Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Fabrication of Pyramid Solar Still for Desalinating Water

Authors: Mr. A. Venkata Dhanunjaya Reddy, G. Adil Basha, B. Krishna, J. Bhavana, K. Dada Peer, T. Divya Teja

DOI Link: https://doi.org/10.22214/ijraset.2024.60411

Certificate: View Certificate

Abstract

The purpose of this project is to design a water distillation system that can purify water from nearly any source, a system that is relatively cheap, portable, and depends only on renewable solar energy. The motivation for this project is the limited availability of clean water resources and the abundance of impure water available for potential conversion into potable water. In addition, there are many coastal locations where seawater is abundant but potable water is not available. Our project goal is to efficiently produce clean drinkable water from solar energy conversion. The use of solar thermal energy in seawater desalination applications has so far been restricted to small-scale systems in rural areas. The reason for this has mainly been explained by the relatively low productivity rate compared to the high capital cost. However, the coming shortage in fossil fuel supply and the growing need for fresh water in order to support increasing water and irrigation needs, have motivated further development of water desalination and purification by renewable energies Adequate quality and reliability of drinking water is vital for all inhabitants? applications. Rapid increase in the world population leads to an increase in the demand of pure water. Many purification methods are available nowadays to make potable water from different resources. Solar desalination is one of the purification methods for getting potable water from brackish or waste in remote areas where there is scarcity of water as well as electricity. In recent years, attention has been focused on development of various designs of solar still to increase the productivity of water and to overcome limitations of single basin single slope solar still. In the present work, an attempt is made to develop a solar distillation device that produces fresh water using direct solar energy.

Introduction

I. INTRODUCTION

Fresh water is the most essential of all natural resources. It is one of the fundamental elements for overall development of the human living such as domestic, industrial and agriculture purposes. The supply of freshwater is now less than the demand of the population. Although more than two-third of the earth’s surface is covered with water, there is still an arisen crisis of water scarcity. Decrease in Water Sustainability Index (WSI) from 1992 to 2020 is a reflection that World's water resources are rapidly depleting and have been managed unsustainably. These situations will affect the world water supply and definitely will cause water shortage in future. In Many countries of the world, women carry water from far places to fulfill the daily needs of the family. According to a UN survey, still two thirds of the people in the world are facing severe water problems. Global warming is also one of the causes for scarcity of water. Diminished flows in rivers and streams can increase concentration of harmful pollutants. Even though Water covers more than two-thirds of the earth?s surface, available freshwater resource is only 2.7% and in that also only 1% of water is accessible. In some countries, sufficient freshwater is not available. In some countries, abundant freshwater is available, but it is expensive to use. Freshwater can also be obtained from seawater by the desalination process. Groundwater is the most plentiful of all freshwater resources. As water percolates into the ground through layers of soil, clay, and rock, some of it adheres to the topmost layers to provide water to plants. But because of the continuous consumption, these resources are depleting. Though there are desalination plants available to convert saltwater into potable, it is very expensive

Mr.S.Shanmugan(1) tested A single slope single basin type solar still has been designed and fabricated. The system has been tested with dripping of saline water on cotton fin wick in the basin liner.

Experiments were conducted on clear sky days by Mr. Ahmed(2) during the month of July in the Kingdom of Bahrain. Preliminary tests were conducted to ensure that the stills and the systems were ready. The actual experiments were then performed for two consecutive days and the average values were taken for each set of data.

MR G. Muralidhar (4) tested The shape of the glass cover in a solar still can vary depending on the design and intended use of the system. Here are several common shapes used in solar stills Pyramid solar still is one in which top cover is in the shape of pyramid. There were mainly two shapes covers and basin available in pyramid solar still: triangular pyramid solar still and square pyramid solar still. The major advantages of pyramid solar still over conventional single slope are as follows:

In a conventional solar still, solar still must be located so that its inclined surface faces directly sun and also continuously to be moved as sun travel for gaining maximum solar radiation

Mr. A.Y. Hashim. (4) In this work, a plain basin Pyramid type solar still and Hemispherical solar still were designed, fabricated and experimentally tested during daytime for four days under outdoors of summer climatic conditions.

II. METHODOLOGY

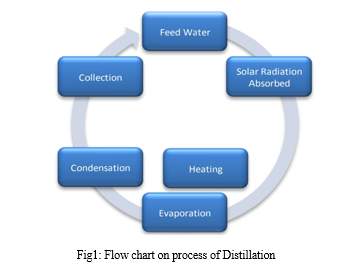

A. Process

Solar water distillers or solar stills are usually used in remote areas where there is limited access to freshwater. The basic principles of solar water distillation are simple, yet effective, as distillation replicates the way nature makes rain. A solar still works on two scientific principles: evaporation and condensation. The salts and minerals do not evaporate with the water. For example, table salt does not turn into vapour until it gets to a temperature over 1400ºC. However, it still does take a certain amount of energy for water to turn into water vapour. While a certain amount of energy is needed to raise the temperature of a kilogram of water from 0ºC to 100ºC, it takes five and one-half times that much to change it from water at 100ºC to water vapour at 100ºC. Practically all this energy, however, is given back when the water vapour condenses.

Looking ahead, the future of solar stills holds promise for further advancements and widespread adoption. As technology continues to evolve and economies of scale drive down costs, solar stills will become increasingly accessible to communities around the globe. Moreover, the integration of smart monitoring systems and remote sensing capabilities will enable real-time tracking of performance metrics and proactive maintenance, ensuring the long-term sustainability of solar still installations. By leveraging the power of innovation, collaboration, and community engagement, solar stills will continue to play a pivotal role in securing water resources for generations to come.

Solar stills stand as a beacon of hope in the relentless battle against water scarcity, particularly in regions afflicted by arid climates or limited access to potable water sources. Their ingenious design harnesses the abundant energy of the sun to transform brackish or contaminated water into a precious resource for hydration, sanitation, and agricultural purposes. At the heart of a solar still lies a simple yet effective process. the sun's rays penetrate a transparent cover, heating the water within and prompting it to evaporate. As vapor rises, it encounters the cooler surface of the cover, causing condensation and the formation of droplets that gradually trickle down into a collection basin. This cycle of evaporation and condensation effectively separates impurities from the water, leaving behind a purified and replenished supply.

B. Working

Solar desalination is the best alternative technology which is simple in operation and eco-friendly. In a solar desalination process, solar energy is utilized to separate salts from brackish water to get pure drinking water. The device, called solar still is used to execute the solar desalination process. The working principle of solar still is the same as that of raining. The basic structure of conventional solar still is shown in the above block diagram. Conventional solar still is one in which single basin filled with saline water, which is covered by single inclined glass cover. The universally acceptable materials for basin are copper, aluminum Sheet. The inner surface of basin is black painted to increase the absorption of solar radiation. The basin is insulated by wood, rom sides and bottom to reduce the heat transfer loss from basin to atmosphere. Top of basin is covered by highly transparent glass so that the maximum solar radiation reaches to the basin as well as generated water vapor cannot escape from the still.

Generally, the cover is inclined at an angle equals to local latitude so that maximum solar radiation can entered in device. The solar radiation penetrates through the cover and absorbed by basin, hence basin temperature increases. This heat conducted to saline water and only water gets evaporated. The water vapor flows up and come in contact with cover which is at lower temperature then the basin hence vapor gets condensed on inner surface of cover and this pure condensed water collected in distillation trough. The inlet port is provided to feed the make-up saline water in the basin and drainage port is provided at the bottom of basin to remove the salts remaining in basin. The thermal module inside the still will spend up the evaporation here. As 97.5% water available on the earth is unsuitable for direct human consumption as well as for other agricultural and industrial application due to its higher salinity and impurity level. The acceptance limit of water salinity for the human consumption is 550 ppm but underground water contains salinity in range of 2000–3500 ppm and sea water contain about 35,000 ppm. Solar desalination process removes all the impurities like salts and heavy metal and also destroys the microbiological organisms. The end result of solar still is water cleaner than the purest rainwater. This can also be revealed from the results of various experimental works on solar still.

III. PYRAMID SOLAR STILL COMPONENTS

- Still Basin

- Side Walls

- Top Cover

- Channel

- Wick Material and Fins

A. Still Basin

It is the part of the system in which the water to be distilled is kept. It is therefore essential that it must absorb solar energy. Hence it is necessary that the material have high absorption or very less reflectivity and very less transmittable. A basin still is a type of solar still that operates on the principle of evaporation and condensation to produce fresh water from saltwater or contaminated water sources. However, it's important to note that the term "pyramid solar still" is not a widely recognized or standard term in the field of solar stills or renewable energy. It's possible that you may be referring to a specific design or variation of a solar still that incorporates a pyramid shape, but without more context or information, it's challenging to provide a detailed explanation.

In general, solar stills are devices used to purify water by harnessing the heat from sunlight to evaporate water, leaving behind contaminants such as salts, minerals, and pollutants. The evaporated water then condenses on a surface (such as a tilted glass or plastic cover) and drips down into a collection basin as freshwater.

B. Side Walls

The side walls of a pyramid solar still play an important role in its design and functionality. Here's how they contribute to the operation of the still:

- Support and Structure: The side walls provide structural support for the pyramid solar still, helping to maintain its shape and stability. They ensure that the still maintains its pyramid shape, which is essential for optimizing sunlight exposure and maximizing the efficiency of the evaporation and condensation processes.

- Reflective Surface: In some designs, the side walls of the pyramid solar still may be coated with a reflective material or painted white to increase sunlight absorption and reflection. This helps to enhance the overall solar energy absorption within the still, which can promote faster evaporation of water from the basin.

It generally provides rigidness to the still. But technically it provides thermal resistance to the heat transfer that takes place from the system to the surrounding. So it must be made from the material that is having low value of thermal conductivity and should be rigid enough to sustain its own weight and the weight of the top cover Different kinds of materials that can be used are:

- Wood of ¾ inch is used.

- Insulation

- RPF (reinforced plastic).

C. Top Cover

In a pyramid solar still, the glass cover serves a similar purpose as in other solar still designs. It is positioned above the basin where the contaminated water is placed. The glass cover helps to create a greenhouse effect within the still, trapping heat from sunlight to increase the temperature of the water in the basin.

As with other solar still designs, the glass cover of a pyramid solar still allows sunlight to enter while minimizing heat loss and providing a barrier to prevent the escape of evaporated water. This setup facilitates the evaporation of water from the basin and subsequent condensation on the underside of the glass cover.

The top cover of a pyramid solar still plays a crucial role in its functionality, as it allows sunlight to enter the still while trapping heat inside, facilitating the evaporation and condensation processes. Here are some key aspects of the top cover:

Material

The top cover of a pyramid solar still is typically made of transparent materials that allow sunlight to pass through effectively. Common materials used for the cover include glass and various types of plastics, such as polycarbonate or acrylic.

- Polythene Glass

- Glass of 5mm thickness and angle of 51 degrees has been used to obtain pyramid shape

D. C- Channel

The C channel in a pyramid solar still typically refers to a collection channel or trough located along the base or the sides of the still. This channel is designed to collect the condensed water that forms on the underside of the glass cover. As sunlight heats the water in the basin of the pyramid solar still, it evaporates and rises. When the evaporated water comes into contact with the cooler surface of the glass cover, it condenses into droplets. These droplets then flow down the inclined surface of the glass cover and collect along the edges into the C channel. The purpose of the C channel is to efficiently gather the condensed water and direct it to a collection point, where it can be accessed for use as purified water. The channel prevents the water from scattering or being lost, ensuring that as much of the condensed water as possible is collected. .

Overall, the C channel is an important component of a pyramid solar still, facilitating the collection of purified water produced through the evaporation and condensation process.

The materials that can be used are:

- P.V.C of C channel is used.

- G.I.

E. Fins and Wick Material

Fins and wick materials can be incorporated into the design of a solar still to enhance its efficiency in water purification. Here's how they function:

- Fins: Fins are thin, extended surfaces typically made of metal or another thermally conductive material. They are placed inside the basin of the solar still and are used to increase the surface area available for water evaporation. By increasing the surface area, fins allow more water to be exposed to sunlight, thus promoting faster evaporation. This can lead to greater water production within the still. Fins also help to distribute heat more evenly across the water surface, improving overall efficiency.

Fins in pyramid solar stills are additional features that can enhance the efficiency of the water purification process. Here's how fins work and their role in pyramid solar stills:

a. Heat Transfer: Fins are thin, elongated structures typically made of metal or another thermally conductive material. When placed inside the pyramid solar still, these fins absorb solar radiation and help to distribute heat more evenly throughout the still.

b. Increased Surface Area: Fins increase the surface area available for heat absorption and transfer within the solar still. This allows for more efficient heating of the water, leading to increased evaporation rates.

2. Wick Material: Wick material is used to draw water from the basin to the condensation surface (such as a glass cover) where it can evaporate and subsequently condense. Wick material is typically made of a porous and absorbent material, such as cloth or felt. It is placed in contact with the water in the basin and extends up to the condensation surface. Through capillary action, the wick material absorbs water from the basin and transports it to the condensation surface, where it can evaporate and be collected as purified water. This mechanism ensures a continuous supply of water to the condensation surface, enhancing the efficiency of the still.

In a pyramid solar still, a wick material can be used to enhance the capillary action and facilitate the movement of water within the system. Here's how wick materials function and their role in a pyramid solar still:

a. Capillary Action: A wick material, typically made of porous fabric or rope, has the ability to draw water through capillary action. When one end of the wick is immersed in water, the water molecules are attracted to the small pores or gaps in the material, causing them to move upwards against gravity.

b. Water Distribution: By placing a wick material at the bottom of the collection basin or at the base of the pyramid solar still, water can be evenly distributed across the surface area. This ensures that the entire surface is moistened, promoting uniform evaporation and maximizing water vapor production.

IV. FABRICATION

Fabrication of Pyramid Solar Still As stated in our titular name, we have proposed a solar still distillation that comprises pyramidal still. A pyramid type solar still is designed and constructed for the purpose of experimental work. Figure -- shows the pyramidal solar still fabricated with plain basin of square aperture of 0.7m x 0.7m. It is fabricated from Aluminum sheet of 24 gauge. The basin surface is coated with black materials such as black silicone gel, black paint or black ink to absorb maximum solar radiation. The four sides of glass cover are of ordinary window glass of 5 mm thickness with a tilt angle of 51 degrees to the horizontal surface. The distillate water is collected by a PVC channel fixed on the one side at the top end of the glass cover and is taken out through pipe. The whole system is made vapor tight using silicone rubber as a sealant to prevent any vapor leakage. The experimental setup is suitably instrumented to measure the amount of distillate. The amount of distillate collected can be read in the distillate collecting slight canes which are graduated in ml.

The still is fabricated from aluminum sheet and normal window glass the basin and square aperture of stills base is made by means of welding the glasses are dimensional and cut for the required shape of triangular to get a pyramid shape of condensing surface, the four glasses are cut like the glasses are in same dimension and shape to produce the pyramid shape, then the four glasses are assembled together in pyramid shape using the adhesive materials. After assembling the glasses in pyramid shape, the distillate collecting channels are prepared to collect the distillate drawn from condensing surface, the collecting channels are made of plastic pipes, cut into C-section, which locate in bottom of pyramid shape glass assembly, the channels assembled in square shape by using silicon gel the collecting surface of still is mounted into the condensing surface by using the adhesive materials then the joining surface of the glasses and the collecting channels are made vapor tight by using the silicone gel as a sealant in the outer side of the collecting channels. The square aperture of the still is surrounded by the wood of thickness ¾ inch and the bottom of the still also surrounded by the wood, the woods which are surrounds the square aperture and bottom of still are joined by the adhesives. The square aperture of the still and the glass and collecting channel assembly are mounted together. The assembly is made vapor tight by using the silicone gel as sealant

A. Working Procedure

The working procedure of a pyramid solar still involves several key steps that harness solar energy to purify water. Here's a detailed explanation of how a pyramid solar still operates:

- Design and Setup

- A pyramid solar still is typically constructed with a base that holds the contaminated water to be purified. The base can be made of various materials such as plastic, metal, or concrete.

- The pyramid shape is formed using transparent material such as glass or plastic. This transparent cover allows sunlight to enter the still while trapping heat inside.

2. Water Pouring

- Contaminated water, such as saltwater or brackish water, is poured into the basin at the base of the pyramid. The water level in the basin should be sufficient to cover the bottom surface evenly.

3. Solar Energy Absorption

- Sunlight enters through the transparent cover of the pyramid. The transparent material allows short-wave solar radiation to pass through and heat the water in the basin.

As the water absorbs solar energy, it begins to evaporate. The heat causes the water molecules to break free from the liquid phase and turn into vapor.

4. Evaporation and Condensation

- The water vapor rises from the basin and comes into contact with the cooler surface of the sloped sides of the pyramid. This temperature difference causes the water vapor to condense back into liquid form.

- The condensed water droplets gather on the inner surface of the transparent cover and trickle down toward the lowest point of the pyramid due to gravity.

5. Contaminant Separation

- During the evaporation process, contaminants present in the water, such as salts, minerals, chemicals, and pollutants, are left behind in the basin. These contaminants do not evaporate and remain in the liquid phase.

6. Purified Water Collection

- The condensed and purified water droplets collect along the sloped surface of the pyramid and flow toward a collection point, such as a channel or groove designed to gather the purified water.

- A collection system, such as a pipe or spout, directs the purified water from the collection point to a storage container or distribution system for use.

7. Continuous Operation

- A pyramid solar still operates continuously during daylight hours as long as there is sufficient sunlight to generate heat for evaporation and condensation.

- The process of evaporation, condensation, and water collection continues cyclically, gradually producing more purified water over time.

8. Maintenance and Monitoring

- Regular maintenance, such as cleaning the transparent cover to remove dust or debris, and monitoring water levels and quality, helps ensure the efficient operation of the pyramid solar still.

- Adjustments to factors such as water input, solar exposure, and environmental conditions may be made to optimize the performance of the solar still.

Overall, the working procedure of a pyramid solar still relies on solar energy to evaporate and purify water, making it a sustainable and potentially valuable technology for producing clean drinking water in areas with limited access to freshwater resources.

- Solar still without Fins, Wick material and Black Coating: The solar still is fabricated as discussed above and then the still is placed where the sun’s radiation can reach into the still without any trouble. The still is filled with water to a depth of 5 cm, and allowed to get heated and evaporated. The still is filled with salty water and allowed to evaporate; the evaporated water gets condensed into water droplets and the condensed water droplets are drawn into the plastic distillate collecting channels. The collected distillate in the channels is flow into the holes provided in the collecting channels, and then the condensed water is collected in the slight canes which are graduated in ml.

- Solar still with Black paint to still Surface with fins and Wick Material: For water depth of 5 cm, In this setup the stills basin and the square aperture are coated with the black paint as absorbing material to improve the radiation absorption of the solar still. The still is filled with the watAer of depth 5 cm height, for this height of water the still occupies 8.5 liters of water. The 5 cm depth of water is allowed to get heated and evaporated, the readings observed variation of the distillate output.

B. Advantages

- Efficient use of space: The pyramid shape maximizes the surface area exposed to sunlight while minimizing the footprint, making it suitable for small or constrained areas.

- Enhanced sunlight capture: The sloped sides of the pyramid allow sunlight to be captured from multiple angles throughout the day, optimizing energy absorption.

- Improved condensation: The inclined surfaces facilitate the flow of condensed water towards the center, where it can be collected more effectively compared to flat designs.

- Stability and durability: The pyramid structure provides stability against wind and other environmental factors, ensuring the solar still remains intact and operational over time.

- Versatility: Pyramid solar stills can be constructed using locally available materials, making them adaptable to various geographic and socioeconomic contexts.

- Scalability: The design can be scaled up or down to meet different water needs, from individual households to larger community installations

- Minimal maintenance: Pyramid solar stills require minimal maintenance, with no moving parts or complex mechanisms, reducing the need for regular servicing or repairs.

- Environmentally friendly: Operating solely on solar energy, pyramid solar stills produce no emissions or waste, offering a sustainable and eco-friendly water purification solution.

C. Disadvantages

Dependency on sunlight: Pyramid solar stills rely solely on sunlight for operation, making them ineffective during periods of cloud cover or limited sunlight.

- Limited water production: The slow rate of evaporation and condensation in pyramid solar stills results in relatively low water production compared to other water purification methods.

- Vulnerability to environmental factors: Pyramid solar stills are susceptible to environmental factors such as wind, dust, and temperature fluctuations, which can affect their efficiency and performance.

- Initial setup and construction: While the design of pyramid solar stills is relatively simple, the initial setup and construction process may require skilled labor and resources.

- Maintenance requirements: Pyramid solar stills require regular maintenance to ensure optimal performance, including cleaning the transparent cover and inspecting for damage.

D. Applications

Pyramid solar stills are devices designed to distill water using solar energy. They are shaped like pyramids to maximize the collection of sunlight and can be used in various applications where access to clean water is limited. Here are some of the applications of pyramid solar stills:

- Water Purification in Remote Areas: Pyramid solar stills are often used in remote or arid regions where access to clean water is limited. They can be set up in locations with access to sunlight and can purify brackish or contaminated water, making it safe for drinking.

- Emergency and Disaster Relief: Pyramid solar stills are valuable in emergency and disaster relief situations where clean water sources may be compromised. They can be quickly deployed to provide safe drinking water to affected populations, reducing the risk of waterborne diseases.

- Military and Expeditionary Uses: Pyramid solar stills are compact and portable, making them suitable for military operations or expeditions in remote areas. Soldiers, campers, and explorers can use them to produce drinking water from various water sources they encounter.

- Agricultural and Livestock Watering: Pyramid solar stills can also be used for agricultural purposes, such as providing clean water for crops or livestock in areas with limited access to water infrastructure. This can help support farming activities in arid regions.

- Desalination: While pyramid solar stills are not typically used for large-scale desalination due to efficiency constraints, they can be used on a small scale to desalinate brackish water or seawater in coastal areas where freshwater is scarce.

- **Education and Research**: Pyramid solar stills are used in educational settings to demonstrate principles of solar energy utilization and water distillation. They are also used in research projects focused on improving solar distillation technologies.

- Off-Grid Water Solutions: Pyramid solar stills can provide off-grid water solutions for communities or households that are not connected to centralized water systems. They offer a sustainable and environmentally friendly way to obtain clean water using renewable energy.

- Humanitarian Aid: Organizations involved in humanitarian aid efforts often use pyramid solar stills to provide clean water to refugee camps, disaster-stricken areas, and communities facing water scarcity due to conflict or environmental challenges.

V. RESULTS

Amount of total solar radiation incident on the still surface depends on the time of the day. The solar radiation varies along the hours after sunrise till a maximum value at mid- day then decreases.

Table 1: Test results of water sample of still with wick material and fins

|

S. No

|

Test Parameter |

Acceptable limits |

Test Results of Raw Sample Water |

Test results of Purified water |

|

1 |

Appearance |

- |

clear |

clear |

|

2 |

Odour |

Unobjectionable |

Unobjectionable |

Unobjectionable |

|

4 |

pH Value |

6.5-8.5 |

7.6 |

7.1 |

A. pH

- Rinse test tube and cap twice with water to be tested.

- Fill a test tube to the 5.0 mL line with sample water.

- While holding dropper bottle or pipet vertically, add 10 drops of indicator solution.

- Cap and mix

- Insert test tube into Octet comparator. Match sample color to a color standard. Record as ph.

- Dispose of waste in proper waste container.

- Rinse test tube and cap with distilled water.

Conclusion

In this work, a plain basin Pyramid type solar still is fabricated and experimentally tested during daytime for four days under outdoors of summer climatic conditions. It was found that, the daily distillate water produced from the normal still ranged from approximately 400ml to 420ml for seven hours per day in pyramid. The efficiency of solar still without black absorber, Wick material, fins, cooling over the glass for water depth about 5 cm is less when compared to still with black cotton wick material, fins and cooling over glass cover for water depth about 5 cm is 750 to 800ml. The experimental results indicated that the still with black paint as absorbing material, fins, wick material has the highest efficiency of 47% than the other absorbing materials for the water depth of 5 cm. The effect of saline water depth on the still efficiency was also studied. It was found that the efficiency of the still decreases as the water depth increases in pyramid and finding the right focal distance increases the efficiency in hemispherical still.

References

[1] Husham M. Ahmed ,“The Effects of Various Types and Layouts of Wick Materials on the Thermal Performance of Conventional Solar Stills”, 2016 the 4th IEEE International Conference on Smart Energy Grid Engineering. [2] S. Shanmugan, “Thermal analysis of single slope single basin solar still with fin wick material in the basin”, Research Center of Physics, Dhanalakshmi College of Engineering, Manimangalam, Tambaram, Chennai - 601 301, Tamilnadu, India. [3] M. Rajyalakshmi, K. I. V. Vandana, M. Venkata Madhuvani, P. Madan Mohan, S. Trinad Raje, Sk. Tabassum Farhana, “Design and Fabrication of Pyramidal-Hemispherical Solar Still”, Dept. of Mechanical Engineering, PVP Siddhartha Institute of Technology, Vijayawada, Andhra Pradesh. [4] A.Y. Hashim, J. M. Al-Asadi, W.A. Taha Alramdhan, “An attempt to solar still productivity optimization; solar still shape, glass cover inclination and inner surface area of a single basin solar still, optimization” , Technical Institute of Basrah, Physics Department College of Education-Basrah University. [5] G. Muralidhar, G. Chinna guravaiah, U. Ravi, B. Ramakrishna, T. Sivashankar, V. Suil kumar, “Solar Still (Pyramid Type)”, Department of Mechanical Engineering, Narayana Engineering College, Gudur, Andhra Pradesh – India. [6] Suha A. Mohammed, Ali Basem, Zakaria M. Omara, Wissam H. Alawee, Hayder A. Dhahad, Fadl A. Essa, Abdekader S. Abdullah, Hasan Sh. Majdi, Iqbal Alshalal, Wan Nor Roslam Wan Isahak and Ahmed A. Al-Amiery, “Pyramidal Solar Stills via Hollow Cylindrical Perforated Fins, Inclined Rectangular Perforated Fins, and Nanocomposites: An Experimental Investigation”, Mechanical Engineering Department, University of Technology, Baghdad 10066, Iraq. [7] A.I. Bakry, Y.A.F. El-Samadony, H.M. El-Gohari and M. Ismail, “Performance of a pyramid solar still with stepped trays: Experimental approach”, Faculty of Engineering, Tanta University, Egypt.

Copyright

Copyright © 2024 Mr. A. Venkata Dhanunjaya Reddy, G. Adil Basha, B. Krishna, J. Bhavana, K. Dada Peer, T. Divya Teja . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET60411

Publish Date : 2024-04-16

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online