Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Fabrication of Waste Food Shredder Compost Maker Machine

Authors: Mr. A. Harish, M. Chandu Kumar, A. Shiva Kumar, K. Akshay, A. Omkar

DOI Link: https://doi.org/10.22214/ijraset.2025.66852

Certificate: View Certificate

Abstract

The Waste Food Shredder Compost Maker Machine represents a breakthrough in addressing the pressing global challenge of food waste management. Integrating shredding and composting functionalities, this innovative technology efficiently processes organic waste materials. By reducing food waste into smaller, manageable pieces through its shredding mechanism, the machine streamlines the composting process. Advanced technology ensures optimal shredding efficiency while minimizing energy consumption, making it a sustainable solution. Moreover, the compost maker aspect transforms shredded food waste into nutrient- rich compost suitable for soil enrichment. Equipped with sensors and controls, the machine maintains optimal composting conditions, including temperature, moisture, and aeration, ensuring high-quality compost output. Its compact design makes it adaptable to various settings, from households to industrial facilities. By diverting food waste from landfills and promoting circular economy principles, the shredder compost maker machine contributes to environmental sustainability while offering a practical waste management solution.

Introduction

I. INTRODUCTION

Waste food shredder machine is using for domestical waste, vegetable waste are are cut in shredder machine of using a man effort by using bicycle pedal man power using working a shredder machine small amount cut the food material in the shradder machine. the main purpose of shreder machine making a better quality of fertilizer using a farmer without any electrical bill its consist of many types of material cutting in the shreeder machine such as green vegetable. And also new idea using shredder machine such as the solar system added in the project to operate the solar system when the man was tired feel then using solar system in shedder machine. Agriculture essential for farmer to making such as vegetable , fruit , soyabean etc number of making product . the farmer working continuously in the agriculture field and lot of hard working and many types of disease in the plant and demotivate the farmer and its physically and mentally not very well and lot of billing using the agriculture such as water bill, pump and many types of equipment work on electricity.

II. LITERATURE REVIEW

1) Mr. Omkumar C S and Mr. Muthukumar K [1]

Investigated the mechanical systemsemployed in non-biological waste treatment processes. Specifically, they focus on using heat to eliminate water from waste food, reducing its volume and weight. This is achieved by grinding the food waste through shredders, resulting in a semi-solid product that includes coffee grounds. This product can be further processed or utilized as feedstock. To transform food waste into small particles suitable for biomass production, the researchers employ dehydrators. Their experiments confirm that the processed waste can be directly used to enhance soil fertility and serve as a compost feedstock, making it a valuable approach for waste management and resource utilization.

2) Ajinkya S. Hande and A. A. Deshpande [2]

Outlines the methodology for designing and fabricating a portable organic waste chopping machine with the aim of obtaining compost.

The study delves into various aspects related to the organic waste chopping process, identifying key factors that influence it. Additionally, the paper explores different design options for the chopping machine, drawing from a systematic analysis of the organic waste chopping process and the testing of a portable chopping machine model.

3) P.B. Khope and J.P. Modak's [3]

outlines the design of an experimental set-up for establishing an empirical relationship concerning a chaff cutter energized by a human-powered flywheel motor. The research was conducted at the Department of Mechanical Engineering, Priyadarshini College of Engineering in Nagpur, Maharashtra, India. The study addresses the development of a human powered chaff cutter, highlighting the lack of available data in this domain. The literature survey reveals the feasibility of creating a system that utilizes muscular energy to operate a flywheel, which stores energy for various applications. In line with this concept, the researchers decided to focus on a chaff cutter powered by human effort and aimed to establish an empirical relationship for the chaff cutting process. Given the nature of this man-machine system, the authors opted for an experimental approach, as a purely theoretical approach would be challenging and unreliable.

III. OBJECTIVE

The specific objective of this project was

- To detail the design and construction of the waste food shredder machine, including the components, mechanisms, and safety features involved in its fabrication.

- To demonstrate the machine's functionality and effectiveness in cutting various types of waste food materials, such as waste vegetables, fruits, and grass, into small, manageable pieces.

- To assess the environmental and sustainability benefits of the shredder machine, particularly in terms of reducing the environmental footprint by eliminating the need for electrical power and promoting pollution-free operations.

- To evaluate the machine's potential applications, both domestically and in agricultural settings, for converting waste food materials into high-quality organic fertilizers.

- To highlight the advantages of human-powered machinery in engaging farmers and promoting sustainable practices while reducing the reliance on conventional energy sources.

IV. COMPONENTS DESCRIPTION

A. Shredder Blades

Shredder blades are crucial components in shredding machines used for reducing materials into smaller pieces. Typically made from high-strength steel, these blades are designed to withstand the rigors of shredding various materials like plastic, wood, metal, and paper. They come in different shapes and configurations depending on the specific shredding requirements, such as single-shaft, double-shaft, or quad-shaft designs. The efficiency and durability of shredder blades play a significant role in the overall performance and longevity of shredding machines. Regular maintenance and proper sharpening are essential to ensure optimal shredding efficiency and prevent premature wear.

Fig:4.1 Shredder blades

B. Pedals

Cycle pedals are an essential component of bicycles, providing the connection between the rider's feet and the bike's drivetrain. They come in various designs, including platform pedals, clipless pedals, and toe clip pedals, each offering different advantages in terms of efficiency, comfort, and control. Materials range from basic plastic to lightweight aluminum and high-performance carbon fiber. Advances in pedal technology often focus on reducing weight, improving grip, and increasing power transfer efficiency for cyclists.

Fig: 4.2 Pedals

C. Crank Arm

Crank arms are the parts of a bicycle's drivetrain that connect the pedals to the chainrings, converting the rider's pedaling motion into forward movement. They are typically made of aluminum alloy or carbon fiber to balance strength, stiffness, and weight. Crank arms vary in length to accommodate different riding styles and preferences, with common lengths ranging from 165mm to 180mm. Longer crank arms can provide more leverage but may also increase the risk of pedal strikes, especially on off-road terrain. Advanced designs may feature hollow construction for weight reduction or aerodynamic shaping to minimize air resistance.

Fig: 4.3 Crank arm

D. Bracket

The bracket, also known as the bottom bracket, is a crucial component of a bicycle's drivetrain system, providing support for the crankset and allowing it to rotate smoothly. It consists of bearings housed within a shell that is attached to the bicycle frame. There are several types of bottom brackets, including threaded, press-fit, and eccentric designs, each with its own installation method and compatibility considerations. Materials commonly used for bottom bracket shells include aluminum alloy and carbon fiber. The choice of bottom bracket can impact the overall performance, durability, and maintenance requirements of the bicycle. Advances in bracket design often focus on reducing weight, improving stiffness, and minimizing friction for a more efficient pedaling experience.

Fig: 4.4 Bracket

E. Chain

The bicycle chain is a critical component of the drivetrain, transferring power from the rider's pedaling motion to the rear wheel, propelling the bike forward. Modern bicycle chains are typically made of steel and consist of a series of interconnected links. These links include inner plates, outer plates, pins, and rollers, each playing a specific role in the chain's function.

Chain designs vary based on the number of speeds the drivetrain supports, with narrower chains used for higher-speed systems to accommodate the closer spacing between sprockets. Chains are also designed to be compatible with specific drivetrain brands and models, ensuring smooth shifting and optimal.

Fig 4.5 Chain

F. Sprocket

Sprockets are toothed wheels that are part of a bicycle's drivetrain, working in conjunction with the chain to transfer power from the pedals to the rear wheel. They are typically found at the crankset (front sprockets) and the rear wheel hub (rear sprockets or cassette). Sprockets come in various sizes and configurations, with the number of teeth affecting the gear ratio and thus the mechanical advantage provided to the rider.

The size and arrangement of sprockets determine the range of gears available on a bicycle, influencing factors such as speed, cadence, and climbing ability. Sprockets are often made of durable materials like steel or aluminum alloy to withstand the forces exerted during pedaling and shifting. Advanced sprocket designs may feature specialized tooth profiles or materials to enhance shifting performance and durability.

Fig 4.6 Sprocket

G. Bearings

Bearings are crucial components in bicycles, providing smooth movement and reducing friction in various parts of the bike. They consist of rolling elements (such as balls or rollers), encased within an inner and outer race, and often held in place by a bearing cage. Bearings can be found in several key areas of a bicycle, including wheel hubs, bottom brackets, headset assemblies, and pedals.

The type of bearing used in a bicycle can vary depending on the application and desired performance characteristics. Common types include ball bearings, roller bearings, and needle bearings, each offering different load capacities, friction levels, and durability.

Maintenance of bearings is essential to ensure optimal performance and longevity of bike components. This typically involves periodic cleaning, inspection for wear or damage, and re-greasing or replacement as needed.

Fig 4.7 Bearings

H. Gears

Gears are mechanical devices with teeth that mesh with each other to transmit power and motion. They're commonly used in machinery to change the speed, torque, or direction of rotation. In a broader sense, "gears" can also refer to the components or mechanisms that drive systems or processes forward.

Fig 4.8 Gears

I. M S Shaft

"MS shaft," it likely means a shaft made of mild steel (MS). MS shafts are commonly used in engineering and construction for transmitting power or motion between mechanical components. They're known for their strength, durability, and affordability, making them suitable for various applications such as in machinery, vehicles, and structures.

Fig 4.9 MS Shaft

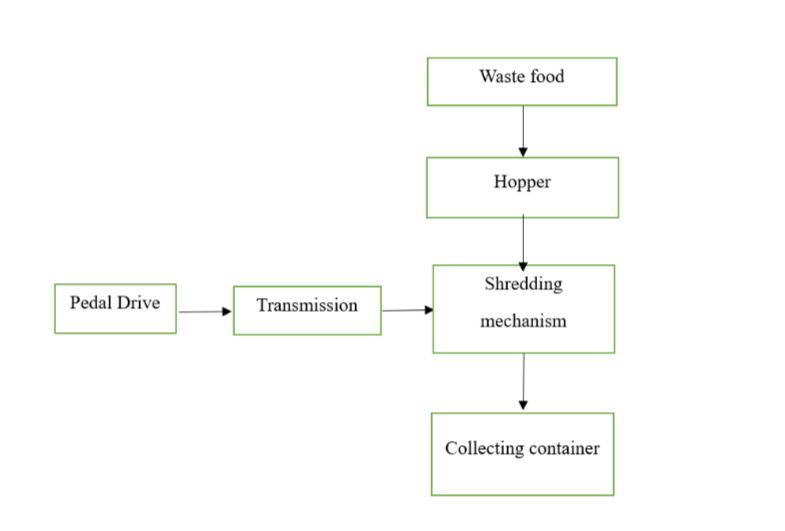

V. BLOCK DIAGRAM

VI. WORKING

The fabrication process of a waste food shredder compost maker machine involves several steps. Firstly, the design and specifications of the machine are outlined based on the intended capacity and functionality. Then, the necessary materials, including metal components, blades, motors, and electronic controls, are gathered.

Next, the metal fabrication work begins, where the frame and housing of the machine are constructed using welding or machining techniques. The blades are then fabricated and sharpened to ensure efficient shredding of waste food materials. After the mechanical components are assembled, the electronic controls and motors are integrated into the machine. This includes wiring and programming to ensure proper operation and safety features.

Once the machine is fully assembled, it undergoes rigorous testing to ensure all components are functioning correctly and safely. Any necessary adjustments are made, and the machine is then ready for use in shredding waste food materials and producing compost.

VII. FUTURE SCOPE

The future scope of pedal waste food shredder compost maker machines holds significant promise in addressing the growing challenges of food waste management and environmental sustainability. As society continues to prioritize eco-friendly solutions and waste reduction initiatives, pedal-operated compost maker machines offer a sustainable and accessible approach to processing organic waste at the grassroots level. These machines can empowerindividuals and communities to actively participate in the composting process, turning food waste into valuable compost for gardening, agriculture, and soil enrichment. With advancements in design, technology, and materials, future pedal waste food shredder compost maker machines may become more efficient, user-friendly, and versatile.

VIII. ADAVANTAGES

- Efficient shredding of organic waste

- No food waste on streets or environment

- No Power needed, Bicycle powered

- Portable System to be used anywhere

- Easy to use

Conclusion

In the endeavor to fabricate a Waste Food Shredder Machine, our project has successfully realized its objectives with promising outcomes. The machine, designed and constructed with care and precision, presents a practical solution for managing waste food materials efficiently and sustainably. The waste food shredder machine demonstrated its ability to convert various waste food items, including vegetables, fruits, and grass, into small, manageable pieces, thus laying the foundation for the production of high-quality organic fertilizers. This outcome not only reduces waste disposal costs but also addresses environmental concerns by eliminating the need for electrical power and promoting pollution-free operations. The incorporation of safety features and the provision of operator training ensure safe and responsible machine operation. The project\'s focus on user feedback and recommendations allows for continuous improvement and adaptability to specific needs and contexts. In conclusion, the Waste Food Shredder Machine project represents an innovative and eco friendly approach to waste management and organic fertilizer production.

References

[1] W Omkumar CSetal, (2010) Experimental Study on Waste Shredder, MAT Journals ,volume 2, Issue 3. [2] Ajinkya S.Hande et al. (December 2010), “Methodology For Design & Fabrication of Portable Organic Waste Chopping Machine To Obtain Compost -A Review”, IJIRST –International Journal for Innovative Research in Science & Technology Volume 1, Issue 7, ISSN (online):2349-6010. [3] P.B.Khope and J.P.Modak,(2011), “Design of experimental set-up for establishing empirical relationship for chaff cutter energized by human powered flywheel motor” , Journal of Agricultural Technology 2013 Vol. 9. [4] Prof. S.A. Bobde , Prof. S.R. Bobde, Prof. D.N. Dubey (2011) “Design And Development Of Waste Leaf Collector And Shredder Machine Using Solar Power” EPRA International Journal of Agriculture and Rural Economic Research, Vol 9, Issue 6. [5] Abhishek K N et al(2012), Fabrication of Agricultural Waste Shredder Machine, IJSER, vol.9 (2018), ISSN 2229-5518, page 112-116,volume -1,Issue – 4.

Copyright

Copyright © 2025 Mr. A. Harish, M. Chandu Kumar, A. Shiva Kumar, K. Akshay, A. Omkar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET66852

Publish Date : 2025-02-06

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online