Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experimental analysis on Self Compacting Concrete by using Nano - Silica Gel

Authors: Kuwar Leena R, Patil Vrundavani G, Girase Vaishnavi P, Wani Shubham R, Prof. J. P. Bhadane, Prof. P. R. Badgujar, Prof. S. Y. Sonawane, Prof. N. R. Borase

DOI Link: https://doi.org/10.22214/ijraset.2024.65475

Certificate: View Certificate

Abstract

Self-Compacting Concrete (SCC) has gained widespread recognition in modern construction due to its ability to flow under its weight, eliminating the need for mechanical vibration. Despite its numerous advantages, challenges such as maintaining stability, durability, and achieving optimal mechanical performance persist. Incorporating nano-silica gel, a material known for its high pozzolanic activity and micro-filling capability, offers a promising solution to address these challenges. This experimental study evaluates the impact of nano-silica gel on the fresh, mechanical, and durability properties of SCC. The research involves preparing SCC mixes with varying nano-silica gel dosages (0.5%, 1%, 1.5%, and 2% by weight of cement) and analyzing their performance through a series of standardized tests. Fresh properties such as slump flow, T500 flow time, and V-funnel tests are used to assess workability and flow characteristics. Hardened properties, including compressive strength, split tensile strength, and flexural strength, are evaluated at different curing ages. Durability is analyzed through Rapid Chloride Penetration and Sulfate Resistance tests to assess the resistance to chemical attacks. Results indicate that the inclusion of nano-silica gel significantly enhances the flowability, compressive strength, and durability of SCC. The optimal performance is observed at 1% nano-silica gel dosage, beyond which a reduction in workability and strength occurs due to increased particle agglomeration. This study demonstrates that nano-silica gel can substantially improve SCC properties, making it a viable material for high-performance and sustainable construction practices. These findings contribute to the ongoing development of advanced concrete technologies, paving the way for future research in optimizing SCC mixes with nano-materials.

Introduction

I. INTRODUCTION

SCC is still not widely used in india in spite of its many advantages including reduction in labour and fast track construction etc. This is because of lack of sufficient data and information of SCC made of materials available in different parts of the country and hence insufficient confidence of engineers in producing this material. India has abundant supply of fly ash, with its source well distributed across the country. SCC generally possesses a high power content which keeps the concrete cohesive with high flow ability. This high powder content is required tomaintain a sufficient yield value of the fresh mix and cement cannot the only powder material in SCC. For achieving economy, a substantial part of this powder could also contain fly ash in SCC. Self-Compacting Concrete (SCC) is characterized by its ability to flow and consolidate under its weight, filling intricate formwork without mechanical vibration. The use of nano-materials, particularly nano-silica gel, has attracted attention for enhancing concrete properties. Nano Silica has been added in order to increase the strength, low permeability and reduces shrinkage. Nano- concrete is defined as a concrete made with Portland cement particles that are less than five hundred Nano- meters as the cementing agent. Currently cement particle sizes range from a few Nano-meters to a maximum of about one hundred micro meters. In the case of micro- cement the average particle size is reduced to 5 micro meters An order of magnitude reduction is needed to produce Nano-cement. Certain unique properties of Portland cement such as: room temperature processing. low shrinkage, temperature resistance up to 600°C, compatibility with a number of fiber types including carbon fibers, reaction capability with currently available Nano- materials such as Nano-silica and nontoxic characteristics can be effectively used to create unique products. It can also be molded to complex shapes; heat cured and coated with other Nano-materials., SCC is an ideal solution for the construction of concrete slabs to maintain the serviceability of slab throughout their service lifespanNano-silica gel, with its high surface area and reactivity, can refine the microstructure of concrete, leading to improved mechanical strength and durability. Its pozzolanic nature reacts with calcium hydroxide to form additional C-S-H gel, densifying the matrix.

II. OBJECTIVES

- To find the workability aspects of M20 grade concrete using Nano silica

- To know the influence of Nano silica on the strength characters of self: compacting concrete.

- To decrease the permeability and to reduce the shrinkage in self compacting concrete.

III. LITERATURE REVIEW

A. Self-Compacting Concrete -

M.C. Nataraja, Anvit Gadkar and Giridhar Jogin (2018) Developed a simple procedure to produce self- compacting concrete based on the requirement of strength by slight modification to IS 10262:2009. Considered the limits prescribed by EFNARC and investigated on 25 mix proportions to obtain the relationship between compressive strength and water cementitious ratio of SCC. For this method, compressive strength ranges from 20MPa to 60MPa were considered by using poly corboxilic ether based high water reducing agent. It was observed that w/c from 0.47 to 0.37 was sufficient to obtain the strength values between 25 to 60MPa. Fresh properties and strength results occurred by this procedure were in good agreement.

Athiyamaan. V & G. Mohan Ganesh (2018) Studied about SCC mix design using nan-su method and trail mixes were carried out by using Design of Experiments method (DOE). In trail mixes central composite design was farmed with variables; cement, superplasticizer, w/c. Fine aggregate and coarse aggregate. 33 trail runs were investigated and M16 numbered mix gave optimum results. And also noted that by decreasing coarse aggregate from 750Kg/m3 to 710 kg/m3 increase the rheological properties but signs against the strength, increasing of fine aggregate will results of maximum packing factor.

M. Sri Rama Chand, P. Rathish Kumar, P.S.N.R. Giri, G. Rajesh Kumar (2018) investigated the durability, strength and microstructures of SCC by addition of self- curing chemicals. Self-curing compounds are used to overcome the improper curing and compacting issues. Hydrophilic, Super absorbent polymers and Hydrophobic chemicals can use as self-curing compounds. Hydrophilic and Hydrophobic efficiencies were tested on M70 and M50 grade concretes. Polyethylene Glycol 4000, Liquid paraffin wax (LPW) with 0%, 0.1%, 0.5% and 1.0% was used in this study, which includes water retention capacity, compressive strength, RCPT, SEM, XRD, absorptivity and Porosity tests. Results shows that LPW at 1% doesn't influence the strength of concrete and by using self-curing compounds the strength obtained is 90% of the water curing specimen. XRD shows they will not increase the effect of freeze thaw effect and SEM confirmed that microstructure is dense in self-curing self-compacting concrete.

Shaik Khaja Sameer, B. Jagadish Chakravarti and V. Ramesh (2017) Designed mix proportion using compressible packing model for M20, M40 and M60 self- compacting concrete grades and suggested a modification zone gradations similar to IS 383 for SCC to achieve optimum mix. Sample mix design was presented to get an idea about the mix calculations for SCC. It was observed that compressive strength increases from 7 days to 28 days at a ratio of 0.71, 0.7 and 0.68 for M20, M40 and M60 grade concretes respectively. The relation between compressive strength and flexural strength, split tensile strength were developed.

B. Nagendra Kumar (2017) High strength self-compacting concrete was developed by replacing natural river sand with quartz sand at a range of 20%, 40%, 60%, 80% and 100%. Specimens were casted in standard sizes and tested at periods of 7 days, 28 days, 90 days and 180 days. For every percentage of replacement, mix satisfies the fresh properties but at 100% replacement mix attains compressive strength of 100MPa for 28 days. Result shows that not only compressive strength but also split tensile and flexural strength increased with increase of quartz sand percentage.

S. Girish (2017) Studied about the importance of volume of paste and powder on hardened properties and of self-compacting concrete(SCC) with perpetual water content, ranging from 175 lit/m3 to 210 lit/m3. Paste contents (0.38, 0.41 and 0.43) chosen to test with cement from 300 kg/m3 to 450 kg/m3. Results show that compressive strength of SCC increase with increase of volume paste for same water cement ratio and water content. 30% increase was observed at 190 lit/m3 and 35% at 175 lit/m3 and maximum compressive strength is noted at volume paste 0.14. By this, increase in strength as the paste is increased but beyond the particular amount strength values decreases due to decrease of coarse aggregate, load transfer within the body gets affected and strength may reduce.

T. H. Patel, J. M. Srihaila, Prahalada. V (2016) explored the durability properties of High Performance Self-Compacting Concrete by using sodium chloride (NaCl), Magnesium Sulphate (MgSO4). Cement was substituted with Fly ash at 10%, 20%, 30% 40%, 50% and GGBS at 10%, 20%, 30%, 40%, 50% separately and experiments conducted and results were compared. Cubes casted at standard size and cured in water for 28 & 56 days but for durability study after 28 days water curing, cubes were cured in 10% concentration of NaCl & MgSO4 solution for 28 and 56 days. Cement with 10% fly ash and cement with 20% GGBS gave maximum compressive strengths.

It was observed that NaCl effects more on self-compacting concrete(SCC) without fly ash and also without GGBS, by adding fly ash or GGBS acid resistance could be increased but, sulphate resistance is higher than chloride resistance.

R. Vasusmitha and Dr. P. Srinivasa Rao (2013) developed M80 grade concrete by using micro silica, quartz powder in addition to the cement, chemical admixtures are used. Water cement ratio maintained at

0.215 and as part of hardened properties; split tensile strength, compressive strength, flexural strengths were calculated. For durability characteristics tests like rapid chloride penetration test (RCPT), acid resistance by using HCL, H2SO4, Na2SO4 were conducted on designed grade of concrete. Acid attack tests are carried out based on weight loss technique, from the results it was perceived that the specimens are more resistant to 5% Na2SO4 than 5% H2SO4 and 5% HCl, Chloride ion penetrability getting decreased by the increasing of age and obtained values are at a range of very low.

N. Venkat Rao, M. Rajasekhar, Mohd Mujeeuddiahmed (2013) studied about durability properties of high strength self-compacting concrete by maintaining water cement ratio at 0.24 and all fresh properties of SCC was examined as per the guidelines given by EFNARC. To study durability properties, acid attack and sulphate attack was considered, for this study 8% HCL, 8% H2SO4, 8% Na2SO4 were used and weight loss technique was used to determine the durability properties. It showed that the designed grade was more resistant against the sodium sulphate than hydrochloric acid and sulphuric acid. Acid attack resistance also determined by conducting compressive strength test after immersing specimens in 5% HCL, 5% H2SO4, 5% Na2SO4 in alternative days and it was observed that compressive strength decreased at 16.31%, 47.07% and 19.8% while using HCI, H2SO4 and Na2SO4 respectively.

B. Workability test on SCC-

Daniel C, Joel Shelton J, Vincent Sam Jebadurai S, Arun Raj E (2016) Studied on high strength self- compacting concrete by using copper slag in place of river sand at an interval of 10% from 0% to 100% with water cement ratio at 0.4 and super plasticizer was maintained at 0.6%. Wet concrete properties like passing ability, flow ability and filling ability was tested by using L-box, U-box, V-funnel, slump flow test. Mechanical properties like flexural strength, split tensile strength, compressive strength were also known at 7 days and 28 days. By the increase of copper slag, workability improves and at 40% replacement shows the optimum values in both fresh and hardened properties.

M. Fadee, R. Mirhosseini, R. Tabatabaei & M.J. Fadace (2015) Investigated about usage of copper slag as cementitious material in self-compacting concrete(SCC); physical and chemical analyses were performed. Cement was replaced with copper slag at 20%, 25%, 30%, 35% and 40%, and tests were conducted to know the variation of fresh and mechanical properties with and without copper slag. V-funnel and J-Ring tests on wet concrete, compressive strength at 7, 14, 28 and 42 days age on hardened concrete were conducted. In the results, it shows that copper with 40% gives better passing ability and filling ability than without copper slag. Copper slag with 20% gives 85 percentage of compressive strength without slag, by this it was recommended to use at 20%.

Karthik, Dr. G. Baskar (2015) Mainly studied about durability of self-compaction concrete with copper slag used as fine aggregate at levels of 20%, 40%, 60% and 80%. By conducting fresh concrete tests like T50, V-funnel, slump flow, L-box, J-ring to examined the fresh properties. Durability properties were studied by using weight loss technique. To conduct durability tests like acid resistance, sulphate resistance and corrosion tests, various chemicals like sulphuric acid, ferrous sulphate and sodium chloride solutions were used. From the results it was concluded that at 60% copper slag in concrete as fine aggregate gave the more durable concrete.

Iman Afshoon and Yasser Sharifi (2014) Investigated about influence of Ground Copper Slag as a binding material on the fresh properties of self-compacting concrete(SCC). In this investigation water powder ratio was maintained at 0.51 and cement replaced at a levels of 0%, 5%, 10%, 15%, 20%, 25% and 30% with ground copper slag. Tests on wet concrete like slump flow, viscosity index, J-ring, V-funnel, L-box, air content and setting times were conducted. Due to usage of ground copper slag as cementing material slump flow increases, viscosity decreases, passing ability decreases, air content also decreased but setting increased.

C. Admixtures in SCC-

C. Sashidhar, B. Radhamma, J. Gurujawahar, C. Yedukondalu (2018) Studied about self-compacting geopolymer concrete with 50:50 proportions using class F fly ash and GGBS with artificial sand as fine aggregate. EFNARC guidelines are considered for trail mixes to get optimum proportions and 8M, 10M, 12M NaoH issued in the experiment.

Various fresh properties like segregation resistance, passing ability and filling ability were examined by using test methods; L-box, T500 slump flow, v- funnel and slump flow. It was observed that by increasing the NaOH morality the fresh properties are decreased and no adverse effect has been marked when self-compacting geopolymer concrete mixes prepared with artificial sand.

K Ganesh Babu and B Chandrasekhar (2018) worked on high performance self- compacting concrete with fly ash of 25%, 35%, 50% and 70% as a cementitious content. Various water powder ratios were used ranging from 0.25-0.72. It was observed that fly ash based SCC ranging from 25-110 Mpa could be produced by replacing 70-25% of cement, charge passing through the specimen is also decreased by increasing the fly ash content. Durability tests like acid attack, corrosion tests shows better results by increasing fly ash percentage.

H. Y. Leung, J. Kim, A. Nadeem, Jayaprakash J and M. P. Anwar (2016) Studied about water absorption of self-compacting concrete with silica fume and fly ash by conducting sorptivity test. For this test two separate mix series were casted namely F- series and FS-series. In F-series ordinary Portland cement was replaced with 0%, 12.9%, 20%, 30%, 40% and 50% but in FS-series Fly ash fixed at 25% and cement replaced at 0%, 5%, 10% and 15% with silica fume. Water to powder ratio maintained at 0.38 and water content at 235.6kg/m3. From the results it can conclude that OPC with silica fume and fly ash reduces sorptivity. Combination of flyash and silica fume decreases sorptivity than only using fly ash and also witnessed that there is no relation between strength and sorptivity. Behaviour of compressive strength and surface absorption depends on proportion of mineral admixture and other environmental factors.

Gritsada Suaiam, Natt Mukal (2015) Studied about self-consolidating concrete which prepared with recycled alumina and fly ash waste as mineral admixtures. Fly ash replaced at fixed 20% and recycled alumina waste replaced at 0%, 25%, 50%, 75% and 100%. Fresh and mechanical properties were examined by using, J-ring, V-funnel, slump flow, compression strength; quality of concrete by using ultra pulse velocity test. In the results it was observed that alumina waste up to 75% as optimum and satisfied all the conditions given by the EFNARC and best results shown than the conventional concrete, achieved compressive strength up to 56MPa at 28 days age.

T. Adhavanathan, V. Vinoth (2015) M30 grade concrete was used to investigate the consumption of copper slag as fine aggregate and cement replaced with fly ash moderately. In this study copper slag used at level of 0%, 10%, 20%, 30% up to 100%. Fresh concrete properties and hardened concrete properties are studied at 7,14,28 days and by results it was concluded that 30% of copper slag obtains the optimum results and concrete replaced by 40% of fly ash increases the compressive strength, the maximum split tensile strength obtained at 40% copper slag and maximum flexural strength at 60% copper slag.

D. Concrete with Nano-silica-

G.Quercia et.al(2013) A new Nano-silica (Ns) can be produced in high quantities and for low prices that allows for a mass application in concrete. It may replace cement in the mix, which is the most costly and environmentally unfriendly component in concrete. The use of Ns makes concrete financially more attractive and reduces the CO2 footprint of the produced concrete products. The nS will also increase the product properties of the concrete: the workability and the properties in hardened state, enabling the development of high performance concretes for extreme constructions. That means. that a concrete with better performance, lower costs and an improved ecological footprint can be designed.

Yuvaraj Shanmugasundaram et.al (2012) Nano concrete could control the carbon dioxide emission from the earth which is shown by using fly ash concrete products instead of cement concrete. Thus the Nano particles which is in the form of silica can easily react with cement particles which are normally in Nano scale initiate the CSH reaction and hence its tend to accelerate the compressive strength of concrete. Nano- silica consumes calcium hydroxide crystals, reduces the size of the crystals at the interface zone and transmute the calciumhydroxide feeble crystals to the C-S-H crystals, and improves the interface zone and cement paste structures.

M. ili et.al(2010) The results show that increasing in nano silica content 1.5% to 4.5% by weight, leads to an increase of compressive strength at all stages. The results also indicate that the specimens which contain both nano and micro silica, due to the high pozzolanic activity, have higher compressive strength than reference ones. However, large quantities of nano silica in the mixtures, due to agglomerate effect, don't lead to increase compressive strength. As it is shown the highest compressive strength at the age of28 days is c01 Tesponding to SF6, NS1.5 mixture.

Laland (1981) Nano-silica is typically a highly effective pozzolanic material. It normally consists of very fine vitreous particles approximately 1000 times smaller than the average cement particles. It has proven to be an excellent admixture for cement to improve strength and durability and decrease permeability (Loland, 1981; Aitcin et al., 1981). S reduces the setting time and increases the strength (compressive, tensile) of resulting cement in relation with other silica components that were tested (Roddy et al., 2008). Nano-silica is obtained by direct synthesis of silica sol or by crystallization of nano-sized crystals of quartz.

IV. METHODOLOGY

The present study deals with the process of preparing of self-constricting concrete and its working. Various tests are conducted on the workability of the self-constricting concrete. The grade of concrete used is M20 which was designed in accordance with IS: 10262-2009, we have chosen mix design of M20 grade, in order to find the properties and working of self-constricting concrete.

A. Materials Used

1) Cement: In the present investigation Birla Shakti, Ordinary Portland Cement (PPC) of 53 Grade confirming to IS: 12269:1999 was used.

2) Fine Aggregate: Locally available river sand confirming to IS: 383:1970 was used as the fine aggregate in the concrete preparation.

Table No. 1 Properties of Fine Aggregates

|

Sr.No. |

Property |

Result |

|

1 |

Specific Gravity |

2.6 |

|

2 |

Fineness Modulus |

2.8 |

|

3 |

Bulk Density [loose] |

15.75 KN/ m³ |

|

4 |

Grading of Sand |

ZONE -II |

3) Course Aggregate:

Table No. 2 Properties of Course Aggregates

|

Sr.No. |

Properties |

Result |

|

1 |

Specific Gravity |

2.60 |

|

2 |

Bulk Density |

KN/m³ |

|

3 |

Water Absorption |

0.5% |

|

4 |

Fineness Modulus |

7.2 |

4) Nano-silica:

Table No. 3 Properties of Nano- Silica

|

Sr.No. |

Property |

Actual Analysis |

|

1 |

Active nano silica content |

35-40% |

|

2 |

pH |

9.3-9.6 |

|

3 |

Specific Gravity |

1.08-1.11 |

|

4 |

Texture |

Milky White Liquid |

|

5 |

Dispersion |

Water |

5) Water : Water used for mixing the concrete ingredients, casting and curing the test specimens is free from impurities which when present can adversely influence the strength of concrete confirming to IS:3025:1964 (part 22 and 23) and IS:456:2000.

6) Super plasticizer : As the locally available PCE based super plasticizers proved to be very effective in SCC; this study is carried out using such type of super plasticizers. CONPLAST SP430 Commercially available poly-carboxylic ether based super plasticizer it is an admixture of a new generation based on modified polycarboxylic ether. CONPLAST SP430 is a super plasticizer manufactured by DOM CONSTRUCTIVE SOLUTIONS, was used in this experimentation. Its use enhances the workability of the mix and strength aspect, helps in producing a better compaction and finishing. It also permits reduction in water content.

B. Conplast SP430

High performance superplasticising admixture

Description Conplast SP430 is a chloride free, superplasticising admixture based on selected sulphurated naphthalene polymers.

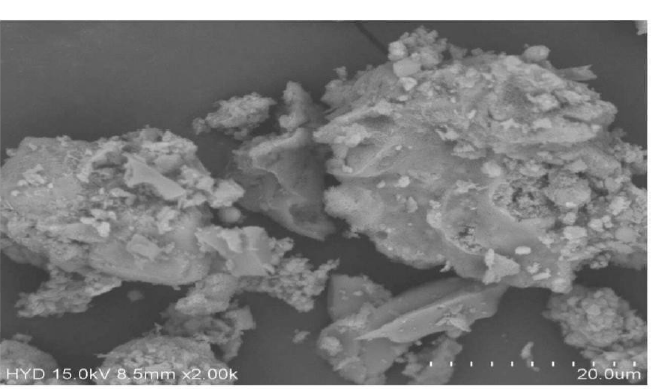

Fig. No. 1 SCC with dosage of 2.5% Nano Silica

C. Properties of Conplast SP430

Table No. 4: Properties of conplast SP430

|

Sr.no |

Properties |

|

Appearance |

Brown liquid |

|

Specific Gravity |

Typically, 1.20 at 20°c |

|

Chloride Content |

Nil to bs 5075 |

|

Aij Entrainment |

Typically , less than 2% additional air is entrained at normal dosages |

|

Alkali Content |

Typically, less than 72.0 g. Na2O equivalent /liter of admixture . |

|

Fire Resistance |

Conplast SP430 is water based and non-flammable |

D. Mixture Proportioning

Table No. 5: Mix proportion of SCC

|

Mixture ID |

Cement [kg/m³] |

Sand [kg/m³] |

C.A [kg/m³] |

Water |

NS [kg/m³] |

SP3% [kg/m³] |

|

SCC |

550 |

910 |

590 |

252 |

0 |

16.5 |

|

SCC 2% NS |

539 |

910 |

590 |

228 |

11 |

16.5 |

|

SCC 2.5%NS |

537.25 |

910 |

590 |

233.3 |

13.75 |

16.5 |

|

SCC 3%NS |

533.5 |

910 |

590 |

242 |

16.5 |

16.5 |

V. RESULT AND DISCUSSION

A. Fresh Properties

Nano-silica gel enhanced SCC’s flowability and reduced segregation up to 1% dosage. Beyond this, the mix became stiff, indicating over-dosage.

Table No. 6 Nano-silica gel enhanced SCC’s

|

|

|

|

|

|

||||||

|

|

|

|

|

|

||||||

|

|

|

|

|

|

||||||

|

|

|

|

|

|

B. Mechanical Properties

Strength tests revealed that SCC with 1% nano-silica gel showed the highest compressive, tensile, and flexural strengths.

Table No. 7 Strength tests

|

|

|

|

|

|

||||||

|

|

|

|

|

|

||||||

|

|

|

|

|

|

||||||

|

|

|

|

|

|

C. Durability Performance

Nano-silica gel significantly reduced chloride penetration and improved resistance to sulfate attack.

Table No. 8 Durability Performance

|

|

|

|||

|

|

|

|||

|

|

|

Conclusion

Experimental results show that nano-silica gel improves the workability, compressive strength, and durability of SCC, with an optimum dosage observed at 1% by weight of cement. The findings contribute to developing sustainable, high-performance concrete for the construction industry. 1) Nano-silica gel enhances both fresh and hardened properties of SCC. 2) The optimum dosage of nano-silica gel was found to be 1% by weight of cement. 3) Durability tests confirm the role of nano-silica gel in improving SCC’s resistance to aggressive environments.Reduction in w/c ratio resulted in increased compressive strength.

References

[1] Rafat Siddique, “Compressive strength, water absorption, sorptivity, abrasion resistance and permeability of self-compacting concrete containing coal bottom ash”,Constr. Build. Mater.(2013) [2] Beata ?a?niewska-Piekarczyk, “The methodology for assessing the impact of new generation superplasticizers on air content in self-compacting concrete”,Constr. Build. Mater.(2014) [3] Mahmoud Khashaa Mohammed et al., “Carbonation of filler typed self-compacting concrete and its impact on the microstructure by utilization of 100% CO2 accelerating techniques”,Constr. Build. Mater. (2014) [4] Cristian Druta et al., “Tensile strength and paste–aggregate bonding characteristics of self-consolidating concrete”, Constr. Build. Mater.(2014) [5] Mostafa Jalal et al., “Comparative study on effects of Class F fly ash, nano silica and silica fume on properties of high performance self-compacting concrete”, Constr. Build. Mater.(2015) [6] Erhan Güneyisi et al., “Fresh and rheological behavior of nano-silica and fly ash blended self-compacting concrete”,Constr. Build. Mater.(2015) [7] T. Hemalatha et al., “Influence of mixing protocol on fresh and hardened properties of self-compacting concrete”, Constr. Build. Mater.(2015) [8] Javier Puentes et al., “Effect of silica-based nano and micro additions on SCC at early age and on hardened porosity and permeability”,Constr. Build. Mater.(2015)

Copyright

Copyright © 2024 Kuwar Leena R, Patil Vrundavani G, Girase Vaishnavi P, Wani Shubham R, Prof. J. P. Bhadane, Prof. P. R. Badgujar, Prof. S. Y. Sonawane, Prof. N. R. Borase. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65475

Publish Date : 2024-11-23

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online