Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experimental Investigations of Bituminous Concrete Using Dissimilar Trash Which Improve the Results

Authors: Ishfaq Ahmad Bhat, Ravi Chahal

DOI Link: https://doi.org/10.22214/ijraset.2024.61333

Certificate: View Certificate

Abstract

Bituminous mixture is an admixture of coarse aggregate, fine aggregate and fill. CRMB is based on a unique technology that permits homogeneity. CRMB is suited for use in heavy load traffic lanes, air fields. In this study, Crumb Rubber Modified Bitumen (CRMB-60) blended with normal asphalt binder VG-30 with various different percentages of crumb rubber in different proportions with constant optimum binder content i.e. 5% which shows improved characteristics when compared with regular bitumen. The cost for Bituminous course for CRMB-60 came out to be Rs 68.23 Lacs per Km which was 20.81% economical than the bituminous work done by normal VG- 30 bitumen. The Marshall Mix design using CRMB 55 with 0.04 % Zycosoil chemical, reflects the significant rise in stability, unit weight and flow values for better compaction and enhancing the workability conditions.

Introduction

I. INTRODUCTION

The construction of the road ways covers a large amount of investment. To invest less, construction engineering must have to design road in such a way so that one can achieve a reliable performance of the road along with the built-in service. There are two factors that must be considered while using flexible pavement as well as the mix design. These two factors are one of the key elements in the engineering-paving design and mixing design. This research deals with mixed design of bitumen. Good design of bituminous mixtures should have following characteristics:

- It should be Strong

- It should be Durable

- It should be free from Fatigue and durable deformation

- It should not cause harm to the environment and

- It should be Economic, etc.

- To examine the effect of CRMB on Asphalt concrete mix.

- To analyze the influence of CRMB at five different percentages, 0.1%, 0.2 %, 0.3%, 0.4% and 0.5% and insertion of marble dust as a filler element.

- To determine the performance characteristics such as Air Void, Stability, flow, Void in Mineral Aggregate, Softening Point and penetration values

A. Crumb Rubber Modified Bitumen (CRMB)

CRMB is based on a unique technology that permits homogeneity, stability and consistent properties of the binder throughout. This can be achieved by adding special stabilizing.additives to form a high performance bituminous binder having unique properties. The use of these commercial polymers in pavement construction increases the cost of construction as these are highly expensive materials. However, CRMB isused as an alternative material which is formed from waste tyre rubbers and is environmentally beneficial and relatively less expensive. In recent years, CRMB bitumen binders have reported many advantages which includes improved rutting resistance due to its high viscosity, high softening point, better resilient modulus, reduction in fatigue/cracking, increase in durability and reduced maintenance cost. Due to these reasons CRMB is suited for use in heavy load traffic lanes, air field

II. LITERATURES REVIEW

Sahu and Joshi (2015) used Crumb Rubber Modified Bitumen (CRMB-60) blended with normal asphalt binder VG-30 with various different percentages of crumb rubber in different proportions with constant optimum binder content i.e. 5% which shows improved characteristics when compared with regular bitumen. The density of the mix was also increased by 25% with the addition of CRMB as compared with normal VG-30 asphalt binder and also cost analysis had done in accordance with 12 years. The cost analysis was performed for both the asphalt binders i.e. VG-30 and CRMB-60 including 12 years maintenance cost. The cost for Bituminous course for CRMB-60 came out to be Rs 68.23 Lacs per Km which was 20.81% economical than the bituminous work done by normal VG- 30 bitumen. Following are the results shown below

Mix Design values of Crumb Rubber Modified Bitumen

|

S. No. |

Crumb Rubber (%) |

Bitumen (%) |

Marshall Stability (kg) |

Flow Value (mm) |

Bulk Density (g/cc) |

Air Voids (%) |

VMA |

VFB (%) |

|

1 |

8 |

5 |

883.86 |

2.4 |

2.48 |

3.90 |

14.84 |

73.66 |

|

2 |

9 |

5 |

988.39 |

2.67 |

2.49 |

3.74 |

14.63 |

74.38 |

|

3 |

10 |

5 |

1049.59 |

2.93 |

2.49 |

3.67 |

14.53 |

74.74 |

|

4 |

11 |

5 |

1122.36 |

3.23 |

2.49 |

3.56 |

14.40 |

75.25 |

|

5 |

12 |

5 |

1230.78 |

3.57 |

2.50 |

3.22 |

14.07 |

77.05 |

|

6 |

13 |

5 |

1155.65 |

3.83 |

2.51 |

3.19 |

13.84 |

76.91 |

|

7 |

14 |

5 |

1137.97 |

4.03 |

2.52 |

2.85 |

13.48 |

78.79 |

|

8 |

MORTH & IRC Specifications |

|

1200 |

2.5– 4.0 |

2.0-3.0 |

3.0-5.0 |

Min.12 |

65-78 |

Anwar (2014) prepared two specimens of different sizes i.e. 100 mm and 150 mm diameter and with different mix design methods. These specimens were tested for properties such as Stability, Flow and Indirect Tensile Strength test (ITS) using crumb rubber as in dense graded bituminous macadam with varying percentages i.e. 10, 15, 20, 25 and 30% respectively of CRMB bitumen. In two different design methods, mix formed by Modified Marshall method shows better results in comparison with simple Marshall method.

Teppala et al (2014) conducted Modified Marshall test using Crumb Rubber Modified asphalt binder (CRMB-55) with and without addition of chemical Zycosoil in small doses i.e.0.03%, 0.04% and 0.06% added by the weight of bitumen. The results showed that with the addition of chemical Zycosoil the penetration value gets decreases and material becomes stiff. With 0.04% dosage of Zycosoil chemical, the change with elastic recovery is also noted indicating more flexibility to the binder and to increase the life of pavement at low temperature. The Marshall Mix design using CRMB 55 with 0.04 % Zycosoil chemical, reflects the significant rise in stability, unit weight and flow values for better compaction and enhancing the workability conditions

Ramprasad et al (2013) investigated the behaviour of bitumen grade 60/70 using both unmodified and modified bitumen with crumb rubber. The various Marshall properties and Indirect tensile strength (ITS) were compared for the specimens of bituminous mixes prepared at optimum binder content (OBC) for grade-2 bituminous concrete (BC). CRMB showed higher Marshall Stability value, reduced flow value, higher ITS value and improvedrheological properties only in terms of rutting. The results also showed that the variation of Complex Modulus (G*) with the temperature; In general, the complex modulus (G*) of plain bitumen is less when compared with CRMB 55 and CRMB 60. Amongst this, CRMB 55 shows higher complex modulus value at lower temperature and it was clearly observed that the virgin bitumen fails i.e. (value of complex modulus is less than 1 kPa) at temperature 64?C, but CRMB 55 and CRMB 60 bitumen fails at higher temperature of 70?C. This clearly indicates that CRMB bitumen grades are less susceptible to temperature changes as compared to plain bitumen.

Nanda et al examined the comparative performance of asphalt binder of grade 60/70 with two types of modified bitumen i.e. Crumb Rubber Modified Bitumen (CRMB-60) and Polymer Modified Bitumen (PMB-70). The rheological properties of both modified and base bitumen were studied using Dynamic Shear Rheometer (DSR) to examine the visco-elastic behavior before & after ageing for both the asphalt binders. The effect of ageing of asphalt binder on the rheological properties and Marshall properties such as stability and flow was studied. The Marshall properties of bituminous mixes were compared at optimum binder content (OBC) for bituminous concrete. Results showed the higher Marshall Stability value, reduced flow value, improved tensile strength & improved rheological properties for the modified bitumen when compared to the base bitumen. PMB-70 and CRMB-60 shows higher.complex modulus value (G*) when compared to base bitumen at the temperature range between 50-70?C.rheological properties only in terms of rutting. The results also showed that the variation of Complex Modulus (G*) with the temperature; In general, the complex modulus (G*) of plain bitumen is less when compared with CRMB 55 and CRMB 60. Amongst this, CRMB 55 shows higher complex modulus value at lower temperature and it was clearly observed that the virgin bitumen fails i.e. (value of complex modulus is less than 1 kPa) at temperature 64?C, but CRMB 55 and CRMB 60 bitumen fails at higher temperature of 70?C. This clearly indicates that CRMB bitumen grades are less susceptible to temperature changes as compared to plain bitumen.

III. SUMMARY OF THE LITRATURE

The cost for Bituminous course for CRMB-60 came out to be Rs 68.23 Lacs per Km which was 20.81% economical than the bituminous work done by normal VG- 30 bitumen. . The Marshall Mix design using CRMB 55 with 0.04 % Zycosoil chemical, reflects the significant rise in stability, unit weight and flow values for better compaction and enhancing the workability conditions. CRMB 55 shows higher complex modulus value at lower temperature and it was clearly observed that the virgin bitumen fails i.e. (value of complex modulus is less than 1 kPa) at temperature 64?C. The Marshall properties of bituminous mixes were compared at optimum binder content (OBC) for bituminous concrete. Results showed the higher Marshall Stability value, reduced flow value, improved tensile strength & improved rheological properties for the modified bitumen when compared to the base bitumen. This clearly indicates that CRMB bitumen grades are less susceptible to temperature changes as compared to plain bitumen.

A. Data Analysis

Mix Design values of Crumb Rubber Modified Bitumen

|

S. No. |

Crumb Rubber (%) |

Bitumen (%) |

Marshall Stability (kg) |

Flow Value (mm) |

Bulk Density (g/cc) |

Air Voids (%) |

VMA |

VFB (%) |

|

1 |

8 |

5 |

883.86 |

2.4 |

2.48 |

3.90 |

14.84 |

73.66 |

|

2 |

9 |

5 |

988.39 |

2.67 |

2.49 |

3.74 |

14.63 |

74.38 |

|

3 |

10 |

5 |

1049.59 |

2.93 |

2.49 |

3.67 |

14.53 |

74.74 |

|

4 |

11 |

5 |

1122.36 |

3.23 |

2.49 |

3.56 |

14.40 |

75.25 |

|

5 |

12 |

5 |

1230.78 |

3.57 |

2.50 |

3.22 |

14.07 |

77.05 |

|

6 |

13 |

5 |

1155.65 |

3.83 |

2.51 |

3.19 |

13.84 |

76.91 |

|

7 |

14 |

5 |

1137.97 |

4.03 |

2.52 |

2.85 |

13.48 |

78.79 |

|

8 |

MORTH & IRC Specifications |

|

1200 |

2.5– 4.0 |

2.0-3.0 |

3.0-5.0 |

Min.12 |

65-78 |

Conclusion

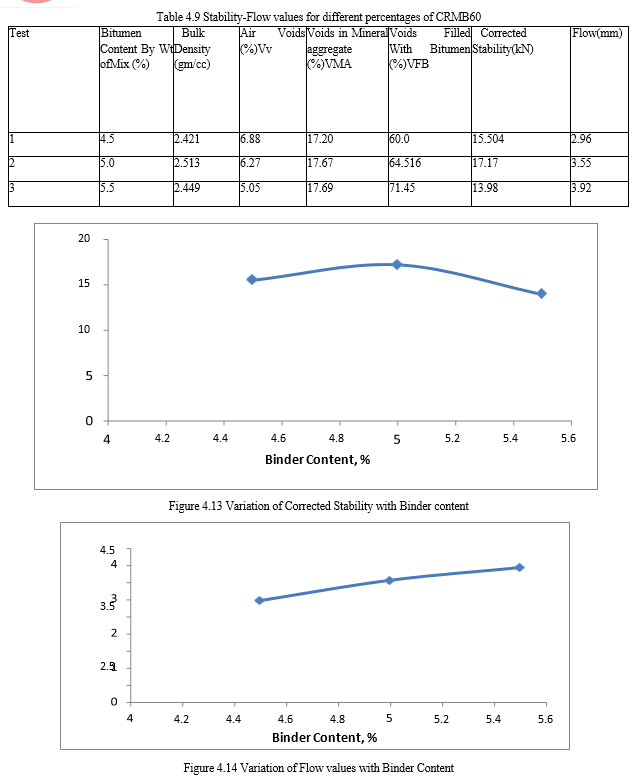

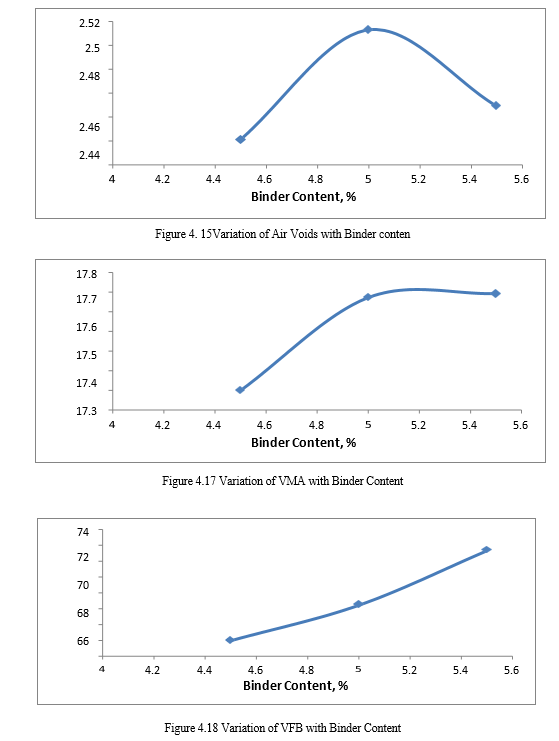

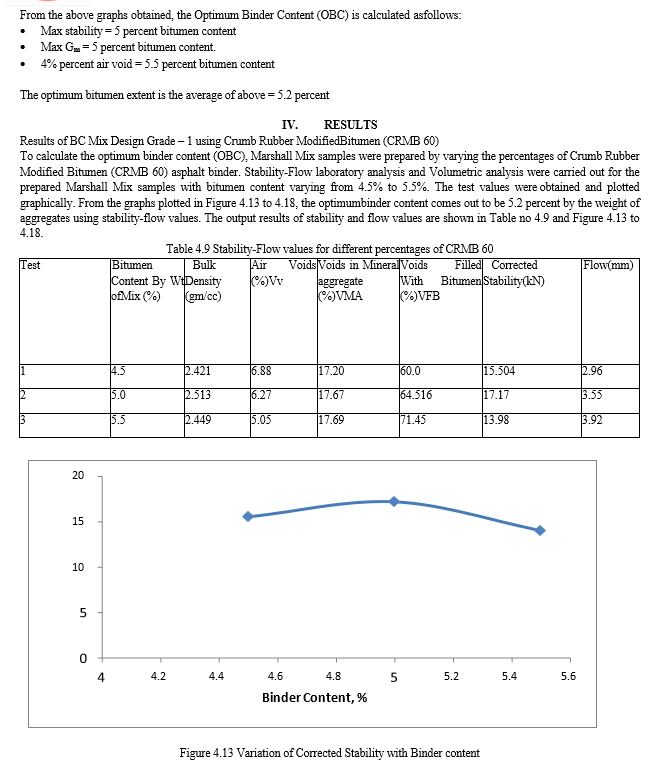

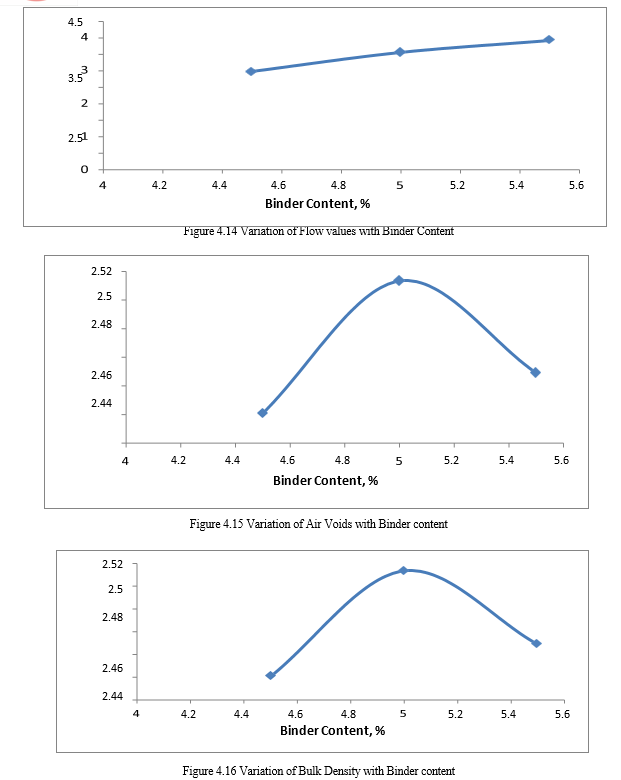

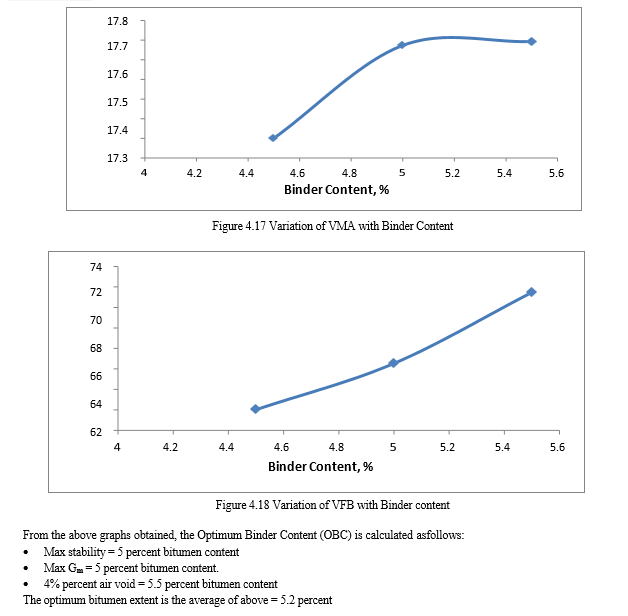

A. General The major conclusions drawn from the study carried out on stability-flow analysis of BC mix (Grade-1) by using different additives are as follows: 1) Initially, normal asphalt binder VG-30 is tested at different percentages for the BC mix grade -1 and optimum binder content (OBC) is calculated .The OBC occurs at5% and flow values are in the limits specified as per MORTH. 2) The stability values for the BC grade-1 mix increase with the replacement of OBC up to 8% of waste plastic but it decreases further with the addition of waste plastic. This waste plastic only indicates that this percentage is the only suited level of replacement. 3) For the addition of discarded tyre tubes, the stability values for the BC grade-1 mix increase with the replacement of OBC (5%) upto 12% of discarded tyre tubes with optimum binder content of 5% but decreases with the addition of tyre tube. However, the stability and flow values lie within the limits specified by MORTH for all % replacements of tyre tubes. 4) The OBC of CRMB and PMB used in BC Grade-1 is 5.2%. 5) Out of the various materials used, replacement of OBC by 12% discarded tyre tube has the highest stability value. 6) The Indirect Tensile Strength (ITS) test was conducted on all the conditioned samples prepared i.e. for VG-30 bitumen, PMB, CRMB, with waste plastic and with discarded tyre tube at constant loading rate of 50.8mm/min and the results comes out to be 1.21, 1.29, 1.38, 1.42, 1.49 respectively and further Elastic Modulus were calculated w.r.t each binder and pavement is designed using IIT PAVE.

References

[1] AASTHO: T 315-10: Standard method of test for “Determining the Rheological Properties of Asphalt Binder using a Dynamic Shear Rheometer (DSR)”. [2] Adedimi1a A., Kennedy T.(1975) “Fatigue and Resilient characteristics of asphalt mixtures by repeated-load Indirect Tensile test”. [3] Akinpelu M., Dahunsi B., Olafusi O., Awogboro O. and Quadri A. (2013) “Effect of Polythene Modified Bitumen on Properties of Hot Mix Asphalt”. ARPN Journal of Engineering and Applied Sciences, 8(4), pp. 290-295. [4] Anwar S. (2014) “Studies On Marshall And Modified Marshall Specimens By Using CRMB” (International Journal of Structural and Civil Engineering Research- IJSCERISSN 2319 – 6009, 3(4) [5] Archana M.R, Sathish H.S., Ashwin M, Hanamant Hunashikatti (2014) “ Effect of waste plastic utilisation on Indirect Tensile Strength properties of Semi Dense Bituminous Concrete Mixes” Indian Highways. pp. 64-72. [6] ASTM - D6931-12: Standard test method for Indirect Tensile (IDT) Strength of Bituminous mixtures. [7] Bhargav N.Gautam (2013) “Warm mix Design of Bituminous Concrete using Rediset WMX” Global Research Analysis, 2(6), ISSn No 2277 – 8160. pp. 70-72 [8] Kalasariya D., Patel K., Raol H. (2016) “Study of Bituminous Concrete under Different Mix Conditions by Using Epoxy Resin as Modifier” IJSRSET, 2(3), ISSN :2395-1990, Online ISSN : 2394-4099 [9] Four Laning of National Highway from Rajkot to Somnath. [10] Gawande A., Zamre G.S, Renge V.C., Bharsakale G. and Tayde S. (2012) “Utilisation of waste plastic in asphalting of roads” Scientific reviews and Chemical communications, SRCC: 2(2), 2012, ISSN 2277-2669, pp. 147-157. [11] IRC:37-2012 “Guidelines for the Design of Flexible Pavements” (3rd Revision) [12] IRC SP:98-2013 “Guidelines for the use of Waste Plastic in hot bituminous mixes”. [13] IRC SP:53 “Guidelines on use of Polymer and Rubber Modified Bitumen in Road Construction” IRC, New Delhi [14] IS 15462:2004 “Polymer and Rubber Modified Bitumen”. BIS, New Delhi. [15] Kazmi S., Rao D.G. (2015), “Utilization of Waste Plastic Materials as Bitumen- Blends for Road Construction in Oman” (Scholars Journal of Engineering and Technology (SJET) Sch. J. Eng. Tech., 3(1A), pp. 9-13 [16] Mahrez A. And Karim M. (2010) “Rheological Evaluation of bituminous binder modified with waste plastic material” 5th International Symposium on Hydrocarbons & Chemistry (ISHC5), Sidi Fredj, Algiers. [17] Malik A. (2014) “Low Density Polyethylene Modified Dense Graded Bituminous Macadam” International Journal of Engineering Trends and Technology (IJETT)16(8), pp. 366-372 [18] MORT&H Specifications for Road and Bridge Works (Fifth Revision) [19] Nanda H M, S V Dinesh, J K Dattatreya and Tadas A. “Comparative study of Rheological and Marshall properties of Base and Modified Bituminous Binders.” [20] Panda M., Prusty B. and Chattaraj U. “A laboratory study on use of waste polyethylene in a Bituminous Concrete Mix” [21] Pareek A., Gupta T. And Sharma R. (2012), “Performance of Polymer Modified Bitumen for Flexible Pavements” IJSCER: International Journal of Structural and Civil Engineering Research, ISSN 2319 – 6009, 1(1) [22] Prasad S.K, Manjunath K. R, Prasad K.V.R. (2012), “Study on Marshall Stability Properties of BC Mix Used In Road Construction by Adding Waste Plastic Bottles” IOSR Journal of Mechanical and Civil Engineering (IOSRJMCE) ISSN: 2278-1684 2(2), pp. 12-23 [23] Ramprasad.D.S, Umesha.T.S, Dinesh.S.V, Dattatreya.J.K (2013) “Comparison Of Physical And Rheological Properties Of Plain And Crumb Rubber Modified Bitumen” IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163, pISSN: 2321-7308, pp. 216-220 [24] Sahu R., Joshi R. (2015) “Economic construction of Bituminous road by Utilisation of Waste Tyre Rubber – CRMB” IJSTE: International Journal of Science Technology& Engineering 1(12), pp. 35-40 [25] Singh J., Gupta P.K. (2015) “Study of Bituminous Concrete under different mix conditions” International Journal of Research in Engineering and Technology eISSN: 2319-1163, pISSN: 2321-7308, pp. 309-312 [26] Swami V., Jirge A., Patil K., Patil S., and Salokhe S. (2012), “Use of Waste Plastic in Construction of Bituminous Road” IJSET, 4(5) [27] Teppala B., Mishra C., Sinha A., Kumar D. (2014) “Experimental Assessment of Properties of Crumb Rubber Modified Bitumen Mix (CRMB 55) With and Without Application of Nanotechnology Additive” International Journal of Innovative Research in Science, Engineering and Technology, 3(10) [28] Wayal1 A., Mudassir. D. Wagle (2013) “Use of Waste Plastic and Waste Rubber in Aggregate and Bitumen for Road Materials” International Journal of Emerging Technology and Advanced Engineering, ISSN 2250-2459, ISO 9001:2008 Certified Journal, 3(7) [29] Joshi C., Patted A., Archana M.R, M S.Amarnath (2013), “Determining the Rheological properties of asphalt binder using Dynamic Shear Rheometer (DSR) for selected pavement stretches” IJRET: International Journal of Research in Engineering and Technology, eISSN: 2319-1163, pISSN: 2321-7308

Copyright

Copyright © 2024 Ishfaq Ahmad Bhat, Ravi Chahal. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET61333

Publish Date : 2024-04-30

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online