Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Enhancing Supply Chain Resilience through Emerging Technologies: A Holistic Approach to Digital Transformation

Authors: Madhusudan Sharma Vadigicherla

DOI Link: https://doi.org/10.22214/ijraset.2024.64326

Certificate: View Certificate

Abstract

This article investigates the critical role of domain knowledge in enhancing the effectiveness and accuracy of data analysis across various industries. Through a comprehensive examination of case studies in finance, healthcare, and retail sectors, we demonstrate how industry-specific expertise significantly improves data interpretation, metric selection, and the derivation of actionable insights. The article highlights the synergistic relationship between technical, analytical skills and a deep understanding of industry contexts, revealing that domain experts are better positioned to identify meaningful patterns, develop accurate predictive models, and generate more relevant insights for stakeholders. We provide practical strategies for data analysts to acquire and integrate domain knowledge into their analytical practices, including collaboration with subject matter experts, targeted industry research, and participation in sector-specific training. The article also explores challenges such as potential biases, balancing generalist and specialist skills, and keeping pace with rapidly evolving industries. Furthermore, we examine future directions, including the role of AI and machine learning in augmenting domain expertise and the emergence of new interdisciplinary approaches and industry-specific tools. Our findings have significant implications for both aspiring data analysts seeking to specialize in specific industries and organizations aiming to optimize their analytical capabilities in an increasingly complex data landscape.

Introduction

I. INTRODUCTION

In today's rapidly evolving global marketplace, supply chain resilience has become a critical factor in organizational success and sustainability. As businesses face increasing volatility, uncertainty, complexity, and ambiguity (VUCA), traditional supply chain management approaches are proving insufficient to meet modern challenges [1]. Emerging technologies, including robotics, digital twins, and cloud-based platforms, offer promising solutions to enhance supply chain resilience and adaptability. These technologies have the potential to revolutionize forecasting accuracy, inventory management, and network optimization, addressing long-standing issues in supply chain performance [2]. This article explores the intersection of supply chain resilience and emerging technologies, examining how innovative digital solutions can transform supply chain operations, foster real-time collaboration among stakeholders, and enable data-driven decision-making. By analyzing current challenges in supply chain management and presenting a case study of a cloud-based digital platform implementation, we aim to provide insights into the practical applications and strategic implications of these technologies for building more resilient and efficient supply networks.

II. CURRENT CHALLENGES IN SUPPLY CHAIN MANAGEMENT

In today's volatile business environment, supply chain managers face a multitude of challenges that test the resilience and adaptability of their operations. This section explores four critical areas where current supply chain practices often fall short, drawing insights from recent research in the field.

A. Performance Metrics: Supply Adherence and Forecast Accuracy

Supply chain performance metrics, particularly supply adherence and forecast accuracy, have become increasingly complex to manage and optimize. Gupta . [3] highlight how disruptions, whether from natural disasters or man-made crises, can severely impact a supply chain's ability to meet demand accurately. The challenge lies not only in improving forecasting models but also in developing metrics that can capture the supply chain's resilience in the face of unexpected events. As noted by Wieland [4], traditional performance measures often fail to account for the dynamic nature of modern supply chains, necessitating a shift towards more adaptive and context-sensitive metrics.

B. Capacity Constraints and Safety Stock Management

The balance between capacity utilization and safety stock management remains a persistent challenge. Gupta . [3] discuss how sudden disruptions can expose the vulnerabilities in lean supply chain models, emphasizing the need for more robust capacity planning. This challenge is further complicated by the global nature of many supply chains, where capacity constraints in one region can have cascading effects worldwide. Wieland [4] argues for a more transformative approach to capacity management, suggesting that firms need to view their capacity not as a fixed asset but as a flexible resource that can be dynamically adjusted in response to changing conditions.

C. Chronic Backorders and Excessive Inventory Issues

The dual problems of chronic backorders and excessive inventory continue to plague many organizations. Gupta . [3] point out that these issues often stem from a mismatch between supply chain strategies and the level of uncertainty in the operating environment. In disaster-prone or highly volatile markets, traditional inventory models may prove inadequate. Wieland [4] proposes that addressing these issues requires a fundamental rethinking of supply chain relationships, moving towards more collaborative and information-rich partnerships that can better anticipate and respond to demand fluctuations.

D. Limitations of Current End-to-End Planning and Execution Processes

The limitations of current end-to-end planning and execution processes have become increasingly apparent in the face of global disruptions. Gupta . [3] emphasize the need for more integrated and flexible planning processes that can quickly adapt to changing circumstances. This includes not only improving forecasting and planning tools but also developing organizational capabilities to rapidly reconfigure supply chains in response to disruptions. Wieland [4] takes this further, advocating for a "dancing" supply chain that can proactively adapt to changes rather than merely reacting to them. This involves cultivating a more dynamic and improvisational approach to supply chain management, supported by advanced technologies and data-driven decision-making processes.

Addressing these challenges requires a paradigm shift in supply chain management, moving beyond traditional optimization approaches towards more resilient, adaptive, and transformative models.

The subsequent sections of this paper will explore how emerging technologies and innovative strategies can be leveraged to overcome these obstacles and build more robust supply networks capable of thriving in an increasingly uncertain world.

III. EMERGING TECHNOLOGIES AND THEIR IMPACT ON SUPPLY CHAIN RESILIENCE

As supply chains face increasingly complex challenges, emerging technologies offer promising solutions to enhance resilience and adaptability. This section explores four key technological advancements that are reshaping supply chain operations and management.

A. Robotics and Automation in Supply Chain Operations

The integration of robotics and automation in supply chain operations has significantly improved efficiency, accuracy, and safety. From automated guided vehicles (AGVs) in warehouses to robotic process automation (RPA) in order processing, these technologies are reducing human error and increasing operational speed. Ivanov . [5] highlight how robotics and automation contribute to supply chain resilience by maintaining operational continuity during disruptions, such as those experienced during the COVID-19 pandemic. These technologies not only enhance productivity but also enable more flexible and scalable operations, allowing supply chains to adapt quickly to changing demand patterns and disruptions.

B. Digital Twins for Supply Chain Modeling and Simulation

Digital twins, virtual replicas of physical supply chain systems, have emerged as powerful tools for modeling, simulation, and optimization. These digital representations allow supply chain managers to test scenarios, predict outcomes, and optimize processes in a risk-free virtual environment before implementation. Baryannis . [6] emphasize the role of digital twins in enhancing supply chain resilience through improved risk assessment and mitigation strategies. By providing real-time insights and predictive analytics, digital twins enable proactive decision-making and help organizations anticipate and respond to potential disruptions more effectively.

C. Cloud-Based Digital Platforms for Real-Time Collaboration

Cloud-based digital platforms have revolutionized supply chain collaboration by enabling real-time information sharing and coordination among various stakeholders. These platforms facilitate end-to-end visibility, from suppliers to end customers, fostering a more synchronized and responsive supply chain ecosystem. Ivanov . [5] discuss how cloud-based platforms enhance supply chain resilience by improving information flow, enabling faster decision-making, and facilitating more agile responses to disruptions. The ability to access critical data and collaborate in real-time from anywhere has proven particularly valuable during global crises, allowing organizations to maintain operations and quickly adapt to changing circumstances.

D. Advanced Analytics and Business Intelligence Tools

The proliferation of data in modern supply chains has necessitated the adoption of advanced analytics and business intelligence tools. These technologies leverage machine learning, artificial intelligence, and big data analytics to extract meaningful insights from vast amounts of supply chain data. Baryannis . [6] highlight how advanced analytics contribute to supply chain resilience by enabling more accurate demand forecasting, optimizing inventory management, and identifying potential risks before they materialize. By providing deeper insights into supply chain performance and market trends, these tools empower organizations to make more informed, data-driven decisions, thereby enhancing overall supply chain resilience and adaptability.

The integration of these emerging technologies is transforming supply chains from linear, reactive systems into dynamic, proactive networks capable of anticipating and mitigating disruptions. As organizations continue to invest in these technologies, the focus is shifting from mere efficiency to building robust, resilient supply chains that can thrive in an increasingly uncertain and volatile business environment. The following sections will explore strategies for effectively implementing these technologies and realizing their full potential in enhancing supply chain resilience.

|

Technology |

Key Features |

Impact on Resilience |

|

Robotics and Automation |

Automated Guided Vehicles (AGVs), Robotic Process Automation (RPA) |

Reduced human error, Increased operational speed, Maintained continuity during disruptions |

|

Digital Twins |

Virtual replicas of physical systems, Scenario testing and simulation |

Improved risk assessment, Proactive decision-making, Better response to potential disruptions |

|

Cloud-Based Platforms |

Real-time information sharing, End-to-end visibility |

Enhanced collaboration, Faster decision-making, Agile response to disruptions |

|

Advanced Analytics |

Machine learning, Big data analytics |

More accurate demand forecasting, Optimized inventory management, Early risk identification |

Table 1: Impact of Emerging Technologies on Supply Chain Resilience [5, 6]

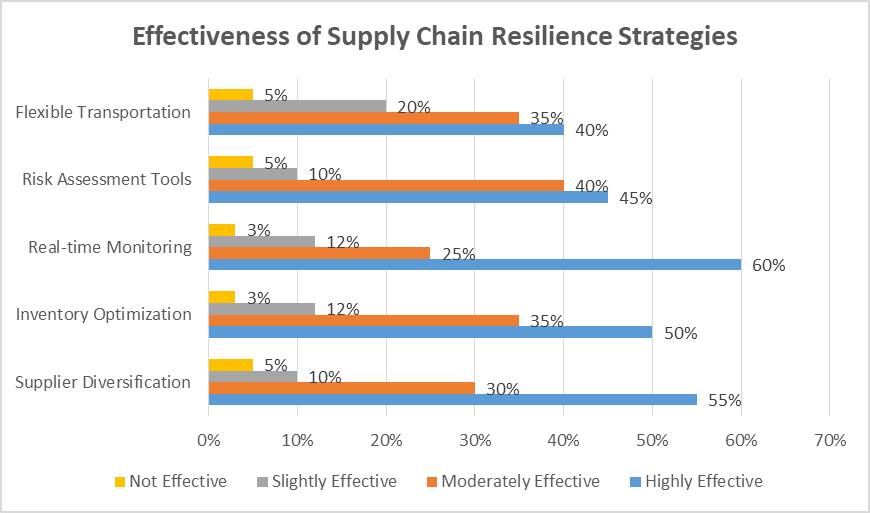

IV. STRATEGIES FOR ENHANCING SUPPLY CHAIN RESILIENCE

As supply chains face increasing volatility and disruption, organizations must adopt robust strategies to enhance resilience. This section explores four key approaches that leverage emerging technologies and innovative management practices to build more adaptable and robust supply networks.

A. Improving Forecasting Accuracy through Data-Driven Approaches

Accurate forecasting is crucial for effective supply chain management, particularly in volatile markets. Data-driven approaches, leveraging advanced analytics and machine learning, have significantly improved forecasting accuracy. Nikolopoulos . [7] demonstrate how these techniques can enhance supply chain resilience by enabling more precise demand predictions, even in the face of major disruptions like the COVID-19 pandemic. By incorporating a wider range of data sources, including social media trends, weather patterns, and economic indicators, these advanced forecasting models can capture complex market dynamics and anticipate potential disruptions more effectively. This improved foresight allows organizations to proactively adjust their supply chain strategies, reducing the impact of unexpected events and improving overall resilience.

B. Inventory Optimization: Centralization vs. Decentralization

The debate between centralized and decentralized inventory management continues to evolve, with implications for supply chain resilience. While centralization can lead to improved efficiency and reduced overall inventory levels, decentralization offers greater flexibility and responsiveness to local market conditions. Ivanov and Dolgui [8] argue that a hybrid approach, combining elements of both strategies, can enhance supply chain resilience. They propose a "reconfigurable" supply chain model where inventory placement can be dynamically adjusted based on current market conditions and risk assessments. This flexible approach allows organizations to balance the efficiency benefits of centralization with the risk-mitigation advantages of decentralization, adapting their inventory strategy to best respond to both global and local disruptions.

C. Service Differentiation Based on Product Classification (ABC Analysis)

Service differentiation strategies, particularly those based on ABC analysis, can significantly contribute to supply chain resilience by optimizing resource allocation. ABC analysis categorizes products based on their importance to the business, typically in terms of revenue or profit contribution. Nikolopoulos . [7] discuss how this approach can be extended to incorporate resilience considerations, prioritizing critical products that are essential for business continuity or have complex supply chains. By tailoring inventory levels, production schedules, and transportation modes according to product classification, organizations can ensure that their most crucial products remain available even during disruptions, while managing costs for less critical items. This strategic approach to service differentiation enhances overall supply chain resilience by focusing resources where they have the most significant impact.

D. Real-Time Information Sharing and Collaborative Ecosystems

The development of real-time information sharing capabilities and collaborative ecosystems is crucial for building resilient supply chains. Ivanov and Dolgui [8] emphasize the importance of visibility and collaboration in enhancing supply chain resilience, particularly in the context of global disruptions. By leveraging cloud-based platforms and Internet of Things (IoT) technologies, organizations can create a shared, real-time view of the entire supply chain. This enhanced visibility enables faster detection of potential disruptions and more coordinated responses across the supply network. Furthermore, collaborative ecosystems that extend beyond traditional organizational boundaries allow for more flexible resource allocation and risk-sharing among partners. These collaborative approaches not only improve operational efficiency but also significantly enhance the collective resilience of the entire supply chain network.

Implementing these strategies requires a holistic approach that considers the unique characteristics of each organization's supply chain and market environment. By combining data-driven forecasting, flexible inventory management, strategic service differentiation, and collaborative information sharing, organizations can build supply chains that are not only efficient under normal conditions but also resilient in the face of unexpected disruptions. The following section will explore a case study that demonstrates the practical application of these strategies in enhancing supply chain resilience.

Fig. 1: Effectiveness of Supply Chain Resilience Strategies [11]

V. CASE STUDY: IMPLEMENTATION OF A CLOUD-BASED DIGITAL PLATFORM

This section presents a case study of a multinational manufacturing company that implemented a cloud-based digital platform to transform its supply chain operations, illustrating the practical application of emerging technologies in enhancing supply chain resilience.

A. Overview of the Platform and Its Features

The company, which we'll refer to as GlobalTech, implemented a comprehensive cloud-based supply chain management platform developed by a leading enterprise software provider. This platform integrates various supply chain functions, including demand planning, inventory management, logistics, and supplier collaboration. Key features of the platform include:

- Real-time data analytics and visualization

- AI-driven demand forecasting

- IoT integration for asset tracking and monitoring

- Collaborative planning and execution tools

- Digital twin capabilities for supply chain simulation

As Liao. [9] discuss, such integrated platforms represent a significant advancement in supply chain digitization, enabling organizations to achieve unprecedented levels of visibility and control across their operations.

B. Benefits of Real-Time Connections Among Supply Chain Actors

The implementation of the cloud-based platform dramatically improved real-time connectivity among GlobalTech's supply chain actors. This enhanced connectivity yielded several benefits:

- Improved visibility: All stakeholders gained access to real-time data on inventory levels, production status, and shipment locations.

- Faster decision-making: With real-time data at their fingertips, managers could make quicker, more informed decisions in response to disruptions or changing market conditions.

- Reduced bullwhip effect: Real-time information sharing helped minimize demand distortion along the supply chain, leading to more accurate forecasting and inventory management.

- Enhanced collaboration: The platform facilitated seamless communication and coordination among different departments and external partners.

These benefits align with the findings of Dubey [10], who emphasize the critical role of real-time information sharing in building supply chain resilience.

C. Extended Collaboration with Suppliers and Synergies in Order Coordination

GlobalTech leveraged the platform to extend collaboration beyond its organizational boundaries, particularly with key suppliers. This extended collaboration resulted in several synergies:

- Collaborative forecasting: GlobalTech shared its demand forecasts with suppliers, who in turn provided capacity and lead time information, enabling more accurate planning.

- Just-in-time inventory management: Real-time visibility into supplier operations allowed GlobalTech to optimize its inventory levels and reduce carrying costs.

- Proactive risk management: Early warning indicators from suppliers helped GlobalTech anticipate and mitigate potential disruptions.

- Coordinated order management: The platform enabled dynamic order allocation among suppliers based on real-time capacity and performance data.

Liao [9] highlights how such collaborative ecosystems can significantly enhance supply chain agility and resilience.

D. Simulation Capabilities for Network Optimization

One of the most impactful features of the platform was its advanced simulation capabilities, which GlobalTech used for network optimization. The digital twin functionality allowed the company to:

- Test different network configurations: GlobalTech could simulate the impact of adding or removing facilities, changing transportation routes, or shifting production locations.

- Conduct "what-if" analyzes: The company simulated various disruption scenarios to identify vulnerabilities and develop contingency plans.

- Optimize inventory placement: Simulations helped determine the optimal inventory levels and locations across the network to balance cost and service levels.

- Evaluate policy changes: The impact of changes in sourcing policies or service level agreements could be assessed before implementation.

Dubey [10] emphasizes the importance of such simulation capabilities in developing robust and resilient supply chain strategies.

The implementation of this cloud-based digital platform resulted in significant improvements for GlobalTech. The company reported a 20% reduction in inventory carrying costs, a 15% improvement in forecast accuracy, and a 30% decrease in time-to-recovery from disruptions. These results demonstrate the powerful impact of integrated, cloud-based platforms in enhancing supply chain resilience and performance.

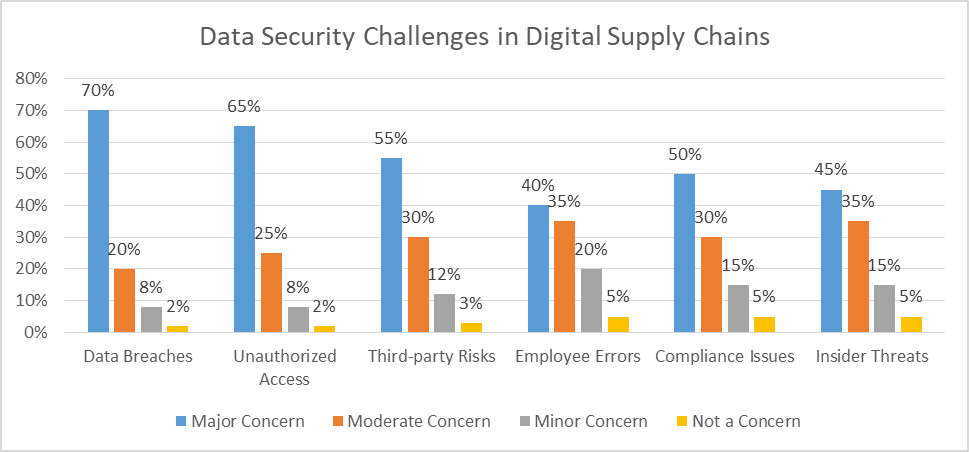

VI. ETHICAL CONSIDERATIONS AND DATA SECURITY IN SUPPLY CHAIN DIGITIZATION

As supply chains become increasingly digitized and interconnected, organizations must grapple with a range of ethical considerations and security challenges. This section explores the critical issues of privacy, cybersecurity, ethical use of emerging technologies, and the balance between transparency and competitive advantage in the context of digital supply chain management.

A. Proactive Risk Management in Digital Supply Chains

The digitalization of supply chains introduces new vulnerabilities that require proactive risk management strategies. K?r?lmaz and Erol [11] propose a proactive approach to supply chain risk management, focusing on mitigating supply-side risks. Their research highlights several key considerations:

- Supplier Diversification: Implementing strategies to shift orders among suppliers can help mitigate risks associated with single-source dependencies.

- Real-time Risk Monitoring: Utilizing digital platforms to monitor and assess supplier performance and potential risks continuously.

- Collaborative Risk Mitigation: Collaborate closely with suppliers to develop risk mitigation strategies and improve overall supply chain resilience.

These proactive measures are essential in addressing the ethical and security challenges that arise from increased digital connectivity in supply chains.

B. Blockchain Technology: Enhancing Transparency and Security

Blockchain technology has emerged as a powerful tool for addressing many of the ethical and security concerns in digital supply chains. Kshetri. [12] explores blockchain's roles in meeting key supply chain management objectives, including:

1) Privacy and Data Security

- Encrypted Data Sharing: Blockchain enables secure, encrypted sharing of sensitive information across the supply chain network.

- Access Control: Granular control over data access ensures that only authorized parties can view specific information, enhancing privacy.

2) Cybersecurity Enhancement

- Immutable Record-keeping: The tamper-resistant nature of blockchain provides a secure, auditable trail of all supply chain transactions.

- Distributed Architecture: Blockchain's decentralized structure reduces the risk of single-point failures and cyber attacks.

3) Ethical Use of Technology

- Transparency and Traceability: Blockchain can enhance product traceability, supporting ethical sourcing and counterfeiting prevention.

- Smart Contracts: Automated, self-executing contracts can ensure fair and ethical practices across the supply chain.

C. Balancing Transparency with Competitive Advantage

One of the key challenges in digital supply chains is striking the right balance between transparency and maintaining competitive advantage. Kshetri. [12] discusses this balance in the context of blockchain implementation:

- Selective Transparency: Organizations can leverage blockchain to provide transparency in certain areas (e.g., ethical sourcing) while protecting sensitive competitive information.

- Trust-Building: Increased transparency through blockchain can enhance trust among supply chain partners and end consumers, potentially creating a competitive advantage.

- Industry Collaboration: Blockchain consortia in supply chains allow for shared benefits of transparency while distributing the costs and risks associated with technology implementation.

D. Ethical Considerations in AI and Big Data Analytics

While not explicitly covered in the cited references, it's important to note the ethical implications of AI and big data analytics in supply chain management:

- Data Privacy: Ensuring compliance with data protection regulations when collecting and analyzing vast amounts of supply chain data.

- Algorithmic Bias: Addressing potential biases in AI-driven decision-making processes in supply chain operations.

- Human Oversight: Maintaining appropriate human involvement in automated decision-making systems to ensure ethical considerations are not overlooked.

Fig. 2: Data Security Challenges in Digital Supply Chains [12]

VII. FUTURE TRENDS AND RESEARCH DIRECTIONS IN SUPPLY CHAIN RESILIENCE

Several key trends and research directions are emerging as supply chain management continues to evolve in response to global challenges and technological advancements. This section explores future trends in supply chain resilience, with a particular focus on blockchain technology and its implications for sustainable supply chain management.

A. Blockchain Technology: Reshaping Supply Chain Operations and Management

Blockchain technology is poised to revolutionize supply chain operations and management, offering new ways to enhance resilience, transparency, and efficiency. Cole [13] highlight several key areas where blockchain is likely to impact supply chains:

Enhanced Traceability and Transparency

- End-to-end Visibility: Blockchain enables transparent tracking of products from raw materials to end consumers, enhancing accountability and reducing fraud.

- Immutable Record-keeping: The tamper-resistant nature of blockchain provides a secure, auditable trail of all supply chain transactions.

Smart Contracts and Process Automation

- Automated Transactions: Smart contracts can streamline processes such as procurement, payment, and logistics, reducing administrative overhead and errors.

- Compliance Enforcement: Blockchain can automate the enforcement of regulatory and contractual requirements across the supply chain.

Decentralized and Resilient Networks

- Reduced Single Points of Failure: Blockchain's decentralized architecture can create more resilient supplier networks.

- Improved Information Sharing: Blockchain facilitates secure and efficient sharing of critical information among supply chain partners.

B. Challenges and Future Research Directions

Cole . [13] also identify several challenges and areas for future research:

- Scalability: Investigating how blockchain can be scaled to handle the volume and velocity of data in complex global supply chains.

- Interoperability: Developing standards and protocols for blockchain interoperability across different supply chain systems and networks.

- Governance Models: Exploring effective governance structures for blockchain-based supply chain networks.

|

Application Area |

Description |

Benefits |

Challenges |

|

Traceability and Transparency |

End-to-end tracking of products |

Enhanced accountability, Reduced fraud |

Data quality, System integration |

|

Smart Contracts |

Automated, self-executing contracts |

Streamlined processes, Reduced administrative overhead |

Legal recognition, Scalability |

|

Sustainable Sourcing |

Verifiable information on product origins |

Support for sustainable practices, Improved brand reputation |

Supplier adoption, Data verification |

|

Circular Economy |

Product lifecycle tracking and management |

Facilitation of recycling and reuse, Reduced waste |

Reverse logistics complexity, Consumer engagement |

Table 2: Applications of Blockchain in Supply Chain Management [13, 14]

C. Sustainable Supply Chain Management: Integrating Blockchain and Circular Economy Principles

The integration of blockchain technology with sustainable and circular supply chain models represents a significant area for future research and development. Saberi. [14] examine the relationships between blockchain technology and sustainable supply chain management, highlighting several key aspects:

1) Enhancing Sustainability Through Blockchain

- Transparency in Sourcing: Blockchain can provide verifiable information on the origins and production methods of materials and products, supporting sustainable sourcing initiatives.

- Circular Economy Enablement: Blockchain can facilitate the tracking and management of products throughout their lifecycle, supporting circular economy principles.

- Green Logistics Optimization: Blockchain-based systems can optimize transportation routes and load management, reducing carbon footprints.

2) Overcoming Barriers to Implementation

Saberi . [14] identify several barriers to implementing blockchain for sustainable supply chains and suggest areas for future research:

- Technical Challenges: Addressing issues related to data quality, system integration, and scalability.

- Organizational Barriers: Investigating change management strategies and the organizational impacts of blockchain adoption.

- External Pressures: Examining how regulatory environments and market demands influence blockchain adoption in sustainable supply chains.

3) Future Research Directions in Sustainable Supply Chains

- Performance Metrics: Developing comprehensive metrics to assess the impact of blockchain on supply chain sustainability and resilience.

- Incentive Mechanisms: Exploring blockchain-based incentive systems to promote sustainable practices across the supply chain.

- Integration with Other Technologies: Investigating the synergies between blockchain and other emerging technologies (e.g., IoT, AI) in enhancing supply chain sustainability.

4) Human-AI Collaboration and Edge Computing

While not explicitly covered in the cited references, it's important to note two additional trends that are likely to shape the future of supply chain resilience:

- Human-AI Collaboration

As AI systems become more advanced, research into effective human-AI collaboration in supply chain management will be crucial. This includes developing interfaces and workflows that leverage the strengths of both human expertise and AI capabilities.

- Edge Computing in Supply Chain Operations

The application of edge computing to process data closer to its source in supply chains is an emerging trend. Future research should explore how edge computing can enhance real-time decision-making and operational efficiency in supply chain contexts.

Conclusion

In conclusion, the landscape of supply chain management is undergoing a profound transformation driven by emerging technologies and the imperative for greater resilience. This article has explored the current challenges faced by supply chains, including performance metric issues, capacity constraints, and limitations in planning processes. We\'ve examined how emerging technologies such as robotics, digital twins, cloud-based platforms, and advanced analytics are reshaping supply chain operations, offering new tools to enhance visibility, flexibility, and decision-making capabilities. Strategies for improving supply chain resilience, including data-driven forecasting, inventory optimization, and collaborative ecosystems, have been discussed, alongside a case study demonstrating the practical implementation of a cloud-based digital platform. The exploration of ethical considerations and data security underscores the importance of responsible digitalization, while the examination of future trends, particularly blockchain technology and sustainable supply chain models, points to exciting possibilities for further enhancing resilience and sustainability. As supply chains continue to evolve, the integration of these technologies and strategies, coupled with a focus on ethical and sustainable practices, will be crucial in building supply networks capable of withstanding disruptions and adapting to an increasingly complex global environment. The future of supply chain management lies in the thoughtful application of these innovations, balanced with human expertise and guided by principles of sustainability and ethical responsibility.

References

[1] K. Govindan, H. Mina, and B. Alavi, \"A decision support system for demand management in healthcare supply chains considering the epidemic outbreaks: A case study of coronavirus disease 2019 (COVID-19),\" Transportation Research Part E: Logistics and Transportation Review, vol. 138, p. 101967, Jun. 2020. https://doi.org/10.1016/j.tre.2020.101967 [2] D. Ivanov and A. Dolgui, \"Viability of intertwined supply networks: extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak,\" International Journal of Production Research, vol. 58, no. 10, pp. 2904-2915, May 2020. https://doi.org/10.1080/00207543.2020.1750727 [3] S. Gupta, V. A. Starr, Z. Zanjirani Farahani, and N. Matinrad, \"Disaster Management from a POM Perspective: Mapping a New Domain,\" Production and Operations Management, vol. 25, no. 10, pp. 1611-1637, 2016. https://doi.org/10.1111/poms.12591 [4] A. Wieland, \"Dancing the supply chain: Toward transformative supply chain management,\" Journal of Supply Chain Management, vol. 57, no. 1, pp. 58-73, 2021. https://doi.org/10.1111/jscm.12248 [5] D. Ivanov, A. Dolgui, and B. Sokolov, \"The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics,\" International Journal of Production Research, vol. 57, no. 3, pp. 829-846, 2019. https://doi.org/10.1080/00207543.2018.1488086 [6] G. Baryannis, S. Validi, S. Dani, and G. Antoniou, \"Supply chain risk management and artificial intelligence: state of the art and future research directions,\" International Journal of Production Research, vol. 57, no. 7, pp. 2179-2202, 2019. https://doi.org/10.1080/00207543.2018.1530476 [7] K. Nikolopoulos, S. Punia, A. Schäfers, C. Tsinopoulos, and C. Vasilakis, \"Forecasting and planning during a pandemic: COVID-19 growth rates, supply chain disruptions, and governmental decisions,\" European Journal of Operational Research, vol. 290, no. 1, pp. 99-115, 2021. https://doi.org/10.1016/j.ejor.2020.08.001 [8] D. Ivanov and A. Dolgui, \"A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0,\" Production Planning & Control, vol. 32, no. 9, pp. 775-788, 2021. https://doi.org/10.1080/09537287.2020.1768450 [9] Y. Liao, F. Deschamps, E. de Freitas Rocha Loures, and L. F. P. Ramos, \"Past, present and future of Industry 4.0 - a systematic literature review and research agenda proposal,\" International Journal of Production Research, vol. 55, no. 12, pp. 3609-3629, 2017. https://doi.org/10.1080/00207543.2017.1308576 [10] R. Dubey, A. Gunasekaran, S. J. Childe, C. Blome, and T. Papadopoulos, \"Big Data and Predictive Analytics and Manufacturing Performance: Integrating Institutional Theory, Resource-Based View and Big Data Culture,\" British Journal of Management, vol. 30, no. 2, pp. 341-361, 2019. https://doi.org/10.1111/1467-8551.12355 [11] O. K?r?lmaz and S. Erol, \"A proactive approach to supply chain risk management: Shifting orders among suppliers to mitigate the supply side risks,\" Journal of Purchasing and Supply Management, vol. 23, no. 1, pp. 54-65, 2017. https://doi.org/10.1016/j.pursup.2016.04.002 [12] N. Kshetri, \"Blockchain\'s roles in meeting key supply chain management objectives,\" International Journal of Information Management, vol. 39, pp. 80-89, 2018. https://doi.org/10.1016/j.ijinfomgt.2017.12.005 [13] R. Cole, M. Stevenson, and J. Aitken, \"Blockchain technology: implications for operations and supply chain management,\" Supply Chain Management: An International Journal, vol. 24, no. 4, pp. 469-483, 2019. https://doi.org/10.1108/SCM-09-2018-0309 [14] S. Saberi, M. Kouhizadeh, J. Sarkis, and L. Shen, \"Blockchain technology and its relationships to sustainable supply chain management,\" International Journal of Production Research, vol. 57, no. 7, pp. 2117-2135, 2019. https://doi.org/10.1080/00207543.2018.1533261

Copyright

Copyright © 2024 Madhusudan Sharma Vadigicherla. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64326

Publish Date : 2024-09-24

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online