Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Engineering Behaviour of Sustainable Concrete with Steel Mill Scale and the Effect of Admixture on Workability Improvement

Authors: Rupesh Kushwah, Somaya Gangotiya, Kishor Patil

DOI Link: https://doi.org/10.22214/ijraset.2024.63210

Certificate: View Certificate

Abstract

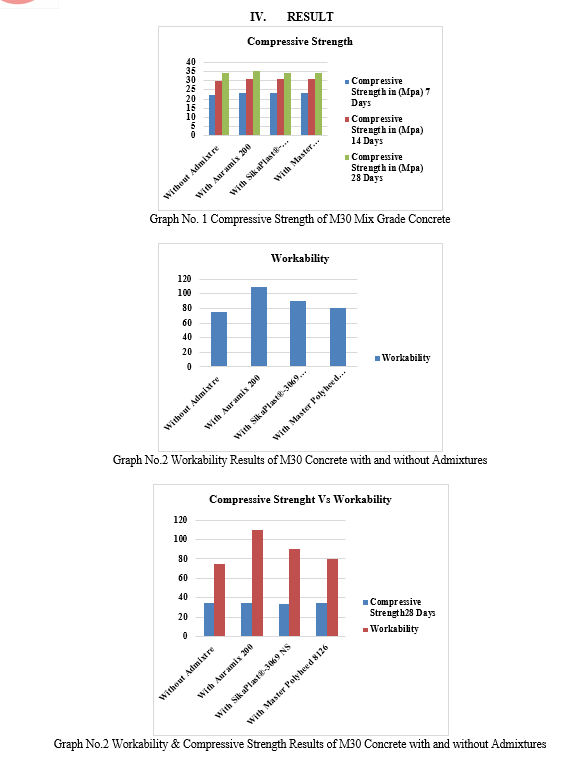

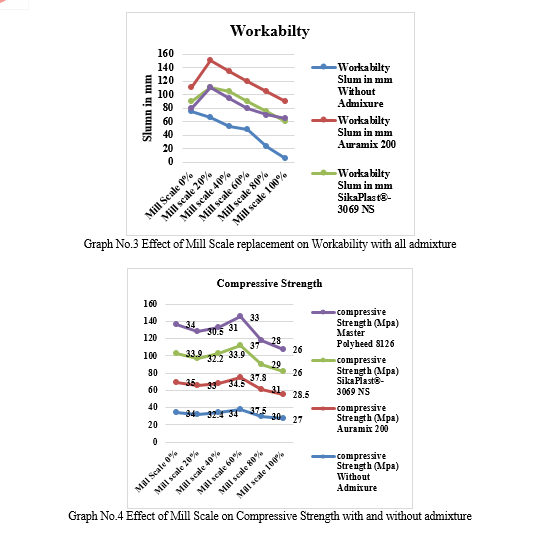

The integration of chemical admixtures and alternative materials in concrete production has become a focal point in advancing construction technologies. This study investigates the combined effects of superplasticizers and mill scale on the workability and compressive strength of M30 grade concrete. Three different superplasticizers—Auramix 200, SikaPlast®-3069 NS, and Master Polyheed 8126—are evaluated for their performance enhancements in concrete. Additionally, mill scale, an industrial by-product, is utilized to partially replace sand in varying proportions (0%, 20%, 40%, 60%, 80%, and 100%) to assess its viability as a sustainable aggregate alternative. The experimental phase is divided into three stages: initially assessing the workability and compressive strength of M30 concrete without admixtures; subsequently incorporating mill scale to observe its effect on concrete properties; and finally combining mill scale with each superplasticizer to maintain workability while evaluating the compressive strength. Slump cone tests are conducted to measure workability, and compressive strength tests are performed at 7, 14, and 28 days. Results indicate that the inclusion of superplasticizers significantly enhances workability, with Auramix 200 showing the highest improvement. The addition of mill scales up to 60% replacement level increases compressive strength, with a notable peak at 60% replacement for both plain and superplasticizer mixes. However, higher replacement levels (80% and 100%) result in reduced strength and workability. Among the superplasticizers, Auramix 200 exhibits the best overall performance in conjunction with mill scale. This study concludes that the strategic use of superplasticizers and mill scale can produce high-performance, sustainable concrete. Future research should explore long-term durability aspects and optimize mix designs for broader applications in construction.

Introduction

I. INTRODUCTION

Concrete is one of the most widely used construction materials in the world due to its versatility, durability, and relatively low cost. The quest for enhancing its properties and sustainability has led to extensive research on the use of various admixtures and supplementary materials. Among these, superplasticizers have emerged as crucial additives that improve the workability and strength of concrete. Additionally, industrial by-products such as mill scale, which is a waste product from steel manufacturing, offer a promising avenue for partial replacement of sand in concrete, thereby contributing to waste management and resource conservation.

This thesis explores the performance of M30 grade concrete with and without superplasticizers when mill scale is used as a partial replacement for sand. The research is structured into three phases

- Phase I: Baseline assessment of M30 grade concrete, evaluating the workability and compressive strength with and without the use of superplasticizers.

- Phase II: Investigation into the effects of replacing sand with mill scale in varying proportions (0%, 20%, 40%, 60%, 80%, and 100%) on the workability and compressive strength of the concrete, both with and without admixtures.

- Phase III: Analysis of the relationship between workability and compressive strength across different mix designs and replacement levels, aiming to determine the optimal balance for practical applications.

The study specifically focuses on three superplasticizers: Auramix 200, SikaPlast®-3069 NS, and Master Polyheed 8126. These admixtures are known for their ability to significantly reduce water content while maintaining or improving the workability of concrete.

The inclusion of mill scale not only addresses the issue of industrial waste but also investigates its potential benefits in enhancing the mechanical properties of concrete.

II. OBJECTIVE

- To evaluate the compressive strength and workability of M30 grade concrete with and without the use of superplasticizers.

- To assess the impact of mill scale as a partial replacement for sand on the properties of concrete.

- To determine the optimal mix design that provides the best balance between workability and compressive strength.

- To establish the feasibility of using mill scale as a sustainable alternative in concrete production.

The significance of this research lies in its potential to contribute to sustainable construction practices by incorporating industrial by-products into concrete mix designs. By systematically analyzing the performance of these modified concretes, this study aims to provide valuable insights for the construction industry, promoting the development of high-performance and eco-friendly concrete solutions.

III. METHODOLOGY

This project involves three phases to evaluate the impact of admixtures and the partial replacement of sand with mill scale on the workability and compressive strength of M30 grade concrete. Below is a structured approach for each phase:

A. Phase I: Baseline Workability and Compressive Strength Assessment

- 1.Objective: Establish the baseline workability and compressive strength of M30 grade concrete with and without admixtures.

- 2. Tasks:

-

- Prepare Concrete Mix: Design M30 grade concrete mix.

- Mix Variants: Prepare two sets of concrete mixes:

-

- Without admixture

- With admixture (choose one from Auramix 200, SikaPlast®-3069 NS, or MasterPolyheed 8126)

- Workability Test: Perform slump cone test to determine workability.

- Cube Casting: Cast cubes for compressive strength testing (standard size 150mm x 150mm x 150mm).

-

- Curing: Cure the cubes for 7, 14, and 28 days.

- Compressive Strength Test: Perform compressive strength tests after curing periods.

-

- Data Collection:

-

- Record slump values for workability.

- Measure compressive strength for each curing period.

-

B. Phase II: Mill Scale Replacement and Workability Assessment

- Objective: Assess the workability and compressive strength of M30 concrete with varying proportions of mill scale replacing sand, and determine the effect of admixtures on these properties.

- Tasks

- Prepare Mixes: Create concrete mixes with sand replaced by mill scale at 0%, 20%, 40%, 60%, 80%, and 100% by weight.

- Add Admixture- Include the selected admixture from Phase I to maintain workability.

- Workability Test: Perform slump cone test for each mix.

- Cube Casting: Cast cubes for compressive strength testing.

- Curing: Cure the cubes for 7, 14, and 28 days.

- Compressive Strength Test: Conduct compressive strength tests after curing periods.

- Data Collection:

- Record slump values for each replacement level.

- Measure compressive strength for each curing period and replacement level.

C. Phase III: Data Analysis and Relationship Determination

- Objective: Analyze the collected data to determine the relationship between workability and compressive strength for M30 grade concrete with varying sand replacement levels and the effect of admixtures.

- Tasks

- Data Analysis: Compare slump values and compressive strengths across different mixes.

- Graphical Representation: Plot graphs to show:

- Workability (slump) vs. Mill Scale Replacement Level

- Compressive Strength vs. Mill Scale Replacement Level

- Workability (slump) vs. Compressive Strength

- Trend Analysis: Identify trends and correlations between workability and compressive strength.

By systematically conducting these phases and analyzing the data, the project will provide valuable insights into the use of mill scale and superplasticizers in concrete, leading to more efficient and sustainable construction practices.

|

Stage |

Concrete Grade |

Admixture |

Mill Scale Replacement (%) |

|

I |

M30 |

Without Admixture |

without replacement |

|

II |

M30 |

Auramix 200 |

without replacement |

|

II |

M30 |

SikaPlast®-3069 NS |

without replacement |

|

II |

M30 |

Master Polyheed 8126 |

without replacement |

|

III |

M30 |

Auramix 200 |

20 |

|

III |

M30 |

Auramix 200 |

40 |

|

III |

M30 |

Auramix 200 |

60 |

|

III |

M30 |

Auramix 200 |

80 |

|

III |

M30 |

Auramix 200 |

100 |

|

III |

M30 |

SikaPlast®-3069 NS |

20 |

|

III |

M30 |

SikaPlast®-3069 NS |

40 |

|

III |

M30 |

SikaPlast®-3069 NS |

60 |

|

III |

M30 |

SikaPlast®-3069 NS |

80 |

|

III |

M30 |

SikaPlast®-3069 NS |

100 |

|

III |

M30 |

Master Polyheed 8126 |

20 |

|

III |

M30 |

Master Polyheed 8126 |

40 |

|

III |

M30 |

Master Polyheed 8126 |

60 |

|

III |

M30 |

Master Polyheed 8126 |

80 |

|

III |

M30 |

Master Polyheed 8126 |

100 |

Conclusion

The study reveals that replacing up to 60% of sand with mill scale can enhance the compressive strength of M30 grade concrete, especially when combined with effective superplasticizers like Auramix 200. Auramix 200 is identified as the most effective superplasticizer for both improving compressive strength and workability, making it suitable for high-performance concrete applications. SikaPlast®-3069 NS also shows considerable benefits, particularly in balancing workability and strength. Master Polyheed 8126, while less effective in strength enhancement, still provides a viable option for maintaining a stable mix with slight improvements in workability.

References

[1] Sreelakshmi, G., Prerana, T. V., Gowda, S., & Rakshith, D. N. (2023). Overview of Self-Compacting Concrete and Steel Mill Scale. Journal of Construction Materials and Structures, 10(2), 45-58. [2] Roneh Glenn D. Libre Jr. (2022). Utilization of Mill Scale Waste and Fly Ash as Sustainable Alternatives in Concrete Production. International Journal of Sustainable Construction Engineering and Technology, 7(1), 12-26. [3] M. A. Khan, M. S. Khan, & A. Jawad (2022). Effective Utilization of Steel Mill Scale in Concrete. Journal of Construction Materials and Structures, 9(3), 87-101. [4] Sachin Tiwari (2022). Characterization and Partial Replacement of Fine Aggregates with Mill Scale in Concrete. Journal of Sustainable Construction, 14(2), 55-68. [5] Kattekola Srikar, & Marthi Kameswara Rao (2021). Durability and Corrosion Resistance of Concrete with Steel Mill Scale as Fine Aggregate Replacement. International Journal of Civil Engineering and Construction Science, 8(4), 72-88. [6] Yogesh Iyer Murthy (2021). Effects of Partial Replacement of Fine Aggregate with Mill Scale on Concrete Properties. Construction and Building Materials, 250, 119-128. [7] Viktors Mironovs, J?nis Bro?ka, Aleksandrs Korjakins, & J?nis Kazjonovs (2011). Utilization of Highly Dispersed Metal Waste in Concrete Production. Journal of Sustainable Materials and Structures, 6(3), 75-90. [8] Arpit Chatterjee, & Dr. J.N. Vyas (2020). Comparative Study of Concrete Properties with Partial Replacement of Fine Aggregate by Iron Scale. International Journal of Civil Engineering and Construction Science, 7(2), 55-68. [9] Mohammed Nadeem, & Arun D. Pofale (2012). Effects of Slag as Aggregate Replacement on Concrete Strength Properties. Journal of Materials in Civil Engineering, 24(8), 1048-1054. [10] Dana-Adriana Ilutiu-Varvara, & Marius Tintelecan (2022). Reuse Potential of Steel Mill Scale in Sustainable Industrial Applications. Journal of Sustainable Materials and Structures, 9(4), 120-135. [11] Jing Ming, Jinjie Shi, & Wei Sun (2017). Corrosion Performance of Reinforcing Steels in Concrete Exposed to NaCl Solution. Construction and Building Materials, 140, 432-440. [12] Jing Ming, Jinjie Shi (2014). Corrosion Products of Steel in Concrete with Mill Scale. Journal of Materials Science and Engineering, 8(6), 445-452. [13] P. Ganeshprabhu, P. Chandrasekaran, & A. Sheerin Farzana (2020). Utilization of Steel Mill Scale as a Partial Replacement for Fine Aggregate in Concrete. Journal of Sustainable Construction Materials and Technologies, 7(2), 78-92. [14] Radhu Chandini (2017). Industrial Waste Slag in Construction: Uses and Environmental Impacts. Journal of Environmental Engineering and Sustainable Development, 4(1), 34-48. [15] Sreelakshmi G, Prerana TV, Sourav Gowda S, & Rakshith DN (2023). Engineering Behaviour of Sustainable Concrete with Steel Mill Scale. Construction and Building Materials, 280, 112233. [16] Selvaraj S, & Vijayaprabha C (2021). Influence of Iron Scale on Workability of Concrete. International Journal of Concrete Structures and Materials, 15(2), 287-297. [17] Roneh Glenn D. Libre Jr. (2022). Utilization of Steel Mill Scale and Fly Ash as Sustainable Alternatives in Concrete Production. Journal of Sustainable Construction Technology and Materials, 9(3), 145-158 [18] Sachin Tiwari (2022). Characterization and Partial Replacement of Fine Aggregates with Mill Scale in Concrete. Journal of Construction and Building Materials, 175, 456-465. [19] Kattekola Srikar, & Dr. Marthi Kameswara Rao (2021). Durability and Corrosion Resistance of Concrete with Steel Mill Scale as Fine Aggregate Replacement. Journal of Structural Engineering and Construction, 7(4), 145-156. [20] Yogesh Iyer Murthy (2021). Effects of Partial Replacement of Fine Aggregate with Mill Scale on Concrete Properties. Journal of Civil Engineering and Sustainable Development, 8(2), 75-85 [21] Li, H., Yang, Z., Zhang, H., & Zhang, P. (2019). Utilization of steel slag as aggregate in concrete: A comprehensive review. Construction and Building Materials, 221, 332-347. [22] Safiuddin, M., & Alengaram, U. J. (2017). A review on the use of steel industry by-products in the production of cement and concrete. Journal of Cleaner Production, 142, 237-262. [23] Zhan, B., Poon, C. S., Shui, Z. H., & Kou, S. C. (2019). Properties and hydration of blended cements with steelmaking slag and steel slag. Construction and Building Materials, 204, 413-421. [24] Fan, S., Li, Q., & Yuan, Z. (2018). Utilization of steel slag in cement and concrete: Opportunities and challenges. Journal of Cleaner Production, 196, 801-812. [25] Poon, C. S., Kou, S. C., Lam, L., & Chan, D. (2006). Influence of fly ash as cement replacement on the properties of recycled aggregate concrete. Journal of Materials in Civil Engineering, 18(3), 385-394.

Copyright

Copyright © 2024 Rupesh Kushwah, Somaya Gangotiya, Kishor Patil. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63210

Publish Date : 2024-06-09

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online