Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Food Spoilage Detection Monitoring and Alerting System

Authors: Dr. N. Usha Rani, Athukuri Priyanka

DOI Link: https://doi.org/10.22214/ijraset.2024.66037

Certificate: View Certificate

Abstract

Tackling Food safety measures and mitigating spoilage are critical Challenges in public health. In the present work, robust solution for the continuous monitoring and management of perishable food products is observed. By incorporating temperature and gas sensors, Food Spoilage Detection and Alerting System using IoT is designed to detect early signs of spoilage, enabling timely intervention to prevent food waste and its safety. The temperature sensor monitors the surrounding environment, emphasizing the crucial role of temperature in accelerating the spoilage of sensitive foods such as dairy and meat. In tandem the gas sensor detects specific volatile compounds such as Ethylene, Ammonia, Methane, Nitrogen Dioxide, and Carbon Dioxide that act as indicators of food degradation, allowing for the identification of spoilage risks before they become significant. NODEMCU microcontroller is central to the system\'s operation which is an efficient and compact IoT platform that gathers and processes data from the sensors. It uses predefined thresholds to evaluate environmental conditions, ensuring accurate spoilage detection. Real-time data is displayed on an LCD screen, giving users immediate access to food storage conditions. If gas levels exceed the predefined thresholds, the system triggers an alert message, notifying users of potential spoilage. Alerts are generated through the UBIDOTS app and delivered via email or registered mobile number, providing timely notifications that enable users to take prompt action in maintaining food quality.

Introduction

I. INTRODUCTION

Food spoilage can manifest in various forms, including changes in appearance, texture, colour, odour, or taste. Traditional manual inspection methods are inefficient and error-prone. These changes not only make food undesirable but can also pose serious health risks. The quality of food is significantly influenced by environmental conditions, which can cause it to rot or decay rapidly [1][2].

Detecting spoiled food using only sight or smell can be challenging, as early signs of spoilage may not be obvious. Moreover, one piece of rotten food can contaminate and spoil other foods stored alongside it, leading to further waste. Detecting and addressing food spoilage at its early stages can play a crucial role in reducing wastage and ensuring food safety. Rotten food releases various gases, such as hydrogen Sulphide, methane, ammonia, ethylene, and nitrogen dioxide, which serve as indicators of spoilage. Among these, Ethylene is one of the most commonly emitted gases [3][4]. Monitoring these gases can help to identify spoiled food early and prevent contamination. Additionally, food quality should be assessed under changing environmental conditions including temperature, to maintain its freshness. Health problems can also arise from consuming improperly prepared or undercooked animal products, which can spoil and become harmful if not handled correctly. To minimize such risks, it is essential to monitor food quality continuously and implement measures to prevent decay caused by adverse atmospheric conditions.

II. LITERATURE SURVEY

Food spoilage is a global issue causing substantial waste and economic loss. Traditional manual inspection methods are inefficient and error-prone [1][2]. Recent advancements utilize real-time surveillance systems with computer vision for maturity and infection detection in fruits and vegetables [3]. Ethanol detection using MQ3 sensors, particularly in bananas, has been effective for ripeness and spoilage identification [4]. AI and ML techniques enhance accuracy in produce classification through image processing and environmental data analysis [5][6]. IoT systems, incorporating NODEMCU platforms and multi-sensors, monitor temperature and gas emissions, optimizing food quality management [7]. CNNs have demonstrated superior performance in fruit feature extraction compared to SVM and KNN techniques [8]. RFID metadata enables/ real-time traceability, enhancing monitoring and management [9][10]. Vegetable conditions and harvesting times are optimized using machine learning, while the EMP-NLCapsNet algorithm ensures fruit quality through deep learning and hyperspectral imaging [11][12]. Techniques involving ANN, SVM, and analysis of colour, texture, and brown spots ensure reliable ripeness and spoilage detection [13][14][15]. These technologies significantly improve food quality control, reduce waste, and enhance economic outcomes.

III. IOT SYSTEM IMPLEMENTATION

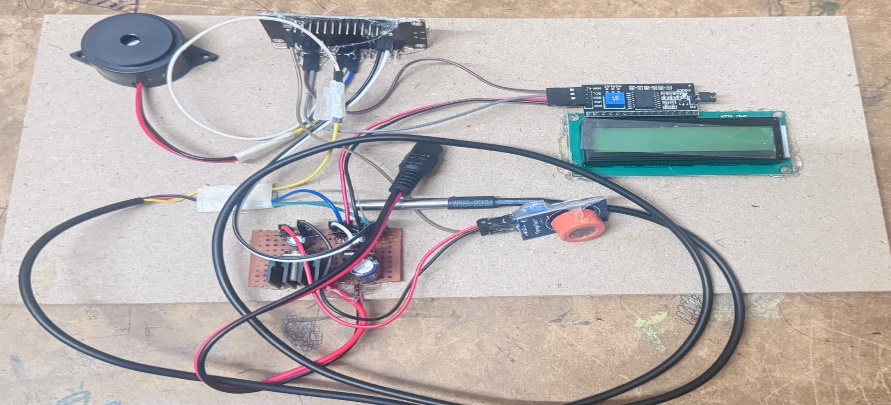

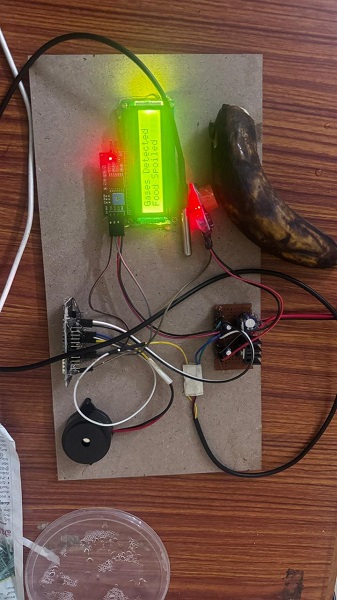

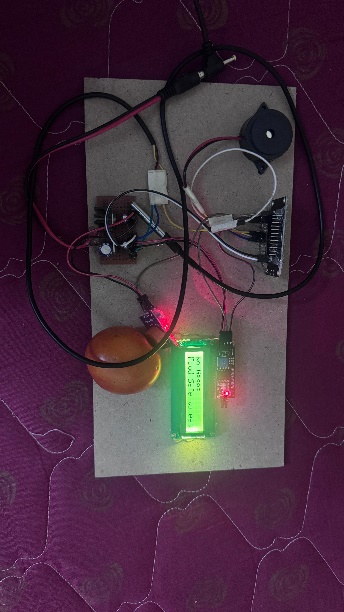

Fig 1: Interfacing all Sensors to NODEMCU

A. NODEMCU

The NODEMCU, powered by the ESP8266 microcontroller with built-in Wi-Fi capabilities, is well-suited for IoT applications such as real-time food spoilage monitoring. It easily interfaces with gas and temperature sensors to detect critical indicators like gas emissions and temperature changes. If the monitored values exceed set thresholds, the NODEMCU sends notifications to users via cloud-based platforms like UBIDOTS, facilitating prompt actions to prevent food spoilage.

B. 16x2 LCD DISPLAY

An LCD (Liquid Crystal Display) is a technology widely used in devices like smartphones and calculators, utilizing liquid crystals to control light and present visual information. In this application, the LCD is connected to a NODEMCU module to display data collected from gas and temperature sensors, offering insights into the quality of food.

C. MQ3 Sensor

The MQ3 sensor is a gas sensor primarily used for detecting alcohol vapours in the air and can also sense other gases like methane, benzene, and carbon monoxide. Due to its sensitivity to alcohol and VOCs, it’s effective for tracking spoilage in foods that emit alcohol, like fermented items. When connected to a microcontroller such as the NODEMCU, it detects rises in ethanol levels. In an IoT setup, it enables real-time monitoring and alerts to help prevent spoilage.

D. Temperature Sensor

The DS18B20 waterproof temperature sensor is encased in a durable sheath, enabling precise temperature measurement in humid or wet environments without risk of damage. It is frequently used in systems for food storage and spoilage prevention to help maintain safe temperature levels and minimize spoilage risks.

E. BUZZER

A waterproof temperature sensor (e.g., DS18B20) is a sensor encased in a waterproof sheath that can accurately measure temperature even in wet or humid environments without risk of damage. It’s widely used in food storage and spoilage detection systems to maintain safe temperature ranges that prevent spoilage.

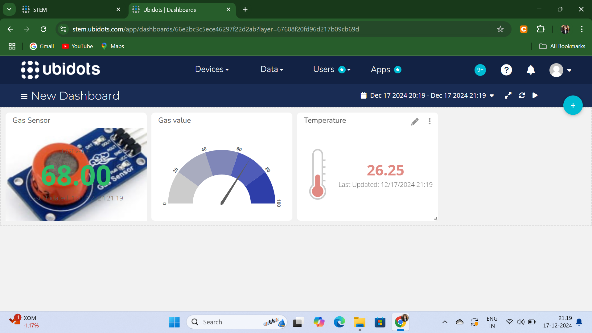

F. UBIDOTS

The UBIDOTS App is a cloud-based Internet of Things (IoT) platform designed to facilitate remote data visualization, analysis, and management of sensor networks. It displays live data from sensors (e.g., temperature, gas levels) on customizable dashboards and sends notifications when conditions exceed safe thresholds.

IV. FOOD PERISHING DETECTION AND ALERTING SYSTEM

The IoT-based food spoilage detection system provides an innovative, real-time solution for monitoring food quality and ensuring safety by leveraging advanced components, including a NODEMCU microcontroller equipped with an ESP8266 Wi-Fi chip, an MQ3 gas sensor, a buzzer, and an LCD display.

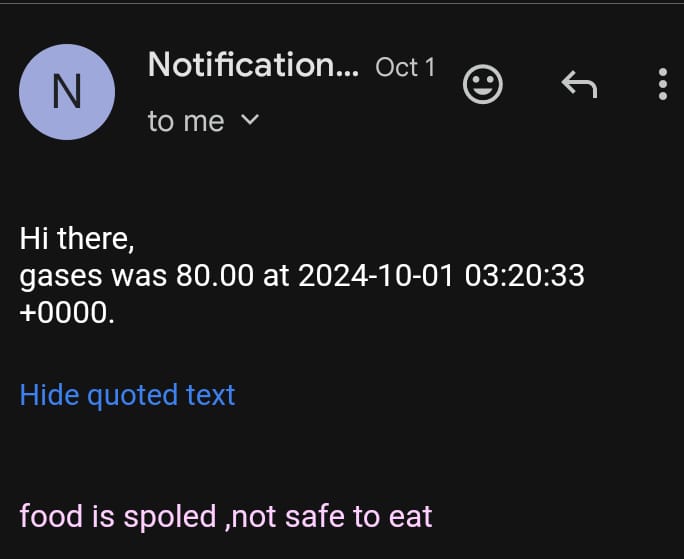

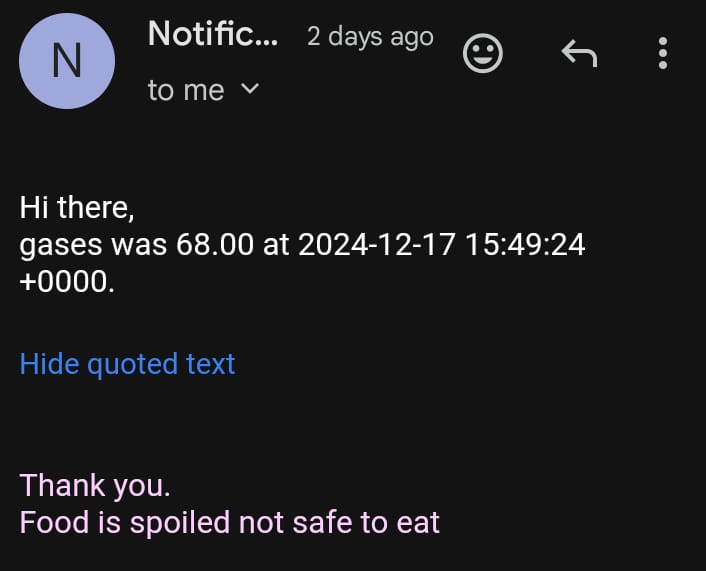

The system integrates seamlessly with the UBIDOTS app, allowing wireless transmission of sensor data and enabling users to remotely monitor food freshness through the app’s terminal widget. Key parameters such as temperature and gas levels are continuously measured, processed, and compared to predefined safety thresholds. If these thresholds are exceeded, indicating potential spoilage, the system activates an audible buzzer, displays a warning message, and sends an automated email alert with the notification: “Food is spoiled.” Conversely, if conditions remain within safe limits, the system reassures users by displaying “Food is safe to eat” on the LCD. For ease of configuration, users can create a project within the UBIDOTS app, assign a name (e.g., "NODEMCU"), and select Wi-Fi as the connection type. An authentication token, provided via email, must be incorporated into the system’s code to establish secure connectivity. This system not only promotes efficient food safety management but also aids in reducing food waste by providing timely alerts.

V. RESULTS AND DISCUSSIONS

An IoT-based food monitoring system has been developed using a sensor integrated with a NODEMCU module. In this configuration, sensors linked to the NODEMCU are strategically positioned near the food items for monitoring purposes. The NODEMCU processes the data collected by the sensors and transmits it to the UBIDOTS mobile application. The transmitted data is evaluated against predefined threshold values to determine food freshness. Critical parameters, including temperature and gas levels, are continuously monitored, with the corresponding readings displayed on the UBIDOTS App homepage.

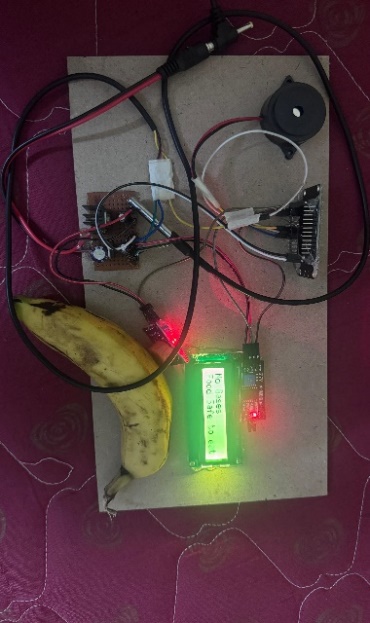

A. Test Case-1: When Fresh Banana is Tested

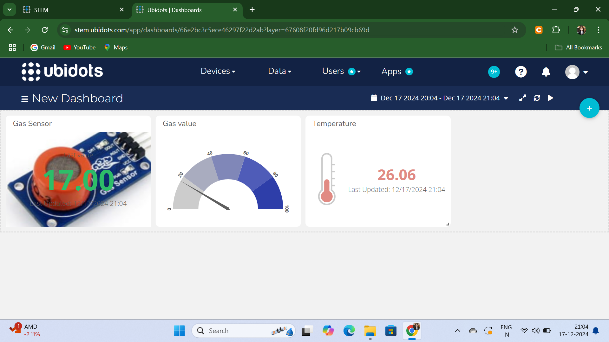

Fig 2: output on Lcd Display Fig 3: UBIDOTS APP Output

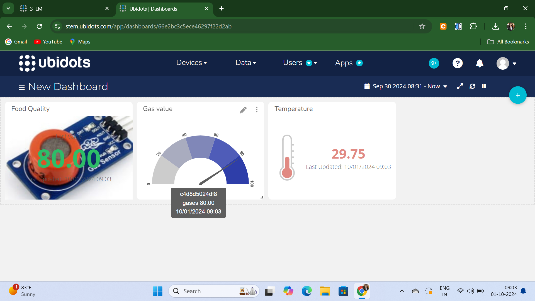

B. Test Case-1: when Stored Banana is Tested

(i)If the gas concentration exceeds 50 ppm, an email alert will be triggered and sent to the user.

Fig 4: Output on LCD Display

Fig 5: UBIDOTS App Output Fig 6: Alert through E-mail

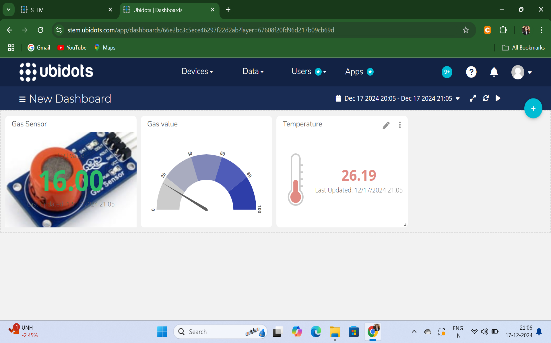

C. Test Case 2: when Fresh Tomato is Tested

Fig 6: Output on LCD Display Fig 7: UBIDOTS App Output

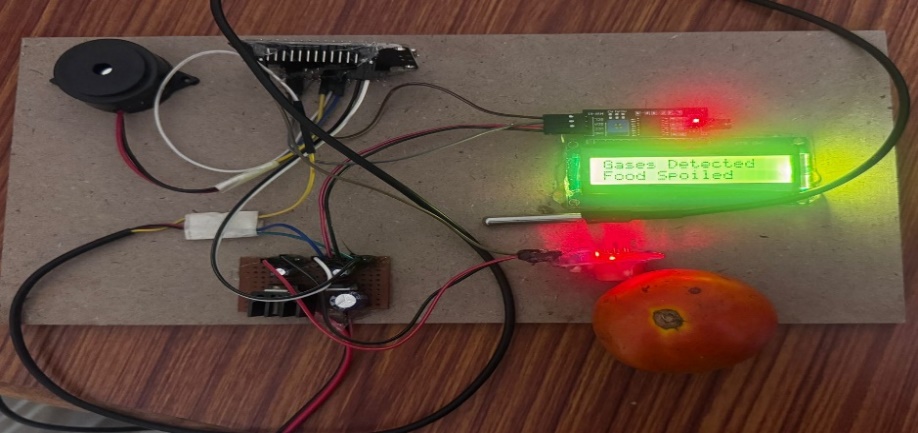

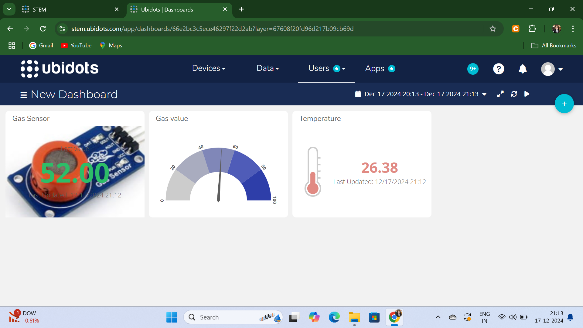

D. Test Case 2: when Stored Tomato is Tested

(i)If the gas concentration exceeds 50 ppm, an email alert will be triggered and sent to the user.

Fig 8: Output on LCD Display

Fig 9: UBIDOTS App Output Fig 10: Alert through E-mail

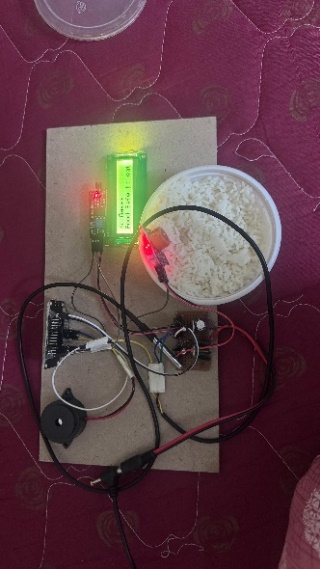

E. Test Case 3: when Fresh Rice is Tested

Fig11: Output on LCD Display Fig12: UBIDOTS App Output

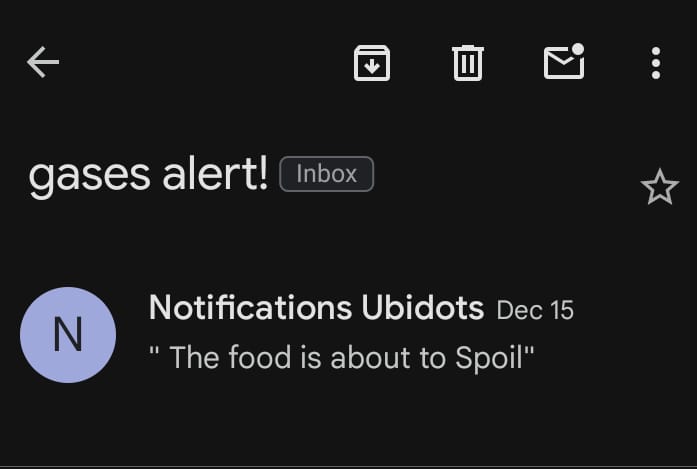

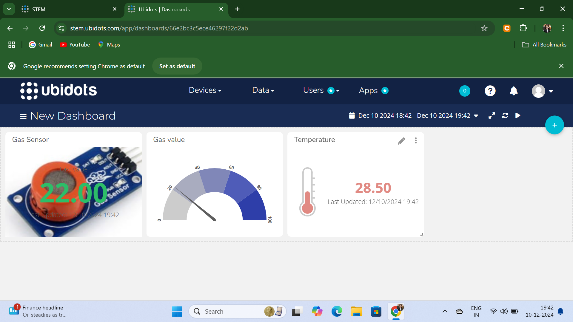

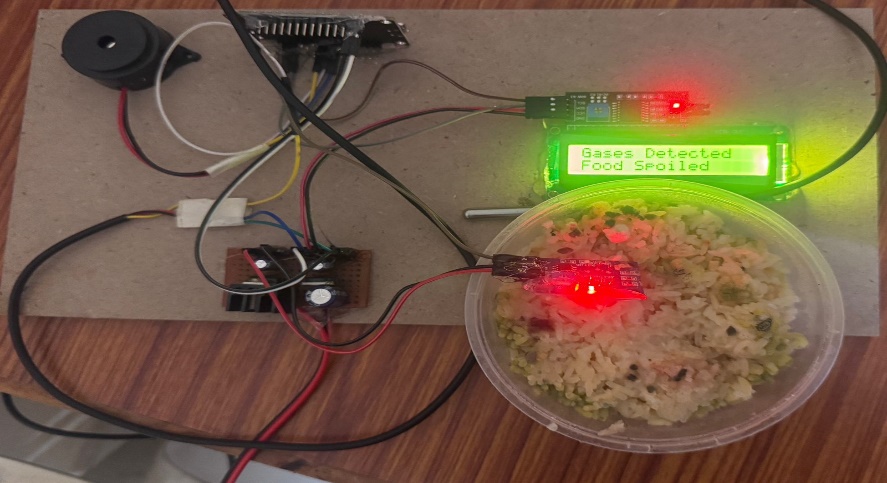

F. Test Case 3: when Stored Rice is Tested

(i)If the gas concentration exceeds 50 ppm, an email alert will be triggered and sent to the user.

Fig 13: Output on LCD Display

Fig16: UBIDOTS App Output Fig17: Alert through E-mail

Conclusion

The system is designed to assess food quality and reduce health risks associated with unhealthy dietary choices, particularly for individuals with weaker immune systems. By employing sensors to track temperature and gases released by food, it allows users to determine the freshness of food items. When gas levels exceed safe limits, the system sends email notifications and provides real-time updates on food status through the UBIDOTS App. Continuous monitoring of these emissions ensures early detection of spoilage gases, offering timely information on food freshness and safety.

References

[1] S. Sasikanth, A. Kumar, N. Kumar, and G. Pradeepkumar, ?IoT based Food Spoilage Detection Monitoring using Blynk, ? 2023 9th International Conference on Advanced Computing and Communication Systems (ICACCS), Mar.2023, doi:10.1109/icaccs57279.2023.10113034. [2] B. V. S. Nithin, K. S. Nithin, B. Sneha, and V. V. Kumar, ?Non-Destructive Approach for Detection of Food Freshness using IoT, 2023 International Conference on Inventive Computation Technologies (ICICT), Apr. 2023, doi:10.1109/icict57646.2023.10134232. [3] K. Jaspin, S. Selvan, J. Dafni. Rose, J. Ebenezer, and A. Chockalingam, “Real-Time Surveillance for Identification of Fruits Ripening Stages and Vegetables Maturation Stages with Infection Detection,” IEEE Xplore, Oct. 01, 2021. [Online]. Available: https://ieeexplore.ieee.org/document/9609441 [4] Nabilah Tabassum Oshin, Fardin Ahsan Shafi, Mahfuzur Rahman, Halima Khatun, Mohammad Rejwan Uddin, Mahady Hasan. \"Food Rotting Prediction and Detection System for Warehouse\", 2023 IEEE Region 10Symposium (TENSYMP), (2023). Pp. 1-5. [5] Harshee Pitroda, Abhay Kolhe. “Freshy Pal: A Proposal of an Interactive Web based Tool to Automatically detect Microbial Growth on White bread”, 2023 IEEE 8th International Conference for Convergence in Technology (I2CT), 1-8, Apr, 2023. [6] B. Sahu, A. Tiwari, J. L. Raheja, and S. Kumar, ?Development of Machine Learning & Edge IoT Based Non-destructive Food Quality Monitoring System using Raspberry Pi,2020 IEEE International Conference on Computing, Power, and Communication Technologies (GUCON), Oct. 2020, doi: 10.1109/gucon48875.2020.9231061. [7] S. U. Shariff, M. G. Gurubasavanna, and C. R. Byrareddy, “IoT-Based Smart Food Storage Monitoring and Safety System,” International Conference on Computer Networks and Communication Technologies, pp. 623–638, Sep. 2018, doi: https://doi.org/10.1007/978-981-10-8681-6_57. [8] J. J. Jijesh, S. shankar, Ranjitha, D. C. Revathi, M. Shivaranjini, and R. Sirisha, “Development of Machine Learning (ML) based Fruit Detection and Grading system,” IEEE Xplore, Nov. 01, 2020. [Online]. Available: https://ieeexplore.ieee.org/document/9315601 [9] Song, C., Wu, Z., Gray, J., & Meng, Z. (2023). An RFID-Powered Multi-Sensing Fusion Industrial IoT System for Food Quality Assessment and Sensing. IEEE Transactions on Industrial Informatics. [10] T. Soewu, J. Gupta, S. Kumar, Shruti and B. Kaur, \"IoT and Machine Learning Based Food Recognition System,\" 2022 5th International Conference on Contemporary Computing and Informatics (IC3I), Uttar Pradesh, India, 2022, pp.1308-1311, doi: 10.1109/IC3I56241.2022.10073315. [11] Pal, H., & Tripathi, S. (2022, April). Design IoT-Based Smart Agriculture to Reduce Vegetable Waste by Computer Vision and Machine Learning. In International Conference on Communications and Cyber Physical Engineering 2018 (pp. 607-621). Singapore: Springer Nature Singapore. [12] Zhao, Y., Kang, Z., Chen, L., Guo, Y., Mu, Q., Wang, S., ... & Feng, C. (2023). Quality classification of kiwifruit under different storage conditions based on deep learning and hyperspectral imaging technology. Journal of Food Measurement and Characterization, 17(1), 289-305. [13] K. A. Ahmad, N. Abdullah, M. K. Osman, S. N. Sulaiman, M. F. Abdullah, and Z. Hussain, “Classification of Starfruit Ripeness using Neural Network Technique,” IEEE Xplore, Aug. 01, 2020. [Online]. Available: https://ieeexplore.ieee.org/document/9204929 [14] I. Indrabayu, N. Arifin, and I. S. Areni, “Strawberry Ripeness Classification System Based on Skin Tone Colour using Multi-Class Support Vector Machine,” IEEE Xplore, Jul. 01, 2019. [Online]. Available: https://ieeexplore.ieee.org/abstract/document/8938457 [15] F. M. A. Mazen and A. A. Nashat, “Ripeness Classification of Bananas Using an Artificial Neural Network,” Arabian Journal for Science and Engineering, vol. 44, no. 8, pp. 6901–6910, Jan. 2019.

Copyright

Copyright © 2024 Dr. N. Usha Rani, Athukuri Priyanka. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET66037

Publish Date : 2024-12-20

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online