Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Literature Review on Experimental Analysis of Domestic Refrigerator

Authors: Dr. A. H. Ingle, Rahil Sheikh, Nadim Khan

DOI Link: https://doi.org/10.22214/ijraset.2024.62567

Certificate: View Certificate

Abstract

This literature review paper delves into the experimental analysis of the performance of domestic refrigerators, a cornerstone of modern household appliances. The review synthesizes a broad spectrum of studies that examine the efficiency, energy consumption, cooling capacity, and overall performance of various domestic refrigerator models. Key focus areas include the impact of different refrigerants, advancements in compressor technology, insulation materials, and the role of smart technologies in enhancing refrigerator performance. The review highlights experimental methodologies employed to assess refrigerator performance, such as standardized testing protocols, real-world usage simulations, and advanced diagnostic techniques. It also discusses the influence of external factors like ambient temperature, door opening frequency, and load variability on refrigerator efficiency. Comparative analyses within the literature reveal trends in energy efficiency improvements, driven by regulatory standards and consumer demand for environmentally friendly appliances. The integration of alternative refrigerants, such as R600a (isobutane), is examined for its environmental benefits and performance implications. The paper concludes by identifying gaps in current research and suggesting directions for future experimental studies. Emphasis is placed on the need for continued innovation in refrigeration technologies to meet growing energy efficiency and environmental sustainability requirements. Overall, this literature review provides a comprehensive overview of the experimental evaluation techniques and findings related to domestic refrigerator performance, offering insights that can guide future research and development in this vital field.

Introduction

I. INTRODUCTION

Domestic refrigerators are essential household appliances, playing a critical role in food preservation and contributing significantly to household energy consumption. With the increasing global emphasis on energy efficiency and environmental sustainability, the performance of domestic refrigerators has become a focal point for both manufacturers and researchers. The drive to improve refrigerator performance encompasses various aspects, including reducing energy consumption, enhancing cooling efficiency, and minimizing environmental impact.

Over the years, a plethora of experimental studies have been conducted to evaluate and enhance the performance of domestic refrigerators. These studies typically focus on key components such as refrigerants, compressors, insulation materials, and smart technologies. Each component's efficiency and effectiveness are crucial for the overall performance of the refrigerator. For instance, the choice of refrigerant not only affects cooling capacity and energy consumption but also has significant environmental implications due to the potential for ozone depletion and global warming.

This literature review aims to synthesize the existing body of research on the experimental analysis of domestic refrigerator performance. By examining a wide range of studies, this paper seeks to provide a comprehensive overview of the methodologies, findings, and trends in this field. It will explore the various experimental setups and protocols used to measure and compare refrigerator performance, highlighting the innovations and advancements that have emerged over time.

Key areas of focus include the impact of different refrigerants, advancements in compressor technology, the effectiveness of insulation materials, and the integration of smart technologies. Additionally, the review will discuss the influence of external factors such as ambient temperature, door opening frequency, and load variability on refrigerator efficiency.

The importance of this literature review lies in its ability to identify gaps in current research and suggest directions for future studies. By understanding the strengths and limitations of existing experimental analyses, researchers and manufacturers can better design and optimize domestic refrigerators to meet the evolving demands for energy efficiency and environmental sustainability.

Overall, this paper aims to provide valuable insights into the experimental analysis of domestic refrigerator performance, contributing to the ongoing efforts to enhance the efficiency and environmental friendliness of this ubiquitous household appliance.

A Domestic cooler is a typical home device that comprises of a thermally protected compartment and which when works, tramsfers heat from within the compartment to its outside climate so that within the thermally protected compartment is cooled to a temperature beneath the surrounding temperature of the room. In domestic refrigeration systems the R134a refrigerant is working as a heat transfer substance [1-3]. The heat transfer is mainly depends on the thermal conductivity of the refrigerant. Investigation shows that the addition of nanoparticles with conventional fluids leads to better enhancement in heat transfer process [4]. Since contrasted with microsized particles, nanoparticles gangs high surface region to volume proportion because of the inhabitance of enormous number of molecules on the limits, which make them profoundly stable in suspensions [5]. Nano liquids have the accompanying attributes contrasted with the typical liquids. I) higher warmth move between the particvles and liquids because of the great surface space of the particles ii) better scattering dependability iii) lessens molecule obstructing iv) decreased siphoning power when contrasted with base liquid to get comparable warmth move [6-11].

The different nanoparticles like CuO, Al2O3, SiO2, precious stone, CNT and TiO2 were utilized with base refrigerants like R11, R113, R123, R134a and 141b were utilized in refrigeration framework [12]. There is another nanoparticle, for example, CeO2, ZnO, and SiO2 are accessible with better thermophysical and warmth move capacities. In this experimentation the Cerium Oxide and Zinc Oxide nanoparticles in the size of around 20-30nm and 30-50nm separately added with the homegrown R134a refrigerant [13,14]. This is around a 6.9 percent rise. In contrast to the R134a refrigerant, the power consumption was also reduced to 50 % [15]. The addition of Nano Al2O3 to the refrigerant suggests an increase in the cooling system's COP. Nano refrigerant use decreases the duration and cost-effectiveness of the capillary channel. Over time, the pressure of the discharge increases and reaches a maximum value and then decreases. For a load mass of 150gm, the maximum discharge pressure is obtained. Initially, the suction pressure decreases and then increases over time [19-22].

The impact of various nano particles concentration in the refrigerant/lubricants of vapour compression refrigeration and observed better exergy destruction results at 0.5% concentration without compromising the performance[23]. The impact of copper (II) oxide (CuO) and copper/silver (Cu/Ag) alloy nanoparticles with HFC-R134a refrigerant in domestic refrigerators. The tribological effects on compressor parts were analysed after including the nano additives into the system and COP was analysed as performance parameter. Nano additives stability was studied using thermos gravimetric analysis. Adding 0.5 vol. % of CuO and Cu/Ag nano particles in POE resulted in great impact over the tribological and performance of VCR. The values of COP during the examination revealed about 20.88% increase due to the incorporation of nano refrigerants. Also, the co-efficient of friction for the developed nano lubricant was observed to be 5.5% lesser than that of CuO lubricant and 9.9% lower than traditional pure lubricants available.

II. LITERATURE REVIEW

- R. Cabello, E. Torrella and J. Navarro-Esbri [1], have analyzed the performance of a vapour compression refrigeration system using three different working fluids (R134a, R407c and R22). The operating variables are the evaporating pressure, condensing pressure and degree of superheating at the compressor inlet. They analyzed that the power consumption decreases when compression ratio increases with R22 thausing the other working fluids.

- B.O. Bolaji et al[2] investigated experimentally the performances of three ozone friendly Hydrofluorocarbon (HFC) refrigerants R12, R152a and R134a. R152a refrigerant found as a drop in replacement for R134a in vapour compression system.B.O. Bolaji[3] discussed the process of selecting environmental-friendly refrigerants that have zero ozone depletion potential and low global warming potential. R23 and R32 from methane derivatives and R152a, R143a, R134a and R125 from ethane derivatives are the emerging refrigerants that are non toxic, have low flammability and environmental-friendly. These refrigerants need theoretical and experimental analysis to investigate their performance in the system.

- James M. Calm [4], has studied the emission and environmental impacts of R11, R123, R134a due to leakage from centrifugal chiller system. He also investigated the total impact in form of TEWI and change in system efficiency or performance due to charge loss. He also summarized the methods to reduce the refrigerant losses by the system like design modifications, improvement in preventive maintenance techniques, use of purge system for refrigerant vapour recovery, servicing and lubricant in system.

- Samira Benhadid-Dib and Ahmed Benzaoui [5], have showed that the uses refrigerants are harmful for environment and the use of "natural" refrigerants become possible solution Here natural refrigerants are used as an alternative solution to replace halogenated refrigerants. The solution to the environmental impacts of refrigerant gases by a gas which contains no chlorine no fluorine and does not reject any CO2emissions in the atmosphere. The researchers showed that emissions have bad effects on our environment. They also concerned by a contribution to the reduction of greenhouse gases and by the replacement of the polluting cooling fluids (HCFC).

- Eric Granryd [6], has enlisted the different hydrocarbons as working medium in refrigeration system. He studied the different safety standards related to these refrigerants. He showed the properties of hydrocarbons (i.e. no ODP and negligible GWP) that make them interesting refrigerating alternatives for energy efficient and environmentally friendly. But safety precautions due to flammability must be seriously taken into account.

- Satheshkumar GOVINDASAMY *1, Mylsamy KALIYANNAN2, Saravanan SADHASIVAM3, Rajaguru KADASARI4 [7] At the present scenario, the action of ensuing the philosophy of reducing energy consumption and saving it for longer period without drop off in performance is increased. On the other hand, global warming and ozone layer depletion become foremost challenges. These concerns are takes place in Thermal systems like refrigerator and air conditioning. To resolve the above challenges, the nano refrigerants are used in refrigeration, which has previously got the attention due to its distinctive properties such as thermal conductivity. They also have the potential to improve the heat transfer performance of refrigeration. This project interrogated on the performance of domestic refrigeration system using normal condenser and microchannel condenser with and without nanoparticles. The Cerium oxide and Zinc oxide nanoparticles in the size of about 20-30nm and 30-50nm respectively with R134a domestic refrigerant were used. The experimentation carried out using 2 gm ofCeO2and ZnO nanoparticles in three different ratios [0.5:1.5,1:1 and 1.5:0.5] with R134a refrigerant. Hereby, the result conquered that 33.3% increase in the Actual COP of domestic refrigeration system using normal condenser with 1:1 ratio of nanoparticles when compared with the refrigeration system using microchannel condenser with and without nanoparticles.

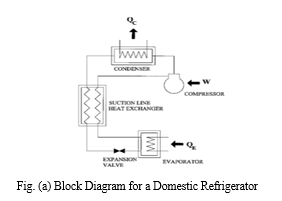

III. BLOCK DIAGRAM

The block diagram represents the basic components and operation of a domestic refrigerator system, which operates on the vapor-compression refrigeration cycle. Here is a detailed explanation of each component and the flow of the refrigerant through the system:

A. Compressor (W)

The compressor is responsible for compressing the low-pressure refrigerant gas from the evaporator into a high-pressure, high-temperature gas. Electrical energy (work, W) is supplied to the compressor, which increases the pressure and temperature of the refrigerant.

B. Condenser

The high-pressure, high-temperature refrigerant gas flows from the compressor to the condenser, where it releases heat (Q_C) to the surroundings and condenses into a high-pressure liquid. The condenser coils allow the refrigerant to dissipate heat to the ambient air, often assisted by a fan.

C. Expansion Valve

The expansion valve reduces the pressure of the high-pressure liquid refrigerant, causing it to cool significantly before entering the evaporator. This component acts as a throttle, controlling the flow of the refrigerant and ensuring it enters the evaporator at a lower pressure and temperature.

D. Evaporator

The low-pressure, low-temperature refrigerant absorbs heat (Q_E) from the refrigerator compartment, evaporating into a gas in the process. The evaporator coils are located inside the refrigerator, where the refrigerant evaporates by absorbing heat from the food and other items, thereby cooling the interior.

E . Suction Line Heat Exchanger

The suction line heat exchanger transfers heat between the cold refrigerant leaving the evaporator and the warmer refrigerant entering the expansion valve. This component improves the efficiency of the refrigeration cycle by ensuring that the refrigerant entering the evaporator is as cold as possible and by pre-cooling the refrigerant before it enters the expansion valve.

F. Refrigeration Cycle Overview

- Compression: The compressor raises the pressure and temperature of the refrigerant.

- Condensation: The refrigerant releases heat to the surroundings in the condenser and changes from a gas to a liquid.

- Expansion: The refrigerant pressure is lowered by the expansion valve, causing it to cool.

- Evaporation: The refrigerant absorbs heat from the refrigerator compartment in the evaporator, cooling the interior space.

G. Heat Transfer Notations

- Q_C: Heat released by the refrigerant in the condenser.

- Q_E: Heat absorbed by the refrigerant in the evaporator.

The compressor is the work input component, driving the entire refrigeration cycle. The condenser and evaporator are the primary heat exchange components, responsible for removing heat from inside the refrigerator and dissipating it to the external environment. The expansion valve controls the refrigerant flow and facilitates the cooling effect by reducing pressure. The suction line heat exchanger enhances the system’s efficiency by optimizing the temperatures of the refrigerant entering and leaving the critical components. This block diagram and explanation provide a clear understanding of the operation and key components of a domestic refrigerator system, crucial for experimental analysis of its performance.

IV. COMPONENTS

A. Digital Temperature Indicator

- The digital temperature indicator is used for processing signals coming from temperature sensors. Depending on your specific needs, the temperature indicator can be ordered with different inputs for thermocouples (type J, K) or resistance thermometers The measurement results are shown on the large digit LED-display of the temperature indicator.

- A temperature indicator can be used in fridges, dryers, furnaces and other technical equipment and many models are also suitable for the measurement and indication of various other physical parameters like weight, pressure, humidity, etc.

- It is useful in many different sectors, for instance in laboratories and in production processes where it is crucial to be aware of changes in temperature. It plays a particularly important role in quality control. A temperature indicator is frequently used to control the quality of raw materials and semi-finish transportation, to easily detect products that may be spoilt, to reduce the risk of manufacturing low-quality, defective products, to name only a few of the numerous possibilities to benefit from a temperature indicator.

B. Thermocouple

A Type K thermocouple refers to any temperature sensor containing Chromel and Alumel conductors. All Thermocouple types work on the same basis, they consist of two wire legs made from dissimilar metals (Nickel-Chromium / Nickel-Alumel in type K) which are fixed together at one end, creating a junction. When this junction experiences a change in temperature a voltage is created, this voltage can then be measured and referenced back to the temperature. K-type thermocouples are formed by the Chromel and Alumel combination of metals, with preferred working conditions between 0-1260? or 32-2300?. Type K thermocouples are the most widely used thermocouples in the Oil & Gas, and refining industries due to their wide range

C. Pressure & Vaccum Gauge

The devices that are used for measuring pressure are called pressure gauges. Gauge pressure is the pressure relative to atmospheric pressure. For the pressures above atmospheric pressure, gauge pressure is positive. For the pressures below atmospheric pressure, gauge pressure is negative. The pressure gauge is also known as pressure meters or vacuum gauges. Most gauges calculate the pressure relative to atmospheric pressure as the zero point. Hence, this form of reading is known as gauge pressure. Pressure gauges are analog as well as digital.

V. ACKNOWLEDGMENT

We would like to express our sincere gratitude to all those who have contributed to the completion of this literature review on the experimental analysis of performance of domestic refrigerators.

Firstly, we extend our heartfelt thanks to our academic institution for providing the necessary resources and support throughout the research process. Our appreciation also goes to the library staff for their assistance in accessing numerous research papers and journals that were crucial for our review.

We are deeply indebted to our supervisor, Prof. Dr. A. H. Ingle Sir, whose guidance, expertise, and insightful feedback have been invaluable. Their encouragement and critical insights have significantly enriched the quality of this review.

We would also like to acknowledge the contributions of various researchers and authors whose works have been reviewed in this paper. Their pioneering studies and findings form the foundation of our understanding and analysis.

Contributors to this Research are:

- Dr. A. H. Ingle, Professor, Mechanical Department, Smt. Radhikatai Pandav College of Engineering, Nagpur.

- Rahil Sheikh, Student, Mechanical Department, Smt. Radhikatai Pandav College of Engineering, Nagpur.

- Nadim Khan, Student, Mechanical Department, Smt. Radhikatai Pandav College of Engineering, Nagpur.

Conclusion

This literature review has provided a comprehensive overview of the experimental analysis of the performance of domestic refrigerators. By synthesizing findings from a wide range of studies, several key insights and trends have been identified that advance our understanding of refrigerator performance, efficiency, and sustainability. The transition towards environmentally friendly refrigerants such as R600a (isobutane) is crucial. These refrigerants offer lower global warming potential and improved energy efficiency, making them viable alternatives to traditional refrigerants. Advancements in compressor technology, including variable speed compressors, have significantly enhanced the energy efficiency and performance of domestic refrigerators. These technologies allow for more precise temperature control and reduced energy consumption. The development and use of advanced insulation materials have improved the thermal efficiency of refrigerators. Better insulation reduces heat transfer, thus lowering the energy required to maintain the desired temperature. Integration of smart technologies, such as IoT and adaptive controls, has led to more intelligent and efficient refrigerator operations. These technologies enable real-time monitoring, remote control, and predictive maintenance, which contribute to overall performance improvements. The impact of external factors, such as ambient temperature and usage patterns, on refrigerator performance is significant. Understanding these influences helps in designing more robust and efficient systems that perform well under varying conditions. The insights from this review highlight the importance of adopting advanced technologies and environmentally friendly materials. Manufacturers should focus on integrating variable speed compressors, innovative insulation materials, and smart technologies to meet consumer demands and regulatory standards. There are several areas where further research is needed. Future studies should focus on optimizing the combination of new refrigerants and compressor technologies, improving the effectiveness of smart systems, and exploring novel insulation materials. Additionally, more research is needed to understand the long-term impacts of these technologies on refrigerator performance and sustainability. The experimental analysis of domestic refrigerator performance is a dynamic and evolving field. The ongoing advancements in technology and materials, combined with a deeper understanding of external influences and user behaviors, will continue to drive improvements in refrigerator efficiency and sustainability. By addressing the identified gaps and focusing on future research directions, both industry and academia can contribute to the development of next-generation domestic refrigerators that are more efficient, sustainable, and user-friendly.

References

[1] R. Cabello, E. Torrella, and J. Navarro-Esbr??, “Experimental evaluation of a vapour compression plant performance using R134a, R407C and R22 as working fluids,” Applied Thermal Engineering, vol. 24, no. 13, pp. 1905–1917, Sep. 2004, doi: 10.1016/j.applthermaleng.2003.12.003. [2] B. S. Reddy, A. B. K. Rao, and G. R. Janardhana, “Modeling and Analysis of Machining Parameters and Responses of Wirecut Electric Discharge Machining of Al2124/SiCp using Response Surface Methodology and Soft Computing Techniques,” International Journal of Recent Technology and Engineering (IJRTE), vol. 9, no. 2, pp. 5429–5434, Jul. 2019, doi: 10.35940/ijrte.b3556.078219. [3] B. O. Bolaji and Zhongjie Huan, “Computational analysis of the performance of ozone-friendly R22 alternative refrigerants in vapour compression air-conditioning systems,” Environment Protection Engineering, vol. 38, no. 4, 2012, doi: 10.37190/epe120404. [4] J. M. Calm, “Emissions and environmental impacts from air-conditioning and refrigeration systems,” International Journal of Refrigeration, vol. 25, no. 3, pp. 293–305, May 2002, doi: 10.1016/s0140-7007(01)00067-6.. [5] A. S. Dalkilic¸ and S. Wongwises, “Comparison of Various Alternative Refrigerants for Vapour Compression Refrigeration Systems,” ASME/JSME 2011 8th Thermal Engineering Joint Conference, Jan. 2011, doi: 10.1115/ajtec2011-44267. [6] K. K. KESHINRO, N. A. IROMINI, and T. A. ALIMI, “DEVELOPMENT OF A RASPBERRY PI SECURED MANAGEMENT SYSTEM FOR HOME AUTOMATION,” i-manager’s Journal on Embedded Systems, vol. 8, no. 2, p. 1, 2020, doi: 10.26634/jes.8.2.17182. [7] Satheshkumar GOVINDASAMY *1, Mylsamy KALIYANNAN2, Saravanan SADHASIVAM3, Rajaguru KADASARI4, “EXPERIMENTAL ANALYSIS OF DOMESTIC REFRIGERATION SYSTEM USING NANOREFRIGERANT”, Reasearchgate.net, January 2021Thermal Science 26(00):244-244, January 202126(00):244-244.

Copyright

Copyright © 2024 Dr. A. H. Ingle, Rahil Sheikh, Nadim Khan. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62567

Publish Date : 2024-05-23

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online