Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experimental and Analytical Investigation of R.C Beam with HPC Containing Nano Silica

Authors: Anjana Prem Mini, Suji. P

DOI Link: https://doi.org/10.22214/ijraset.2022.46192

Certificate: View Certificate

Abstract

Concrete is the most widely used construction material in the world. It is a heterogeneous material composed of cement, fine aggregate, course aggregates and water. The proportion of these constituents affect the mechanical properties and durable properties of concrete. Also it is a versatile material due to the continuous demand. In recent years, lot of researches has been focused on improving the quality of concrete. This lead to the extension in the limitations to improve the performance of concrete with the addition of various admixtures super plasticizers subsidiary cementitious materials like silica fume, fly ash, blast furnace slag, metakaoiln, rice husk, etc. the properties like compressive strength, flexural strength, durability and workability of concrete enhances due to the addition of these materials. The concrete thus formed with high strength and durability compared to normal concrete are called High Performance Concrete. The compressive strength of HPC may be greater than 50Mpa. This HPC with compressive strength greater than 50Mpa can be used for structural members like beam, column, slab etc In this investigation the cement is replaced by 1%, 2% and 3% of Nano silica. Experimental and analytical investigation were done to investigating the flexural behaviour of conventional RC beam and R.C beam with HPC containing optimum percentage of Nano silica. Analytical investigation was done by ANSYS. This chapter discusses about the HPC, its mechanical strength properties like compressive strength, split tensile strength, flexural strength, effect of Nano materials like Nano Silica in HPC, determining the optimum percentage of Nano silica which gives maximum strength, investigating its durability property, investigating the strength development of RC beam with HPC containing optimum percentage of Nano silica, examining the load deflection behaviour of beam with HPC containing Nano silica and finally analysing the deflection of beam using Ansys. The key objective of this project is to investigate the importance of Nano silica as a replacement for cementitious materials in normal concrete and this paper presents strength and durable properties of HPC containing Nano silica.

Introduction

I. INTRODUCTION

The usage of concrete is increasing day by day. An estimate says that around 2 billion tons of concrete is being produced every year around the world. A lot of researches has been focused on improving the quality of concrete. This leads to the addition of various admixtures, super plasticizers, subsidiary cementitious materials like silica fume, rice husk, fly ash, ground granulated blast furnace slag, etc. High Performance Concrete is a type of concrete which possess high strength and durability when comparing with normal concrete. It is a heterogeneous mixture of cement, fine aggregate, coarse aggregate, water, admixtures and super plasticizers. The usage super plasticizers like High Water Reducing Agents and the addition of mineral admixtures plays a vital role in the strength and durability properties of concrete mix. HPC concrete will helps to make the concrete denser and workable. This will help to control the slump loss to a great extent. The compressive strength of HPC is greater than 50 Mpa can be used for structural members like beam, column, slab etc. In this investigation the cement is replaced by 1%, 2% and 3% of Nano silica. Experimental and analytical investigation were done to investigating the flexural behaviour of conventional RC beam and R.C beam with HPC containing optimum percentage of Nano silica. Analytical investigation was done by ANSYS. This chapter discusses about the HPC, its mechanical strength properties like compressive strength, split tensile strength, flexural strength, effect of Nano materials like Nano Silica in HPC, determining the optimum percentage of Nano silica which gives maximum strength, investigating its durability property, investigating the strength development of RC beam with HPC containing optimum percentage of Nano silica, examining the load deflection behaviour of beam with HPC containing Nano silica and finally analysing the deflection of beam using Ansys. The key objective of this project is to investigate the importance of Nano silica as a replacement for cementitious materials in normal concrete and this paper presents strength and durable properties of HPC containing Nano silica.

II. METHODOLOGY

The first step in this study is to determine the material properties of cement, fine aggregate, coarse aggregate which are used for the concrete production. The cement is replaced with 1%, 2% and 3% of Nano silica. To study the strength properties like compressive strength, tensile strength and durable properties, specimens were casted with conventional concrete and concrete containing different percentages of NS and cured for 7, 14, 28 days and tested. RC beam of conventional concrete and RC beam with HPC containing optimum percentage of Nano silica were casted and tested after 28 days of curing to investigate the strength development. Examining the load deflection behaviour of beam with HPC containing Nano silica and finally analysing the deflection of beam using ANSYS.

III. EXPERIMENTAL PROGRAM

A. Materials

OPC 53 grade confirming to IS: 12269-1987 was used. Material tests on cement were conducted as per IS 4031-1988. The specific gravity of cement is 3.13g/cc. Fine aggregate conforming to zone II of IS 383 of specific gravity 2.56 g/cc were used. Coarse aggregate of maximum size 12.5 mm of specific gravity 2.60g/cc were used. Water used for the study is free from harmful impurities. Poly carboxylic ether based super plasticizer named Master Glenium Sky 8233 were used. Admixture used here is Nano silica of specific gravity 1.15 g/cc.

B. MIX Design

The mix proportion were done by using the properties obtained from material tests and as per recommendations of ACI 211.4R

The mix proportion for M60 grade concrete is shown in Table 1 and mix proportion for M6o grade concrete containing Nano silica is shown in Table 2.

Table 1 Details of M60 grade concrete mix

|

Material |

Cement |

Fine aggregate

|

Coarse aggregate

|

Water |

Super plasticizer

|

Slump mm |

|

Weight (Kg/m3) |

538 |

666 |

1049 |

156.17 |

3.766 |

100 |

|

Ratio |

1 |

1.238 |

1.95 |

0.29 |

0.007 |

|

Table 2 Mix proportion of M60 grade concrete containing Nano silica

|

Mix ID |

Cement (kg/m3) |

Nano silica (kg/m3) |

Fine aggregate (kg/m3) |

Coarse aggregate (kg/m3) |

Water (%) |

Super plasticizer (%) |

Slump (mm) |

|

1 (1% N.S) |

533.295 |

5.38 |

657.754 |

1049 |

0.29 |

0.825 |

70 |

|

2 (2% N.S) |

527.908 |

10.77 |

650.297 |

1049 |

0.29 |

0.99 |

55 |

|

3 (3% N.S) |

522.522 |

16.16 |

640.82 |

1049 |

0.29 |

1.209 |

30 |

C. Specimen Preperation

For determining compressive strength, split tensile strength and flexural strength concrete cubes of size 15 x 15 x 15 cm, cylindrical specimens having 15 cm dia and 30 cm height and beams of size 10 x 10 x 50 cm of size were casted then cured for 28 days and tested. To determine the workability of concrete standard test as described in IS BIS 1199-1959 are conducted. To determine the strength development of RC beam with HPC containing optimum percentage of Nano silica RCC beam of size 200 x 250 x 1000 mm were casted and tested after 28 days of curing.

???????D. Investigation On RC Beam

In order to investigate the effect of Nano silica on the strength and behavior of RCC beam, two RCC beams each of size 200 × 250 × 1000mm were casted with one of them is normal mix and the other one is with 2% Nano silica.

The beams are designed as under reinforced, and the reinforcement detailing is done as per the design as per the criteria in IS 456:2000.

Table 3 Reinforcement details

|

Bottom reinforcement |

3# 20mm diameter bars |

|

Top reinforcement |

2# 12mm diameter bars |

|

Stirrups |

8mm diameter bars @ 150mm c/c |

IV. RESULTS AND DISCUSSIONS

A. Compressive Strength

The compressive strength at 28days obtained for normal M60 mix is 62.96N/mm2. The partial replacement of cement with different percentages of Nano silica increases the compressive strength of cube up to 2% N.S, and then decreases with percentage increase in Nano silica. Fig.1 shows the compressive strength for various mixes with age.

???????B. Split Tensile Strength

The split tensile strength of normal M60 mix is 3.95MPa. The split tensile strength of concrete with Nano Silica increases by 9.36% and 23.5% for 1% N.S and 2% N.S. Then there comes a slight reduction in strength with further increase in N.S percentage. Fig 2 shows the split tensile strength values for various mixes with age.

???????C. Flexural Strength

The flexural strength of normal M60 mix is 6.28N/mm2. Flexural strength increases with increase in percentage of N.S is shown in fig 3

???????D. Durability Tests

Durability study is important for determining the quality of concrete. The main purpose of this study is to investigate the durability performance of concrete at different environmental conditions. The tests carried out for determining the durability properties of normal M60 concrete and M60 concrete with N.S include water absorption test.

Water Absorption Test: The amount of water absorbed by the specimen when immersed in water for a stipulated period of time is water absorption. 150mm cubes cured for 28days were used for water absorption test.

From the table, it is seen that the water absorption for concrete cubes with partially replacing cement by 2% N.S is 2.656% , which is 21.489 % lesser than that of normal M60 grade concrete cubes.

???????E. Experimental Investigation On RC Beam

The load deflection behaviour, ultimate load carrying capacity and crack patterns of two RC beams were investigated (1 beam with normal M60 mix (CB), 1 beam with mix containing 2% N.S (NSB).

- Load deflection behaviour of RC Beam: The mid span deflection of all the two RC beams corresponding to each load is observed. Also the load which causes the development of initial crack is recorded. The load deflection behavior of beams is shown in f5g 4 .

2. Failure Modes: All the two beams fail by flexural mode of failure. Cracks get initiated at tension zone and propagated towards the compression zone. Shear cracks are then formed as secondary cracks from the supports and are propagated diagonally towards the centre.

3. Ultimate Load Carrying Capacity: Control Beam CB containing normal M60 grade failed at a load of 500kN, and NSB containing concrete with 2% N.S failed at an average load of 560kN respectively.

V. ANALYTICAL PROGRAM

The software used for the study is Ansys Mechanical Apdl (Ansys Parametric Design Language). ANSYS can carry out advanced engineering analyses quickly, safely and practically by its variety of contact algorithms, time based loading features and nonlinear material models.

???????A. Material Property

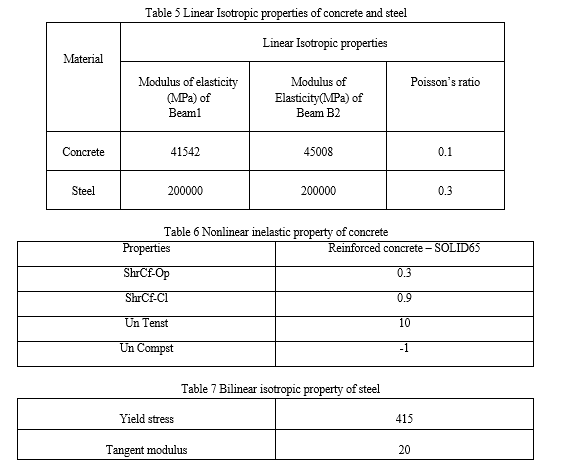

Material properties are required for most of the elements. Depending upon the application, material properties may be linear or non linear; Isotropic, orthotropic or anisotropic; constant temperature or temperature independent. Here, steel of Fe415 grade and concrete of M60 grade are the two materials selected. Beam B1 is modeled using properties of normal M60 mix, and Beam B2 is modelled using properties of concrete containing 2% of N.S. The material properties given in ANSYS are shown in Table 5, 6 and 7.

???????B. Creating the model geometry

The next step in the analysis is generating a finite element model, nodes and elements that describe the geometry. There are two methods to create the finite element model, Solid modeling and direct generation. In solid modeling, it is required to describe the geometric shape of the model. Then instruct the ANSYS program to automatically mesh the geometry with nodes and elements. There is a control over the size and shape of the elements that program creates. In the case of direct generations, it is required to define the location of each node and connectivity of each element manually. Here, the method of solid modeling is adopted for creating model. Model is created as volume. Model is then meshed with an edge length of 25mm. Mesh model is shown in Fig 5.

???????C. Solution Stage

Solution stage includes the loading and applying constraints.

???????D. Applying Loading Conditions

Loads can be applied either by solution processor or pre-processor. Loading conditions includes boundary conditions i.e. constrains or supports, other externally or internally applied loads. Loads in ANSYS program are divided into different categories: DOF constraints, forces, surface loads, body forces, inertia loads and coupled field nodes. Most of these loads are applied in the key points, nodes, lines or areas of finite element model.

???????E. FEM Analysis

The ANSYS program offers the following analysis types: Static, Modal, Transient, harmonic, spectrum, Eigen buckling, and sub structuring/ CMS. Analysis options allow customization of analysis types. It is required to select the analysis type and begin the solution.

VI. RESULTS AND DISCUSSION FROM FEM ANALYSIS

Load deflection behaviour and ultimate load carrying capacity of RC beams were analyzed using ANSYS software.

???????A. Load Deflection Behaviour Using Ansys Software

Various loads are applied on RC beam model with load increment of 10kN. Static analysis is performed in two RC beams with different properties (Beam B1 with normal M60 concrete, Beam B2 with concrete containing N.S also), in order to determine the load deflection behaviour. The maximum deflection corresponding to each load is shown in fig 8.

???????B. Ultimate Load Carrying Capacity of Beam

The ultimate load carrying capacity of normal M60 (B1) beam is 500kN, and that of beam (B2) with concrete containing Nano silica is 550kN.

VII. COMPARISON OF EXPERIMENTAL AND ANALYTICAL RESULTS

The experimental and analytical values obtained for load deflection, crack patterns and ultimate load carrying capacity of beams were compared.

A. Comparison of Load Deflection Values

The maximum deflection obtained for normal M60 beam (CB) from experimental study is 12.93mm and for beam B1 from analytical study is 15.216mm. The maximum deflection for beam with M60 grade concrete containing 2% N.S is 12.83 mm from experimental study and from analytical study is 14.32mm.

B. Failure Modes and Crack Patterns

For all the beams, it is observed that initial crack starts from the tension zone and propagated to the compression zone for both experimental study and analytical study.

The failure of beam is by flexure failure.

C. Ultimate Load Carrying Capacity

The ultimate load carrying capacity from the experimental study of beam CB is 500kN, and that of NSB is 560kN. Analytical study shows the failure of Control beam B1 at 500kN and Beam with concrete containing N.S, B2 at 550kN.

???????

???????

Conclusion

1) Characteristics compressive strength obtained for M60 grade mix is 69.03%. 2) Slump values indicate that workability of fresh concrete decreases with the increase in percentage of Nano silica. This is due to high surface area and high reactivity of Nano particles. 3) Compressive strength, split tensile strength and flexural strength of concrete increases with increase in percentage of Nano silica up to 2%, and further increase in Nano silica causes decrease in compressive strength. So the optimum percentage of Nano silica which gives maximum strength is 2%. 4) Compressive strength of cube for mix with partial replacement of cement by 2% of Nano silica is 81.03MPa, which is 17.4% more than normal M60 mix. 5) Split tensile strength of cylinder for mix with partial replacement of cement by 2% of Nano silica is 4.88MPa, which is 23.5% more than that of normal M60 mix 6) Flexural strength of beam for mix with partial replacement of cement by 2% of Nano silica is 8.308MPa which is 32.29% than that of normal M60 mix. 7) Durability tests such as water absorption test indicates that, There is decrease in water absorption by 21.489% in N.S mix than normal M60 mix a) The ultimate load carrying capacity of RC beam with normal M60 grade concrete (CB) is 500kN, beam with M60 grade containing Nano Silica (NSB) is 560kN. b) The maximum deflection of RC beam with normal M60 grade concrete is 12.83mm, beam with M60 grade containing Nano Silica is 12.93mm. c) From FEM analysis, it is obtained that maximum load carrying capacity of normal M60 beam is 500kN and that of beam with concrete containing N.S is 550kN.

References

[1] A.Lazaro, G.Querica, J.H Browers, J.W Geus (2013), Synthesize of a green Nano silica material using beneficial waste and its application in concrete, World journal of Nano science and Engineering. [2] B.B Das and ArkadeepMitra (2014), Nano materials for construction Engineering” International journal of material mechanics and manufacturing, Volume 2 [3] Dr. D.V Prasada Rao (2016), Effect of Nano silica on concrete containing metakaolin, International journal of Civil Engineering and technology, Volume 7, Isuue 1,pp 104-112 [4] Jayalin D, Prince Arulraj G, Karthik V (2015), Analysis of Composite Beam Using ANSYS, International Journal of Research in Engineering and Technology, Volume 04, Issue 09 [5] Jonbi, Ivindra Pane, BinsarHariandja, Iswandi Imran (2012), “The use of Nano silica for improving concrete compressive strength and durability, Applied mechanics and materials. [6] Jemimah Carmichael M, Prince Arul Raj.G (2012), Influence of Nano materials on consistency, setting time and compressive strength of cement mortar, IRACST- Engineering science and technology: An international journal (ESTIJ),volume 2. [7] L. Ranjith Kumar, Q Roger, P. Santhosh, K. Gowtham (2016), Durability Study of Concrete using Nano Silica, International Journal of Advanced Research in Civil , Structural, Environmental and Infrastructure Engineering, Volume 2, Issue 2. [8] Maheswaran S, Bhuvaneswari B, Palani G.S, Nagesh R. Iyer and Kalaiselvam S (2013), An overview on the Influence of Nano Silica in Concrete as a Research Initiative, Research journal of recent sciences, volume 2, 17- 24. [9] M Iyappan, Dr. A. Jagannathan (2014), High strength self compacting concrete with Nano silica, International journal of Emerging trends in Engineering and Development, Volume 5, Issue 4, page 163-168. [10] P.Janani, S Ganesh Kumar, M Harihanath (2016), Mechanical Properties of Nano Silica Concrete, International Journal of Innovative Research in Science Engineering and Technology, Volume 5, Issue 3, 3496-3502 [11] Dr. Rahel .Kh. Ibrahim, Dr. Faris Rashied Ahmed (2015), The effect of Nano silica in compensating the strength loss caused byusing high volume flyash in high strength mortar, International journal of Engineering sciences nad innovation Technology, Volume 4, Isuue 2. [12] Rattan A, Sachdeva P, Chaudhary A (2016), Use of Nano material in concrete”, International journal of latest Research in Engineering and Technology, Volume 2, Issue 5, pp 81-84. [13] R shashank, E.Balaji (2016), Flexural Behaviour of Nnao Silica Concrete, International Research Journal of Engineering and Technology, Volume 03, Issue 04, 799-803 [14] S. Chithra, S.R.R Senthil kumar and K. Chinnaraju (2016), The effect of colloidal Nano silica on workability, mechanical and durability properties of HPC with copper slag as partial fine aggregate, Construction and building materials (113), 794-804. [15] S. Saundarya, Sowmya M, Sujitha E and Deepa A (2015), A review on advancement in concrete using Nano materials, International journal for Innovative research in science and technology, Volume 1, Issue 8. [16] S. Tanveer Hussain, K.V.S Gopala Krishna Sastry (2014), Study of strength properties of concrete by using micro silica and Nano silica, International journal of research in Engineering and technology, Volume 3, Issue 10, 103-108. [17] Thallapaka Vishnu Vardhan Reddy, K. Rajasekhar and Seelamani Janardhana (2015), Study and Performance of High Strength Concrete Using with Nano Silica and Silica Fume, International Journal of Civil Engineering and Technology, Volume 6, Issue 11, 184-196 [18] ACI Committee 211.4R-08, Guide for Selecting Proportions for High- Strength Concrete Using Portland Cement and Other Cementitious Materials, American Concrete Institute, U.S.A [19] ACI Committee 201.2R-01, Guide to durable Concrete, American Concrete Institute, [20] USA [21] IS 456:2000, Indian Standard for Plain and Reinforced Concrete- Code of Practice, Bureau of Indian Standards, New Delhi. [22] IS 516:1959, Methods of Tests for Strength of Concrete, Bureau of Indian Standards, New Delhi [23] IS 5816:1999, Method of Test Splitting Tensile Strength of Concrete, Bureau of Indian Standards, New Delhi. [24] IS 1199-1959, Methods of Sampling and Analysis of Concrete, Bureau of Indian Standards, New Delhi [25] IS 383:1970, Specifications for Coarse and Fine aggregates from Natural Sources for [26] Concrete, Bureau of Indian Standards , New Delhi [27] IS 4031 (Part3):1988, Methods of Physical Tests for Hydraulic Cement, Bureau of Indian Standards , New Delhi. [28] IS 2386 (Part1): 1963, Methods for Tests for Aggregates for Concrete, Bureau of Indian Standards , New Delhi. [29] IS 12269:2013, Ordinary Portland Cement 53 Grade- Specification, Bureau of Indian Standards , New Delhi.

Copyright

Copyright © 2022 Anjana Prem Mini, Suji. P. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET46192

Publish Date : 2022-08-05

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online