the remaining cold storage in the country is used to house potatoes leaving disproportionate hordes of other perishable foods like fresh fruits unguarded. The final outcome is that major part of the produce that is being lost is on farms post-harvest and on the way from farms to the markets. Hence there is an urgent need to conduct primary post-harvest processing and to store the produce on farm until it is being transported to main market. But in the country, major population of farmers is landless and poor. Cold storage being costly and requires high maintenance, farmers cannot afford it for on farm storage. For this reason, a technology which has low initial cost and maintenance is required for processing of farm produce. The necessity for research work in this field was felt to overcome the limitations of cold storage as mentioned above. Solar drying technology is not only economical but also solar energy is abundantly available in India. This technology can be used for 2 purposes :( a) Food processing (b) To save the excess production from deterioration. The crops that are being considered here are peas and tomatoes. These two crops are major horticultural crops of Jabalpur District, Madhya Pradesh. Both these crops have surplus production and post-harvest loss is also high. In Madhya Pradesh there is 1960322 MT and 959533 MT of excess production of tomatoes and peas respectively. Also, 112015 MT peas and 470263 MT tomatoes are lost following harvesting. A comparative is study is conducted on different types of solar dryers. The study is carried out on direct and indirect solar dryers that are further extended to indirect solar dryers with and without latent heat storage. The prime motivation for the study of role of latent heat storage in solar drying is its huge potentiality to store energy and to regulate the drying temperature.

Introduction

I. ACRONYMS AND ABBREVIATIONS

MT Metric Tonne

PCM Phase Change Material

GDP Gross Domestic Product

PCT Phase Change Temperature

TES Thermal Energy Storage

GHG Green House Gases

SHS Sensible Heat Storage

LHS Latent Heat Storage

LHSS Latent Heat Storage System

PEG Polyethylene Glycol

P Total pressure

Pw Partial pressure of water vapor

pow Saturated vapor pressure

H Humidity

M2 Meter Square

oC Degree Celsius

T Temperature

Twb Temperature wet basis

Tdb Temperature dry basis

RH Relative Humidity

Mw Molecular weight of moisture vapor

Mg Molecular weight of dry air (gas)

OSD Open Sun Drying

FPO Farmers Producers Organization

SHG Self Help Group

NGO Non-Governmental organization

PEN Planters Energy Network

SEED Society for Energy Environmental Development

DSD Direct Solar Drying

ISD Indirect Solar Drying

II. PROBLEM STATEMENT

India stands second in the yield of horticultural produce globally. But at the same time, India stands 94 among 107 countries in the Global Hunger Index. India wastes fruits and vegetables worth Rs 13,300 Crore annually. This accounts for approximately 35% of the total horticultural produce. It is estimated that saving the food that is currently lost every year would be enough to feed 194.6 million hungry people in the nation. But due to high water content of fruits and vegetables it cannot be saved without processing. Therefore, post-harvest processing is necessary to prevent the deterioration of the produce. At times, there are facilities and scope for processing but due to failed logistics system, produce cannot be transported to processing plants in time. Hence it becomes vital for the producer/farmer to independently process fruits and vegetables immediately after harvesting.

In India 63% of the total population is involved in agriculture and its allied sector. Out of which 82% is small scale and marginal farmers owning less than 2 hectares of land. However primary sector accounts only for 17.32 percent of the GDP. The large families of marginal farmers are dependent on that small piece of land. Therefore, it becomes crucial to make the major population involved in secondary sector. Hence post-harvest processing should be encouraged among farmers.

Conventional open sun drying has been an integral part of the nation’s tradition and culture. Nevertheless, it leads to the contamination of dried product via insects, birds, dust etc. Moreover, the product thus formed is not uniform in texture, color and taste due to uneven drying. As a consequence of which, the product thus obtained is of inferior quality. For this reason, solar dryers play a vital role in food producing. The structure of solar dryer with transparent covering not only ensures prevention of losses (insects, birds etc) but will also guarantee hygienic and safe food.

But in direct solar dryer (where radiation falls directly on the produce) leads to over drying due to increased temperature. Therefore, an indirect solar dryer (in which the ambient air is heated first with solar energy and in turn air dries the food product) assures upgraded quality of the product.

Since the indirect solar dryer has slight high initial cost, it is required to make it available at affordable for small scale farmers. Also, another limitation is unavailability of sunlight at night time.

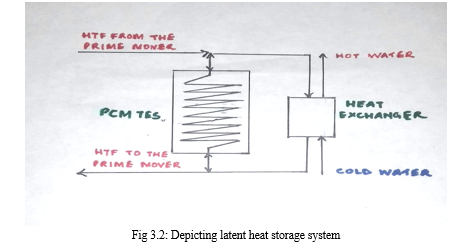

III. JUSTIFICATION

To maintain uninterrupted drying during night hours, latent heat storage system can be introduced in indirect solar dryers. Latent heat storage system will guarantee 5 to 6 additional hours of drying apart from normal sunshine hours. Phase Change Materials (PCMs) like paraffin wax can be used in latent heat storage system. During day time, when drying is carried out at normal optimum temperature. Above optimum temperature, phase change material will liquefy. This is endothermic process where phase change material will absorb heat. At night time, when temperature drops the phase change material will solidify and heat will be released out resulting in temperature rise of air which in turn will dry the produce. This process will save time.

The indirect solar dryers with phase change materials can be made available to small scale farmers via Farmers Producers organizations (FPOs) working in different states. FPOs can set up solar dryers in nearby villages and can ask farmers for crop scheduling. (For instance: Some farmers can sow seeds 5 days ahead of scheduled time, some on planned time and some after the given time.) This way every farmer can go to the FPO and can take advantage of processing units set up by them without over burdening the whole drying system.

IV. INTRODUCTION

India's diverse climate ensures availability of all varieties of fresh fruits & vegetables. It ranks second in fruits and vegetables production in the world, after China. As per National Horticulture Database published by National Horticulture Board, during 2015-16, India produced 90.2 million metric tonnes of fruits and 169.1 million metric tonnes of vegetables. The area under cultivation of fruits stood at 6.3 million hectares while vegetables were cultivated at 10.1 million hectares. But due to perishable nature of horticultural crops, the estimated losses in fruits and vegetables are higher and reached from 30 to 38.1per cent.

Madhya Pradesh is producing about 19.77 m MT of horticulture produce from an area of 20 m ha, and accounts for 7.1% of total horticulture production of the country. The major share of horticulture produce is from vegetables (65.8%) and fruits (28.8%). Madhya Pradesh is the second largest producer of peas and tomatoes with Jabalpur district being the largest producer of peas and 5th largest producer of tomatoes in Madhya Pradesh. The other horticultural crops that are grown in Jabalpur are brinjal, cabbage, cauliflower, okra, onion, potato, mango and some citrus fruits. For the reason that peas have high initial moisture content of 75% and tomatoes being at 92% moisture content, it is necessary to remove the excess moisture by food processing and engineering methods to protect them from post-harvest loss. Also, Jabalpur being surplus in production of peas and to some extent in tomatoes, it is necessary to minimize losses of excessive production.

India being in the equatorial belt, receives abundant radiation energy. It receives 4-7kWh of solar radiation per square meter per day with 250-300 sunny days in a year. The annual global radiation varies from 1600-2200kW/hr. So, there is a good opportunity for tapping solar energy in food processing industry especially for drying and dehydration processes.

V. LITERATURE REVIEW

A detailed study of the available literatures was done in order to understand the subject and to identify the research gap.

The previous works on various types of solar dryers has been reviewed and the details are as follows–

Rabha et al. (2017) investigated the performance of a solar dryer integrated with a latent heat storage unit employing energy and energy analyses. A study was performed on a forced convection solar dryer integrated with a paraffin wax-based shell and tube latent heat storage unit. Twenty kg of red chili was successfully dried in the dryer in four consecutive sunny days. The latent heat storage helped in maintaining higher drying air temperature than the solar air heater outlet temperature. It also reduced the fluctuation in the drying air temperature during cloud cover. The newly developed hybrid dryer saved 122.8% of the drying time of chili in Comparison with the open sun drying. The energy efficiency of the solar air heater increased with increase in the solar radiation intensity. The performance parameters evaluated are Indicative of the feasibility of the intended objective of the development of the integrated solar drying system.

Salve et al. (2016) also developed the compact and portable forced convection solar dryer for drying chilies with thermal energy storage. The developed solar dryer with a phase change material is used for drying food items in the evening and till midnight hours also solar dryer is having capacity of 15kg of perishable food items and it consist of the flat plate collector-based air heating system with thermal energy storage, which used paraffin wax as Phase Change Material (PCM). Result shows that drying of chilies is technically feasible with heat storage Dryer. Temperature in drying chamber was observed 6-9o C higher than the ambient Temperature after sunshine hours. The drying experiment tested with chilies and the complete Drying process completed with 17 hours in solar dryer, for open drying it takes place around 27 hours which was 38 % less. The temperature in drying chamber was observed 6-9 ºC higher than the ambient temperature for at least 6-7 hours.

Agrawal et al. (2014) designed and tested solar dryers with different heat storage material like rock bed heat storage, sand as the heat storage material and PCMs, to minimize the gap between energy supply and energy demand during the non-sunshine hours or night. The results obtained from the above experiments are as follows: drying time is reduced, high quality product is obtained, drying became possible during night time etc.

Shalaby and Bek et al. (2014) experimentally investigated a novel indirect solar dryer design using phase change material (PCM) as energy storage medium. The system consists of two identical solar air heaters, drying compartment, PCM storage units and a blower. It was tested under no load with and without PCM at a wide range of mass flow rates (0.0664 –0.2182 kg/s). It is found that after using the PCM, the temperature of the drying air is higher than ambient temperature by 2.5–7.5 ºC after sunset for five hours at least. In addition, the mass

flow rates of 0.1204 and 0.0894 kg/s give the peak values of the drying temperature when the isd is operated with and without PCM, respectively. The novel design successfully maintains the desired temperature for seven consecutive hours every day. This helps reaching the final moisture content of ocimumbasilicum and thevetianeriifolia after 12 and 18 h respectively.

Palaniappan et al. (2013) focused on the charging and discharging behavior of encapsulated PCM based packed bed thermal storage unit coupled with a solar collector as a source of supplying energy at constant temperature and to extend the duration of operation beyond the sunshine hours at different mass flow rates. The setup consists of a solar air heater, a centrifugal blower to supply hot air to the storage tank, a cylindrical shaped packed bed type PCM thermal storage unit to store the excess thermal energy, and a drier. It was found that at high mass flow rates, the collector efficiency is higher, in addition to the increase in the value of the heat transfer co-efficient. It avoids the overheating of air during the peak sun shine hours, due to the absorption of heat by the phase change material and utilizes the maximum capacity of the

storage system.

Rahima et al. (2012) presented a generous holistic view on different air heating system with and without storage systems and its potential applications. Solar energy is intermittent in nature and time dependent energy source. Owing to this nature, pcms based thermal energy storage system can achieve the more popularity for solar energy-based heating. Energy storage process reduces the rate of mismatch between energy supply and its demand. A detailed research work is accumulated for air heating system without thermal energy storage, latent heat storage-based air heating system and pv/t hybrid air heating systems. It was found that flat plate air heater produces hot air at low temperature and hybrid pv/t type solar air heater shows their viability in force convection type air heating with electricity production. Many investigations reported that PCM based thermal energy storage solar heater is suitable for crop drying applications.

Tunde et al. (2011) studied the drying characteristics of chili pepper by sun and solar drying and developed a mathematical model for describing the thin-layer drying process for the sun and solar drying of chili pepper. Chili pepper was pretreated by water and steam blanching and by soaking in osmotic solutions of 60 and 700 brix. Untreated chili pepper was taken as a control. The pretreated chili pepper dried faster than untreated chili pepper while the drying of both samples occurred in falling rate period. Four thin-layer drying models (newton, Henderson and pabis, logarithmic and page) were fitted to the experimental data to select a suitable drying equation. The page model was found to best describe the drying behavior of chili

Pepper for sun and solar drying.

Satya et al. (2011) attempted to summarize the investigation of the solar drying system Incorporated with phase change materials (PCMs) for drying agricultural food products.

Because of discrepancy between the energy supply and demand in solar heating applications, thermal energy storage (TES) device has to be used for the most effective utilization of the energy source. this concept of ‘solar thermal energy storage using PCM in the solar dryer’ reduces the time between energy supply and energy demand, thereby playing a vital role in energy conservation and improves the solar drying energy system so by smoothening the output and thus increasing the reliability for continuous drying of agricultural food products.

VI. THERMAL ENERGY STORAGE SYSTEMS

Thermal energy storage (TES) refers to the technology that allows the transfer and storage of heat energy or, alternatively, energy from ice or cold air or water. This method is built into new technologies that complement energy solutions such as solar and hydro. It is a technology that stocks thermal energy by heating or cooling a storage medium, so that the stored energy can be used later, either for heating and cooling applications or for power generation.

A. Features Of Thermal Energy Storage Systems

- TES systems can help balance energy demand and supply on a daily, weekly and even seasonal basis.

- They can also reduce peak demand, energy consumption, emissions and costs, while increasing overall system efficiency.

- The conversion and storage of solar and wind energy helps to further increase the share of renewable in the energy mix.

- TES is becoming particularly important for electricity storage in combination with concentrating solar power (CSP), whereby solar heat can be stored for electricity production when sunlight is not available.

B, Advantages Of TES Systems

- Reduction of energy consumption.

- Increase of energy efficiency.

- Increased energy security.

- Increased energy reliability.

- Reduction of energy costs.

- Reduce GHG emissions

C. Types Of Thermal Energy Storage Systems

It is classified into 3 categories as follows:

- Thermo Chemical Heat Storage Systems

Thermo chemical energy storage can be considered an energy-efficient approach that offers a wide opportunity for conserving primary energy sources as well as reducing greenhouse gas emissions. When compared to sensible heat and latent heat storage, thermo chemical energy storage can yield the highest heat storage capacity without producing any thermal losses during the storage period. The working pairs of materials incorporated in thermo chemical energy storage system including silica gel/water, magnesium sulfate/water, lithium bromide/water, lithium chloride/water, and NaOH/water have been considered the most prominent materials for achieving increased heat storage capacity.

By using the high porous structured carrier materials dispersed with the reactive material inside, the heat and mass transfer processes can be improved. Besides, the incorporation of chemical heat pumps working on the principles of chemical sorption processes can help acquire enhanced heat storage capacity even at very high temperatures, where the conventional heat pump does not need to be suited for the desired purpose. However, the thermo chemical energy storage if blended with long-term seasonal TES techniques can still result in enhanced thermal performance of the storage system without sacrificing energy efficiency and environmental sustainability.

.

2. Sensible Heat Storage Systems

Sensible heat storage (SHS) is the most straightforward method. It simply means the temperature of some medium is either increased or decreased. This type of storage is the most commercially available out of the three, as the others are still being researched and developed Sensible heat storage materials undergo no change in phase over the temperature range encountered in the storage process, and store thermal energy by sensible heat in solid or liquid materials Solid materials, like concrete and cast able ceramics have low price and good thermal conductivities. Concerning liquid materials, a variety of fluids have been tested to transport the heat, including water, air, oil, and sodium, before molten salts were selected as best. Water remains the most widely used material in sensible heat storage systems with best compromise between cost, heat storage capacity, density and environmental impact

3. Latent Heat Storage System

In this system, the material stores heat while changing phase. As it stores energy at constant temperature, this increases the scope for the application of LHSS. Because Latent Heat Storage (LHS) is associated with a phase transition, the general term for the associated media is Phase-Change Material (PCM). During these transitions, heat can be added or extracted without affecting the material’s temperature, giving it an advantage over SHS-technologies. Storage capacities are often higher as well.

D. Phase Change Materials

Is a substance which releases/absorbs sufficient energy at phase transition to provide useful heat/cooling. Generally, the transition will be from one of the first two fundamental states of matter - solid and liquid - to the other. The phase transition may also be between non-classical states of matter, such as the conformity of crystals, where the material goes from conforming to one crystalline structure to conforming to another, which may be a higher or lower energy state.

By melting and solidifying at the phase change temperature (PCT), a PCM is capable of storing and releasing large amounts of energy compared to sensible heat storage. Heat is absorbed or released when the material changes from solid to liquid and vice versa or when the internal structure of the material changes; PCMs are accordingly referred to as latent heat storage (LHS) materials.

VII. CLASSIFICATION OF PCMs

It is classified into 3 types

- Organic

- Inorganic

- Eutectics

A. Organic PCM

Organic PCMs include paraffin’s, fatty acids and polyethylene glycol (PEG). They present a congruent phase change, they are not dangerous, and they have a good nucleation rate.

- Advantages

a. Freeze without much super cooling

b. Ability to melt congruently

c. Self-nucleating properties

d. Compatibility with conventional material of construction

e. No segregation

f. Chemically stable

g. Safe and non-reactive

2. Disadvantages

Low thermal conductivity in their solid state. High heat transfer rates are required during the freezing cycle. Nano composites were found to yield an effective thermal conductivity increase up to 216%

a. Volumetric latent heat storage capacity can be low.

b. Flammable

Organic phase change is further classified as paraffin and non-paraffin compounds

- Paraffin based compounds- These are the most common PCMs. Paraffin is usually a mixture of straight chain n- alkanes.

- Non-Paraffin compounds- They are most widely used families of PCMs. In addition to their different properties compared to paraffin, they have very similar property to each other. Researchers have used various types of ethers, alcohol and glycol as TES materials.

B. Inorganic PCMs

They have mainly high capacity for TES (about twice as much as organic PCMs) as well as higher thermal conductivity. Inorganic PCMs are salt hydrates (MnH2O), nitrates, and metallic having a rather high heat of fusion.

- Advantages

a. High volumetric latent heat storage capacity.

b. Availability and low cost

c. Sharp melting point

d. High thermal conductivity

e. High heat of fusion

f. Non flammable

2. Disadvantages

a. Difficult to prevent incongruous melting and phase separation upon cycling, which can cause a significant loss in latent heat enthalpy.

b. Change of volume is very high in some mixtures.

c. Super cooling can be a problem in solid liquid transition.

d. Corrosive to many other materials, such as metals. This can be overcome by encapsulation in small quantities in non-reactive plastic.

Inorganic phase change materials can be further classified as salt hydrates and metallic.

- Salt Hydrates: It may be regarded as alloys of inorganic salts and water forming a typical crystalline solid of general formula M.NH20. The solid liquid transformation of salt hydrates is actually a dehydration of hydration of salt, although this process resembles melting or freezing thermodynamically. At the melting point the hydrate crystals break up into anhydrous salt and water, or into lower hydrate and water.

- Metallic: It includes the low melting metals and metal eutectics. Because of its weight metallic are not of prime importance. However, when volume is consideration, they are likely candidates because of high heat of fusion per unit volume,

C. Eutectics

A eutectic contains at least 2 types of phase change materials. They have exceptional properties. In eutectics, the melting solidification temperatures are generally lower than the constituents and do not separate into composition through the phase change. Therefore, phase separation and super cooling phenomena are not observed in these materials. Eutectics typically have a high thermal cycle than salt hydrates. Inorganic-inorganic eutectics are most commonly used. However, in recent studies, organic-inorganic and organic-organic varieties have received more attention.

- Selection Criteria of PCMs

a. Melting temperature in the desired operating temperature range

b. High latent heat of fusion per unit volume

c. High specific heat, high density, and high thermal conductivity

d. Small volume changes on phase transformation and small vapor pressure at operating temperatures to reduce the containment problem

e. Congruent melting

f. Kinetic properties

g. High nucleation rate to avoid super cooling of the liquid phase

h. High rate of crystal growth, so that the system can meet demands of heat recovery from the storage system

i. Chemical properties

j. Chemical stability

k. Complete reversible freeze/melt cycle

l. No degradation after a large number of freeze/melt cycle

m. Non-corrosiveness, non-toxic, non-flammable and non-explosive materials

n. Economic properties

o. Low cost

p. Availability

VIII. THEORETICAL BACKGROUND

A. Principle of Drying

Drying is one of the oldest methods of fruits and vegetables preservation. It is currently a versatile and widespread technique in the food industry as well as subject of continuous interest in food research. Drying is a critical step in the processing of dehydrated products because of the high energy requirement of the process (due to low thermal efficiency of dryers). The main aim of drying fruits and vegetables is the removal of moisture up to certain level at which microbial spoilage and deterioration chemical reactions are greatly minimized. In addition to preservation, the reduced weight and bulk of dehydrated products decreases packaging, handling, and transportation costs. Furthermore, most food products are dried for improved milling or mixing characteristics in further processing. In contrast, with literally hundreds of variants actually used in drying of particulates, solids, pastes, slurries, or solutions, it provides the most diversity among food engineering unit operations. Currently, dehydrated fruits, vegetables, grains and spices command considerable importance in the Indian and international market. These dehydrated products are the single largest import item in Europe and United States both in quantity and value items, as these products are used by every home, canteen, cafeteria, restaurant and other institutional food establishment .At present, instant beverage powders, dry soup mixes, spices, coffee, and ingredients used in food transformation are the major food products that are dehydrated. Also in India, dehydrated products are required for armed forces. In India, generally the agricultural production exceeds the requirement. Due to lack of proper post-harvest management and storage facility for agricultural products, a considerable percentage of it produced goes as waste. Therefore, India needs processing of agro produce to convert them into stable products so as to minimize losses due to waste during the post-harvest phase. Fresh agricultural product is a perishable commodity in tropical countries as higher temperature causes it to wilt and gives a poor appearance. Therefore, the refrigeration and controlled atmosphere storage have been used to increase their storability. The shelf life of agricultural products can also be enhanced by drying. These products are generally dried by hot air. Sun drying is the most common method to preserve the agricultural products in most of tropical countries. However, this technique is extremely weather dependent and has the problems of contamination with dust, soil, sand particles and insects. Also, the required drying time can be quite long. Therefore, mechanical dryers, which are rapid, providing uniformity in drying and hygiene, are inevitable for industrial food drying processes. Agricultural material are dried by several methods like sun drying, hot air drying, fluidized bed drying, heat pump drying, freeze drying, microwave hot air/vacuum drying, vacuum drying and hybrid drying. For improving quality of dehydrated products the pretreatments like osmotic dehydration, blanching, dipping in chemical solutions and microwave heating are common.

In short the main objectives of drying are:

- Extended Storage Life

- Quality Enhancement

- Ease of Handling

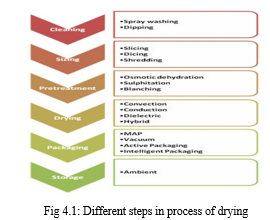

- Further Processing

The drying requires different processing operations of the product. These operations are based on the product requirement. The Figure 4.1 shows steps to be carried in drying operation.

B. Theory of Drying

As most of drying operations require air to remove moisture from the product, it is necessary to know the some important properties of air related to drying. These properties are used to estimate the drying rate of the product. The properties of air water vapor mixture are also known as psychometric properties of air.

There are three inter-related factors that control the capacity of air to remove moisture from a food:

- The amount of water vapor already carried by the air

- The air temperature

- The amount of air that passes over the food.

Fundamental properties of water vapor and air mixtures related to drying

The most important psychometric properties of air are as follows:

a. Relative Humidity (RH): The relative humidity is a measure of moisture saturation. It is defined as the ratio of the partial pressure of water vapor in a gaseous mixture with air to the saturated vapor pressure of water at a given temperature. The relative humidity is expressed as a percentage.

b. Dry Bulb Temperature (Tdb ): It is the temperature of the air as measured by a thermometer freely exposed to the air but shielded from radiation and moisture.

c. Wet bulb Temperature (Twb ): It is measured by a gas passing rapidly over a wet thermometer bulb. It is used along with dry bulb temperature to measure the relative humidity of a gas.

d. Dew point Temperature: It is the temperature at which air becomes saturated with moisture (100%RH) and any further cooling from this point results in condensation of the water from the air.

C. Classification Of Moisture Content In Food Matrix

a. Bound Moisture: Bound moisture is the amount of water tightly bound to the food matrix, mainly by physical adsorption on active sites of hydrophilic macromolecular materials such as proteins and polysaccharides, with properties significantly different from those of bulk water.

b. Free Moisture Content: Free moisture content is the amount of water mechanically entrapped in the void spaces of the system. Free water is not in the same thermodynamic state as liquid water because energy is required to overcome the capillary forces. Furthermore, free water may contain chemicals, especially dissolved sugars, acids, and salts, altering the drying characteristics. An important term in drying is the equilibrium moisture content, which is the moisture content of a product in equilibrium with the surrounding air at given temperature and humidity conditions. Theoretically, it is the minimum moisture content to which a material can be dried under these conditions

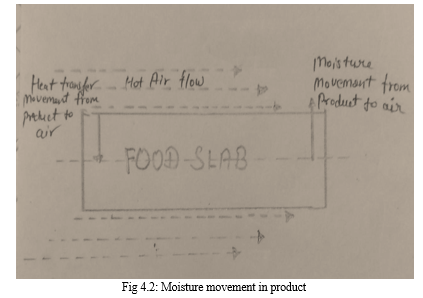

3. Moisture Migration During Drying: Water migration in foods is an important phenomenon in drying. During drying heat flows over the product and goes in to the product. This heat increases the temperature of product and moisture which converts the moisture in to water vapor which results in to increase in the vapor pressure that moves moisture towards the surface. From the surface, the moisture moves in to the environment. To make easy movement of moisture from product surface to environment there should not be any resistance. The resistance is generally arrived if there is more moisture in the air (which is related to relative humidity of air). Therefore, it is always necessary to use the drying air having low relative humidity. For this purpose, most commonly used convection drying method uses the hot air having temperature in the range 50° to 90°C. Due to increase in the air temperature relative humidity decreases which helps to remove the moisture from the product rapidly and high temperature of air transfers heat to product to evaporate the moisture within the product Also, it can be understood as a driving force for drying. It is defined as the difference in partial pressure of water vapor in the air and the pressure of the moisture in the product. This is a simple theory of moisture movement during drying. Actually the drying is very complicated phenomenon. Moisture in foods is subdivided into ionic groups, such as carboxyl and amino acids; hydrogen groups, such as hydroxyl and amides and unbound free moisture in interstitial pores and intercellular spaces.

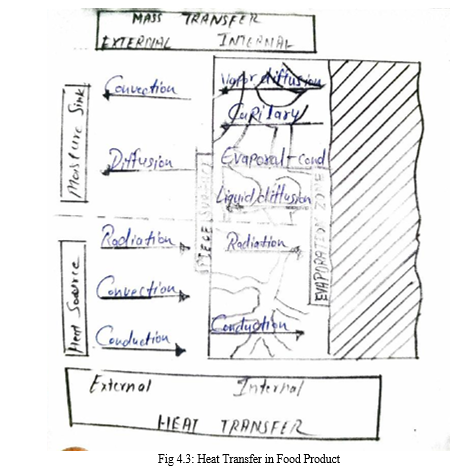

4. Therefore, the moisture movement within product (internal mass transfer) takes place by combination of several phenomenon like vapor diffusion, liquid diffusion, pressure diffusion, capillary movement, flow by evaporation – condensation sequence and gravity flow. Internal mass transfer is generally recognized to be the principal rate-limiting step during drying. After the moisture reaches the surface of the product it can be removed by convection and diffusion in to the atmosphere (external mass transfer). Therefore diffusion is one of the most important transport phenomenon in the drying and dehydration. While drying takes, the heat transfer also takes place in the product either by conduction, convection or radiation as shown in the figure below

D. Mechanism Of Drying

Drying basically comprises of two fundamental and simultaneous processes:

- Heat is transferred to evaporate liquid

- Mass is transferred as a liquid or vapor within the solid and as a vapor from the surface.

The factors governing the rates of these processes determine the drying rate. The different dryers may utilize heat transfer by convection, conduction, radiation, or a combination of these. However in almost all solar dryers and other conventional dryers heat must flow to the outer surface first and then into the interior of the solid, with exception for dielectric and microwave drying.

- Internal Mechanism of Liquid Flow

The movement of moisture within the solid result from a concentration gradient which is dependent on the characteristics of the solid that may be porous or nonporous. Thus the structure of the solid determines the mechanism for which internal liquid flow may occur and these mechanisms can include:

a. Diffusion in continuous, homogeneous solids,

b. Capillary flow in granular and porous solids,

c. Flow caused by shrinkage and pressure gradients,

d. Flow caused by gravity, and

e. Flow caused by a vaporization-condensation sequence.

In general, one mechanism predominates at any given time in a solid during drying, but it is not uncommon to find different mechanisms predominating at different times during the drying cycle. In the plots shown in figure, the curves indicate that capillary flow is typified by a moisture gradient involving a double curvature and point of inflection while diffusional flow is a smooth curve, concave downwards. They also showed that the liquid diffusion coefficient is usually a function of moisture content which decreases with decreasing moisture

E. Periods of Drying

- Constant-Rate Period

In the constant rate period moisture movement within the solid is rapid enough to maintain a saturated condition at the surface, and the rate of drying is controlled by the rate of heat transferred to the evaporating surface. Drying proceeds by diffusion of vapor from the saturated surface of the material across a stagnant air film into the environment and as the rate of mass transfer balances heat transfer, the temperature of saturated surface remains constant. If the heat supplied for drying is solely by convection, the surface temperature approaches the boiling point temperature rather than the wet bulb temperature. This mode of heat transfer is typically seen in indirect dryers. Radiation is an effective mode of heat transfer as it increases the constant rate by augmenting the convection heat transfer and raising the surface temperature above the wet bulb temperature.

The magnitude of the constant rate depends upon three factors:

- The heat or mass transfer coefficient

- The area exposed to the drying medium

- The difference in temperature or humidity between the gas stream and the wet surface of the solid.

All these factors are the external variables. The internal mechanism of liquid flow does not affect the constant rate.

2. Falling-Rate Period

The falling?rate period begins at the critical moisture content when the constant rate period ends. This is generally divided into two zones viz.

- The zone of unsaturated surface drying and

- The zone where internal moisture movement controls.

In the first zone, the entire evaporating surface can no longer be maintained and saturated by moisture movement within the solid. The drying rate decreases from the unsaturated portion, and hence the rate for the total surface decreases. Generally, the drying rate depends on factors affecting the diffusion of moisture away from the evaporating surface and those affecting the rate of internal moisture movement. As drying proceeds, the point is reached where the evaporating surface is unsaturated. The point of evaporation moves into the solid, and the dry process enters the second falling rate period. The drying rate is now governed by the rate of internal moisture movement; the influence of external variables diminishes. This period usually predominates in determining the overall drying time to lower moisture content.

F. Equilibrium Moisture Content

A wet solid exposed to a continuous supply of fresh gas continues to lose moisture until the vapor pressure of the moisture in the solid is equal to the partial pressure of the vapor in the gas. The solid and gas are then said to be in equilibrium, and the moisture content of the solid is called the equilibrium moisture content under the prevailing conditions. Further exposure to this air for indefinitely long periods will not bring about any additional loss of moisture. The moisture content in the solid could be reduced further by exposing it to air of lower relative humidity. This means that moisture desorption from the product is in dynamic equilibrium with the absorption of the environmental air moisture contain. Relative humidity at this point is known as the “equilibrium relative humidity”, and is characterized by the curves of moisture content plots against equilibrium humidity known as moisture equilibrium isotherms.

G. Working Principle Of Sun Dryers

Solar energy dryers can broadly be classified into direct, indirect and hybrid solar dryers. The working principle of these dryers mainly depends upon the method of solar energy collection and its conversion to useful thermal energy for drying.

- Open Sun Drying (OSD)

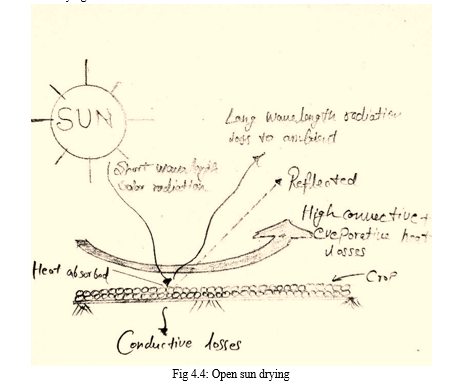

Figure shows the working principle of open sun drying by using only the solar energy. The crops are generally spread on the ground, mat, cement floor where they receive short wavelength solar energy during a major part of the day and also natural air circulation. A part of the energy is reflected back and the remaining is absorbed by the surface depending upon the color of the crops. The absorbed radiation is converted into thermal energy and the temperature of the material starts to increase. However there are losses like the long wavelength radiation loss from the surface of crop to ambient air through moist air and also convective heat loss due to the blowing wind through moist air over the crop surface. The process is independent of any other source of energy except sunlight and hence the cheapest method however has a number of limitations as discussed in section. In general, the open sun drying method does not fulfill the required quality standards and sometimes the products cannot be sold in the international market. With the awareness of inadequacies involved in open sun drying, a more scientific method of solar energy utilization for crop drying has emerged termed as solar drying

2. Direct Solar Drying (DSD)

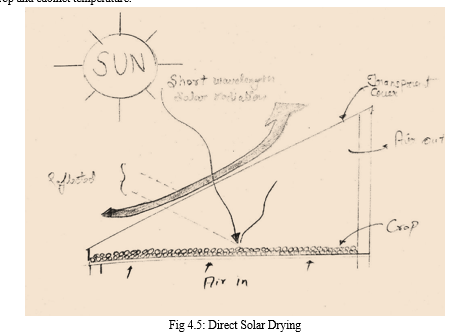

The working principle of direct solar crop drying is shown in figure, also known as a solar cabinet dryer. Here the moisture is taken away by the air entering into the cabinet from below and escaping through at the top exit as shown in figure. In the cabinet dryer, of the total solar radiation impinging on the glass cover, a part is reflected back to atmosphere and the remaining is transmitted inside the cabinet. A part of the transmitted radiation is then reflected back from the crop surface and the rest is absorbed by the surface of the crop which causes its temperature to increase and thereby emit long wavelength radiations which are not allowed to escape to atmosphere due to the glass cover. The overall phenomena cause the temperature above the crop inside the cabinet to be higher. The glass cover in the cabinet dryer thus serves in reducing direct convective losses to the ambient which plays an important role in increasing the crop and cabinet temperature.

The advantages of solar drying over open sun drying are as follows:

a. Simpler and cheaper to construct than the indirect type for the same loading capacity.

b. Offer protection from rains, dews, debris etc.

A cabinet dryer has the following limitation:

- Liability to overheat locally, causing crop damage.

- Poor vapor removal rates leading to relatively slow overall drying rates

- Small capacity limits it to small scale applications.

- Discoloration of crop due to direct exposure to solar radiation.

- Moisture condensation inside glass covers reduces its transitivity.

- Insufficient rise in crop temperature affects moisture removes.

3. Indirect Solar Drying (ISD)

These differ from direct dryers with respect to heat transfer and vapor removal. Figure describes the working principle of indirect solar drying. The crops in these indirect solar dryers are located in trays or shelves inside an opaque drying cabinet and a separate unit termed as solar collector is used for heating of the entering air into the cabinet. The heated air is allowed to flow through/over the wet crop that provides the heat for moisture evaporation by convective heat transfer between the hot air and the wet crop. Drying takes place due to the difference in moisture concentration between the drying air and the air in the vicinity of crop surface.

The advantages of indirect solar drying are:

a. Offers a better control over drying and the product obtained is of better quality than sun drying.

b. Caramelisation and localized heat damage do not occur as the crops are protected and opaque to direct radiation.

c. Can be operated at higher temperature, recommended for deep layer drying.

d. Highly recommended for photo sensitive crops.

e. Have inherent tendency towards greater efficiency than direct solar drying.

They are, however, relatively elaborate structures requiring more capital investment in equipment and incur larger maintenance costs than the direct drying units.

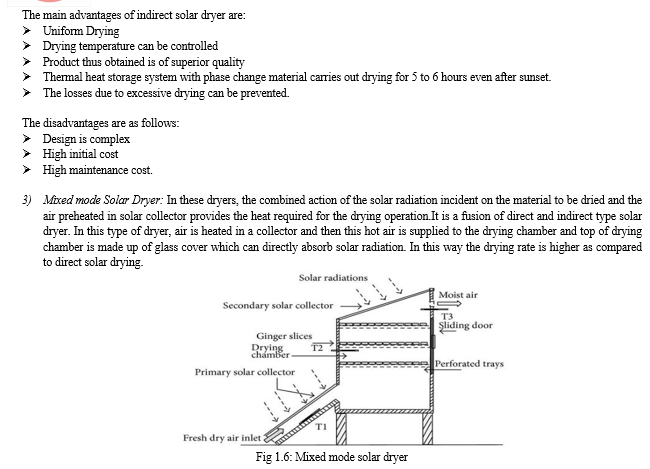

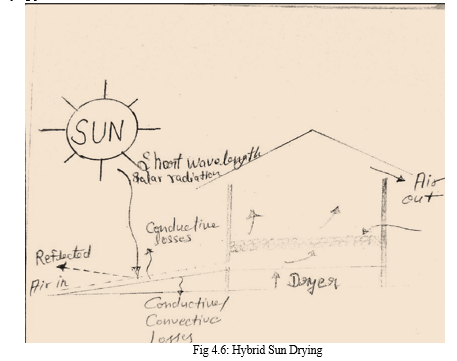

4. Hybrid Solar Drying (HBD)

The hybrid solar dryers combine the features of the direct and indirect type solar energy dryers. Here the combined action of incident direct solar radiation on the product to be dried and air pre heated in a solar collector heater produces the necessary heat required for the drying process.

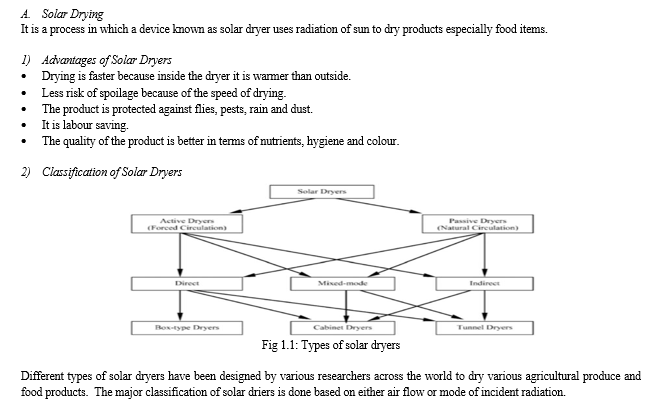

IX. CLASSIFICATION OF SOLAR DRYERS

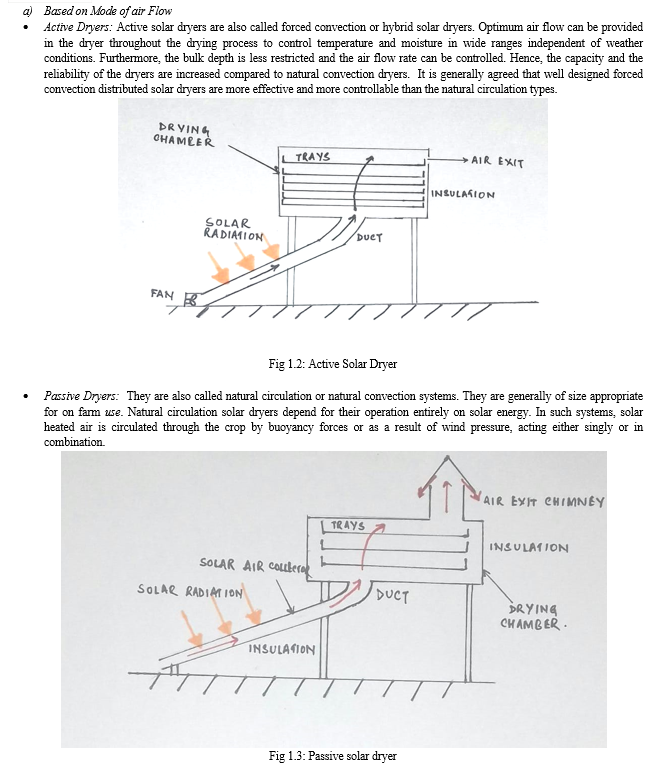

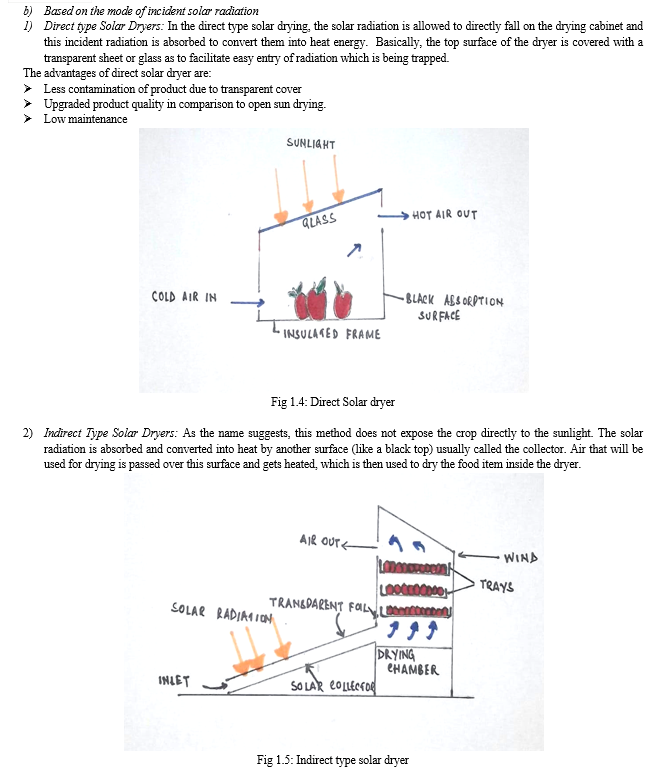

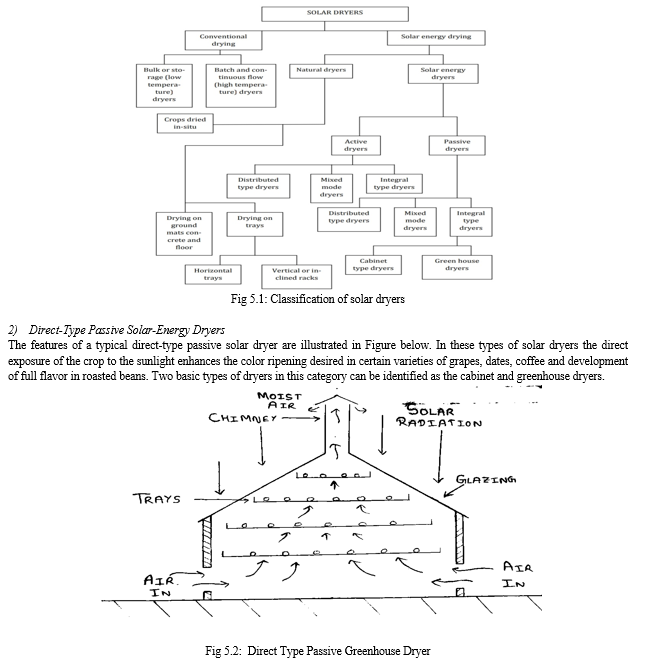

On the basis of the mode of drying, e.g. direct or indirect, solar dryers may be classified as passive and active ones: (a) Passive dryers, where crops are dried by direct impingement from the sun’s radiation with or without natural air circulation, and (b) Active solar dryers, where hot drying air is circulated by means of a ventilator (forced convection).

A. Passive Solar Drying Systems

In a passive solar dryer, air is heated and circulated naturally by buoyancy force or as a result of wind pressure or in combination of both. Normal and reverse absorber cabinet dryer and greenhouse dryer operates in passive mode. Passive drying of crops is still in common practice in many Mediterranean, tropical and subtropical regions especially in Africa and Asia or in small agricultural communities. These are primitive, inexpensive in construction with locally available materials, easy to install and to operate especially at sites far off from electrical grid. The passive dryers are best suited for drying small batches of fruits and vegetables such as banana, pineapple, mango, potato, carrots etc.

1) Indirect-Type Passive Solar-Energy Dryers

These are indirect?type dryers with natural convection of air for drying. In order to increase the capacity of a dryer i.e. operate with more than one layer of trays with crops within the available area, the trays are generally placed in vertical racks with some space in between consecutive trays. The additional resistance generated for the air movement due to this arrangement of the

Trays is achieved by the “chimney effect”. The chimney effect increases the vertical flow of air as a result of the density difference of the air in the cabinet and atmosphere. A typical indirect passive solar energy dryer used for crop drying are shown in figure. The designs generally comprise of an air heating solar energy collector, an insulated ducting, a drying chamber and a chimney.

a. Solar Cabinet Dryers

The passive solar cabinet dryers are generally simple and inexpensive units having high applications for domestic purposes. They are suitable for drying of agricultural products, spices and herbs etc., constructed normally with a drying area of 1?2 m2 and capacities of 10?20 kg. Figure shows a typical passive solar cabinet dryer. The heat for drying is transmitted through the glass cover and is absorbed on the blackened interior and crops as well. The required air circulation is maintained by the warm moist air leaving via the upper vent under the action of buoyancy forces and generating suction of fresh air from the base inlet. Pioneering works on solar cabinet dryers were reported by the Brace Research Institute, (1980).

A number of other designs of passive solar cabinet dryer in configuration to that developed by Brace Research Institute have been built and tested for a variety of crops and locations. The passive solar cabinet dryer have an advantage of being cheap and easy in construction from locally available material, however their major drawback is poor moist removal rates and very high temperature (70-100o) causing overheating of the product.

b. Natural-Circulation Greenhouse Dryers

These are also called as tent dryers and are basically modified greenhouses. They are designed with vents of appropriate size and position to have a controlled air flow. They are characterized by extensive glazing by the transparent cover of polyethylene sheet. Figure shows the earliest form of passive solar greenhouse dryer with slanted glass roof, allowing direct solar radiation over the product. The length wise north?south alignment of the dryer had black coated internals for improved absorption of solar radiation with the ridge cap over the roof for exit vent. A black poly?ethylene sheet was also spread on the floor inside the tent to enhance the absorption of solar radiation. The air flow into the tent was controlled by rolling/ unrolling of the cladding at the bottom edge of front side and the vents at the top served as the exit for the moist exhaust air.

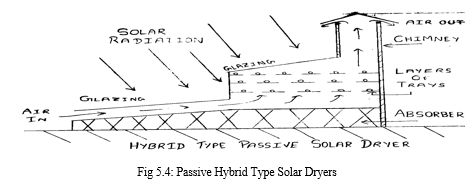

3) Hybrid-Type Passive Solar-Energy Dryers

A hybrid type passive solar energy dryer would have the same typical structural features as the indirect type and direct type (i.e. a solar air heater, a separate drying chamber and a chimney), and in addition has glazed walls inside the drying chamber so that the solar radiation impinges directly on the product as in the direct type dryers. Exell et. al. (1980), Sodha et al. (1987), at Asian Institute of Technology developed the widely reported solar rice dryer. Ayensu and Asiedu (1986) designed the hybrid dryer consisting of an air heater with a pile of granite functioning as an absorber cum heat storage. The multi stacked design enables the simultaneous drying of a variety of crops.

B. Active Solar Drying Systems

Active solar drying systems are designed incorporating external means, like fans or pumps, for moving the solar energy in the form of heated air from the collector area to the drying beds. Thus all active solar dryer are, by their application, forced convection dryer. A typical active solar dryer depends on solar energy only for the heat source, while for air circulation uses motorized fans or ventilator. These dryers find major applications in large scale commercial drying operations in combination with conventional fossil fuel to have a better control over drying by consolidating the effect of fluctuations of the solar insulation on the drying air temperature. Active solar dryers are known to be suitable for drying higher moisture content foodstuffs such as papaya, kiwi fruits, brinjal, cabbage and cauliflower slices. A variety of active solar energy dryers exist which could be classified into either the direct type, indirect type or hybrid dryers.

- Indirect-Type Active Solar Drying Systems

These active dryers as discussed for indirect dryer in section have a separate collector and drying unit. They are generally comprised of four basic components viz., a solar air heater, drying chamber, a fan for air circulation and ducting. Due to the separate air heating unit higher temperatures can easily be obtained with a control on air flow rate. However as the efficiency of collector decreases at higher temperature operation, an optimum temperature and airflow rate has to be determined to have a cost effective design. While most solar collectors are made up of metal or wood absorbers with appropriate coatings, materials like black polythene are also used as they form an economic substitute. Figure shows a typical indirect type active solar dryer. A few designs also employ the recirculation of drying air that ensures low exhaust air temperature and thereby efficient use of energy. Figure illustrates a system employing partial air recirculation, in a polyethylene tube solar collector. The efficiency of the indirect type active solar dryer also depends on the location of the fan, though not so significantly in small batches. The prime objective of the fan is to maintain a desired flow rate in the drying cabinet causing uniform evaporation of moisture from the wet material and in the collector is the collection of heat maintaining a negative pressure, reducing the heat losses.

2. Direct-Type Active Solar-Energy Drying Systems

The direct type active solar dryers are designed with an integrated solar energy collection unit. Generally, three distinct designs of direct type active solar dryers can be identified viz., the absorption type, storage type and greenhouse dryers.

a. Absorption Dryers

The direct absorption dryer as the name suggests are designs of the direct type active dryers wherein the crops absorb the solar radiation directly. Typical practical design for large scale commercial forced convection greenhouse dryer, are of the type of solar kilns for timber drying. Transparent roof solar brans and small scale force convection dryers equipped with auxiliary heating. Typical designs include with the roof or wall of the dryer functioning as a collector of the drying chamber. Figure shows the greenhouse dryer designed by Huang et. al (1981) with a semi cylindrical structure made of a Tedlar coated clear corrugated fiber glass and an internal dry chamber of rotary or stationary drum with a black painted outer surface to effect solar absorption.

3. Hybrid-Type Active Solar-Energy Dryers

The hybrid solar dryers combine the features of a solar energy with a conventional or some auxiliary source of energy and can be operated either in combination or in single mode with either source of energy. These dryers generally are medium to large installations operating in the range of 50-60%, and compensate the temperature fluctuations induced by the climatic uncertainties. Figure shows the features of a typical active type hybrid solar dryer. Bena and Fuller (2002) described a direct?type natural convection solar dryer combined with a simple biomass burner suitable for drying fruit sand vegetables in regions without electricity. Figure shows a hybrid solar dryer, a modification of the dryer in Figure with auxiliary source of heating. The ambient air flows through a heat exchanger where it is heated to the desired temperature, by combustion gas. Part of the used air is exhausted from the north wall of the dryer and the rest is recycled through the recycling tube and the cooled gas exits through the chimney to the ambient.

X. DIFFERENT ORGANIZATIONS WORKING WITH SOLAR DRYERS

A. Society for Energy, Environment and Development (SEED)

SEED is a NGO started in 1987, mainly to promote rural Entrepreneurs. Currently, it is engaged in drying of fruits and Vegetables using solar cabinet dryer. It has also started manufacturing Solar dryer for its customers. SEED has installed around 180 solar Dryers, both demonstration and commercial models, in 18 states of India, starting from Kashmir to Trivandrum and Gujarat to West Bengal. Five solar dryers were exported to Saudi Arabia, Australia, Malaysia, and Mauritius. Five productions cum training centers have also been established in different regions of the country to conduct skill Development in the food processing industry. About 1,000 women and SHGs, NGOs, and youth were trained in solar processing of various Food products in solar dryers. NABARD Award for Rural Innovations 2012 for Solar Food Processing and Dryers was awarded to the SEED.

B. Planters Energy Network (PEN)

PEN was started as registered society in 1989 at Madurai Kamaraj University, India to promote renewable energy in the field of solar drying of various agricultural produce. PEN has introduced many solar dryers of capacities varying from 250 Kg to 1000 Kg per batch. It has also installed. These units were tested in South India as well as in Ladakh. A factory near Kodaikanal processes organically grown dehydrated cut fruits, which are very popular in Europe using solar Heat. Shyam Cooperative in Ladakh operates a 400 kg capacity solar drying unit gets higher price for its finished products due to higher quality and appearance. Nearly 8 large units for drying fruits and vegetables are in usage in Ladakh region including one in Kargil. A 55 m2 area solar collector generated sufficient hot air to dehydrate in 8 hours around 120 kg of mango concentrate. This unit has a backup heating with bio-mass fuel. This project will handle a minimum of 30 Tons of fruit concentrate per annum and create employment of 1500 Man-days per year. These kinds of unit could be replicated throughout the country mainly on the mango and other fruits growing areas.

C. Kraft work Solar Private Limited

Kraft work is the pioneer of solar water heating technology in Kerala with over 18 years of experience in manufacturing and commissioning solar energy systems. Kraft work has over 7000 solar thermal installations all over Kerala and Tamilnadu. Kraft work has been in the cutting edge of research and developing solar driers for the market. They have developed several models of solar dryers both in house and in association with several universities that cater to a wide range of Industries and products such as Nagarjuna Herbal Concentrates and P.D.D.P Milk Dairy.

D. Raheja’s Solar Dryer

Raheja founded Raheja solar food Processing Pvt. Ltd. (RSFP) in 2018 to create a low cost, accessible solar dryer in India for farmers. This was an extension of a “waste-to-wealth” project that he started at the Jimmy McGilligan Center for Sustainable Development, under the guidance of Padma Shri Janak Palta McGilligan. Raheja is passionate about creating value from waste and believed that solar dryers would be an effective and economical way to manage waste while supporting farmers’ livelihoods. The U.N. has also recognized the RSFP for designing this affordable solar dryer in India and training farmers to use them. Raheja describes the dryer as a “frugal innovation” that uses locally available material to reduce the costs involved with setting up the dryer and implements a portable “folding design” that decreases transportation costs. Moreover, the simple, self-building design eliminates the need to hire an expert to install the dryer. Raheja’s “self-sustainable” dryer also does not need electricity to operate and uses “stainless steel mesh” to dry produce, avoiding the production of harmful gases, unlike plastic mesh material. Additionally, the dryer retains the nutrients, aroma, taste and color of the product with an enclosure that keeps out dust and insects. Raheja’s solar dyer is sold at 14,750 rupees, or $200, which is 50% cheaper than other dryers in India.

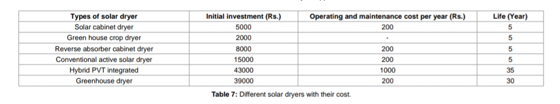

E. Economical Aspect of Solar Dryers

Solar dryers are generally capital intensive and therefore the Financial feasibility is the key to compete with any of the other commercial dryers. The financial analysis generally includes the cost of dryer (fixed cost), cost of drying (operating cost) and payback. They can be viable only if the annual cost of extra investment on the solar dryer could be balanced against fuel savings, or if the equipment cost could be reduced. The user or dryer designer optimizes cost, energy efficiency, quality, and price of the final product. Payback is the measure of time (number of days/months/years) it takes to recoup the total investment Made on a dryer, in the form of operational cash inflow. Continued use of the dryer rather than seasonal use will decrease the drying cost and payback. Economic analysis on a solar dryer should also incorporate The cost benefits due to improved quality, higher yields, less floor area And quicker drying. The cost of a solar dryer of 50 kg capacity ranges From about Rs. 30,000 to Rs. 50,000. Larger industrial – scale systems May cost between Rs. 4 lakhs to 10 lakhs. (FICCI report). The cost of

Different types of solar dryer is listed below in Table.

F. Government Initiatives to Promote Solar Dryers in India

Jawaharlal Nehru National Solar Mission (JNSSM) was launched On the 11th January, 2010 by the Prime Minister to encourage Ecologically sustainable growth while dealing with India’s energy Security challenges. The objective of the JNNSM is to establish India as A global leader in solar energy, by creating the policy conditions for its promotion. The immediate aim of the Mission is to focus on establishing a favorable environment for solar technology penetration in the country both at a centralized and decentralized level. The first Phase (up to 2013) will focus on capturing of the low hanging options in solar thermal; on promoting off-grid systems to serve populations without access to commercial energy and modest capacity addition in grid-based systems. In the second phase, after taking into account the experience of the initial years, capacity will be aggressively worked up to create conditions for up scaled and competitive solar energy penetration in the country. Under this scheme 30% subsidy can be provided for the installation of solar energy driven equipment. However, some states, such as Tamil Nadu, also provide subsidy up to 50% for setting up solar dryers.

Ministry of new and renewable energy (MNRE) proposed a framework for promoting application of distributed renewable energy (DRE) in rural areas.DRE applications are those which are powered by renewable energy and used for earning livelihoods directly such as solar dryer, solar powered cold storage, solar charkha, and solar lighting systems. With this, the ministry plans to enable a market-oriented framework to attract the private sector for development and deployment of DRE livelihood applications, provide easy access to end user finance, introduce standards, monitoring and evaluation mechanisms.

The framework for promotion of DRE livelihood applications allows interventions to assess demand for their deployment across sectors of the rural economy.

“This demand assessment activity will help in mapping needs of beneficiaries with appropriate fit to DRE livelihood applications. MNRE will develop a list of DRE livelihood applications in consultation with stakeholders, which will be updated regularly,” it said. For the standardization of research and development, MNRE and other ministries would be helping in development of new devices and applications for the rural economy. “In addition, private sector, technology incubation centers, bilateral and multilateral agencies and NGOs will participate in the research and development activities,” the draft policy said.

MNRE would be pursuing financial institutions for credit facilitation. The market for distributed solar products for rural areas – such as solar lanterns, pump sets and mini-grids – was estimated to grow to Rs 10,117 crore by 2023 before the pandemic hit. It is now reeling under financial stress due to lack of liquidity to support operations and government schemes yet to make a visible impact.

Conclusion

The prime objective of the project was to research and conduct a study on different types of solar dryers, which can overcome the shortcomings of cold storage and to save the surplus produce from deterioration. Based on the work carried out during the project, following things can be concluded: 1) Solar dryer is the best alternative option to avoid disadvantages of conventional drying methods. Solar dryer is designed particularly for drying agricultural products. In this after discussing all the dryer, it is found that- a) Time required for drying in mixed mode solar dryer is less than other type of dryer. b) Force circulation drying gives better result than natural circulation solar dryer. 2) According to the study, it can be concluded that phase change material is the key factor. Latent heat storage system will guarantee 5 to 6 additional hours of drying apart from normal sunshine hours. Phase Change Materials (PCMs) like paraffin wax can be used in latent heat storage system. The working principle of Phase Change Material proves to be fruitful because during sunshine hours it maintains optimum temperature of drying and after sunset it provides additional 5 to 6 hours of drying time. It is possible due to the fact that phase change material store excess energy during day resulting in maintaining roughly optimum temperature all through the process of drying and when there is unavailability of solar power and when temperature drops then PCM solidify resulting in exothermic reaction. The heat generated from exothermic reaction is thus used to resume drying even after sunset. A. Recommendation The country is already excelling in building different kinds of new technologies working to improve the quality and quantity of farm produce but the loopholes in storage management can put whole of the efforts in vain hence in the future we need more of the efforts in protecting the post-harvest produce on which our above study can be proven successful. The Phase Changing Material paraffin wax and solar power used in the solar dryer can be found in abundance. But indirect solar dryers with PCMs have high initial cost and maintenance is also expensive in comparison to direct solar dryers. Since, in India major population accounts for small scale farmers, therefore, it is recommended that Farmers Producers Organizations (FPOs) should take up the initiative and should act as a link between farmers and modern technology. FPOs can set up and install solar dryers at a particular place (closer to farms) and can encourage farmers to bring their produce for processing. This is a win-win situation for both farmers and FPOs. B. Future Scope Of Work It includes: 1) Solar drying with & without preprocessing of food produce and its effect on quality 2) Designing solar dryers which works exactly at optimum temperature 3) Study on variation of melting point of Phase Change Material/ Paraffin Wax and its effect on performance of dryer 4) Testing solar dryers (with latent heat storage) with different quantities of PCMs and its effect on overall efficiency of dryer. 5) Conducting study to attain higher overall efficiency of solar dryer (with latent heat storage)

References

[1] M.T. Kumpavat, P.P. Sutra “Drying and Storage Engineering”, eBook ICAR ecourse. [2] A.Tiwari, “A Review on Solar Drying of Agricultural Produce,” J. Food Process. Technol., vol. 7, no. 9, 2016. [3] A.Fudholi,“Energy-economic-environmental analysis of solar drying system: a review”, International Journal of Power Electronics and Drive System (IJPEDS) Vol. 11, No. 2, June 2020 [4] Megha S. Sontakke, Prof. Sanjay P. Salve,”Solar Drying Technologies: A review”, International Refereed Journal of Engineering and Science (IRJES)Volume 4, Issue 4 (April 2015) [5] B.K.Singh, A.H. Laskar, A.A. Hazarika, S. Dutta, “A PROJECT REPORT ON A COMPARATIVE STUDY OF BOX TYPE SOLAR DRYER WITH AND WITHOUT LATENT HEAT STORAGE”, Jorhat Engineering College, Jorhat Dibrugarh University:Dibrugarh [6] N.B. Haramain, “DEVELOPMENT OF SOLAR DRYER SYSTEM FOR FOOD DRYING PURPOSES”, Faculty of Mechanical Engineering, University of MALAYSIA PAHANG, JUNE 2012 [7] Applications of Thermal Energy Storage Systems S. Kalaiselvan, R. Parameshwara, in Thermal Energy Storage Technologies for Sustainability, 2014, www.sciencedirect.com [8] www.irena.org [9] Google Images [10] www.mphorticulture.gov.in [11] www.financialexpress.com [12] Thecsrjournal.in [13] Economictimes.indiatimes.com [14] www.google.com [15] Kenisarin, M; Mahkamov, K (2007). \"Solar energy storage using phase change materials\". Renewable and Sustainable –1965. 11 (9): 1913–1965. [16] Sharma, Atul; Tyagi, V.V.; Chen, C.R.; Buddhi, D. (2009). \"Review on thermal energy storage with phase change materials and applications\". Renewable and Sustainable Energy Reviews. 13 (2): 318–345. [17] ENRG Blanket powered by Bio PCMs. Phase Change Energy Solutions. Retrieved March 12, 2018. [18] (PDF) by Mary Anne White, brings a list of advantages and disadvantages of Paraffin heat storage. A more complete list can be found in Access Science website from McGraw-Hill, DOI 10.1036/1097-8542.YB020415, last modified: March 25, 2002 based on \'Latent heat storage in concrete II, Solar Energy Materials, Hawes DW, Banu D, Feldman D, 1990, 21, pp.61–80. [19] Floros, Michael C.; Kaller, Kayden L. C.; Poopalam, Kosheela D.; Narine, Suresh S. (2016-12-01). \"Lipid derived diamide phase change materials for high temperature thermal energy storage\". Solar Energy. 139: 23–28.

Copyright

Copyright © 2023 Swejal Khemariya. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET55725

Publish Date : 2023-09-14

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online