Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

An Experimental Study of Strength Properties of Galvanized Iron (GI) Fiber Reinforced Concrete

Authors: Mrs. Nupur Dewangan, Nagesh Soni, Dinanath Sahu, Lomash Sahu, Priyanshu Rathore

DOI Link: https://doi.org/10.22214/ijraset.2024.61840

Certificate: View Certificate

Abstract

Fiber Reinforced Concrete is one of the most quality construction techniques of modern times. The utilization of locally available galvanized iron or metallic fiber as a bridging material. The concrete with metallic or nonmetallic fiber is very useful and its enhanced concrete mechanical properties. Therefore, a research has been conducted to study the performance of locally available GI wire fiber reinforced concrete (GWRC). This paper presents the findings of the research that made an effort to explore several basic characteristics of GWRC primarily related to strength, ductility and durability. This research was, therefore, conducted to compare the concrete strength performance of GI fiber with different lengths and a control specimen. The objective of this study is to explore the effect of GI fiber in terms of compressive strength, splitting tensile strength, and flexural strength with ‘Galvanized Iron’ fiber using several cutting lengths of 25 mm and 35mm with various mix proportions including 1.0%, 1.5%, 2.0%, and 2.5% by weight of the concrete.

Introduction

I. INRODUCTION

Building construction materials such as concrete which is produced through a carefully proportioned mixture of cement, sand, gravel or other aggregates, and water and hardened in different forms and dimensions for the specified structure. The materials are amalgamated to ensure the voids within the aggregates are satiated to produce a consistent dense concrete. It is important to note that concrete has been the foremost widely used construction material throughout the planet with those made using hydraulic cement observed to be having certain characteristics while plain and unreinforced concrete is a friable material with a picayune strain capacity. Concrete is relatively sturdy in compression but languid in tension and tends to be fragile. This, therefore, makes it important from the engineering perspective and there has been a continuing effort to upgrade its performance. The greatest abridgment for concrete is the lack of ductility and the improvement of this aspect is a prime concern for civil engineers. This has, therefore, led to a considerable number of studies incorporating different fibers such as steel, jute, glass, and polymer in concrete the concept is generally known as the Fiber Reinforced Concrete (FRC) and has been found to be one of the foremost promising new construction materials due to its enhanced ductility and decreased brittleness. The inclusion of the fibers also modifies the behavior of the fibermatrix composite after it has cracked, thereby, upgrading its toughness. The real contribution of the fibers is to extend the toughness of the concrete which has been described to be an area under a load-deflection curve. This is due to the fact that plain concretes fail suddenly once the greatest strength is surpassed while fiber ferroconcrete continues under considerable loads even at deflections considered more than the fracture deflection in plain concrete. This means fiber reinforced concrete is in a position to sustain load or strain much greater than plain concrete.

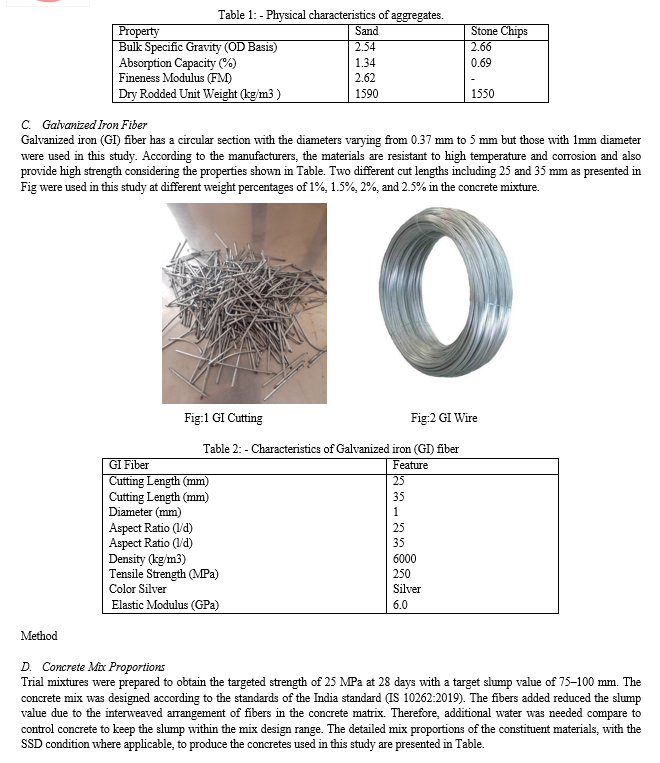

Fiber ferroconcrete is also generally defined as a material made with hydraulic cement, aggregate, and incorporating discrete discontinuous. Galvanized steel wire or iron (GI) formed from zinc-plated steel is presently used as a reinforcement to improve concrete properties mainly due to the ability of the protective layer of zinc to inhibit corrosion. Several studies have been conducted to investigate the suitability of GI fibers as an alternative to steel or hybrid fibers. This is important considering the fact that steel fiber is the most prominent metallic fiber with the ability to augment concrete properties but it is expensive to be used in Bangladesh due to additional cost attached to its unavailability in the local market. Studies have also been conducted to determine the substitute reinforcing material to emulate steel fiber in improving the mechanical properties of concrete at a lower cost. Some others also focused on using different mix proportions of steel fiber to determine their effectiveness but there is no significant research on the use of GI fiber with different cutting length and at several mix proportions. This means it is considerably important to determine the influence of the effective utilization of galvanized iron (GI) fiber to produce ennobled concrete. Therefore, the foremost objective of the study was to develop galvanized iron (GI) fiber reinforce concrete composites, and determine the suitable length and content (volume fraction) of fibers based on concrete mechanical behavior.

As a matter of recent development, very little background knowledge about GI wire fiber reinforced concrete is available at present. A research has lately been carried out to investigate the properties of GI wire so that a proper comparison can be established between the properties of steel fiber and GI wire fiber. It was also studied if GI wire fiber conforms to the ACI and ASTM standards for steel fibers to be used in SFRC (Steel Fiber Reinforced Concrete). In addition, compressive strength of GWRC (Galvanized Wire Reinforced Concrete) was determined and was compared to compressive strength of SFRC to assess the performance of GI wire fiber as fiber in concrete. The study is regarded as one of the pristine attempts to incorporate GI wire fiber as a substitute for steel fiber in FRC. Therefore, the research followed the guidelines and specifications available in the literature concerning steel fiber reinforced concrete. Considering this study as a stepping stone, the present research attempts to move the current state of affairs forward and to lay the groundwork for future research in this field by exploring the prospects of GI wire fiber reinforced concrete.

II. REVIEW OF LITERATURE

F. Akter, S. S. Das, A. Rahman at all (2022): - An Experimental Study On Compressive Strength Of Fiber Reinforced Concrete Using Gi Wire. This paper principally focused on the compressive strength enhancement due to the addition of the Galvanized Iron Wire Fiber (GIWF) to concrete. Galvanized Iron Wire Fiber Reinforced concrete (GIWF) is a concrete in which small doses of galvanized iron wires are added as a fiber component to the concrete mix. GIW is a low-cost material and usually accessible in the local market of Bangladesh. However, the concept of GIW as fiber to improve the strength and properties of concrete is very new in the domain of fiber reinforced concrete technology. For these reasons and in order to enhance knowledge, an experimental investigation was carried out to study the effectiveness of galvanized iron wire as a fibrous material. For this purpose, a total of 18 concrete cylinders were cast with two different volume fractions of GI wire fiber contents with 0.7% and 1.4% of the total composite. The cylinder specimens were tested statically loaded under compression until crushed. It was found that the addition of 0.7% GIWF significantly increased 28 days compressive strength of the concrete by 22.5% whereas 1.4% GIWF enhanced 29.85% compressive strength with respect to the reference cylinder specimens (0% GIWF). Finally, the test results were analyzed with respect to the available published literature and concluded that the Galvanized Iron Wire Fiber with 0.7% and 1.4% volume fractions may be a potential alternative and safe fibrous material in the fiber reinforcement concrete technology, especially for Bangladesh

R. Sadi at all (2022): - An Experimental Investigation Of The Mechanical Behavior Of Galvanized Iron Wire Fibers In Reinforced Concrete The behavior of concrete is strong in compression but weak in tensile strength. Various methods and materials have been utilized to improve its tensile strength, which has been introduced as reinforced concrete. The characteristics of concrete have been improved because of fiber reinforcement.

A case study has been carried out to improve concrete quality in Bangladesh through the use of locally available, inexpensive galvanized iron (GI) wire fibers that alter the concrete's behavior in terms of compressive and tensile strength. Specimens were cast with fibers of 0%, 0.5%, 1.0%, and 1.5% of the total concrete weight to find the mechanical properties of concrete in a cylinder (150 mm x 300 mm) test. In the results, compressive strength (20.12 N/mm2 ) and tensile strength (1.92 N/mm2 ) without fibers were shown, whereas maximum compressive and tensile strengths were shown in 1.0% fiber using concrete (26.74 N/mm2 ) and (3.52 N/mm2 ) on 28 days. Compared to these results, the better improvement is in tensile strength (83.33%), and the slight upgrade is in compressive strength (32.90%).

It has been seen that galvanized iron (GI) wire fiber-reinforced concrete (GFRC) is much better than standard concrete. Additionally, it has been found that, for the specific mix design, a fiber component of 1% by weight provides substantially better results. According to the results of the slump test, the galvanized iron wire reinforcement had a substantial impact on workability. The workability declined as the fiber concentration increased.

III. MATERIAL AND METHOD

A. Portland Cement

Ordinary hydraulic Cement containing 95–100% and 0–5% of clinker and gypsum respectively at a precise gravity of 3.12 was used in this study.

B. Coarse and Fine Aggregates

River sand was utilized as the fine aggregate while crushed stone chips were treated as the coarse aggregate using a grading consistent with IS 383(1970). The aggregates were collected from Sylhet and their physical properties are presented in Table.

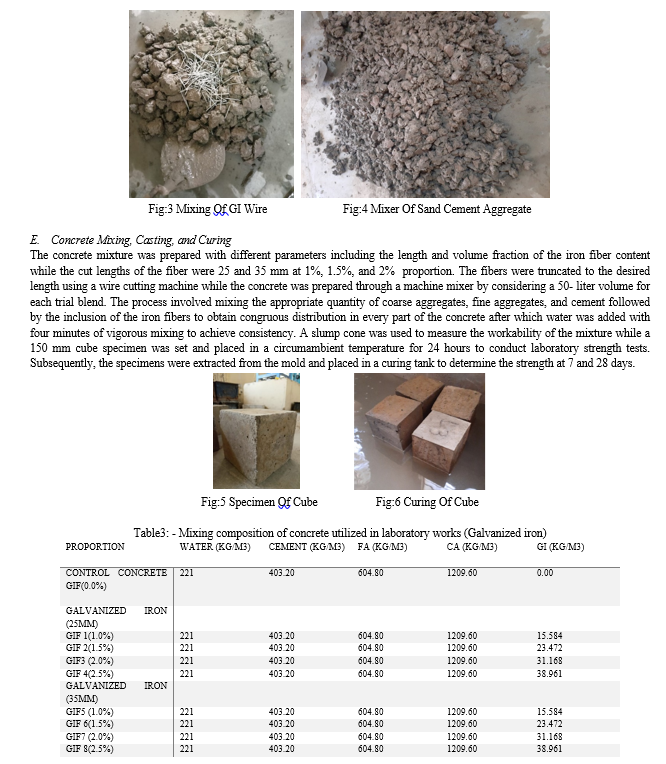

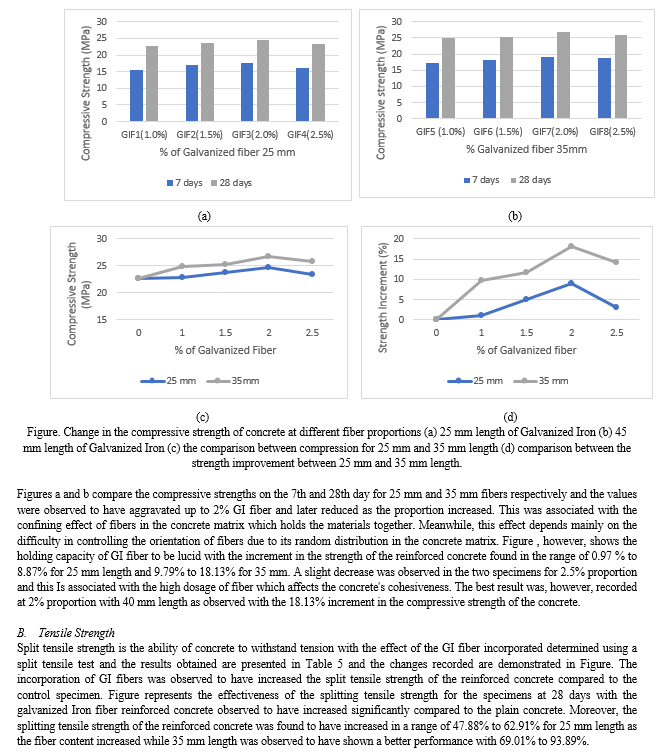

Conclusion

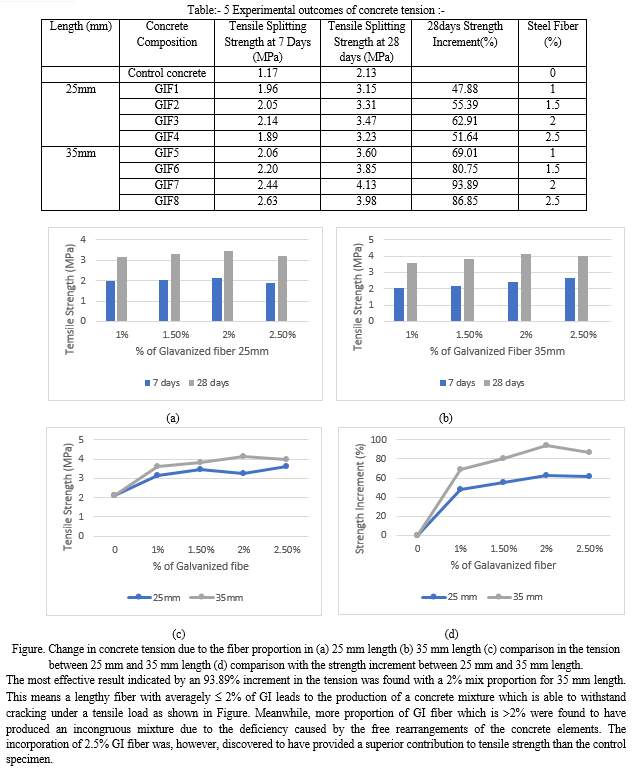

Laboratory experiments were conducted to determine the compression, and tension of the concretes reinforced with ‘Galvanized Iron’ fiber. The results showed 25mm length galvanized iron fiber was able to aggravate concrete compressive strength by 0.97 % - 8.87%, increased tension by 47.88% to 62.91%. The use of a 35 mm length for 2% GI fiber proportion was found to be the best mixture as observed in its effect on the compression with a 18.13% increase, tension with 93.89% increase. In comparison with steel fiber, the utilization of GI fiber showed a bit smaller enhancement in concrete compression and tension and has the potential to be used as a substitute for the expensive imported steel fiber in India. This is due to the local availability of the GI fiber in the country which makes it a viable low-cost substitute in fiber reinforced concrete and its ability to improve the mechanical properties of concrete.

References

[1] R. Sadi1, M. R. Tith, A. Amin, J. Podder, M. A. K. Azad (2022)An Experimental Investigation Of The Mechanical Behavior Of Galvanized Iron Wire Fibers In Reinforced Concrete.(ICACE-2022) [2] F. Akter, S. S. Das, A. Rahman , M. Rahmatullah, T. Ahmed, H.A. Mamun (2022) An Experimental Study On Compressive Strength Of Fiber Reinforced Concrete Using Gi Wire. (ICACE-2022) 21-23 December 2022 CUET, Chattogram, Bangladesh www.cuet.ac.bd/icace [3] Sristi Das Gupta* , Md Shah Newaz Aftab Chayon, Chaity Kamaka, Hasan Mohammad Zakaria (2020) The Study of the Strength Properties of Galvanized Iron (GI) Fiber Reinforced Concrete Journal of the Civil Engineering Forum, September 2020, 6(3): 285-294 DOI 10.22146/jcef.56896 [4] Lijuan Zhang, Jun Zhao, Cunyuan Fan and Zhi Wang (2020) Effect of Surface Shape and Content of Steel Fiber on Mechanical Properties of Concrete. Hindawi Advances in Civil Engineering Volume 2020, Article ID 8834507, 11 pages https://doi.org/10.1155/2020/8834507 [5] Shah Newaz Aftab, Chaiti Karmakar, Hasan Mohammod Zakaria and Sristi Das Gupta (2020) Experimental study of fiber reinforced concrete using metallic and nonmetallic fibers. hInternational Conference on Civil Engineering for Sustainable Development (ICCESD2020), 7~9 February 2020, KUET [6] S Layang* and W Wiratno Compressive strength and modulus of elasticity of concrete using iron fibers. IOP Conf. Series: Journal of Physics: Conf. Series 1469 (2020) 012036 IOP Publishing doi:10.1088/1742-6596/1469/1/012036 [7] Md. Abul Bashar Emon , Tanvir Manzur, Md. Salehin Sharif (2017) Suitability of locally manufactured galvanized iron (GI) wire fiber as reinforcing fiber in brick chip concrete. http://dx.doi.org/10.1016/j.cscm.2017.08.003 [8] Vikrant S. Vairagade and Kavita S. Kene (2013) Strength of Normal Concrete Using Metallic and Synthetic Fibers. 2 Published by Elsevier Ltd. Selection and/or peer-review under respon [9] R.S. Olivito, F.A. Zuccarello(2009) An experimental study on the tensile strength of steel fiber reinforced concrete. 1359-8368/$ - see front matter 2009 Elsevier Ltd. All rights reserved. doi:10.1016/j.compositesb.2009.12.003 [10] M.A. Baltazar-Zamora, E. Maldonado-Bandala1 , M.U. Loya Tello, G. Santiago-Hurtado, F.J. Olguín Coca, A. Ortiz-Cedano1 , C. P. Barrios D , R. E. Núñez J , P. Zambrano, C. Gaona-Tiburcio, F. Almeraya-Calderón (2012) Efficiency of Galvanized Steel Embedded in Concrete Previously Contaminated with 2, 3 and 4% of NaCl. Int. J. Electrochem. Sci., 7 (2012) 2997 – 3007 [11] Paulo B. Cachim a, Joaquim A. Figueiras b, Paulo A.A. Pereira Fatigue behavior of fiber-reinforced concrete in compression. 0958-9465/02/$ - see front matter 2002 Elsevier Science Ltd. All rights reserved.

Copyright

Copyright © 2024 Mrs. Nupur Dewangan, Nagesh Soni, Dinanath Sahu, Lomash Sahu, Priyanshu Rathore. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET61840

Publish Date : 2024-05-09

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online