Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

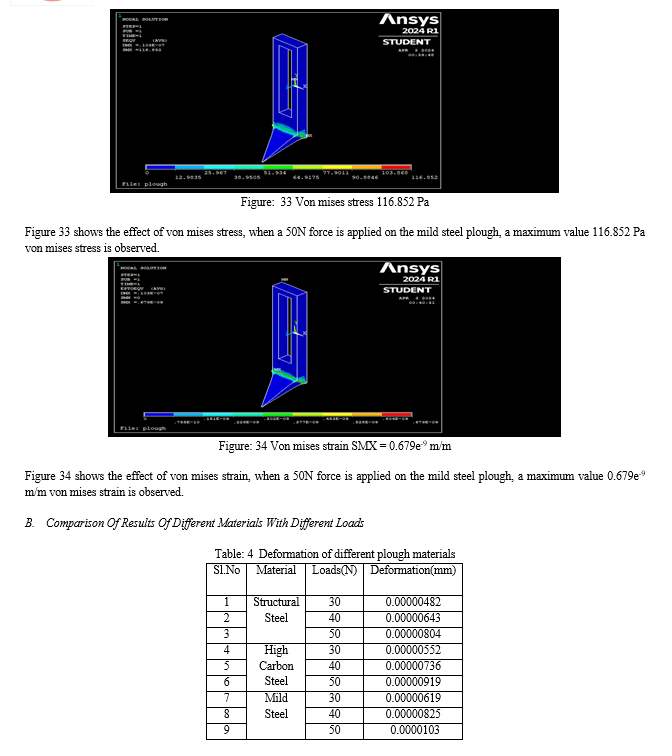

- Introduction

- Conclusion

- References

- Copyright

Design, Analysis and Fabrication of Manually Operated Seed Sowing Machine

Authors: Dr. D. Sai Chaitanya Kishore, E. Vamsi, B. Manjunath, T.V Rohith, B. Sai Charan, B. Hareesh Kumar Reddy

DOI Link: https://doi.org/10.22214/ijraset.2024.60031

Certificate: View Certificate

Abstract

Sowing machine should be suitable to all farms, all types of corps, robust construction, also it should be reliable, and this is basic requirement of sowing machine. Manually operated seed sowing machine reduces the efforts of farmers thus increasing the efficiency of planting also reduces the problem encountered in manual planting. Manually operated seed sowing machine can plant different types and different sizes of seeds also can vary the space between two seeds while planting. This increases the planting efficiency and accuracy. The focus of this research work is to design, analysis of plough and fabricate a low-cost Manually Operated Seed Sowing Machine for effective handling of the machine by any farmer or by any untrained worker with simplified design. The components of seed sowing machine were modelled by using Auto CAD 2022. Analysis of plough was performed by using Ansys 2023-student version. The fabricated seed sowing machine perform the various simultaneous operations and saves labour requirement so as labour cost, labour time and also save lots of energy.

Introduction

I. INTRODUCTION

The Indian economy heavily relies on agriculture, and its development is crucial for the country's economic growth. However, farmers in India face several challenges such as a shortage of labor, the use of inefficient farming equipment, and the traditional, time-consuming methods of farming. This project aims to enhance seed sowing and pesticide spraying operations in farming by introducing a multifunctional seed sowing machine. The primary goal is to accurately place seeds in each row at the correct depth and spacing, thus reducing planting time, labor costs, and increasing production efficiency. Traditional seed sowing methods are based on assumptions and are inefficient, often resulting in physical strain for farmers. Additionally, farmers also struggle with pest control due to changing climates, requiring them to spend significant time and effort on pesticide spraying. This machine addresses these issues by incorporating pesticide spraying functionality, making it multifunctional and beneficial for farmers. By improving agriculture processes like seed sowing and fertilizer distribution, this project aims to enhance productivity while requiring less manual labor and energy input. Overall, this project contributes to the mechanization of the agriculture industry in India, which is essential for meeting the growing demand for produce as the population increases.

Klocke (1) described the construction of two experimental planters, one with a smooth coulter and the other with a ripple-edged coulter, both followed by hoe openers, which performed satisfactorily with adequate soil moisture for seed placement.

Kumar et al. (2) developed a manually operated seeding attachment for an animal-drawn cultivator, achieving a seed rate of 43.2 kg/hr and a field capacity of 0.282 ha/hr.

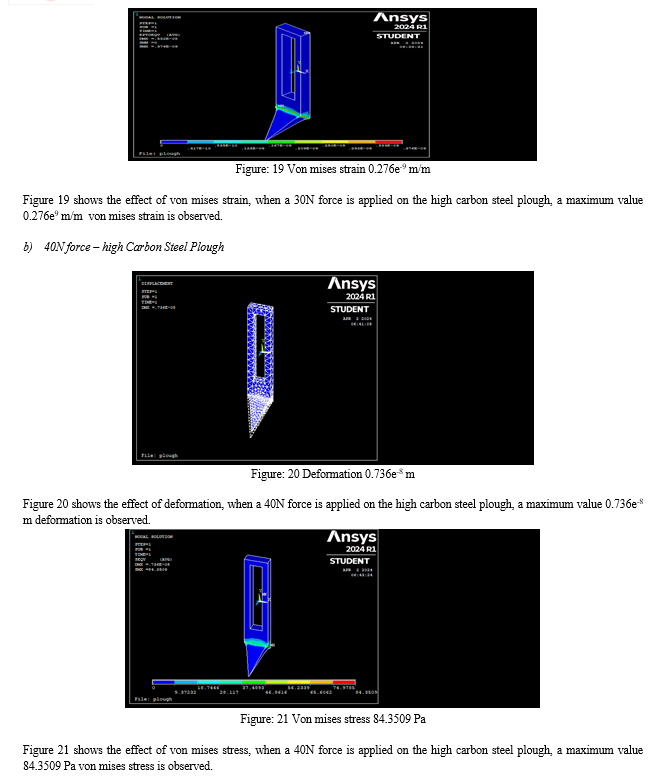

Ladeinde and Verma (3) compared three Jab planter models with traditional planting methods, finding similar field capacities and labor requirements but reduced backaches and fatigue with the planters.

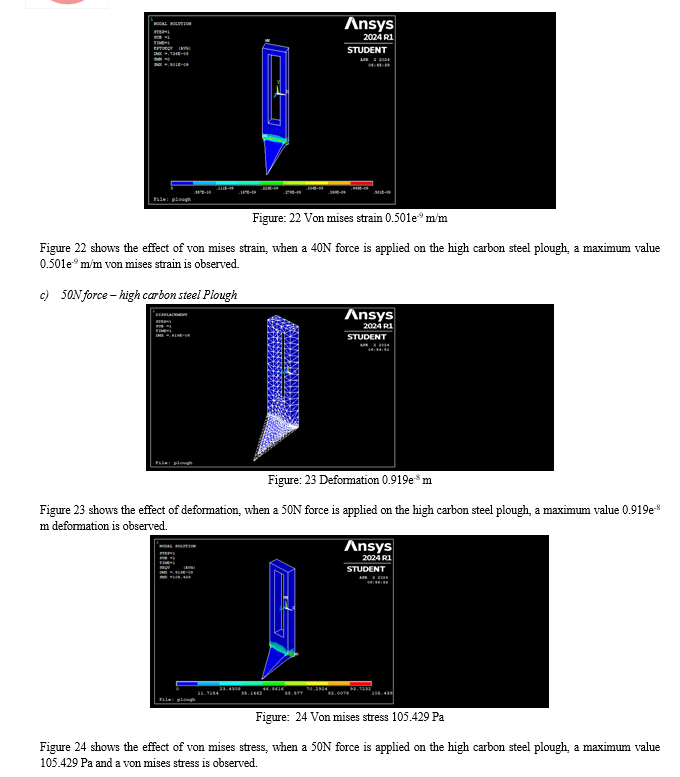

Molin et al. (4) created a rolling planter for stony conditions with 12 spades, cam-activated doors, and a plate seed meter, leading to improved planting efficiency and accuracy.

Bamgboye et al. (5) devised a manually operated two-row Okra planter with a field efficiency of 71.75% and a field capacity of 0.36 ha/hr, with low seed damage. Gupta and Herwanto (6) designed a direct paddy seeder for a two-wheel tractor, boasting a field capacity of 0.5 ha/hr and minimal seed damage.

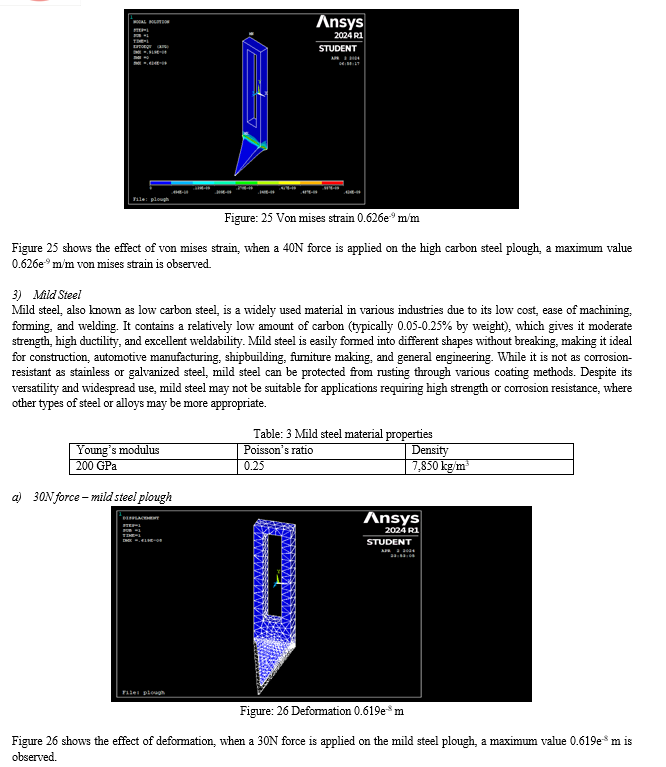

Marode et al. (7) proposed sowing seeds in multiple lanes simultaneously to reduce labor and time consumption. Hannure et al. (8) developed an automatic seed feeder for nurseries to decrease labor and time in seed feeding.

Sagar et al. (9) studied a semi-automatic seed feeding vehicle to plant seeds at the required depth and spacing, reducing effort and cost. Singh (10) designed a two-row tractor-drawn ridge planter for winter maize.

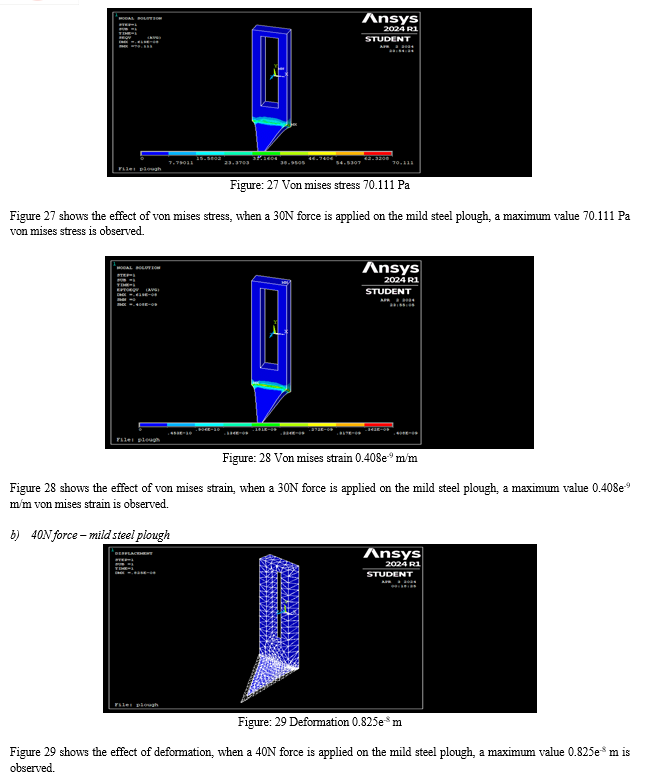

Bamgboye et al. (11) tested a manually operated two-row Okra planter with a field capacity of 0.36 ha/hr and a field efficiency close to 72%.

Pundkar et al. (12) investigated innovations in seed sowing machines for agriculture, highlighting the impact on cost and yield. Raut et al. (13) explored the importance of mechanization in agriculture for input conservation, higher productivity, and lower unit cost.

Ramesh et al. (14) examined innovations in seed sowing equipment for optimal yields and efficiency in agriculture.

Sawalakhe et al. (15) discussed the need for new sowing techniques in India to increase crop production without affecting soil texture.

Pundkar (16) emphasized the importance of high precision pneumatic planters for uniform seed distribution and higher yield. Shelke (17) noted the increasing necessity of bullock-drawn planters due to a diminishing workforce, highlighting the importance of planting distance and plant population for maximizing crop yields.

Soomro et al.(18) evaluated different sowing methods and seed rates for wheat, recommending drilling at 125 kg/ha for optimal yield and quality Adalinge et al. (19) developed a manually operated seed sowing machine for simultaneous tasks involved in seed sowing, with a simple design.

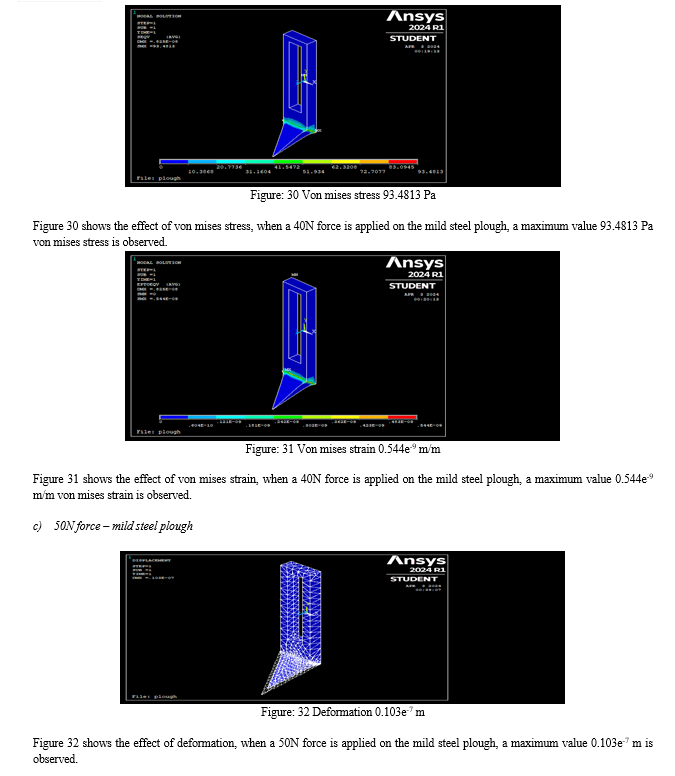

Rohokale et al. (20) compared conventional and modern sowing methods, highlighting the benefits of modern machines in reducing human effort. Shriprasad et al. (21) described a seeding and fertilizing agriculture robot using microcontrollers, aimed at improving agricultural efficiency and productivity.

II. DESIGN

A. Main Frame

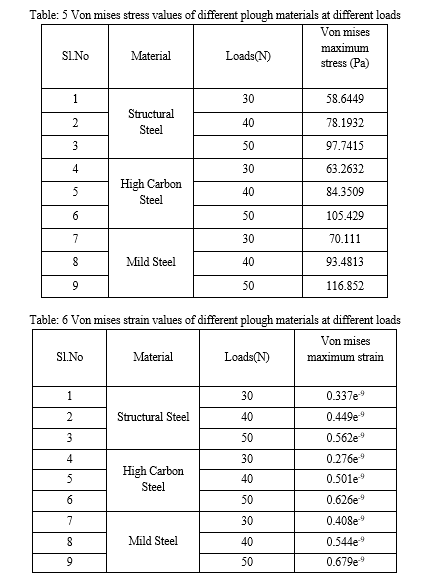

The main frame is constructed using 20*20 mm square pipe and 20*40 mm mild steel rectangular pipe. And for the handle 20 mm diameter pipe is used. The main frame has all provisions to install wheels, plough and seed dispenser. First the steel pipes are cut and a basic frame is welded. To install the wheels, holes are drilled on the main frame to hold the bearing block and for guiding the machine handle is welded. A frame to install the seed dispenser is also provided.

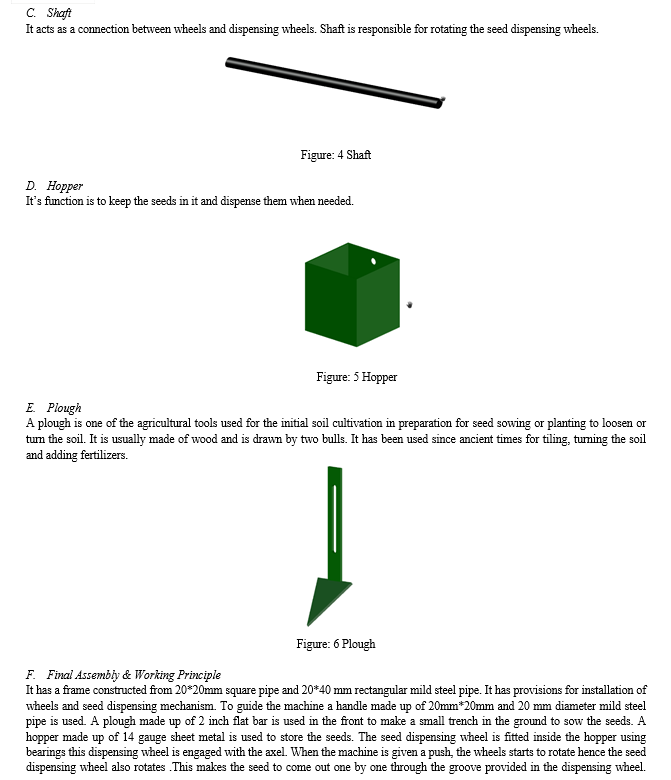

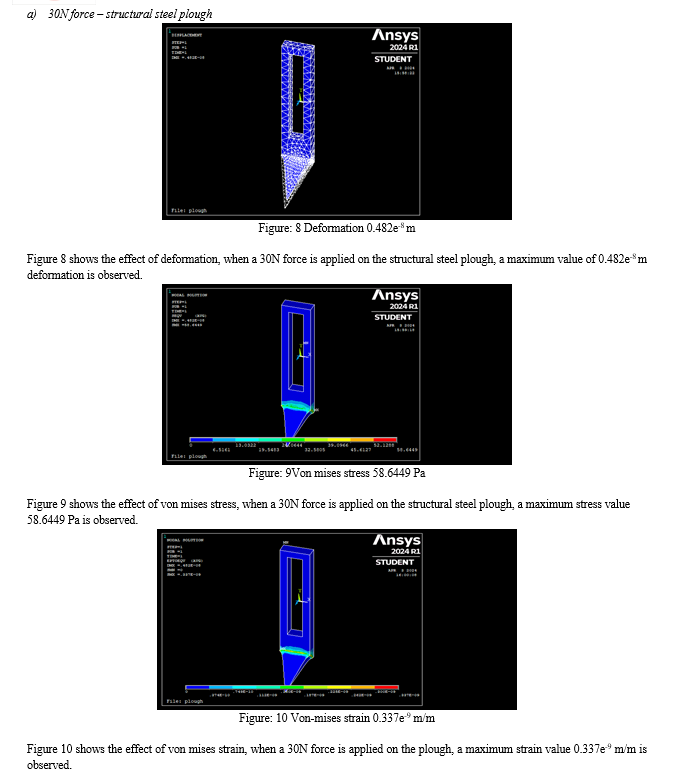

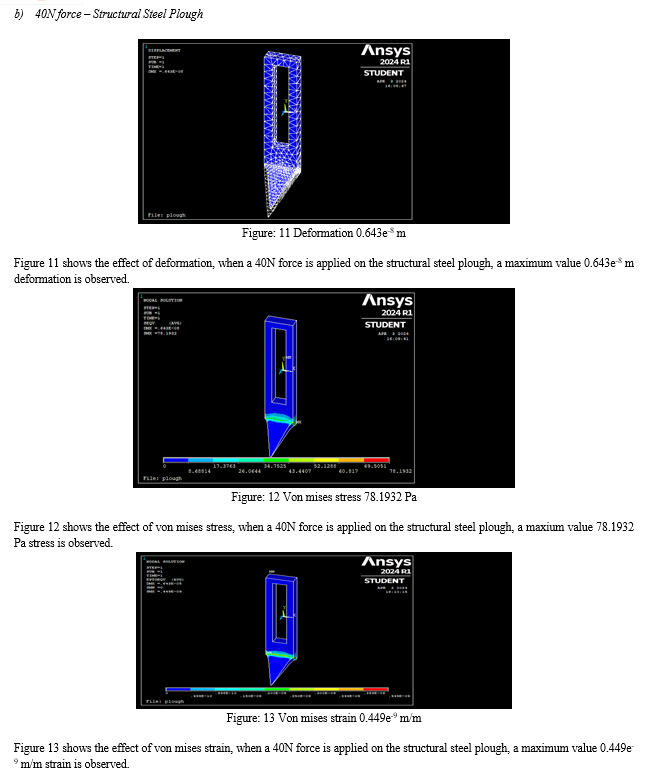

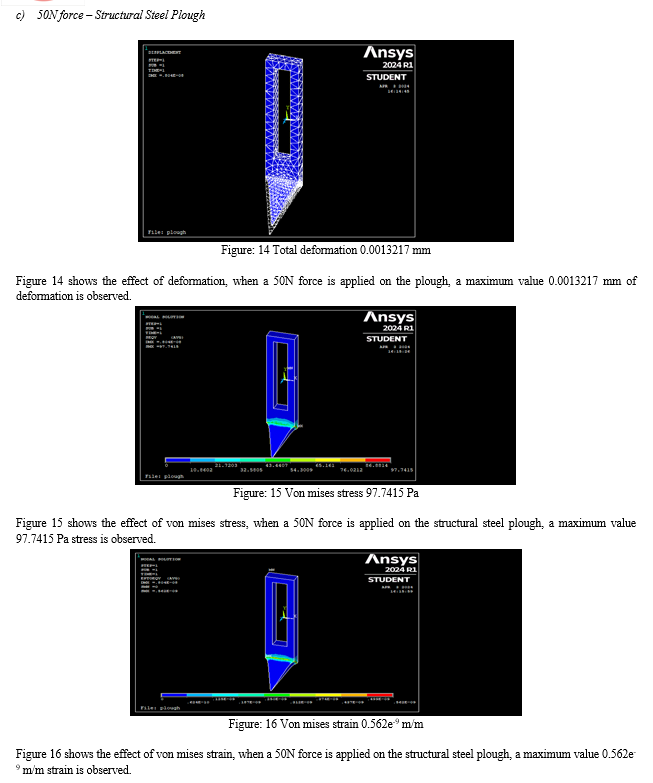

III. ANALYSIS OF PLOUGH

With the emerging importance of CFD and finite element analyses, it is of great necessity that engineering students get a good base of knowledge on one of the most used software packages in the industry of simulation, ANSYS.

ANSYS is a finite element analysis package used widely in industry to simulate the response of a physical system to structural loading, and thermal and electromagnetic effects. ANSYS uses the finite-element method to solve the underlying governing equations and the associated problem-specific boundary conditions.

FEM, A computer based analysis technique for calculating the strength and behavior of model during the given limits. In the FEM the model is represented as finite elements and is joined at special points which are called as nodes. Finite element analysis is the numerical solution of the mechanical components that are acquired by discretizing the mechanical elements into a small finite number of building blocks (known as elements) and by investigation those mechanical components for their acceptability and reliability. FEM is the simple technique as compared as the theoretical methods to discover the stress developed in a pair of gears. Models for numerical analysis have been prepared in SOLIDWORK and these have been bring in into ANSYS as IGES files for further analysis. The proportions of gear obtained from theoretical analysis have been used for preparing geometric model of gear. The condition for analysis has been assumed as static. This manual includes the procedure of solving the (static structural, Fluent) problems.

A. Analysis For Different Materials Of Plough At Different Loads

1) Structural Steel

Structural steel is a versatile and durable construction material composed primarily of iron and carbon, with additional elements for strength and stability. Known for its high strength-to-weight ratio, it can support heavy loads while being relatively lightweight. Steel components, such as beams, columns, and plates, are fabricated off-site and assembled on-site, reducing construction time and costs. With its resistance to corrosion, fire, and pests, structural steel is used in a wide range of applications, including building frames, bridges, industrial structures, and high-rise buildings. Its recyclability also makes it an environmentally friendly choice for construction projects.

Table: 1 Structural steel material properties

|

Youngs modulus |

Poissons ratio |

Density |

|

210 GPa |

0.3 |

7900 kg/m3 |

IV. FABRICATION OF MANUALLY OPERATED SEED SOWING MACHINE

A. Process used

To make seed sowing machine, we are mainly using two process.

1) Metal Cutting: Metal cutting is the process of removing unwanted material in the form of chip, from a block of metal, using cutting tool.

2) Welding: Welding is a fabrication of sculptural process that materials, usually metals (or) thermoplastics, by using high heat to melt the parts together and allowing them to cool causing fusion. Welding is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal.

In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc), can be stronger than the base material (parent metal). Pressure may also use in conjunction with heat, or by itself, to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated 0r oxidized.

Conclusion

In this present study a seed sowing machine was modelled to meet the key requirements of stability, comfort, and hand control. Seed sowing machine was modelled by using AutoCAD and CATIA, The machine was constructed in six distinct subsections: Main Frame, Dispensing Wheel, Hopper, Plough, Shaft, and UC Bearings. Finite element analysis was performed on plough for the materials high carbon steel, structural steel and mild steel and by using Ansys 2023 student version. From the analysis it was identified that structrural steel plogh was subjected to lower deformation, less amount of Von mises stresses and less strain values. Prototype of seed sowing machine was fabricated by using mild steel. Each subsection was fabricated separately and then assembled to create the final product. This approach ensures that the design can be replicated effectively in the future. During sowing the fabricated seed sowing machine controls seed rate, control the seed depth and proper utilization of seeds can be done with less wastage. The fabricated seed sowing machine perform the various simultaneous operations and hence saves labour requirement so as labour cost, labour time and also save lots of energy.

References

[1] Adisa A F, Braide F. G, “Design and Development of Template Row Planter”, Transnational Journal of Science and Technology, vol. 2, No.7, 2012. [2] Aditya Kawadaskar1, Dr. S. S. Chaudhari2, Aditya Kawadaskar, Review of methods of seed sowing and concept of multi-purpose seed sowing machine? by, IJPRET, 2013; Volume 1(8): 267-276, ISSN: 2319-507X. [3] Calvin Hung, Juan Nieto, Zachary Taylor, James Underwood and Salah Sukkarieh,“Orchard Fruit Segmentation using Multi-spectral Feature Learning”, IEE/RSJ International Conference on Intelligent Robot System Tokyo,Japan,3-7,November 2013. [4] D. Ramesh and H. P. Girishkumar, “Agriculture Seed Sowing Equipment: A Review”, International Journal of Science, Engineering and Technology Research, Volume 3, Issue 7, Pp-1987-1992, 2014. [5] Enhanced agriculture robotic system? by Mr.Sagar R. Chavan , Prof. Rahul D. Shelke, Prof. Shrinivas R. Zanwar, International journal of engineering sciences & research technology, ISSN: 2277-9655 Scientific Journal Impact Factor: 3.449 2015. [6] Kyada, A. R1*, Patel, D. B., Design and development of manually operated Seed planter machine? , 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014) December 12th–14th, 2014. [7] Laukik P. Raut, Smit B. Jaiswal and Nitin Y. Mohite, “Design, development, and fabrication of agricultural pesticides with weeder”, International Journal of Applied Research and Studies, Volume 2, Issue 11, Pp-18 .2013. [8] Mahesh R. Pundkar”:-“A seed sowing machine: A review” IJESS volume 3, Issue 3. ISSN: 2249-9482, International journal of engineering and social science. [9] Mahesh. R. Pundkar and A. K. Mahalle, “A Seed-Sowing Machine: A Review” International Journal of Engineering and Social Science, Volume3, Issue3, Pp-68-74 [10] P.P. Shelke:-“frontline demonstration on bullock-drawn planter enhances yield of soya bean crop.” International journal of farm science 1(2):123-128, 2011. [11] Pranil V. Sawalakhe, Amit Wandhare, Ashish Sontakke, Bhushan Patil, Rakesh Bawanwade and Saurabh Kurjekar, “Solar Powered Seed Sowing Machine”, Global Journal of Advanced Research, Vol-2, Issue-4, Pp-712717 . [12] PrasannaRaut, PradipShirwale, AbhijeetShitole “A Survey On Smart Famer Friendly Robot Using Zigbee”, International Journal of Emerging technology and Computer Science ,Volume: 01, Issue: 01, February 2016 [13] Rolando P, Automatic Seed Planter Punching Type”, “International Journal of Emerging Technology & Research Volume 1, Issue 3, (www.ijetr.org) ISSN (E): 2347-5900 ISSN (P): 2347- 6079. Mar-Apr, 2014. [14] Shivaraja kumar. a1, parames waramurthy, Design and development of wheel and pedal operated sprayer? by, Volume 2, Issue 6, June 2014. [15] Sridhar H .S “Development of Single Wheel Multi-Use Manually Operated Weed Remover”, International Journal of Modern Mahesh. R. Pundkar and A. K. Mahalle, “A Seed-Sowing Machine: A Review” International Journal of Engineering and Social Science, Volume3, Issue3, Pp-68-74 [16] Shrinivas R. Zanwar, R. D. Kokate, “Advanced Agriculture System”, International Journal of Robotics and Automation (IJRA), Vol. 1, No. 2, pp. 107~112 , June 2012. [17] Swetha S. and Shreeharsha G.H., “Solar Operated Automatic Seed Sowing Machine”, Cloud Publications International Journal of Advanced Agricultural Sciences and Technology 2015, Volume 4, Issue 1, pp. 67-71, Article ID Sci-223, 26 February 2015.

Copyright

Copyright © 2024 Dr. D. Sai Chaitanya Kishore, E. Vamsi, B. Manjunath, T.V Rohith, B. Sai Charan, B. Hareesh Kumar Reddy. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET60031

Publish Date : 2024-04-08

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online