Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experimental Study on Fiber Reinforced Concrete by Using Carbon Fiber in Different Aspect Ratios

Authors: Dr. K. Baskar, M. Ramya, P. Saiteja, B. Srikanth

DOI Link: https://doi.org/10.22214/ijraset.2024.60440

Certificate: View Certificate

Abstract

This experimental study investigates the effects of varying aspect ratios of carbon fiber on the performance of fiber reinforced concrete. The research aims to determine how different aspect ratios influence the mechanical properties, such as compressive strength, splitting tensile strength, and flexural strength of the composite material. The study involves preparing concrete specimens with varying proportions of carbon fibers, ranging from short to long aspect ratios and deals with experimental investigations carried out on M20 grade of concrete reinforced with carbon fiber dosages of 5 cm in length & 1 cm in width, 2.5 cm in length & 0.5 cm in width by volume of concrete. Due to its improved mechanical characteristics and increased durability, fiber reinforced concrete (FRC) has attracted a lot of attention in the building industry. Carbon fiber stands out among the numerous kinds of reinforcing fibers for its remarkable strength-to-weight ratio and resistance to corrosion. This experiment looks at how adding carbon fibers to concrete at different ratios affects the strength and durability of the structure. Fibers are used to improve the properties of concrete. The fibers were added at the volumes. Adding carbon fiber to the concrete changes in the mechanical properties of concrete. Hence, we expect the Compressive strength of CFRC increases with increasing fiber content up to a certain percentage, after which increasing fiber content becomes unbeneficial.

Introduction

I. INTRODUCTION

Fiber-reinforced concrete (FRC) has gained significant attention in recent years due to its potential to enhance the mechanical properties and durability of conventional concrete. Carbon fibers, known for their high strength-to-weight ratio and excellent mechanical properties, have emerged as a promising reinforcement material for concrete structures. In this experimental study, the focus is on investigating the effect of different aspect ratios of carbon fibers on the performance of M20 grade concrete. By varying the aspect ratios of the carbon fibers, ranging from short to long lengths, the study aims to analyze their influence on the key properties of fiber-reinforced concrete, such as compressive strength, flexural strength, and durability. The experimental investigation involves casing and testing of concrete specimens containing varying proportions of carbon fibers, followed by comprehensive analysis and comparison of results. The findings of this study are expected to contribute valuable insights into the effectiveness of carbon fiber reinforcement in enhancing the performance of M20 grade concrete. By elucidating the role of carbon fibers in FRC and their impact on M20 concrete properties, this study aims to advance the knowledge base in structural engineering and facilitate the adoption of innovative materials and techniques for sustainable and resilient infrastructure development.

II. LITERATURE REVIEWS

A. S. Muthukumaran.et,al (2017)

The Carbon fiber is composed mostly of carbon atoms a widely solution for repairing and strengthening in the field of innovative construction world. They are thin, strong and flexible. It has high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance and low thermal expansion and Possessing strength up to five times that of steel and being one-third its weight. In this project the carbon fiber is used to strengthen the concrete. The mix design was done for M25 grade concrete. The strengthening of the concrete using CF in the strengthening system provides an economical and versatile solution for extending the service life of concrete structures.

B. Koothan Baskar, et.al (2018)

The performance of conventional concrete is enhanced by the addition of fibers in concrete. Consequently the brittleness in concrete is reduced, and its acceptable ductility is also ensured by this addition. In this paper the strength of concrete cubes, cylinders and beams cast using M25 grade concrete and reinforced with steel and polypropylene fibers is presented. Also hybrid fibers with crimped steel and polypropylene were used in a concrete matrix to study improvements in the strength properties of steel, polypropylene and hybrid polypropylene as well as steel (crimped) fibers of various proportion ie, 0.25%, 0.5%, 0.75%, 1% and 0.5%(0.25% of steel and 0.25% of polypropylene), 0.75%(0.5% of steel and 0.25% of polypropylene, 0.25% of steel and 0.5% of polypropylene) and 1% of various combinations of hybrid fibers for 7, 14 and 28 days. The main reason for synthetic fibers in the concrete matrix is to improve the post cracking response of the concrete to improve the energy absorption capacity and ductility as well as to provide crack resistance and control. The introduction of this type of concrete was brought in as a solution to develop concrete with enhanced flexural and tensile strength. In this paper we analysed and present a comparison between conventional concrete and fibre reinforced concrete, leading to a crack free structure.

C. Navya H A,et,al (2018)

This paper deals with experimental investigations carried out on M25 grade of concrete reinforced with carbon fiber dosages of 0%, 0.75%, 1.00% and 1.25% by weight of concrete. The strength and durability characteristics are studied. The mechanical properties studied are compressive, split tensile and flexural strengths. The test specimens were also subjected to acid and sulphate attacks and tested for their durability. The results show that there is an increase in compressive, split tensile and flexural strengths of carbon fiber reinforced concrete. Inclusion of 1% carbon fibers showed the maximum enhancement in strength and it can be considered as optimum dosage. When compared to conventional concrete, the crack width also reduced in carbon fiber reinforced concrete.

III. MATERIALS AND ITS PROPERTIES

A. Materials Used

- Cement ( As per IS: 8812 – 1989)

- Course aggregate (As per IS: 383 – 1970)

- Fine aggregate (As per IS: 383 – 2016)

- Water

- Conplast WL Xtra

- Carbon fiber

B. Properties

- Carbon Fiber

Carbon fibers are relatively lightweight, and their incorporation in concrete does not significantly increase the overall weight of structures. This is beneficial for applications where weight constraints are a concern, such as in the construction of lightweight bridge decks. Carbon fibers provide tensile strength to concrete, significantly increasing its ability to withstand tensile and flexural loads. This is especially valuable in structures where cracking and flexural strength are critical, such as bridge decks and pavements. The use of carbon fibers helps control and limit the development of cracks in concrete. By bridging micro cracks that may form in the material, carbon fibers prevent them from becoming larger and compromising the integrity of the structure. Carbon fibers enhance the durability of concrete by improving its resistance to various forms of deterioration, including freeze-thaw cycles, chemical attack, and corrosion. This is particularly important for structures exposed to harsh environmental conditions. Carbon fiber-reinforced concrete can exhibit increased ductility, which means it can deform and absorb energy before failure. This property is essential in earthquake- prone areas, as it helps structures withstand seismic forces. Carbon fibers enhance the toughness of concrete, making it more resistant to impact and sudden loading, which is important for structures that may experience dynamic forces.

2. Mix Design

According to the code book IS 12062:2019 mix proportions for M20 grade and the quantities for 1m3 of concrete as follows:

Table 1: Mix design

|

Grade |

Cement |

F.A |

C.A |

Water |

|

Mix M20 |

403.2 |

705.6 |

1281 |

240 |

|

1.0 |

1.5 |

3.0 |

0.48 |

Initially, the carbon fiber were to be added to concrete. Subsequently, normal concrete was used for concrete mix. For this project, 3 mixes were done which consist of 1 control mix without carbon fibers and the remaining are concrete mixes that contain different aspect ratios 1 is of 5cm in length and 1cm in width, and the other one is of 2.5cm in length and 0.5cm in width. For each mix, 3 cubes, 3 beams, 3 concrete cylinders were produced as samples for testing.

IV. METHODOLOGY

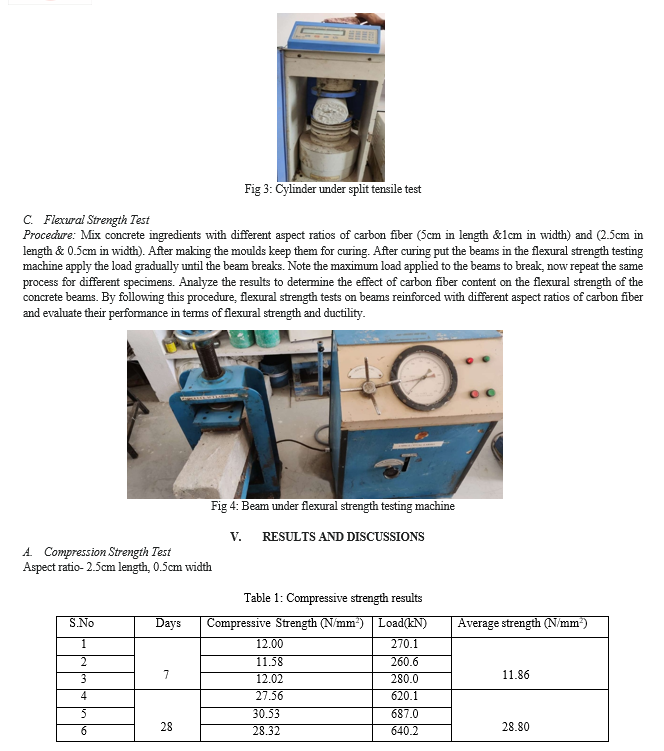

A. Compression Strength Test

Procedure: Mix concrete ingredients with different aspect ratios of carbon fiber (5cm in length &1cm in width) and (2.5cm in length & 0.5cm in width). Pour the mixture into cube moulds and let them set. Keep the cubes in a moist environment for at least 7 days after curing, test the cubes in a digital compression machine, applying force until a crack appears. Repeat the process for other specimens. Note the maximum force applied to each cube and analyze the compressive strength results obtained for each percentage of carbon fiber reinforcement. Compare the strengths of the different mixes to evaluate the effect of carbon fibers on the compressive strength of concrete. By following this experimental procedure, the compressive strength of concrete cubes reinforced with varying aspect ratios of carbon fibers and assess the impact of Fiber reinforcement on the mechanical properties of the concrete.

Conclusion

The experimental study on fiber-reinforced concrete (FRC) by utilizing carbon fiber in various aspect ratios has yielded valuable insights into enhancing the mechanical properties and performance of concrete structures. Carbon fiber reinforced concrete having aspect ratio of 5cm length, 1cm width has a maximum strength when compared to 2.5cm length, 0.5 width. According to our project, if the aspect ratio of carbon fiber increases then the compressive strength, split tensile strength, and flexural strength increases.

References

[1] S.MUTHUKUMARAN, N.MURALI MOHAN and P.SUDHA “EXPERIMENTAL INVESTIGATION ON PROPERTIES OF CONCRETE BY THE ADDITION OF CARBON FIBER” Indian J.sci.Res.17 (1): 100-106, 2017 [2] Koothan Baskar, G Elangovan, K Mohan Das“Flexural behaviour of fiber reinforced concrete beams with different aspect ratios” Fibers & Textiles in Eastern Europe, 2018 [3] Navya H A, Dr. Nayana N Patil “EXPERIMENTAL STUDIES ON BEHAVIOUR OF CARBON FIBER REINFORCED CONCRETE” International Journal of Civil Engineering and Technology (IJCIET) Volume 9, Issue 7, July 2018 [4] Baskar K, Arul Raj C“Experimental Investigation on Flexural behavoir of steel fiber and nylon fiber reinforced concrete beam” SSRG International Journal of Civil Engineering, April 2017 [5] Nada Mahdi Fawzi Aljalawi1, Haider M.K. Al-Jelawy “Possibility of Using Concrete Reinforced by Carbon Fiber in Construction” International Journal of Engineering & Technology, 7 (4.20) (2018) 449-452 [6] Guruswamy. J, Ashwini Joish, Dr. Sadath Ali Khan Zai, Dr. Shashishankar. A “Experimental Studies on Compression and Flexure Test on Nano based Carbon Fiber with Reinforced Concrete” International Journal of Engineering Research & Technology, Vol. 8 Issue 02, February-2019 [7] Arne Spelter, Sarah Bergmann , Jan Bielak and Josef Hegger “Long-Term Durability of Carbon-Reinforced Concrete: An Overview and Experimental Investigations” MDPI Journal Applied Sciences, 2019 [8] Vinoth and K Baskar, “Experimental Investigation on concrete with AGRO waste as a partial replacement of cement using recycled coarse aggregate” The International Journal of Analytical and Experimental Modal Analysis, Volume: 12 Issue: 11 | November 2020 [9] S M Subash A Hemalatha, K Baskar, K Mohan Das, C Selvin Ravikumar, D Kanagaraju Yadav, “Effects of Geogrid reinforcement on the static liquefaction behavior of granular fill by Triaxial test method” Apr 2021 [10] Ms. K. Nanchari, Mohammed Akram Khan, Mohammed Raziuddin, Mohammed Sohail Farhan “An Experimental Study on Mechanical Properties of Carbon Fiber Reinforced Concrete” International Research Journal of Engineering and Technology (IRJET), Volume: 08 Issue: 04 | Apr 2021 [11] K Baskar, K.Mohan das, C.Selin Ravikumar, “Comparative Study between Analytical and Theo-retical Retrofitting of RC Beam with Different Resins Bonded CFRP Laminates” International Journal of Recent Technology and Engineering (IJRTE), Volume: 10 Issue: 01 | May 2021 [12] Mr.A.Manoj Kumar Dr.K.Baskar, Mrs.T.Rohini Reddy, “An Experiment on Flexural Strength of Reinforced Concrete Beam with Steel Fibers” Turkish Online Journal of Qualitative Inquiry (TOJQI), Volume: 12 Issue: 08 | July 2021 [13] George Soupionis and Loukas Zoumpoulakis “Reinforced Concrete Structures Containing Chopped Carbon Fibers with Polymer Composite Materials” MDPI Journal Polymers, 2021 [14] Vikas Suresh Jagtap Dr.K.Vibhav, Dr.K.Ramadevi, A.Gandhimathi, Dr.Ravindra D Nalawade, Dr.Adiyya NitinBhai, M.Uma Chakaravarthy, Dr.G.Prabakaran, Dr.K.Baskar, K.Amutha, Dr.K.SunilKumar, Dr.S.Deepak, “Smart Devices Automatically detect the Strength of Buildings and land during the construction of Multistorey buildings” Apr 2022 [15] P.Manikandan Dr.K.Baskar, Dr.G.Vani, Ms.Ganagam Saileela, Mr.Prasoon PP, “Development of Process for creation of Low-Cost Artificial Sand from Fly Ash” Dogo Rangsang Research Journal, Volume: 12 Issue: 08 | August 2022 [16] Ms.Ganagam Saileela Dr.M.S.V.K.V.Prasad, Dr.K.Baskar, Mr.Nelakuri Manoj Kumar, B.Sharath Chandra, “Experimental Investigation and Strength Aspects of Self Compacting Concrete”, Dogo Rangsang Research Journal, Volume: 12 Issue: 09 | September 2022 [17] M. Vadivel Dr.K. Baskar , Sonal Banchhor , Dr. Hemadri Prasad Raju , Yukti Sharma , Ravi Goutam, “Performance of Fiber Reinforced Polymers in Concrete for Sustainable Construction Industry”, Volume: 12 Issue: 8 | May 2023 [18] Dr.K.Baskar , Pradeep Kumar Ram, “EXPERIMENTAL INVESTIGATIONS ON FIBER REINFORCED CONCRETE WITH COCONUT FIBERS”, European Chemical Bulletin, Volume: 12 Issue: 10 | July 2023 [19] Andrew Patchen, Stephen Young and Dayakar Penumadu “An Investigation of Mechanical Properties of Recycled Carbon Fiber Reinforced Ultra-High-Performance Concrete” MDPI Journals Materials, 2023

Copyright

Copyright © 2024 Dr. K. Baskar, M. Ramya, P. Saiteja, B. Srikanth. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET60440

Publish Date : 2024-04-16

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online