Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Strength and Durability Assessment of Bacteria Based Self-Healing Concrete

Authors: C Krishnamoorthy, Mrs. S. Narmadha

DOI Link: https://doi.org/10.22214/ijraset.2023.55968

Certificate: View Certificate

Abstract

Crack formation is very common phenomenon in concrete structure which allows the water and different type of chemical into the concrete through the cracks and decreases their durability, strength and which also affect the reinforcement when it comes in contact with water, CO2 and other chemicals. For repairing the cracks developed in the concrete, it requires regular maintenance and special type of treatment which will be very expensive. So, to overcome from this problem autonomous self-healing mechanism is introduced in the concrete which helps to repair the cracks by producing calcium carbonate crystals which block the micro cracks and pores in the concrete. The selection of the bacteria was according to their survival in the alkaline environment. The condition of growth is different for different types of bacteria. For the growth, bacteria were put in a medium containing different chemical at a particular temperature and for a particular time period. Bacteria improves the structural properties such as tensile strength, water permeability, durability and compressive strength of the normal concrete which was found by the performing different type of experiment on too many specimens had varying sizes used by different researchers for their study of bacterial concrete in comparison with the conventional concrete. So, I am using Bacillus Subtilis bacteria in concrete of different cell concentrations and detecting optimum cell concentration by performing strength and durability studies.

Introduction

I. INTRODUCTION

Concrete is the most common material used for all types of construction. Due to its strength and durability, concrete became inevitable. It is a very good material to resist the compressive load to a limit but if the load applied on the concrete is more than their limit of resisting load, it causes the strength reduction of concrete by producing the cracks in the concrete and the treatment of the cracks in very expensive. Some of the property like durability, permeability and strength of the concrete structure is also decreases. Due to increase in the permeability of the concrete the water easily pass through the concrete and come in contact with the reinforcement of the concrete structure and after some time corrosion occurs it leads to reduction in the strength of the concrete structure so it is necessary to repair the cracks. By incorporating the bacteria in concrete it producing calcium carbonate crystals which block the micro cracks and pores in the concrete. In concrete micro cracks are always avoided but to some extent they are responsible to their failure in strength. The selection of the bacteria is depend on the survive capability of bacteria in the alkaline environment. Most of the micro-organisms die in an environment with pH value of 10 or above. Strains of the bacteria genus Bacillus will be found to succeed in high alkaline environment. The bacteria survive in the high alkaline environment that formed spores comparable to the plant seeds. The spores are of very thick wall and they activated when concrete start cracking and water transude into the structure. The pH of the highly alkaline concrete lowers to the values in the range 10 to 11.5 where the bacterial spores become activated.

II. MECHANISM OF SELF-HEALING

When cracks appear in a concrete structure and water starts to seep in through, the spores of the bacteria starts microbial activities on contact with the water and oxygen. In the process of precipitating calcite crystals through nitrogen cycle, the soluble nutrients are converted to insoluble CaCO3. The CaCO3 solidifies on the cracked surface, thereby sealing it up.

- To find out the optimum Bacterial cell concentration for strength and durability characteristics.

- To find out the effectiveness in Crack Closure.

III. TEST ON BACTERIA

A. Haemocytometer Test

The hemocytometer (or haemocytometer) is a counting-chamber device originally designed and usually used for counting blood cells. The hemocytometer consists of a thick glass microscope slide with a rectangular indentation that creates a chamber. This chamber is engraved with a laser-etched grid of perpendicular lines. The device is carefully crafted so that the area bounded by the lines is known, and the depth of the chamber is also known. By observing a defined area of the grid, it is therefore possible to count the number of cells or particles in a specific volume of fluid, and thereby calculate the concentration of cells in the fluid overall. I performed this test in Environmental Lab at Anna University Regional Campus, Trichy. The Result says that the Solution contains 2 x 109 cells/ml.

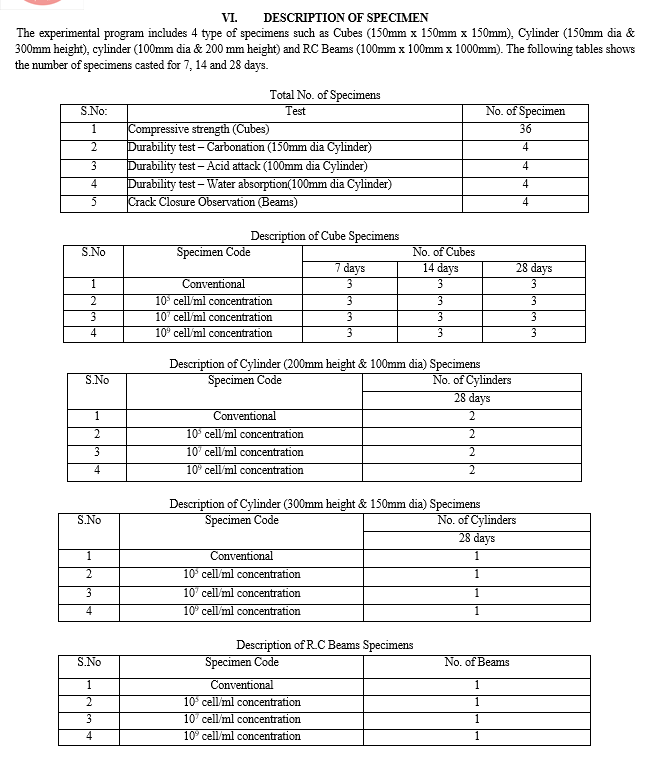

VII. TESTS ON CONCRETE

A. Compressive Strength Test

The compressive strength tests of the specimens were conducted to determine the compressive strength of specimen. For each curing period, three identical specimens were prepared and the average of the strengths was reported as the compressive strength of the mix. Specimens are tested to determine the average compressive strength at the ages of 7, 14 and 28 days. All specimens were prepared, cured and tested under room temperature. The Maximum capacity of CTM is 50 tones.

B. PH Test on Concrete

PH test on concrete is one of the vital test in bacterial concrete because if the pH value of concrete exceeds 13, the bacteria will not survive inside the concrete. When the pH paper is dipped on concrete wet surface, the pH paper changes its colour from its original colour. By matching the changed colour with the pH chart, we can find the pH value. To confirm the survival of bacteria inside the concrete this test should be conducted.

C. Creation of Fault Plane Using Leaf Spring Machine

Creating cracks on the beams of size 100x100x1000mm using Leaf Spring Machine for the study of Crack closure. The Maximum Load applied on the beams were 12 KN. The generated cracks size varies from 0.1 to 1.5mm. The cracked Beams are kept under normal room temperature for about 40 days to observe crack closure.

D. Ultrasonic Pulse Velocity Test

An ultrasonic pulse velocity (UPV) test is an in-situ, nondestructive test to check the quality of concrete. In this test, the quality of concrete is assessed by measuring the velocity of an ultrasonic pulse passing through a concrete structure. This test is conducted by passing a pulse of ultrasonic through concrete to be tested and measuring the time taken by pulse to get through the structure. Higher velocities indicate good quality and continuity of the material, while slower velocities may indicate concrete with many cracks or voids.

E. Microstructure Analysis

The microstructure of the cement matrix is a function of the composition of the cement mortar and is a measure of the strength properties. The microstructure analysis of cement mortar is carried out using SEM study.

1. Scanning Electron Microscope

Scanning Electron Microscope is a type of electron microscope that depicts the sample surface through the scan process by using a high-energy electrons beam in a raster scan pattern. Electron interaction with atoms of the sample helps in generating a signal that is most frequently used to study sample's surface topography, composition and other properties such as electrical conductivity. It is capable of generating high resolution images, which allow to examine the characteristics with a high magnification and detail. SEM has a large depth of field, which can focus on the more samples at a time and produce good shadow of three dimensional samples. SEM also produces high-resolution images, which means approaching shadows that can be tested with high magnification. Higher magnification, dark field, greater resolution, and composition & information of crystallography are the important features of SEM.

F. Durability Studies

Durability of the concrete is defined as the capability of concrete to resist weathering action, chemical attack and abrasion while maintaining its desired engineering properties. Factors affecting durability of concrete are cement content, compaction, curing, cover, Permeability. The following durability tests were studied:

1. Water Absorption

For water absorption test the cylinder size of 100mm dia and 50mm height was used. After demoulding the specimen are immersed in a water for 28 days. After 28 days of curing the specimen were taken out to measure saturated weight (w2). Thus the specimen were dried in oven at a temperature of 105o C for 72 hours and taken it as an oven dried weight (w1).

The water absorption was calculated as: (????2−????1) / ????1 X100

2. Acid Resistance

Acid resistance test was performed on Concrete cubes of size 150mm × 150mm× 150mm were cast and stored in a place at room temperature for 24 hours and then the specimens were demolded and kept for curing in water for 28 days and Specimen were taken out placed in room temperature and weight was taken as (w1) . After 28 days of curing, the specimens were taken out and allowed to dry for one day. Weights of the cubes were taken as (w2). Sulphuric acid solutions with 0.3 normality per litre were prepared in acid- resistant tanks. The 0.3 Normality H2SO4 water solution (8.24 mL/litre water). The percentage of weight loss were calculated.

The acid resistant is calculated as (????2−????1) / ????1 X100

3. Carbonation

Carbonation of the concrete occurs when the carbon dioxide in the atmosphere in the presence of moisture, reacts with hydrated cement minerals to produce carbonates. This test is to determine the depth of concrete affected due to combined attack of atmospheric carbon dioxide and moisture causing a reduction in level of alkalinity of concrete. Phenolphthalein spray is sprayed on a concrete after 56 days which is placed in an open exposure. It is noted that the colour of concrete is changed to pink. The change of colour of concrete to pink indicates that the concrete is in the good health. Cylinder dimensions of 300mm height and 150 mm dia was used.

VIII. ACKNOWLEDGMENTS

First and foremost, we express our thanks to almighty, the great architect of the universe, who has blessed us successfully accomplish the project. I express our profound sense of thanks with deepest and gratitude to our project guide Mrs.S.Narmatha, M.E., for his valuable and precious guidance for our project. I specially thank our TEACHING and NON-TEACHING staff members of our Department. As they supported us in many ways, encourage and boosted our enthusiasm to continue and complete our project to reach bounds.

Conclusion

Based on the experimental results, the following conclusions are made. 1) The Bacillus subtilis bacteria plays a significant role in increasing compressive strength of concrete by 8.3% 2) From the durability studies, the bacterial concrete results are almost same as that of the conventional concrete. 3) Bacterial concrete exhibited lower rate of water absorption than conventional concrete. This is due to the bacteria induced formation of Calcium Carbonate in the pores present in concrete, leading to a lesser voids and hence a lesser permeability. 4) From the UPV Test Results, it is found that the internal cracks are closed for all Bacterial Concrete, Especially for 107 cells/ml concentration, the rate crack healing is more. 5) From the SEM Analysis, it is confirmed that the formation of calcium carbonate crystals on the concrete to seal the microspores. 6) The Optimum cell concentration was found – 107cells/ml 7) The study accomplishes that the use of bacteria (Bacillus Subtilis) in concrete enhances its strength and durability hence using this type of bacteria for self-healing mechanism in concrete can produce cost effective strong or durable structures.

References

[1] Bang SS, Galinat JK, Ramakrishnan V (2001) Calcite precipitation induced by polyurethane-immobilized Bacillus [2] DeGraef B, deWindt W, Dick J, Verstraete W, deBelie N (2005) Cleaning of concrete fouled by lichens with the aid of Thiobacilli. Materials and Structures 38(284):875–88. [3] DeMuynck W, deBelie N, Verstraete W (2007) Improvement of concrete durability with the aid of bacteria. [4] Gavimath C.C, Mali B.M, Hooli V.R, Patil A.B, Potential application of bacteria to improve the strength of cement concrete, International Journal of Advanced Biotechnology and Research (2011), pp 541-544. [5] Ghosh.S, M. Biswas a, Chattopadhyay B.D, S. Mandal, Microbial activity on the microstructure of bacteria modified mortar ,Journal of cement and concrete research(2009) , pp 93-98 [6] Henk M Jonkers, Erik Schalengon, A two composite bacteria based self-healing concrete, Journal Of Cement And Concrete Research, pp 215-220 [7] Jagadeesha Kumar B G, R Prabhakara, Pushpa H. “Bio Effect of Bacterial Calcite Precipitation on Compressive Strength of Mortar Cubes”, International Journal of Engineering and Advanced Technology (IJEAT), vol. 2, no. 3, 2013, pp 486-497. [8] Jagadeesha Kumar B G, R Prabhakara, Pushpa H. “Bio Mineralization of Calcium Carbonate by Different Bacterial Strains and their Application in Concrete Crack Remediation”, International Journal of Advances in Engineering & Technology, vol. 6, no. 1, 2013, pp 202- 213. [9] Jonkers H.M, Bacteria-Based Self-Healing concrete. [10] Jonkers.H.M & Erik Schlangen, A two component bacteria based self- healing concrete. [11] Jonkers.H.M and Erik Schlangen, Crack Repair By Concrete- Immobilized Bacteria. [12] Kantha D. Arunachalam, K.S., Studies on the characterisation of Biosealant properties of Bacillus sphaericus [13] Kim Van Tittelboom and Nele De Belie, Self- Healing in Cementitious Materials. [14] Kim Van Tittleboom, Nele de Belie, Willem De Muyunk, Use of bacteria to repair cracks in concrete, Journal of Cement concrete and Research (2010), pp 157-166. [15] Klaas van Breugel, Self-Healing Material Concepts As Solution For Aging Infrastructure, 37th Conference on Our World in Concrete & Structures 29-31 August 2012, Singapore [16] Li VC, Yang E (2007) Self-healing in concrete materials. In S. van der Zwaag (ed.) Self-healing materials — An alternative approach to 20 centuries of materials science. Springer, the Netherlands; pp: 161–194. [17] Mayur Shantilal Vekariya, Prof. Jayeshkumar Pitroda, Bacterial Concrete vol 4. [18] Mayur Shantilal Vekariya, Prof. Jayeshkumar Pitroda. “Bacterial Concrete: New Era for Construction Industry”, International Journal of Engineering Trends and Technology (IJETT), vol. 4, no. 9, 2013, pp 2231-5381. [19] Navneet Chahal, Rafat Siddique, Anita Rajor. “Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of concrete incorporating silica fume”, Construction and Building Materials, vol. 37, 2012, pp 645-651. [20] Nele De Belie, Ghent University, Belgium, “Self-Healing of Concrete”. [21] Neville AM (2002) Autogenous healing—A concrete miracle? Concrete Int 24(11):76–82.

Copyright

Copyright © 2023 C Krishnamoorthy, Mrs. S. Narmadha. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET55968

Publish Date : 2023-10-02

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online