Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Electrical Substation Design for Safety, Reliability and Sustainability

Authors: Ashok Ram Tripathi, Binaya Kumar Sahoo

DOI Link: https://doi.org/10.22214/ijraset.2024.64290

Certificate: View Certificate

Abstract

Electrical substations’ design is critical for safe, efficient and reliable electricity distribution. Safety and operational flexibility demand for optimized layout design. The fundamental ideas and elements of creating an efficient electrical substation structure that guarantees reliability and maximum performance. Selecting the optimum substation site in industrial operations necessitates a delicate balance of safety, efficiency, and environmental sensitivity. The main ideas and considerations that support the optimization of electrical substation design have been painstakingly addressed in this paper. Adequate space and smooth grid connectivity improve distribution efficiency and allow for future growth. Regulation adherence and effective security measures ensure ethical and secure siting. Adequate assessment of electromagnetic and radio interference is essential. Substation placement optimization connects industrial competence with environmental responsibility in this sophisticated decision-making process, establishing a healthy balance for reliability and sustainability. Beginning with the careful selection of a site that strikes a delicate balance between closeness to power sources and environmental sensitivity, each decision has far-reaching consequences for the grid\'s integrity. The thorough layout of equipment provides not only performance but also ease of maintenance, thus increasing the operational flexibility and reliability of the substation.

Introduction

I. INTRODUCTION

Electrical substations, which are critical components of the power distribution network, necessitate good layout design to provide continuous, dependable, and safe power while reducing environmental impact. This article discusses the fundamental ideas and factors to consider while designing a substation layout.

These recommended clearance and distance criteria serve as a foundation for the design of Industrial plants. Exact distances are determined by local regulations, project requirements, and extensive safety assessments, with an emphasis on unshakable dedication to safety and environmental preservation.

To ensure safety, dependability, and efficiency, the site of the Substation should consider several critical considerations.

II. SITE SELECTION

The first critical step is to find a good location for the substation. The accessibility for maintenance and repair, environmental impact studies, and land availability are all factors to consider. To minimize transmission losses, site selection should also include proximity to load centres.

Sometimes physical, electrical, aesthetic, or surrounding factors limit the use of locations that are optimal from a technical and cost perspective.

Prioritizing safety and environmental preservation throughout facility design is critical. Remember that substation design is not one-size-fits-all; it is dependent on local legislation and project objectives. Thorough safety assessments, including hazard analysis and environmental impact assessments, are required for each individual site. The NEC and IEC rules give a basis, but customisation is essential accordance with national and local codes and maximum protection of the public and employees.

- Considerations for Safety and Security: Safety issues are crucial in substation design. Identifying and avoiding hazardous zones, such as those containing flammable gases, is critical for reducing the danger of electrical fires and explosions. Providing convenient access for maintenance and emergency responders, as well as adequate clearances around the substation, improves safety. In addition, to prevent accidents, the layout should include safety zones, fences, warning signs, and proper space between equipment. Adequate illuminations, surveillance systems, security precautions, alarms, CCTVs are required to protect the substation from damage, theft, and unauthorized entrance, highlighting the importance of safety in substation design.

- Grid Integration: Grid Integration considers how the substation's location fits into the current electrical infrastructure and how it enables power delivery to end consumers.

- Environmental Considerations: Substation plans must be environmentally friendly, considering noise pollution, EMF exposure, and aesthetics. Substations can be blended into their surroundings through landscaping and design.

- Greenhouse gases reduction - elimination of SF6 gas wherever possible, move towards utilization of SF6 gas free switchgears.

- Process Hazard Analysis (PHA): A complete Process Hazard Analysis (PHA) is necessary in addition to meeting regulatory standards. PHA detects and analyses potential hazards based on the plant's particular characteristics and threats and may prescribe specific safety measures and clearance distances.

- Aesthetics: Visual influence considers the substation's visual influence on the surrounding area. Landscape design and architectural characteristics can help the substation blend into its surroundings and decrease its visual impact.

- Future extension: Substation architectures should account for future electrical grid development and extension.

- Automation and monitoring: Automation and remote monitoring and controls have added values and has become a norm. These technologies allow for remote data gathering, analysis, and control of substation operations in real time. This data-driven approach promotes informed decision-making, increases efficiency, and decreases the need for on-site employees, all of which contribute to safer and more effective substation site selection.

- Regulatory Compliance: At all times, local, national, and international rules and regulations must be respected. Substations must meet the safety, environmental, and technical requirements of the competent authorities. Zoning Regulations examine whether the proposed location complies with local zoning limitations, land use rules, and environmental legislation. Obtain permissions and approvals from the appropriate establishments.

Finally, the site of a substation design should strike a compromise between features to improve safety, dependability, and sustainability inside the process plant. Collaboration among engineers, environmental experts, and regulatory authorities is critical for making informed decisions that are consistent with project goals and industry best practices.

III. CLEARANCES AND SPACING FROM PROCESS PLANT

Industry standards, best practices, and related electrical codes such as the NEC, IEC, and other standards often set substation clearance requirements from various elements such as industrial facilities, highways, flammable storage tanks, and flare lines. These clearances are required to assure electrical substation safety and dependability. Specific clearance distances will vary based on factors such as substation voltage level and local restrictions, however, below are some broad guidelines:

All drainage should be directed away from buildings. Emergency evacuation and egress routes should be considered. Buildings should be in accordance with applicable zoning, building regulations, API RP 752, and the results of risk assessment analyses.

Portable occupied buildings should be in accordance with API RP 753. Requirements for clearances for electrical lines over roadways, walkways, rail, water, open land, buildings, and other structures are specified in NFPA 70, Tables 225.60 and225.61, and IEEE C2, Section 23.

- Process Plants: Process unit is a group of equipment performing a predetermined process operation as defined by the enclosing battery limit lines. If feasible, buildings should be located upwind (based on prevailing wind direction) of process units, or storage tank areas containing combustible or flammable gases, liquids, or solids. Buildings should be located upwind or cross wind from cooling towers. It's crucial to note that clearance distances can vary depending on local restrictions and project specifications. To calculate the correct clearance distances for a specific substation installation, reference applicable industry standards, rules, and municipal authorities.

PIP PNE00003 recommended Process Units spacing from Substation:

|

Process Unit |

Recommended Clerance (in Meter) |

|

Coolers Air Fan / Cooling Towers |

15.0 M

|

|

Drums Containing Flammables |

|

|

Exchangers Containing Flammables |

|

|

Furnace (Process Fired Equipment) |

|

|

Pumps (Flammable)/ Towers (Flammable) |

|

|

Reactors, Towers (Flammables) |

|

|

Compressor Gas |

|

|

Pumps (Non-Flammable) |

8.0 M |

|

Natural Gas Metering Station and Flare Lines |

30.0 M |

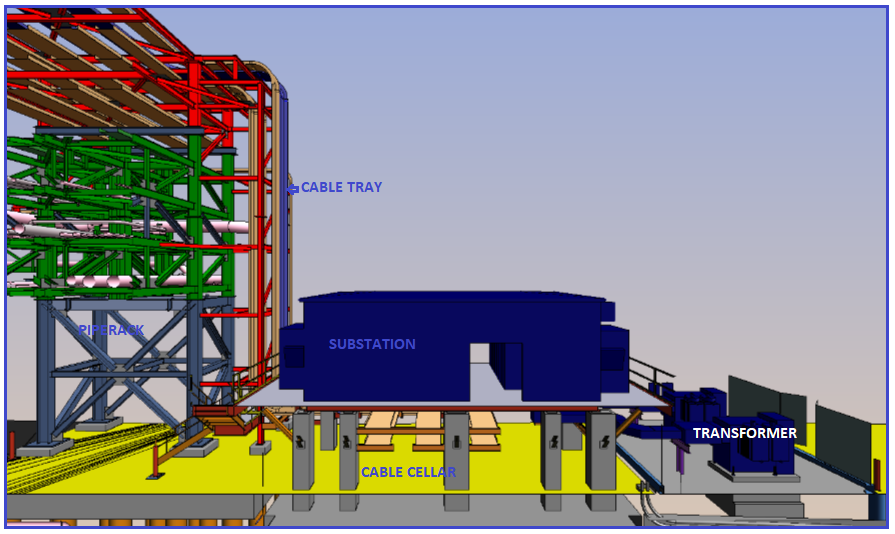

- Space Required for Cable Rack: Sufficient space required for cable pulling from pipe rack to Substation. Outgoing above-ground cable substation space is carefully planned to route cabling effectively to plant loads. To prevent interference and maximize safety, cable routes are built with adequate spacing, cable trays, and supports. To provide orderly, accessible, and dependable power distribution within the plant, cable trenches or racks may be employed. In general, keep a minimum of 3 to 6 meters between Piperack (cable rack) to substation for easy cable waterfall to substation. This distance can vary based on substation size and quantity of cabling.

- Underground facilities: Adequate development and maintenance of these UG facilities are critical for the substation's reliable and safe operation while avoiding visible and physical road obstacles. Maintain adequate space between a road and a substation for Underground (UG) infrastructure, which commonly comprise a fire water line, a power cable trench/conduit, communication cables, street light conduits, and sewer utility holes, septic tanks etc. In general requirement of spaces 6 meters ddistances from roads to substation to accommodate UG facilities.

- Clearances between Electrical Equipment: Substation design entails careful consideration of clearances and spacing between electrical components to ensure safety, reduce flashovers, and protect equipment. Clearances are the safe minimum distances determined by voltage and equipment between various substation components. These distances stress safety by preventing electrical sparks or flashovers. Encasing electrical equipment within safety barriers or enclosures for greater protection may be necessary in some situations, with clearances within these enclosures complying with manufacturer standards and regulatory requirements.

Here is a quick rundown of equipment arrangement considerations:

|

Clearances between Electrical Equipment |

Recommended Clerance (in Meter) |

|

Front clearance for HV Switchboard including HV GIS |

2.5 M |

|

Front clearance for all other switch boards/panels |

2.0 M |

|

Rear clearance for Switch board having maintenance access from front |

0.75 to 1.0 M or less than 0.2 M |

|

Rear clearance for Switch board having maintenance access from rear |

1.5 M (HV) 1 M (MV) |

|

Between Low Voltage where only working space required |

1.5 M |

IV. SUBSTATION DESIGN

- Transformer Positioning: The placement of transformers with a substation is an important part of maximizing energy distribution. These devices are critical in changing voltage levels, guaranteeing efficient power transmission, and meeting local grid requirements. Furthermore, they require adequate clearance and airflow for cooling and maintenance.

- Fire Wall: The firewalls depend on multiple factors, including the type of substation, transformer layout and using insulation oil like mineral oil or Synthetic Ester or Natural Easter (FR3) fluid filled. The flash point of mineral oil is 155°C. However, FR3 has a much higher flash point of 330°C. It is being encouraged to use oil with high fire point, less flammable, natural or synthetic ester fluids. Important factors to consider include the size (both in terms of surface area and depth) of a potential oil leak, the construction of the surrounding structures, the kind and amount of exposed equipment (such as transformers, breakers, motor control centre (MCC) equipment, and high-line structures). There must be fire-separation barriers built between any two or more transformers that are installed side by side. This firewall works as a protective barrier, preventing fires or explosions from spreading between the two regions. According to NFPA 850, transformers storing more than 500 gallons (1900 L) of oil must be protected by a 2-hour fire wall that extends 1ft (300 mm) vertically and 2ft (600 mm horizontally) beyond the transformer. This protects important electrical infrastructure and reduces risks connected with potential dangers.

- Distance between Substation and Transformer: As per FM Global property loss prevention data sheet, a minimum 3’ horizontal distance from containment to exposed building wall is required. Sprinklers and gas-based fire suppression systems are also used to quickly mitigate transformer fires and reduce the potential of catastrophic damage.

- Burnt Oil Pit: A burnt oil pit is a critical safety element for transformers. It must fulfil specified specifications, such as having a capacity of at least 110% of the transformer's oil volume to withstand spills and fire expansion. To avoid contamination and risks, the collected oil is transported to an authorized disposal or recycling site while complying with environmental rules and safety protocols. Proper containment is critical for preventing environmental damage and fires. Regular inspections and maintenance are critical for efficacy and compliance with local requirements.

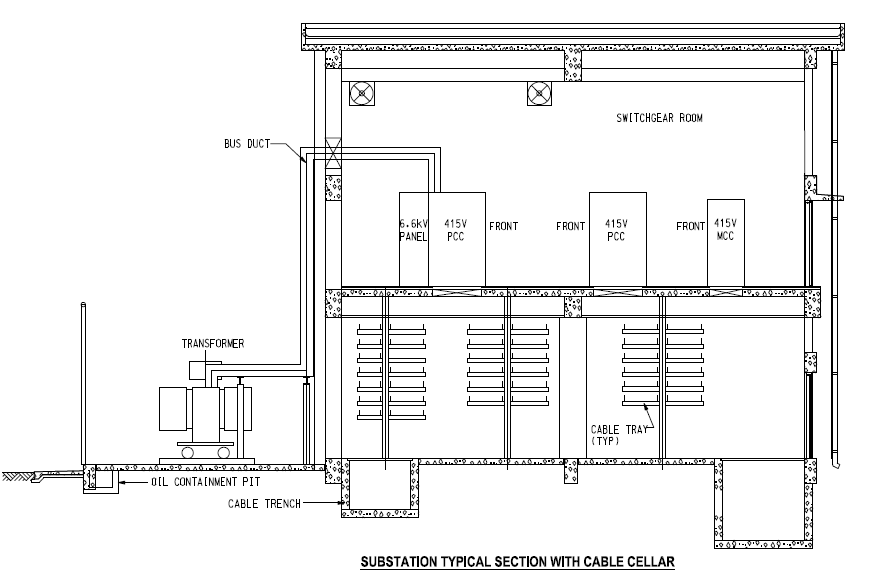

- The cabling between switchboards and transformers: In substations it is an important part of providing effective power distribution. Transformer bus ducts connect transformers and switchgear, maximizing power supply while requiring substantial support structures for stability and safety. Accessibility for maintenance and compliance with safety regulations are critical. Alternatively, underground trenches with conduit connectivity provide a covert channel for cable protection and routing. This strategy minimizes aesthetic interruptions while requiring adequate conduit depth, material selection, and cable separation to ensure a reliable and disguised electrical distribution system. These elements must be carefully considered for effective substation design. Each opening in a substation must be appropriately sealed using a project recommended fire rating. The right design of Multi-Cable Transitions (MCTs) considers the sizes of the cables that will be used.

- Fire Sealing: To achieve a two-hour fire rating (as per NEC) or to meet project-specific design criteria, all cable and duct holes, whether above or below ground, must be sealed in substations. This requirement improves fire safety by minimizing the spread of fire and smoke, as well as protecting essential infrastructure and employees within the substation area. There are many fires rated sealing systems available that claim their product is suitable penetrations with cables present, but it must be carefully decide with configuration achieve the fire rating as required.

- Redundancy and Reliability: It is critical for uninterrupted power delivery to maintain redundancy and dependability in substation architecture. This can be accomplished by including redundant features such as DG rooms, battery rooms, and multiple transformers and circuit breakers. These redundancies provide backup in the event of equipment failure, assuring continued power delivery. Redundancy not only improves reliability but also reduces downtime and interruptions, making it an essential component of substation design for guaranteeing a strong and dependable electrical infrastructure.

- Battery and DC Systems: Battery rooms at substations are critical components of the power infrastructure, necessitating strong safety measures to ensure the reliability of backup power systems and the safety of workers. Backup power batteries and DC systems should be kept in a separate location with proper ventilation and safety precautions. Proper ventilation is required to ensure hydrogen gas produced shall not exceed 2% by volume.

- DG Location: DG units can be installed indoors or outside, as determined by project guidelines with local code authorities after considering all relevant factors. Indoor DG sets can be considered if sufficient smoke exhaust and ventilation air are provided. The exhaust of diesel engine shall be kept away from the process/hydrocarbon handling areas and day tanks shall be located outside the DG room. The outdoor installation of DG Sets is to be check with local code and standards.

- Capacitor Bank: Power factor is the ratio between the useful (true) power (kW) to the total (apparent) power (kVA) consumed by AC electrical equipment or a complete electrical installation. It is a measure of how efficiently electrical power is converted into useful work output. The ideal power factor is unity. A high-power factor is generally required in a transmission system to reduce transmission losses and improve voltage regulation at the load. It is often advisable to adjust the power factor of a system to near 1.0. When reactive elements supply or absorb reactive power near the load, the apparent power is reduced. Power factor correction is performed by using synchronous condensers or 3? capacitor banks at substation level or load level.

- Grounding Systems: Effective grounding systems are critical for substation safety and performance. They include grounding electrodes, grids, and conductive routes to dissipate fault currents and protect persons and equipment. A ground resistivity survey shall be conducted prior to detail design to determine the type and total length of ground electrode that shall be installed at each substation. It reduces the effects of electromagnetic fields (EMFs) and interference with sensitive electronics. Grounding grids provide low-resistance fault current routes for transformers, switchgear, and circuit breakers. System integrity is ensured through regular maintenance, which includes soil resistivity readings and inspections.

- Escape route and door requirement: Fire exits at substations are crucial for guaranteeing human safety. They should be clearly marked, well-lit, and easily accessible, leading to safe outdoor places away from potential threats and enabling quick escape during emergencies in the substation environment. The requirements for escape routes are determined depending on rated voltage, ensuring simple access throughout the substation. Minimum aisle widths and safety clearances are specified in IEC61936-1. Substations with rated voltages greater than 52 kV require escape pathways no longer than 40 meters. Escape pathways of less than 20 meters are required for substations with rated voltages of up to 52 kV. If a service aisle is longer than 10 meters, it must have two exits, one of which is designated as an emergency exit. These laws prioritize worker safety during emergencies by requiring access doors to open outward, be airtight when closed, be fire-resistant, and have panic latches.

- Lighting: Substation lighting is critical for safety and operational efficiency. It should provide appropriate visibility for personnel, particularly at night and in confined environments. To facilitate operations, like as equipment inspection, maintenance, and monitoring, lighting levels must match criteria, which are frequently set by regulatory organizations. Emergency backup lighting is also essential for maintaining visibility during power outages or breakdowns. In general, a minimum of 200 lux is maintained for general area and for specific task 400~500 lux where requires more detailed visual work.

- Exit Signage: Clear signage and unobstructed exits are essential. If a fire or other catastrophic catastrophe occurs, it is advisable to designate multiple exits or escape routes to avoid personnel from becoming trapped. It is important to label escape routes explicitly. The substation staff should get regular training on evacuation routes, fire suppression safety features and/or equipment, and practice drills. It is important to indicate evacuation routes to any visitors to the electrical substation.

- Heating, Ventilation, and Air Conditioning: To maintain appropriate environmental conditions, HVAC (Heating, Ventilation, and Air Conditioning) or pressurization systems are required in substations. They regulate temperature, humidity, and air quality, preventing overheating and corrosion of equipment. These systems aid in the reliability of equipment, the reduction of the danger of electrical problems, and the provision of a safe working environment for workers. Proper HVAC or pressurization is critical for the functionality and lifetime of substations. Keep provision for drainage of water from condensing units of HVAC.

- Safety equipment within Substation: Substation shall have fire extinguishers, first aid boxes and other safety equipment as per statutory requirements. Insulating mats of required voltage rating shall be in front and rear of switchboards and GIS panels.

- PA/GA and Smoke monitoring System within Substation: Safety in Substations is ensured through vital accessories. A Public Address (PA) system facilitates clear communications during emergencies, while General Alarm (GA) system alerts personal. Alarms signal varies conditions, providing early warnings. Smoke detectors are crucial for swift fire detection, triggering rapid responses. CO2 systems act as fire suppressants. These safety measures, combined with protective relays and control panels, create a robust defence against potential hazards.

- Fire Water and Portable Water: Substations also require separate fire water systems, which include hydrants, tanks, pumps, and distribution networks for fire suppression. It is critical to have adequate pressure and flow rates. Portable water is also essential for operational functions such as cooling and hydration of equipment, as well as assuring compliance with safety regulations and functionality.

- Cable Cellar: A cable cellar beneath an electrical substation, equipped with sufficient head clearance and a waterfall design for cable racks, is vital. It ensures efficient cable laying, minimizes stress on cables, and facilitates maintenance. Headroom allows easy access, while the waterfall design aids in managing cable arrangement, enhancing the overall reliability of the substation. In general, the cable cellar shall have a minimum clear height of 2.5 m and shall house all cable trays and their supports.

- Switchgear Room Clear Hight: There is no set minimum clear height for a substation room that is applicable everywhere. It depends on local building codes, safety regulations, HVAC ducting, Arc Plenum for releasing Arc out of the building, false ceiling requirements in room and the specific equipment installed. To find the exact minimum clear height, always consult the applicable rules and laws in that local area. In general, the substation switchgear floor needs to have a minimum of 4 meters of clear height. This might go up if substations need to use overhead EOT cranes to erect heavy-duty HV panels like GIS panels. The finished floor level of the room shall be above the approach road and the surrounding grade level.

- Substation Building Expansion Joint: Although local building standards determine the quantity and placement of expansion joints, it is generally recommended for concrete buildings to have 45 meters.

- Considerations for Future growth: Design the layout with future growth in mind. Make room and provisions within substation for extra equipment or capacity upgrades to meet rising power demands.

Conclusion

Substation design is a vital crossroads in electrical engineering where the imperatives of safety, dependability, and sustainability elegantly merge. The main ideas and considerations that support the optimization of electrical substation design have been painstakingly addressed in this report. Beginning with the careful selection of a site that strikes a delicate balance between closeness to power sources and environmental sensitivity, each decision has far-reaching consequences for the grid\'s integrity. The thorough layout of equipment provides not only performance but also ease of maintenance, thus increasing the reliability of the substation. The consistent use of required clearances and spacing’s, along with the strict execution of industry standards, fortifies substations against the looming threat of electrical dangers. The importance of redundancy and adaptability in providing the grid with resilience and the potential to grow in line with rising power demands cannot be emphasized. Furthermore, the astute adoption of automation and monitoring technology ushers in an era of operational efficiency, in which substations respond quickly to changing requirements. Engineers and designers are responsible for maintaining high standards and embracing new technology that advance electrical substations into the future. In doing so, they not only protect the pillars of safety, dependability, and sustainability, but they also usher in an era in which electrification serves as a transformational force, accelerating growth and innovation across the global landscape.

References

[1] McDonald, John D. \"Electric Power Substations Engineering.\" CRC Press, 2012. [2] Glover, J. Duncan, and Mulukutla S. Sarma. \"Power System Analysis and Design.\" Cengage Learning, 2017. [3] Ghosh, Arindam, and Gerard Ledwich. \"Power Quality Enhancement Using Custom Power Devices.\" Springer, 2002. [4] Codes and Standards: [5] The Institute of Electrical and Electronic Engineers (IEEE) – IEEE C2 – National Electrical Safety Code 10.8. [6] IEEE Standard 605 - IEEE Guide for Bus Design in Air Insulated Substations: This standard provides guidelines for the design of bus bars and the arrangement of equipment in air-insulated substations. [7] IEEE Std 80 - IEEE Guide for Safety in AC Substation Grounding: This standard offer guidance on substation grounding to ensure safety. [8] IEC 61936-1 - Power installations exceeding 1 kV A.C.- Part 1: Common rules: An international standard that outlines general principles and requirements for high-voltage power installations, including substation layouts. [9] IEC 61850 for substation automation and IEC 62271 for high-voltage switchgear and control gear. [10] NFPA 70: National Electrical Code (NEC): The NEC includes safety requirements for electrical installations, and it often addresses clearances, spacings, and other safety considerations in substations. [11] CIGRE Technical Brochures: The International Council on Large Electric Systems (CIGRE) produces technical brochures and publications that cover various aspects of electrical substations, including layout design. [12] IEC 61936-1 : The required minimum aisle width and safety clearances are specified. [13] API RP 500 – Classification of Locations for Electrical Installations at Petroleum Facilities Classified as Class 1 Division 1 and Division 2 [14] API RP 505 – Classification of Locations for Electrical Installations at Petroleum Facilities Classified as Class 1 Zone 0, Zone 1, and Zone 2 [15] API RP 752 – Management of Hazards Associated with Location of Process Plant Buildings [16] https://electrical-engineering-portal.com/civil-engineering-installation-substation-buildings-switchboard-rooms

Copyright

Copyright © 2024 Ashok Ram Tripathi, Binaya Kumar Sahoo. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64290

Publish Date : 2024-09-20

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online