Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Dry Ice Acetylene Power Plant (Dia Power Plant)

Authors: Gaurav Singh Patel, Saurabh Kumar Gautam, Sonali

DOI Link: https://doi.org/10.22214/ijraset.2022.41969

Certificate: View Certificate

Abstract

As we all know that in today\\\'s time of modernity, energy plays an important role, somewhere today we are getting almost every need of our energy in the form of electricity. And with this, today we generate 77% of electricity from coal power plants in India. According to the report of the Ministry of New and Renewable Energy, gross electricity consumption in 2019 was 1208 kWh per capita. From this data, we understand one thing that distribution of so much electricity in such a large population is a challenging task. Keep the production of your electricity in such a way that it is efficient in cost and does not harm the environment; whereas in today\\\'s time we do not get to see this, the environment is being polluted in the production of electricity, then in this paper proposal After reaching the root of this problem, we have proposed a new power plant, which is named Dry Ice Acetylene Power Plant (DIA Power Plant).

Introduction

I. INTRODUCTION

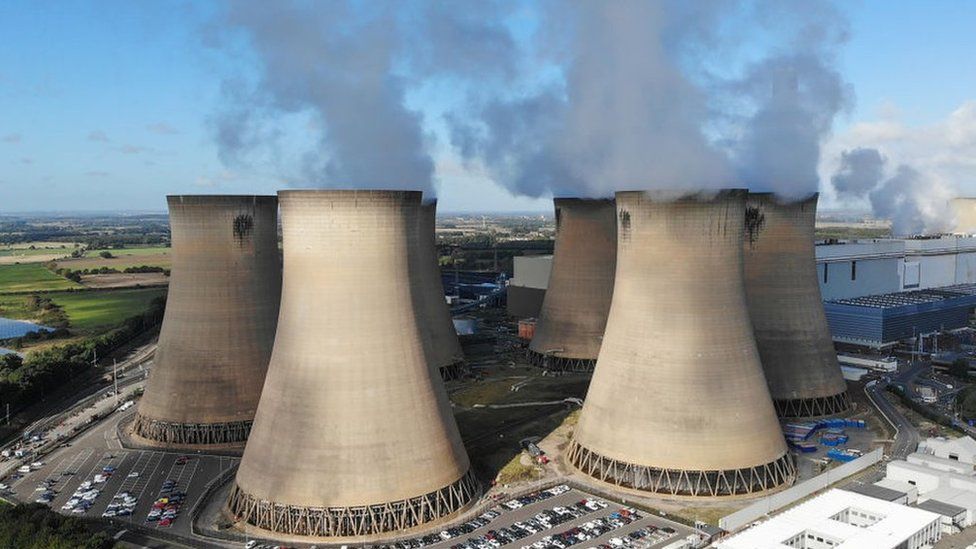

A. Problem of Modern Power Plant

According to the report of Economic Times, the power received through different means and their percentage in the power generation capacity in India are as follows.

|

Sources |

Share (MW) |

Percentage |

|

Thermal |

2,21,803 |

64% |

|

Renewable |

70,648 |

21% |

|

Hydro |

45,487 |

13% |

|

Gas |

24,867 |

7.21% |

|

Nuclear |

6780 |

2% |

|

diesel |

838 |

0.24% |

As we have seen above, in India, 64% of the power generation source is thermal and in thermal power generation we use coal. When coal burns, we give the energy obtained from it to the boiler, in which the water is converted into steam; and later this steam spins the turbine, which generates power.

But there is a serious problem here, which is often ignored today; but we cannot leave the future on this situation. The problem arises when we look at exhaust produced by burning coal. Let's take a look at pulses once on the exhaust caused by burning coal –

|

Exhaust Gases |

Percentage |

|

N2 |

72-77 % |

|

CO2 |

12-14 % |

|

H2O |

8-10 % |

|

O2 |

3-5 % |

After studying this chart, 2 problems arise in front of us.

B. Problem-1

As we are seeing that by burning coal, the highest amount of N2 gas and then CO2 is produced, which has very harmful effects on the environment and humans.

- Nitrogen Effect

- If we see deeply, then we will find that nitrogen is safe to breathe only when mixed with the appropriate amount of oxygen.

- Excess nitrogen in the atmosphere can produce pollutants such as ammonia and ozone, which can impair our ability to breathe, limit visibility and alter plant growth. When excess nitrogen comes back to Earth from the atmosphere. It can harm the health of forests, soils and water ways.

2. Carbon Dioxide Effect

- They cause climate change by trapping heat, and they also contribute to respiratory diseases from smog and air pollution.

- Exposure to CO2 can produce a variety of health effects. They may include headaches, dizziness, restlessness, a tingling or pain or needles, feeling, difficulty breathing, sweating, tiredness, increased heart rate, elevated blood pressure, coma, asphyxia and convulsions.

3. NOx Effect

- High levels of NOx can have a negative effect on vegetation by making it more susceptible to disease and frost damage.

- NOx gas has adverse effects on the ozone layer in the troposphere area of the earth’s atmosphere, which results in the green house effects and global warming.

The poison that we are leaving in our society today, we have to stop it somewhere for the future.

C. Problem-2

After pollution and health loss, another problem that comes to our notice is that coal is being used only to provide heat to the boiler. The exhaust generated by it is not being used.

Actually, we cannot even use the exhaust obtained from coal because it contains a mixture of many gases like nitrogen, carbon dioxide etc. and to make it useful, the gases will have to be separated first, which will not be a profitable industry idea for us. So our final problem is, how can we use that exhaust in our own way.1.4 proposal

Our main task is to deliver heat to the boiler by any means; and from that heat the water turns into steam, and that steam spins the turbine to generate power.

But it is not necessary that all the time we provide heat to the boiler by burning coal, now the time has come that in some way we should use some other fuel instead of coal which does not spread much pollution in the environment and with its energy. Along with this, we can also make full use of its exhaust.

We will use acetylene in place of time in our paper proposal and will also produce it in our plant and will also produce exhaust complete carbon dioxide after burning it and supply the product made from it in the market; in this way the environment will be completely safe.

D. About Acetylene Gas

Acetylene also called ethyne, is the simplest and best known member of the hydrocarbon series, containing one or more pairs of carbon atoms linked by triple bonds [ C2 H2 ] called the acetylenic series, or alkynes. It is a colorless inflammable gas widely used as a fuel in oxyacetylene welding and cutting of metals and as raw materials in the synthesis of many organic chemicals and plastics.

III. WORKING

The entire process of generating electricity and making full use of the exhaust is completed in 10 steps in this DIA power plant. In the first step, we purify the water and store it. In the second stage store, we produce acetylene gas by mixing calcium carbide with pure water. In the third step, by burning acetylene, the generated heat is sent to the boiler, due to which the water is converted into steam. In the fourth stage, steam is sent to the turbine, due to which the turbine starts rotating. In the fifth stage, the turbine is connected to the generator, which generates electricity.

Now we turn our attention back to the exhaust and in the sixth step, carbon dioxide is purified from the exhaust. Generally, only carbon dioxide is obtained in the combustion of acetylene. But sometimes carbon monoxide is formed along with carbon dioxide in low combustion, which is harmful; it is very necessary for us to separate it. After purifying, in the next seventh stage, the carbon dioxide gas is sent to the compressor, after that the compressed carbon dioxide is sent to the condenser in the next eighth stage and the condensed gas is passed through the expansion valve in the next ninth stage, after that in the next final stage Dry ice is separated by separator.

IV. PRECAUTION

Incomplete combustion of acetylene produces carbon monoxide [CO] gas, which acts as a poison, and if we do not have complete combustion at all, then we can skip our truncated phase which will increase the cast efficiency further.

V. COST ESTIMATION

Before designing a power plant, we need to know whether the new design we have made is cost efficient or not. In cost estimation we will compare this power plant with thermal power plant.

A. Dry Ice Acetylene Power plant (DIA Power Plant)

In this new proposal we are using acetylene gas in place of time and converting exhaust into dry ice.

Combustion heat of acetylene = 48.2 MJ/kg

Mean per kg acetylene gas can generate 48.2 MJ energy after combustion. Now we will calculate how much we have to pay for generate 1 kg acetylene.

CaC2 (g) + 2H2O (l) C2H2 (g) + Ca(OH)2 (aq.) [biproduct]

For generation of 1 mole acetylene we have to need 1 mole calcium carbonate and 2 mole water.

Mass of 1 mole C2H2 = 26.03708 gram

Mass of 1 mole CaC2 = 64.0994 gram

For generation of 26.036708 gram C2H2 we have to required 64.0994 gram of calcium carbide. So to get 1 kg of acetylene, we will need 2.461850 kg of calcium carbide. And according to exportsindia.com and Madhuraj Industrial Gases Pvt Ltd,

the price of calcium carbide is 11000 - 12500 / metric ton.

So feet say calcium carbide price = 11-12.5 Rs

On taking the middle = 11.75 Rs

Factor of Safety = 2.0

Final foot kg calcium carbide price = 23.5 Rs

Therefore, to produce one kilogram of acetylene, we will have to invest 57.853475 Rs, from which we will get 48.2 MJ of energy and we will get two new products which we can sell in the right market and make our power plant profitable.

- A calcium hydroxide

CaC2 (g) + 2H2O (l) C2H2 (g) + Ca(OH)2 (aq.)

From 1 kg of calcium carbide, 1.155915 kg of calcium hydroxide is produced. Therefore, 2.461850 kg of calcium carbide will be required to produce 1 kg of acetylene and 2.845689 kg of calcium hydroxide will be produced.

And according to today's market, calcium hydroxide is sold at Rs 7.5/kg, so in producing 1 kg of acetylene, we will make calcium hydroxide byproduct worth 21.3426675.

2 Exhaust carbon dioxide

We will convert the exhaust carbon dioxide again into dry ice by rotating it in a cycle.

2C2H2 (g) + 5 O2 (g) 4CO2 (g) + 2 H2O (g)

So, on complete combustion of 1 kg of acetylene, we will get 3.3801 kg of carbon dioxide, which goes on to be converted into dry ice.

Factor of Safety = 1.7

So out of 3.3801 kg of carbon dioxide, only 1.98,892 kg of carbon dioxide was converted into dry ice and the minimum price of dry ice according to today's market is Rs.45/kg. So after burning one kilogram of acetylene, we will get dry ice worth Rs.89.472.

3. Total revenue with carbon dioxide and calcium hydroxide

For per kg acetylene gas

Total revenue = revenue with calcium hydroxide + revenue with carbon dioxide

= 21.342667 Rs + 89.472 Rs

= 110.814 Rs

B. Thermal Power Plant

Bituminous coal, subbituminous coal or lignite coal are used in thermal power plants.

|

Coal |

Calorific value |

|

Bituminous |

24 MJ/Kg |

|

Subbituminous |

22 MJ/Kg |

|

lignite |

17 MJ/Kg |

Average calorific value = 21 MJ/kg

Acetylene calorific value = 48.2 MJ/kg (with 1.4 factor of safety)

Therefore, we have to burn 2.295 times (2.295 kg) of coal to get as much energy as 1 kg of acetylene, which costs 10 rupees per kg in today's market, in which 20% carbon is present.

In the end, we have to invest Rs 22.95 to get the energy from as much as 1 kg of acetylene. While 57.85 rupees have to be invested in acetylene to get the same energy, yet our DIA power plant is more efficient than thermal power plant, let's see it further.

VI. EXHAUST UTILIZATION PROCESS

The exhaust utilization process is completed in 5 steps; in the first step, a small amount of carbon monoxide mixed with carbon dioxide is passed through a high pressure water container, which separates carbon dioxide and carbon monoxide. From here we take CO formed in an economiser, in which CO reacts with oxygen to generate carbon dioxide gas and energy.

2CO(g) + O2 (g) 2CO2 (g) + Energy

After this, the carbon dioxide gas is taken again into the high pressure water container. After this, in the second stage, we send the received carbon dioxide to the compressor, and in the third stage we send the compressed gas to the condenser; after that in the fourth stage we send the condensed gas to the expansion valve, after which the carbon dioxide starts converting into dry ice. After that, in the final stage, the dry ice is separated in the separator and the carbon dioxide, which could not be converted into dry ice, is sent back to the compressor for recycling.

VIII. RESULT

Therefore, in this way, by replacing coal in power generation, the advantage of acetylene gas is that there is not much gas mixture in the exhaust that comes out in it, so we can use those gases also. We also make acetylene gas through calcium carbide, and purified water. In this process we get biproduct calcium hydroxide, for which the market doors are open.

Therefore, through this type of power plant, we can not only generate power but also save our environment from harmful gases. And if the products generated by the power plant like calcium hydroxide and dry ice are properly transported to the right market, then we will find this multipurpose power plant more economical than the old power plant.

Conclusion

Comparative Study of Thermal Power Plant and Dry Key Power Plant (DIA Power Plant) on the basis of Result obtained - Here we will compare coal and acetylene by assuming that the energy obtained from them (MJ / kg) will be equal. Fuel type Gain Energy Fuel required/Kg Cost of Fuel Biproducts name Biproducts in Kg Biproducts price Total Pollution Coal 48.2 MJ 2.295 Kg 22.95 Rs - - - -22.95Rs CO2,NOx Acetylene 48.2 MJ 1 Kg 57.85 Rs Ca(OH)2 2.46 Kg 23.45 Rs +55.07Rs - Dry Ice 1.98 Kg 89.472 Rs So we can clearly see where we are getting only energy in thermal power plants; on the other hand, we get the same amount of energy in dry acetylene power plants as well as 95.19% return as its biproduct. And almost our entire power plant will run free of cost. Also, we will not harm our environment in the form of pollution.

References

[1] Thermodynamic Properties of R744 (Carbon Dioxide - CO2) Engineering Thermodynamics by Israel Urieli. [2] A comparative study of CO2 refrigeration systems by Evangelos Bellos Christos Tzivanidis [3] Czapla, Nicholas & Inamdar, Harshad & Barta, Riley & Groll, Eckhard. (2016). Theoretical Analysis of the Impact of an Energy Recovery Expansion Device in a CO 2 Refrigeration System. [4] Wang, Zhifang & Zheng, Danxing & Jin, Hongguang. (2009). Energy integration of acetylene and power polygeneration by flowrate-exergy diagram. Applied Energy. 86. 372-379. 10.1016/j.apenergy.2008.05.011. [5] Anand, M. & Devi, G. & Srinivasan, Gokul & Prakasha, G S & Thangavelu, Lakshmanan. (2021). A critical study on acetylene as an alternative fuel for transportation. AIP Conference Proceedings. 2396. 020005. 10.1063/5.0066773.

Copyright

Copyright © 2022 Gaurav Singh Patel, Saurabh Kumar Gautam, Sonali . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET41969

Publish Date : 2022-04-28

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online