Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Food Quality Control & Assurance Using Artificial Intelligence: A Review Paper

Authors: Shobha Bhatt

DOI Link: https://doi.org/10.22214/ijraset.2023.55898

Certificate: View Certificate

Abstract

This review article explores the role of artificial intelligence (AI) in the food industry and its impact on food safety. It explores several AI technologies that have been used to deliver quality products to customers. As people have gained knowledge over the years, their demands have grown, and this article clearly shows who AI brings into the picture. AI is more efficient than humans in terms of specification, classification and uniformity and has helped improve efficiency and reduce food costs. For example, ML (Machine Learning) and DL (Deep Learning) have been used to make various products such as fruit-based pastries, ketchup, juices etc. Food Associates now closely monitors every aspect of daily operations, from the formation of microorganisms and bacteria to the quality and size of the cookies. In this way, other sectors can also adopt and utilize the benefits of artificial intelligence in their production activities. Artificial intelligence helps gather graphical representation of data for better data optimization, which helps in forecasting growth, quality control and assurance. Further studies have shown a strong positive relationship between the independent variables Machine Learning (ML), Deep Learning (DL), NLP improvement in SQ. Secondary journals have supported these findings, and AI technologies have been shown to improve the quality of services in the healthcare and food industries.

Introduction

I. INTRODUCTION

The food industry is one of the fastest growing industries in the world. From the humble task of selling homemade products to customers' homes, we have grown into large companies that prepare millions of meals every day. As we expand, we must constantly monitor quality and other parameters that do not depend on product demand or other external factors. This cannot be achieved by humans or computers alone. Therefore, machines and humans must work together to achieve this goal, and this collaboration is called artificial intelligence (AI). The main reason for the inclusion of AI in the food industry is the ability of AI to act as a robot and a human at the same time. With the help of artificial intelligence, it is possible to achieve an optimal harvest taking into account all factors such as the quality of raw materials, environmental temperature, fermentation and bacterial development when purchasing final products.

Artificial Intelligence (AI) is a vast technology in itself. Figure 1 illustrates some of the branches of AI that have been developed in response to the needs of the industry. Machine Learning (ML) is one of the most commonly used fields of AI, as it is used in almost all industries. ML has significantly simplified the data analysis process. Deep Learning (DL) is the next stage of ML development. DL is used for large-scale data analysis in the fields of image processing and speech recognition, as well as for object identification in other disciplines. Recently, DL has gained acceptance in the disciplines of food science and engineering. Computer vision is the process of taking digital images or videos as input and making a decision after scanning all of the surrounding areas. Natural Language Processing (NLP) and Robotics are the most prominent areas of AI. A robot is a mechanism, particularly one that can be programmed by the computer and is capable of performing a complex set of tasks autonomously. The robot can be guided by an external control device or the control device can be integrated within the robot.

From a food industry perspective, Machine Learning, Deep Learning, Robotics, and Computer Vision are widely employed in the four stages of the food supply chain: Harvesting, Processing, Packaging, and Palletizing. This article will explore how Artificial Intelligence (AI) is employed at each stage and its advantages over traditional methods. An illustrative example of how AI can be used in each stage of the 4P is provided. In this article we will learn about the pattern recognition on the production of fruit-based drinks like pineapple where AI leads for the better growth of and quality production of the product.

II. LITERATURE REVIEW

The neural network judging method outlined in this paper can be used to evaluate the appearance quality of pineapple core and differentiate the grade of the specification. This can lead to a highly accurate rate of production, which is expected to have a positive effect on pineapple production and industry growth. The study analyzes the image processing approach employed in assessing the quality of pineapple where several amplitudes of output designs are generated using national standard data.

In [2], data can be derived from agriculture, food processing/manufacturing; supply chain; traceability; or consumers. Sensors are the primary collection points on the Internet of Things (IoT), while opinions posted on social media platforms are the primary sources of data from customers. Data processing is now typically done from remote locations using high-performance computers, commonly referred to as cloud computing. The data collected about the system may be used to evaluate the performance of activities or to make appropriate recommendations. This paper outlines a robust yet straight-forward approach to detect dairy products containing fibers, bromelain, manganese and Vitamin C as well as to differentiate organic from non-organic food products, using neural networks trained with acoustic frequency responses. While a trial-and-error approach would take a considerable amount of time to reach a decision, an AI algorithm can be employed to extract high-level properties of a material's response to a range of frequencies and compare them to other materials.

The study [4] describes the utilization of 4.0 Industrial Revolution technologies such as Computer Vision and Artificial Intelligence in agriculture and the food sector. This review provides a comprehensive overview of Computer Vision and Intelligence methodologies that are used in a range of agricultural applications, such as Food Processing, Agriculture-based Applications, Agriculture, Plant Data Analysis, Smart Irrigation, and Next-Generation Agriculture. Additionally, the article addresses the fundamental concept of using Sustainable 4 IR Technologies to guarantee that humanity has access to sufficient food by 2050 while also being environmentally friendly. The article also highlights the importance of Agri-Tech industry, as well as the investment opportunities associated with AI and vision technologies, with relevant resources and use cases.

In [5], a virtualization approach has been proposed for the food manufacturing process, which is supported by a cloud-based platform. At the core of the virtualization is a collection of intelligent algorithms (ANNs) which utilize NIR spectrometric data from samples to evaluate organoleptic characteristics.

The virtualization technique has been applied to the cheesemaking process as a case study. Key agents (Quality Manager, Tasters, Tasting Organizers, Quality Inspectors) collaborate and exchange information from different points using the cloud-based platform, with instrumental data being incorporated systematically.

Machine vision-based grading is a method of assessing product quality through the use of both hardware and software, depending on the product being graded.

This involves the use of hardware such as cameras, conveyer belts, light sensors, speed control sensors, and image processing techniques. The characteristics of the images obtained are extracted, and the images are pre-treated using image processing techniques. In certain industries, a grading process is being developed to assess the quality of products. Finally, the appropriate AI model is employed for categorization, as well as for analyzing the approximate value of quality detection. AI is most commonly used in agricultural products.

III. PROPOSED METHODOLOGY

Fruits has become a staple in our diets, with some people preferring it with juices, shakes and Cake. A poll indicates that the average American consumes 71 pounds of fruits annually, which is indicative of the size of the industry. With the market expanding, it is essential to maintain quality at the same price, which is difficult to do with traditional methods. Artificial Intelligence (AI) has made this task much easier. In this article, we will discuss the various stages of Pineapple juice production and packaging, from the raw fruit to the bottle, and how Machine Learning, Deep Learning, Computer Vision, and Robotics are employed in each stage.

A. Picking

It is widely accepted that the best pineapple juices are selected for the production of raw pineapple fruit itself. To ensure this, it is essential to select the most suitable core for the purpose. Of the numerous samples brought to the factory, only golden yellow color is chosen. To this end, machine learning is employed to identify the most suitable seed among the variety of seeds available for growing pineapple, taking into account factors such as growth rate, water requirements, sweetness and sourness factor, and more. For this purpose, Machine Learning (ML) uses an algorithm to collect and classify data.

Fig. 2 illustrates all the perimeters that have been evaluated in order to predict crop production. Each quality syncarp is collected and the predictions are made using a Linear Regression / Logistic regression / K-mean clustering system. This is the initial stage of the project as it takes place before the juice production plant is established. Prior to the installation of a manufacturing unit, a similar linear regression is applied to determine the optimal location for the unit, taking into account factors such as market, location, transportation facilities, etc. With these forecasts, the entire profit of the company is projected based on numerous parameters, which cannot be achieved manually.

- Computer Vision in Picking

First, the pineapple is harvested and washed. After they have been cleaned, they are passed through a conveyor belt where they must pass through a scanner. This scanner utilizes Computer vision technology to verify the quality of the fruit prior to being passed on to the next stage. All raw/rotten/under size pineapple are filtered out using Computer vision technology. The algorithm is designed to scan all criteria such as diameter, color, and discoloration due to bacterial impact. If any of them give a false judgement for a pineapple, it will be thrown away. Prior to this process, a significant amount of labor and time had been invested, resulting in an increase in production costs. The same method is used to scan all raw materials to guarantee the quality of pineapple juice.

B. Pre-Processing

- Deep Learning in Processing of Pineapple juice

The pineapple is one of the most widely produced and consumed agricultural products. The primary function of these systems is to harvest, sort, and grade fruits, while calibrations are conducted to determine color, size, weight, shape, flaws, and more. Therefore, the development of an effective fruit identification system and mass estimation system is necessary for the development of a fully automated farming and packaging pipeline. The three main stages of this method are object detection, classification, and analysis.

Imaging segmentation is a key factor in image processing, as it determines whether the analysis is focused on the target sample or not. To accurately estimate the final weight of pineapple fruit from the volume, multiple artificial intelligence methods were employed to draw a connection between the size of the two-dimensional image and the weight of the three-dimensional image. These methods were then trained and evaluated based on the geometry module's estimated dimensions to estimate the final weight using the pineapple dataset.

The Mask-RCNN is a comprehensive framework for feature extraction backbone networks, region proposal networks (RPNs) for the generation of anchors, and FCNs running in parallel to fully connected networks that generate instance-wise semantic masks and target detection with classifying outputs, as illustrated in the figure below.

C. Computer Vision in Processing Pineapple

Once the finest pineapple and other ingredients have been obtained, they are blended and processed into the final product. Computer vision is employed to monitor the mixture and its temperature in order to ascertain the temperature, the mixing rate, and the time of addition of a component. Before, the worker would have had to manually inspect each perimeter, which could have resulted in over processing of the juice, resulting in the destruction of the entire batch and the company's financial loss. Due to the importance of color and density in juice production, machine vision is closely monitored as the juice is heated and processed. This eliminates the need to manually test each batch and perform the necessary calculations. This Machine Vision output is also used as an input for Deep Learning to anticipate the time required to make the optimal decision.

D. Packaging and Palletizing

- Computer Vision in Packaging

Computer Vision is an essential tool in the packaging industry. After pineapple processing, juice is packaged and palletized. After the pineapple juice bottles have been cleaned and filled, a check is conducted to ensure that they are all full and clean. This is done using Computer Vision/Machine Vision. A combination of a camera and a sensor is used to generate a digital image. Figure 6 illustrates how a partially filled ketchup bottle is taken off the convey belt prior to the cap being applied. Machine Vision is then used to guarantee uniformity and accuracy.

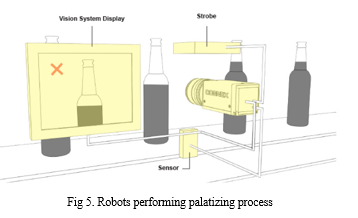

2. Robotics in Palatizing

Prior to Palletizing, the price and production and expiration dates are verified and printed on the sticker by a robot unit. This information is obtained based on the date of production and its contents. The robotic arm then collects twelve bottles and places them into a box which is packaged and stacked onto a pallet by a fully automated robot. 100 boxes are placed on the pallet, shrink wrapped, and stored in warehouses; from there, they are transported according to the requirements. The robot keeps track of all pallets according to their production date and selects them when the time comes to send them. The labor and time required to pack and palletize these large and fragile items is labor intensive, resulting in a decrease in productivity and an increase in total production costs. There is also the potential for human error, but with robots, accuracy and error-free products are guaranteed.

Conclusion

In the modern era, it is difficult to conceive of mass-producing a product without the utilization of Artificial Intelligence (AI). There are a variety of sub-disciplines of AI, including Machine Learning, Deep Learning, Computer Vision, Robotics, Natural Language Processing, and more, which are being utilized in the food industry to ensure the highest quality of product. AI has become an essential component of food production. Artificial Intelligence (AI) has revolutionized manufacturing and quality assurance, providing precise, cost-effective, hygienic, and efficient production that is large-scale and of high quality. When it comes to decision-making, AI can operate independently, eliminating the need for human intervention. Despite this, many industries and processes are still lacking the advantages of AI; however, once fully adopted, it will undoubtedly help us to achieve the ideal of fully automated manufacturing that is managed with a single click.

References

[1] H. Zhong-Zhi, L. Yan-Zhao, L. Jing and Z. You-gang, \\\"Quality Grade-Testing of Pineapple Based on Image Processing,” 2010. Third International Conference on Information and Computing, 2010, pp. 333-336, DOI: 10.1109/ICIC.2010.270. [2] N. N. Misra, Y. Dixit, A. Al-Mallahi, M. S. Bhullar, R. Upadhyay and A. Martynenko, “IoT, big data and artificial intelligence in agriculture and food industry,” in IEEE Internet of Things Journal, DOI: 10.1109/JIOT.2020.2998584. [3] Gokce Iymen, Gizem Tan River, Yusuf Ziya Hayirlioglu, Onur Ergen, Artificial intelligence-based identification of juice variations as a model study for detecting food adulteration, Innovative Food Science & Emerging Technologies, Volume 66,2020,102527, ISSN 14668564, https://doi.org/10.1016/j.ifset.2020.102527. [4] Vijay Kakani, Van Huan Nguyen, Basivi Praveen Kumar, Hakil Kim, Visweswara Rao Pasupuleti, A critical review on computer vision and artificial intelligence in food industry, Journal of Agriculture and Food the Research, Volume 2, 2020, 100033, ISSN 2666-1543, https://doi.org/10.1016/j.jafr.2020.100033. [5] J. A. García-Esteban, B. Curto, V. Moreno, I. González-Martín, I. Revilla and A. Vivar-Quintana, “A digitalization strategy for quality control in food industry based on Artificial Intelligence techniques,” 2018 IEEE 16th International Conference on Industrial Informatics (INDIN), 2018, pp. 221-226, DOI: 10.1109/INDIN.2018.8471994. [6] N. Elakkiya, S. Karthikeyan and T. Ravi, \\\"Survey of Grading Process for Agricultural Foods by Using Artificial Intelligence Technique,” 2018 Second International Conference on Electronics, Communication and Aerospace Technology (ICECA), 2018, pp. 1834-1838, DOI: 0.1109/ICECA.2018.8474663. [7] Lili Zhu, Petros Spachos, Erica Pensini, Konstantinos N. Platanista’s, “Deep learning and machine vision for food processing: A survey,Current Research in Food Science”, Volume 4,2021,Pages 233-249,ISSN 2665-9271,https://doi.org/10.1016/j.crfs.2021.03.009. [8] Vijay Kakani, Van Huan Nguyen, Basivi Praveen Kumar, Hakil Kim, Visweswara Rao Pasupuleti, “A critical review on computer vision and artificial intelligence in food industry”, Journal of Agriculture and Food Research, Volume 2, 2020, 100033, ISSN 2666-1543,https://doi.org/10.1016/j.jafr.2020.100033.

Copyright

Copyright © 2023 Shobha Bhatt. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET55898

Publish Date : 2023-09-26

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online