Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

An Experimental Investigation on CO2 Adsorption Zero Cement Concrete with Partial Replacement of Aggregates

Authors: Rubel Das

DOI Link: https://doi.org/10.22214/ijraset.2023.54789

Certificate: View Certificate

Abstract

Cement production has a significant environmental impact, causing air pollution in the form of dust, gases, and noise during quarrying and milling. To address this concern, modified cement, a cementitious material that surpasses Portland cement\'s performance by incorporating recycled and waste materials, is proposed as a sustainable construction option. By reducing the use of raw materials, modified cement can lead to essential environmental benefits. In this experimental study, the feasibility of using sea shell and Titanium Di Oxide as alternative cementitious materials is explored. These materials demonstrate good pozzolanic reactivity and the ability to absorb carbon dioxide from the atmosphere. A mix design based on the Indian standard method of M25 is adopted, and three replacement levels (10%, 15%, and 20%) are considered for investigation. CO2 emissions from cement production are a major concern in the building industry. By utilizing sea shell and Titanium Di Oxide as cement substitutes, this study aims to contribute to energy conservation and environmental preservation. Trial mixes are prepared for each composition, and the results are compared with conventional concrete at different design mixes. The use of sea shell and Titanium Di Oxide as cement alternatives shows potential for achieving CO2 adsorption and reducing environmental impacts. This research offers insights into sustainable construction practices, paving the way for eco-friendly and resource-efficient building materials.

Introduction

I. INTRODUCTION

Cement and concrete are important materials for rapid urbanization. Concrete is considered as one of the key elements in the social, economic, and infrastructural development of human society. Ordinary Portland cement- (OPC-) based concrete is one of the significant construction materials in the globe. Up to now, we are still dependent on cement and concrete for the construction of many infrastructures such as buildings, towers, roads, bridges, flyovers, tunnels, industries, and river training works. Approximately 25 billion tons of concrete are produced and consumed annually all over the world. Cement consumption increased to 2.9 billion tons globally in a year and is predicted to increase to 4 billion tons by 2020. An alternative technology for the production of concrete without the use of cement does not currently exist. OPC is an energy-intensive material after steel and aluminum. OPC emits huge quantities of CO2 gas to the atmosphere, about 7% of global emission. These phenomena have necessitated the use of supplementary and/or pozzolanic materials such as slag, fly ash (FA), and rice husk ash (RHA) in cement and concrete manufacturing. However, the use of pozzolanic materials, either natural, agricultural, or industrial by-products, in the production of composite cements has gained increasing interest because of various ecological, economical, technical, and diversified product quality reasons. Sustainable concrete manufactured from pozzolanic materials is one of the solutions recommended by several researchers in the past few decades. The sea shells are high potential materials to become partial cement replacement and filler in concrete. The calcium carbonate (CaCO3) in the sea shells is more than 90% and is similar to the contain of calcium carbonate in the limestone dust that been used in the Portland cement production. Impressively, the crystal structures of seashells are largely composed of calcite and aragonite, which have higher strengths 2 and density than limestone powder. Also, the particle size of seashells is between 36μm to 75μm and are similar to the particle size of Portland cement . This study develops CO2 absorbing zero-cement concrete, where we try for replacement of the cement is replaced with sea shells powder and titanium di oxide etc dramatically improved environmental impact. This project will unlock the potential of our eco-innovation by performing a techno-economic feasibility study focused on replacement of cement for commercial development.

A. Need to use Carbon Dioxide Gas

Reducing the flow of the greenhouse gases that shoot global warming could prevent up to 3 million premature deaths annually by the year 2100, a new study suggests.

Greenhouse gases such as carbon dioxide trap heat, helping warm the globe. The surge in carbon dioxide levels due to human activity since the Industrial Revolution is now causing an overall warming of the planet that is having impacts around the globe. And the burning of fuel generates not only carbon dioxide, but also air pollutants that are harmful to human health. Hence it is required to use the produced carbon dioxide for different purpose to reduce its concentration in the air. Carbon dioxide is needed to be used so as to reduce the pollution; due to lack of fresh air most of the peoples are having different air borne diseases. As the construction work is going so rapidly and need huge time for curing it, by the use of carbon dioxide we can reduce the curing period to 8 hours. This helps in fastest mode of construction.

Sources of carbon dioxide gas There are both natural and human sources of carbon dioxide emissions. Natural sources include

- Decomposition

- Ocean release

- Respiration

Human sources come from activities like

a. Cement production

b. Deforestation

c. Burning of fossil fuels like coal, oil and natural gas

d. Transportation

e. Thermal power plant

B. Research Objectives

This research was carried out to develop a CO2 absorbing zero cement concrete for structural applications using 100% waste by-product.

In particular, this project investigates:

- The optimum mixing procedure and mix design for Sea shell with titanium oxide.

- The mechanical properties of Sea shell with titanium oxide under different curing condition.

- The durability, repair applicability of this concrete.

- Cost of this concrete

- The important objective is whether it absorb CO2 from environment or not.

- New innovation in concrete industry.

C. Scope Of Study

The scope of the study is to produce good structural work for performing the optimum mixing procedure and mix design for Sea shell with titanium oxide. To mechanical properties of concrete and reduction of carbon emission to environment and mainly used this technology in precast construction.

II. PROCEDURE FOR PAPER SUBMISSION

The following steps are carried out in the project.

These are

- The first step is to read the literatures and did comparative study.

- The 2 nd step is to decide the proportion of material to mix in concrete.

- The 3 rd step is to trial mix for different proportion and comparing with conventional concrete practice.

- The 4 th step is to carry out tests of cubes at different curing dates.

- The last step is to carry out cost of concrete and checking the economical to concrete industry

III. LITERATURE REVIEW

In order to serious climate change, deep reduction in CO2 emission will be required in coming decades. CO2 absorption is one of the key technologies to control the global warming. Global warming is caused by sharply increased greenhouse gases emission by human activities. In building industry, CO2 emission mainly come from cement production. Capturing of CO2 from point source, from ambient air and reducing atmospheric CO2 concentration by using Titanium Oxide and Sea shell. Sea shell Concrete with Titanium Oxide as a supplement material can absorb large quantity of CO2. Introducing Titanium Oxide material into the concrete absorbs CO2 from the atmosphere. It has the good concrete properties and ability to absorb carbon dioxide from the atmosphere hence it will be eco-friendly. Absorb CO2 and reduces the air pollution, Keep environment clean and full of oxygen. In this literature review we studied all journals related to our major project , this ways we can deeply understand our project and its test procedures and materials properties. In literature review we collected many journals related to our project and we referred some contents for our project one of them given below:

“A review on seashells ash as partial cement replacement by Wan Ahmad Soffian Bin Wan Mohammad , Nor Hazurina Othman , Mohd Haziman Wan Ibrahim , Masazurah A Rahim , Shahiron Shahidan and Raha Abd Rahman.”

IV. EXPERIMENTAL INVESTIGATION

Cementitious material used in this project.

A. Sea Shell Powder

The sea shell are formed by limey secretions from a tiny calcium carbonates, they can be used to increase soil pH . The effective of raising soil pH depends on the degree of fineness to which they are crushed. The finer particle the greater is this effectiveness because of greater surface area of reaction. The calcium (Ca) in the form of silicates may have value primarily as a liming material and can correct acidity. CaCo3 calcium which is more in the seashell. It can be used upto 20% of material. where it gives low workability. There are types of the sea shell like oyster, calm, mussel and scallops. The sea shells are high potential materials to become partial cement replacement and filler in concrete. The calcium carbonate (CaCO3) in the sea shells is more than 90% and is similar to the contain of calcium carbonate in the limestone dust that been used in the Portland cement production. Impressively, the crystal structures of seashells are largely composed of calcite and aragonite, which have higher strengths and density than limestone powder. Also, the particle size of seashells is between 36μm to 75μm and are similar to the particle size of Portland cement

B. Titanium Oxide

Titanium, as a material which fulfils these conditions, is used more and more often. Thanks to its specific properties, such as high mechanical strength, low weight and corrosion resistance, it is widely used in the aerospace and aviation industry , automotive industry and medicine, and recently also in civil engineering. Titanium compounds also possess interesting characteristics. Titanium IV dioxide (TiO2), which is the most durable of all oxides of this metal, deserves a special attention. There are three polymorphic variants of TiO2, which occur in nature as minerals: tetragonal rutile and anatase, and orthorhombic brookite. Titanium dioxide is a compound, which is used in many industrial sectors. The special importance for the most applications is its color. Properly powdered titanium (IV) oxide is called titanium white and is used in many industries. As a white pigment it is used in production of inks and printing inks, plastic products (e.g. window and door profiles, wall and floor coverings, roofing), cosmetics (e.g. gels, eye shadows, lipsticks, preparations for sunbathing) etc. A high refractive index is an important characteristic of titanium dioxide. Depending on the variety of TiO2, it is of 3.8 for rutile and 2.5 ÷ 3.0 for anatase. For comparison the diamond refractive index is of 2.42.

A high value of this factor makes the TiO2 a very good photocatalyst material, i.e. a substance, which initiates a catalytic reaction in presence of light and what is more it is not consumed. According to the development of photocatalytic building materials can contribute to environmental purification and improve the level of sustainable development. Thanks to the excellent photocatalytic properties TiO2 is recently used in many different construction technologies, including technology of cement and concrete. Technologies using photocatalytic properties of TiO2 are increasingly used for production of self-disinfecting materials, self-cleaning surfaces and purification the air from odours.

- Effect of Titanium Oxide

The effect of TiO2 on cement clinker phase formation, ion substitution as well as hydration properties were evaluated by free lime test, X-ray diffraction (XRD), scanning electron microscope-energy dispersive spectrometer (SEM-EDS), isothermal heat-conduction and nuclear magnetic resonance (NMR). Results indicated that titanium was preferentially incorporated in the interstitial phases, especially in C4AF, then C3A, C2S and C3S, which could be attributed to the lattice substitution of Ti4+ to Fe3+ in C4AF and consequently weakened its crystallinity. Meanwhile, the threshold limit for TiO2 incorporated into clinker was 1.5 wt%, beyond which, the crystal form of C3A transformed from cubic to orthorhombic. These changes of C3A and C4AF promoted the formation of C3S by decreasing the liquid phase viscosity during the sintering process. TiO2-doped promoted the hydraulic activity of clinker in initial period while postponed the hydration process of C3S in later period. However, after 28 days hydration, C–S–H gel polymerization degree did not decrease but improved as the TiO2 dosage was below 1.5 wt%. Alkali activator: NaOH, Na2Sio3, lime etc.

E. Water

Water is a most important ingredient in concrete which actively participates in the chemical reaction with cement. Water for making concrete should have the pH value range between 6 and 8. Potable tap water available in the laboratory was used in the present project work.

V. EXPERIMENTALPROCESS

General It explains about the Batching, mixing of concrete, casting of concrete specimens and testing of concrete specimens such as cubes and cylinder.

A. Collection of Materials

Sample of aggregate for each batch of concrete shall be of desired grading and in air-dried condition. In general, the aggregate shall be separated into fine and coarse fraction and recombined for each concrete batch in such a manner so as to produce the desired grading.

B. Batching of the Materials

Materials according to mix design calculation was weighted and placed separately so that it will be easy for mixing. After the exact proportion kept ready it should be taken for the mixing process.

C. Mixing of Concrete

The concrete was mixed perfectly in laboratory batch mixer in such a manner so as to avoid loss of water or other materials. Each batch of concrete shall be of such a size so as to leave about 10 per cent excess after moulding the desired number of test specimen.

D. Casting of Cubes

All the cubes and cylinders were properly mixed with exact amount of materials by the machine as shown in the figure casted firstly by tamping in three layers to fill all the corners of the moulds. Casting should be completed within 30 minutes of the mixing.

Cubical mould of size 150mm x 150mm x 150mm were used to prepare the concrete specimens for the determination of compressive strength of concrete. Care was taken during casting and vibrator was used for proper compaction. Cylindrical mould of size 100mm Diameter and 200mm height were used to prepare the concrete specimens for the determinations of split tensile strength. All the specimens were prepared in accordance with Indian Standard Specifications IS: 516-1959. All the moulds were cleaned and oiled properly. These were securely tightened to correct dimensions before placing of concrete. Care was taken that there is no gaps left from where there is any possibility of leakage out of slurry.

Compaction of test specimens

Specimens were compacted by the help of the table vibration. Vibration should be provided uniformly to all the specimens for specified time.

E. Curing of Test Specimens

Curing of the specimens was done according to the curing methods applied for specified time as explained below.

- Curing at room Specimens were kept in the room at normal room temperature and supply water at through gunny bag for 48 hours. After the 24 hours of the curing process the specimens were kept curing rapidly for next 24 hour. Fig. 6.3 gunny bag curing At room

- Curing in water The test specimens shall be stored on the site at a place free from vibration, under damp matting, sacks or other similar materials for 7days. 14 days, and 28 days. The temperature of the place of storage shall be within the range 25±2 0C. They shall be sent to the testing laboratory well packed in a damp sand, damp sack or othersuitable materials so as to arrive there in a damp condition not less than 24 hours before the time of test. Fig. 6.4 Curing in

VI. TEST ON FRESH CONCRETE

A. Slump Test

Slump test is the most well-known and widely used test method to characterize the workability of fresh concrete. The apparatus consists of a mold in the shape of a frustum of a cone with a base diameter of 20cm, a top diameter of 1 cm, and a height of 30cm. A graduated steel tamping rod 16 mm diameter and 60 mm long rounded at one end graduated in mm is used for tamping of concrete. The mould is filled with concrete in three layers of equal volume. Each layer is compacted with 25 strokes of a tamping rod. The slump cone mould is lifted vertically upward and the change in height of the concrete is measured. Initial slump is measured after just lifting of cone and final slump is recorded after 45 minutes of lifting of cone.

B. Procedure

- Clean the internal surface of the mould and apply oil.

- Place the mould on smooth horizontal non – porous base plate.

- Fill the mould with the prepared concrete mix in four approximate equal layers. Tamp each layer with 25 stokes of the rounded end of the tampingrod in a uniform manner over the cross-section of the mould. For the subsequent layers the tamping should penetrate into the underlying layer.

- Remove the excess concrete and level the surface with a trowel.

- Clean away the mortar or water leaked out between the mould and the base plate. Raise the mould from the concrete immediately and slowly in vertical direction. f) Measure the slump as difference between the height of the mould and that of highest point of specimen being tested.

C. Compaction Factor Test

The compaction factor test is carried out to measure the compact ability of concrete which is an important aspect of workability. This test works on the principal of measuring the amount of compaction achieved by a standard amount of compaction achieved by a standard amount of work done by allowing the concrete to fall through a standard height. This test is more accurate than slump test, especially for concrete mixes of medium and low workability i.e. compacting factor of 0.9 to 0.8. The compaction factor test is more popular to determine the workability of concrete mix in laboratories. The compaction factor is the ratio of weight of partially compacted concrete to the weight of fully compacted concrete. Compaction factor test was performed to measure the inherent characteristics of the concrete which relates very close to the workability requirements of concrete particularly for concrete mixes of very low workability and mixes that are relatively dry and insensitive to slump test.

The Sump values and compaction factor values of partial replacement of mineral admixtures have been tabulated below:

D. Test On Harden Concrete

Compressive strength test for cubes.

- One of the most important and useful property of concrete.

- Primarily meant to withstand compressive stress and can be used as an approximate qualitative measure for other properties of hardened concrete.

- Compressive strength test is carried out on cubesfor various curing methods.

- The compressive strength of cubes was tested on 7, 14 and 28 days.

- Formula for compressive strength of concrete: = Load/area =……. N/mm2

Split tensile strength test for cylinders:

The tensile strength of concrete is one of the basic and important properties. Splitting tensile strength test on concrete cylinder is a method to determine the tensile strength of concrete. Need: The concrete is weak in tension due to its brittle nature and is not expect to resist the direct tension. The concrete develops cracks when subjected to tensile forces. Thus, it is necessary to determine the tensile strength of concrete to determine the load at which the concrete member may crack.

E. CO2 Adsorption Test

In this test we have presented the test results of all the specimens for the 7 days, 14 days, 21 days, 28 days curing and types of the curing methods. The various proportion used in mix to check the CO2 adsorption quantity in concrete. The mix used in this concrete is 10%, 20%, & 30% of sea shell powder along with 10% titanium oxide.

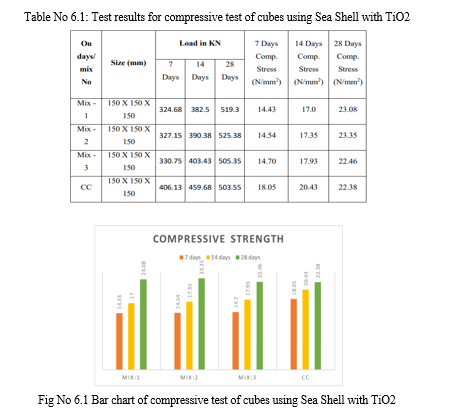

VII. TEST RESULT

In this chapter we have presented the test results of all the specimens for the 7 days, 14 days, 28 days curing and types of the curing methods.

A. Compression Test Results for Cubes

VIII. ACKNOWLEDGMENT

I sincerely acknowledge and express my heartfelt gratitude to the Almighty for granting me the grace and strength to successfully complete this project.

At this joyous moment of accomplishment, I would like to extend my thanks to the management of our college and our Honorable Chairman, Dr. A.K. NATESAN, M.COM. MBA (NIT), M.Phil., Ph.D., FTA, and Dr. N. MATHAN KARTHICK, M.B.B.S, MISTE, PHF., the Vice Chairman of our college, for providing all the necessary facilities during my study.

My sincere appreciation goes to the Principal of the college, Dr. K. BOMMANNA RAJA, M. Tech., Ph.D., for the generous support in facilitating the Bachelor of Engineering Programme.

I am grateful to Dr. S. SHANMUGASUNDARAM, M.E., Ph.D., Professor, and Head of the Department of Civil Engineering, for the unwavering support, valuable suggestions, and guidance throughout my study and during the course of this project.

A special word of thanks goes to my project guide, Mr. S. SASIKUMAR, M.E., Assistant Professor, Department of Civil Engineering, for the guidance, encouragement, and constant support during the project.

I also acknowledge and appreciate the guidance provided by all the staff members of the Civil Engineering Department during the course of my study.

Conclusion

The experimental investigation involving the use of sea shell and titanium oxide as cementitious materials in concrete, with a replacement rate of 15%, has demonstrated promising results. The compressive and tensile strength of the concrete samples were found to be nearly equivalent for both materials. However, based on the overall performance, it is recommended to prefer sea shell as the cementitious material. One of the significant advantages of the Sea Shell and Titanium Oxide concrete is its ability to absorb CO2 without emitting it. During a 28-day period, the concrete blocks of size 15x15x15 cm were capable of absorbing approximately 3.16 moles of CO2, showcasing its potential as an environmentally friendly option. Furthermore, the concrete exhibits exceptional durability and strength, ensuring its applicability in various construction projects without compromising its performance over time. Considering the cost-effectiveness of this concrete type, it is highly suitable for widespread applications, such as road pavements, residential construction, factory chimneys, and building facades. Moreover, with a reduced usage of cement, this eco-friendly concrete contributes to sustainable construction practices and aligns with environmental conservation efforts. To maintain its performance and longevity, it is crucial to adhere to the appropriate water-cement ratio, ensure proper compaction during construction, and provide suitable coatings to protect the reinforcement bars. In conclusion, the utilization of sea shell and titanium oxide as cementitious materials in concrete shows promising potential in terms of strength, environmental friendliness, and affordability. This innovative concrete type offers a greener alternative for various construction applications, contributing to sustainable and eco-conscious building practices. Further research and real-world applications are warranted to fully explore the benefits and potential challenges of this novel concrete mix in diverse engineering projects.

References

[1] Neville A M 1996 Properties of concrete 4th and final ed. (Addison Wesley Logman) 43-44 [2] Harrison A W John 2003 New cements based on the addition of reactive magnesia to Portland cement with or without added pozzolan CIA Conference: concrete in the third Millenium CIA (Brisbane, Australia) [3] Meyer Christian 2009 The greening of the concrete industry Cement and concrete composites 31 8 601-605 [4] Patel A J, Patel V M and Patel M A 2015 Review on Partial Replacement of Cement in Concrete UKIERI Concrete Congress – Concrete Research Driving Profit and Sustainability 1 7 831-837 [5] Mahasenan Natesan; Steve Smith; Kenneth Humphreys; Kaya Y 2003 The Cement Industry and Global Climate Change: Current and Potential Future Cement Industry CO2 Emissions Greenhouse Gas Control Technologies – 6th International Conference 2 995-1000 [6] Mosher Shad, Gregory W Cope, Frank X Weber, Damian Shea, and Thomas J. Kwak 2012 Effects of lead on Na+, K+-ATPase and hemolymph ion concentrations in the freshwater mussel Elliptio complanata Environmental toxicology 27 5 268- 276 [7] Nor Hazurina Othman, Badorul Hisham Abu Bakar, Mashitah Mat Don and Megat Azmi Megat Johari 2013 Cockle Shell Ash Replacement for Cement and Filler in Concrete Malaysian Journal of Civil Engineering 25(2) 201–211. [8] Lertwattanaruk Pusit, Makul N and Siripattarapravat C 2012 Utilization of ground waste seashells in cement mortars for masonry and plastering Journal of Environmental Management 111 133–141 [9] Noel D. Binag 2016 Powdered Shell Wastes as Partial Substitute for Masonry 47 Cement Mortar in Binder, Tiles and Bricks Production International Journal of Engineering Research & Technology 5 7 70-77 7 1234567890 GCoMSE2017 IOP Publishing IOP Conf. Series: Materials Science and Engineering 271 (2017) 012059 doi:10.1088/1757-899X/271/1/012059 [10] Arroyo G Maria Antonia, Macias P Katrina Anna, Tayzon M Karlo Emir, Lorenzo D Maria Abigail 2005 The Feasibility of a Mollusk Shell – Based Adhesive as a Substitute for Mortar Bato balani, Sophomore 24(2) 2004-2005 [11] Martínez-García Carolina, Belén González-Fonteboa, Fernando MartínezAbella, and Diego Carro-López 2017 Performance of mussel shell as aggregate in plain concrete Construction and Building Materials 139 570-583 [12] Muthusamy K and Sabri N A 2012 Cockle shell: a potential partial coarse aggregate replacement in concrete International Journal of Science, Environment and Technology 1 4 260- 267 [13] Gengying Li, Xiaoyang Xu, Chen E Jie Fan and Guangjing Xiong 2015 Properties of cementbased bricks with oyster-shells ash Journal of Cleaner Production 91 279-287. [14] Sugiyama M. 2004 The Compressive Strength of Concrete Containing Tile Chips, Crushed Scallop Shells & Crushed Roofing Tiles, edited by Limbachiya M C & Roberts J J in Sustainable Waste Management & Recycling: Construction Demolition Waste, London, Thomas Telford Publishing 165-172 [15] Yusof M, Ujai S J J, Sahari F, Taib S N L & Noor Mohamed N H 2011 Application of Clam (Lokan) Shell as Beach Retaining Wall Proceeding of EnCon 2011: 4th Engineering Conference (Kuching, Sarawak) [16] Limbachiya M C 2009 Bulk engineering and durability properties of washed glass sand concrete. Construction and building materials 23 1078-1083 [17] Etuk B R, Etuk I F and Asuquo L O 2012 Feasibility of using seashells ash as admixtures for concrete. Journal of environmental science and engineering 1 121- 127 48 [18] Olivia, M., Mifshella, A.A. and Darmayanti, L., 2015 Mechanical properties of seashell concrete.Procedia Engineering, 125 760-764 19. Olivia, M. and Oktaviani, R., 2017 Properties of Concrete Containing Ground Waste Cockle and Clam Seashells. Procedia Engineering, 171 658-663

Copyright

Copyright © 2023 Rubel Das. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET54789

Publish Date : 2023-07-15

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online