Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Footwear Pattern Making and Grading Calculations Based on International Standard of Measurements

Authors: Hafiz Obaidullah

DOI Link: https://doi.org/10.22214/ijraset.2024.64002

Certificate: View Certificate

Abstract

Footwear pattern making and grading are fundamental processes in footwear design, critical for creating shoes that are well-fitting, balanced, and aesthetically appealing. Key considerations in pattern making include accurately calculating essential measuring parameters of the last to ensure perfect fit and balance. Additionally, grading is vital for developing different size ranges from the master pattern. This research paper investigates the calculations of essential measuring points of footwear based on foot anatomy and discusses longitudinal and transverse grading factors. By exploring calculations involved in pattern making and grading according to international measurement standards, the paper aims to determine the ideal calculations and grading parameters for various footwear styles. The study examines footwear measuring terminologies and derives standard formulas by analyzing diverse techniques and standards, providing insights into best practices for footwear designers and pattern developers to achieve consistency and quality in their products.

Introduction

I. INTRODUCTION

Footwear pattern making and grading are crucial components of the footwear design and manufacturing process. Achieving a perfect fit is one of the most significant challenges faced by designers, pattern developers, and manufacturers. A comprehensive understanding of pattern making and grading calculations is essential for creating well-fitting and balanced footwear.

This research paper explores the complete pattern making parameter calculations based on foot anatomy for various footwear styles. Additionally, it discusses the essential parameters for grading a master size into several size sets. By utilizing the insights and methodologies presented in this paper, designers, researchers, and pattern makers can accurately calculate the perfect fit and balance parameters for any footwear style.

The primary objective of this research paper is to develop standardized pattern making and grading calculations for all size ranges without compromising the perfect fit and balance of the footwear products. Both manual and CAD pattern masters require precise calculations of pattern making and grading parameters to create ideal footwear patterns. Without appropriate calculations, achieving a perfect fit and balanced footwear patterns is impossible.

One of the most notable features of this research is the provision of easily calculable parameters for pattern making and grading for all size ranges, from infants to adults, for both men and women. This is achieved through experienced and examined derivative standard formulas, providing a reliable foundation for practitioners in the footwear industry.

II. LITERATURE REVIEW

Footwear pattern making, a crucial element in shoe design and manufacturing, involves creating templates that outline the shape and structure of various shoe components. Historically, this craft has evolved alongside technological, material, and manufacturing advancements. Initially, ancient craftsmen used trial and error methods, shaping materials directly onto the foot or last with no standardized parameter calculations, and knowledge was often closely guarded and passed down through generations. The Industrial Revolution marked a significant shift with the introduction of machinery and standardized processes, leading to the creation of lasts from materials like wood, metal, and plastic, and the development of parameter calculations based on precise foot measurements.

The 20th century brought further innovations with new materials such as rubber and synthetics, and the rise of mass production demanded more sophisticated parameter calculations incorporating ergonomics, biomechanics, and anthropometry. The advent of computer-aided design (CAD) revolutionized pattern making, allowing for highly accurate and customizable designs.

Today, contemporary practices blend traditional craftsmanship with modern technology, emphasizing parameter calculations to create comfortable, functional, and aesthetically pleasing footwear. Despite advancements, a standardized method for parameter calculations across all sizes is still lacking. CAD software, advanced scanning techniques, and 3D printing enable the creation of bespoke footwear tailored to individual needs, but comprehensive knowledge of pattern making and grading calculations remains essential.

Key parameters in footwear pattern making include measurements of foot and last length, width, height, arch dimensions, ball girth, instep circumference, toe configuration, heel dimensions, shank length, material elasticity, grain orientation, and allowances for seams and assembly techniques. These parameters are vital for ensuring a proper fit, support, flexibility, and durability of the footwear.

Previous studies, such as "Parameter Calculations in Footwear Design: A Comparative Analysis" by Chen Xin and Liu Wei, compare traditional manual measurements with digital scanning techniques, evaluating their accuracy and efficiency in capturing foot morphology and generating precise patterns. Another study, "Integration of Foot Anthropometric Data into Footwear Pattern Making" by Santos Maria and Oliveira Jose, explores the integration of foot anthropometric data into pattern making to enhance accuracy and customization. These studies provide valuable insights into the methodologies, techniques, and considerations involved in footwear pattern making and grading calculations, contributing significantly to the field.

III. METHODOLOGY

A. Pattern Making Calculation

The pattern making process begins with selecting the appropriate last according to the design style. For instance, if creating sneaker shoes, one must start with the standard sizes of sneaker lasts.

Before calculating the essential measuring points for each design style, it is crucial to understand the various types of last lengths.

- Last Length

There are the following kinds of last lengths:

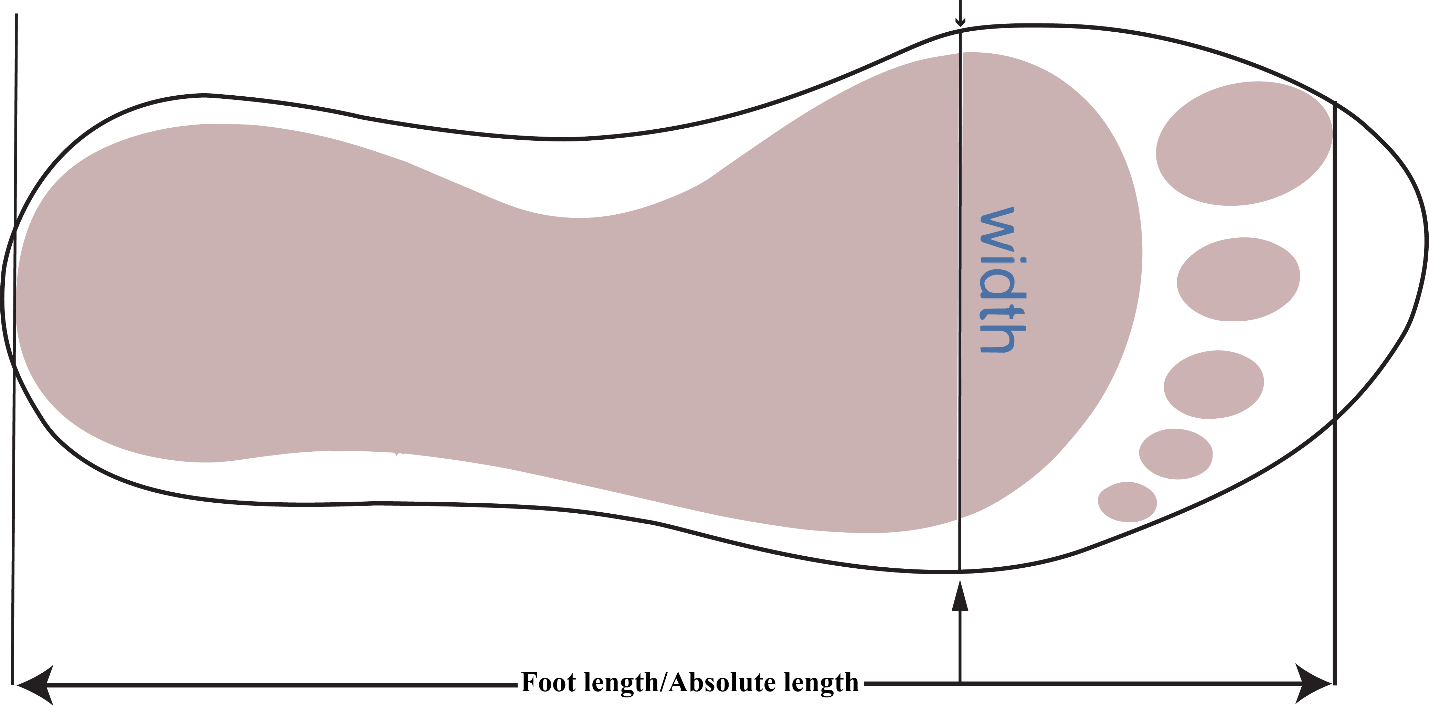

- Absolute Length: The exact length of the foot from seat to toe, also known as the foot length, illustrated in Figure 1.

Absolute Last Length = Foot Length

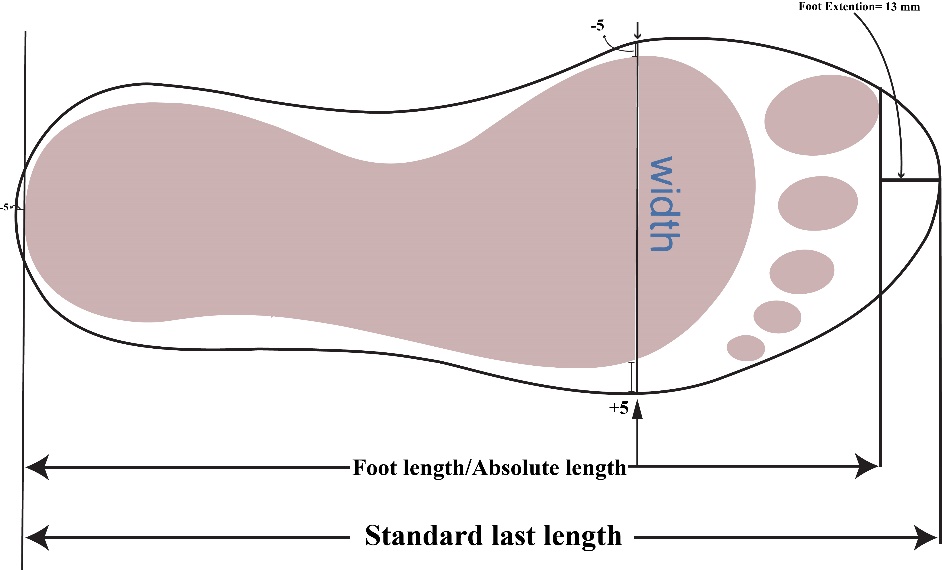

- Standard Last Length: This length is fixed for any shoe style and is derived from the foot length plus an extended allowance due to applied body weight. It is categorized as follows:

- Infant Standard Last Length (ISLL)

- Children Standard Last Length (CSLL)

- Adults Standard Last Length (ASLL)

Data on foot dimension expansion with body weight application has been collected from various age groups. The average length expansion is 13 mm, and width expansion at the metatarsophalangeal joints/ball girth is 10 mm, illustrated in Figure 2.

Hence, Standard Last Length = Foot Length + Extension Allowance (13 mm)

Another way to calculate the standard last length is:

- Standard Last Length for Least Foot (SLL) = (Size) X 1/3 Here, Size = English Points, 1/3 = the difference between two English sizes

The least foot is the origin of the sizing system, equal to 12 English points. Hence, SLL = Size * 1/3 = 12/3 = 4 Inches = 101.6 mm

- Standard Last Length for Children (CSLL) = (Size) X 1/3” + 4” Here, Size = English Size System, 1/3 = the difference between two English sizes

Children size range is (1-13) English Points.

For example, CSLL for size 1 = (1/3) + 4” = 4.33 Inches = 110 mm CSLL for size 13 = (13/3) + 4” = 8.33 Inches = 211.5 mm

After size 13-1/2 English Points, sizes start again from 1, 2, 3, 4 for Ladies and Men's sizes.

- Standard Last Length for Adults (Women’s and Men’s Sizes) = (13 + Size in EP) * 1/3 + 4” For example, for size 1: (13 + 1) * 1/3 + 4 = 14/3 + 4 = 8.66 Inches = 220.13 mm

All pattern design parameter calculations for any shoe style are based on the standard last length.

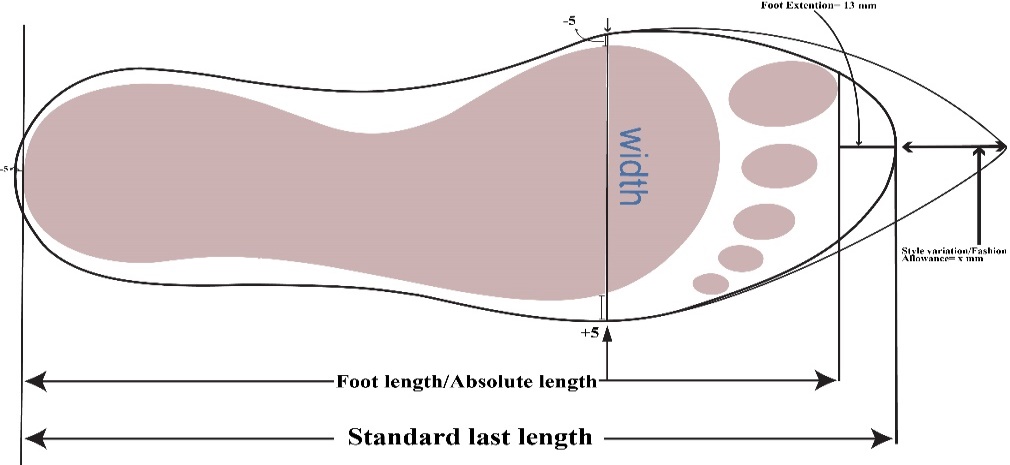

- Relative Last Length: This length is variable based on the design style and is directly proportional to the fashion allowance.

Hence, Relative Last Length = Standard Last Length + Fashion Allowance

The pattern making process begins with selecting the appropriate last according to the design style. For instance, if creating sneaker shoes, one must start with the standard sizes of sneaker lasts.

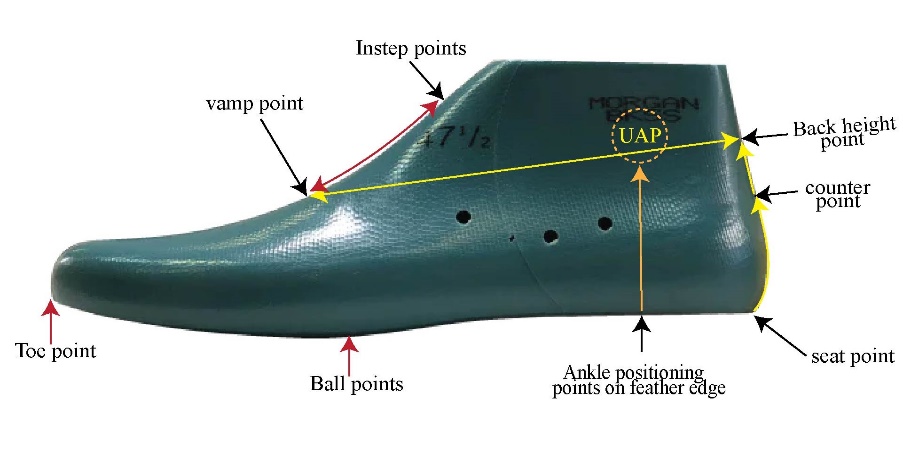

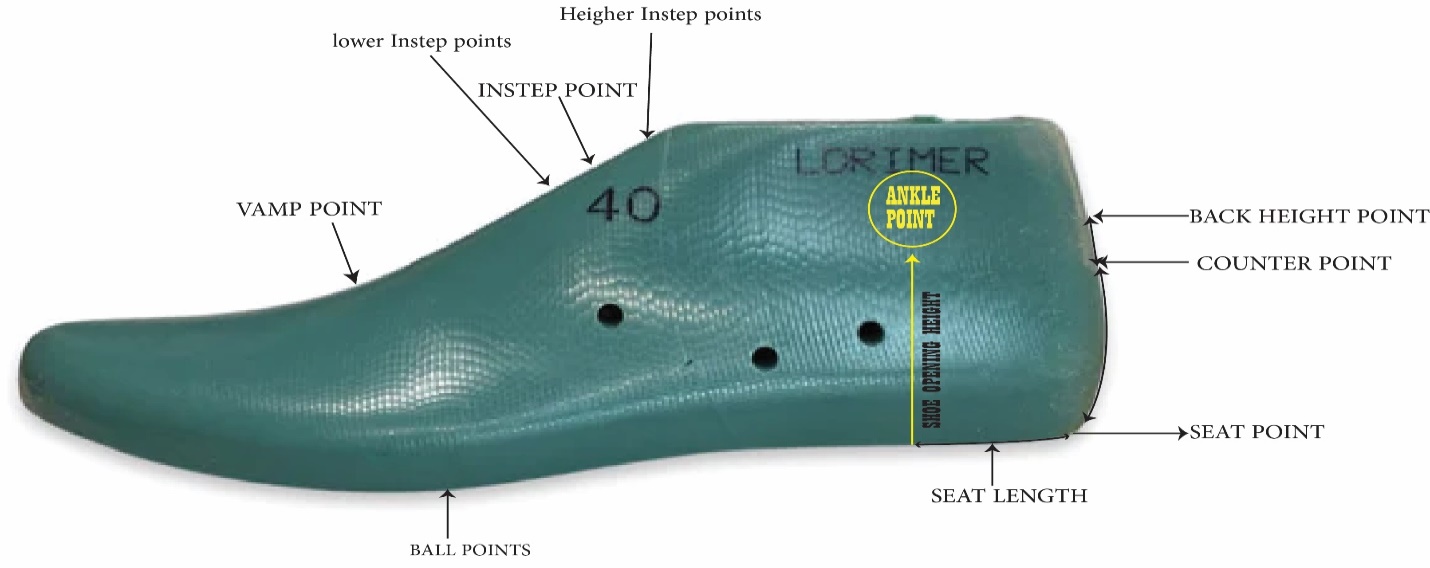

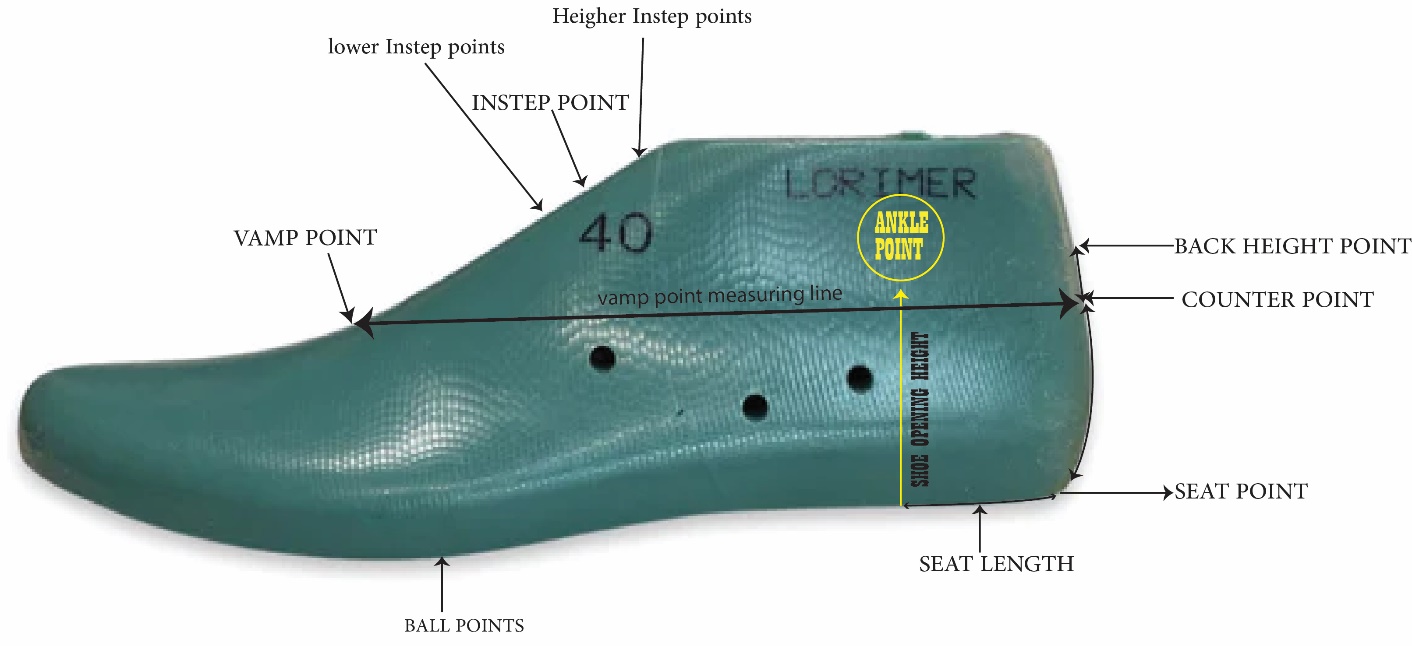

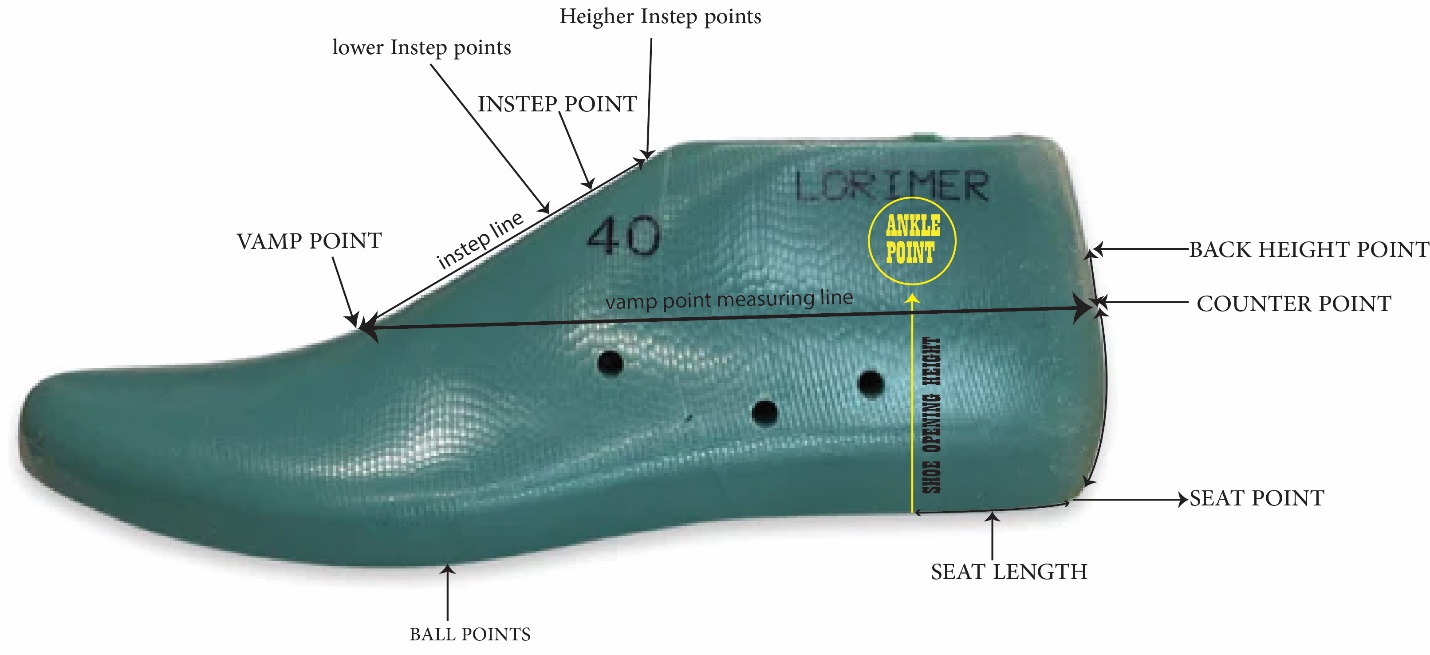

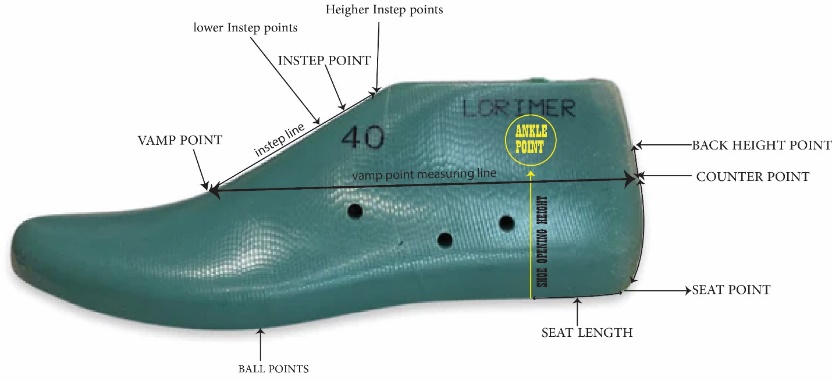

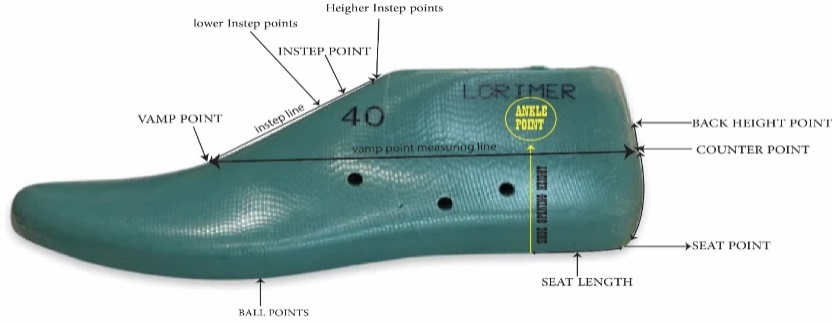

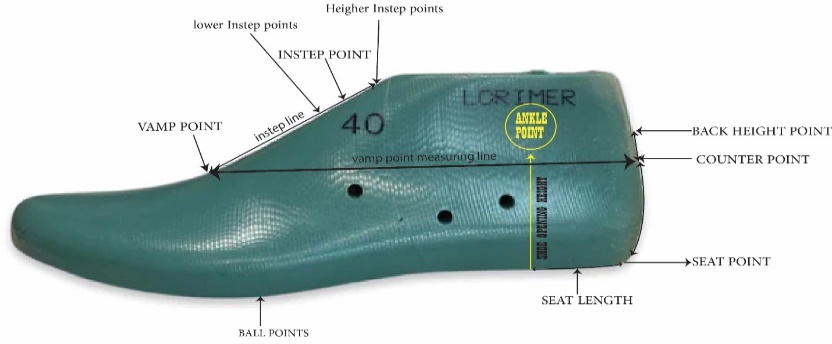

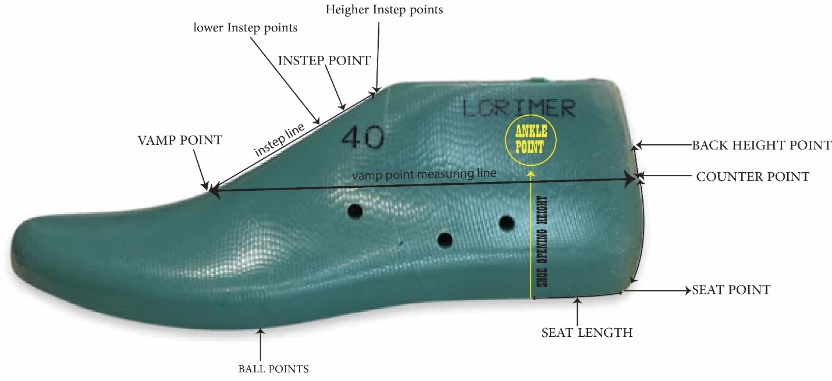

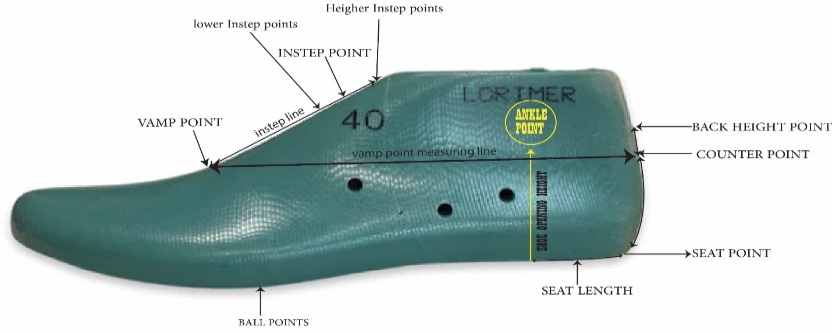

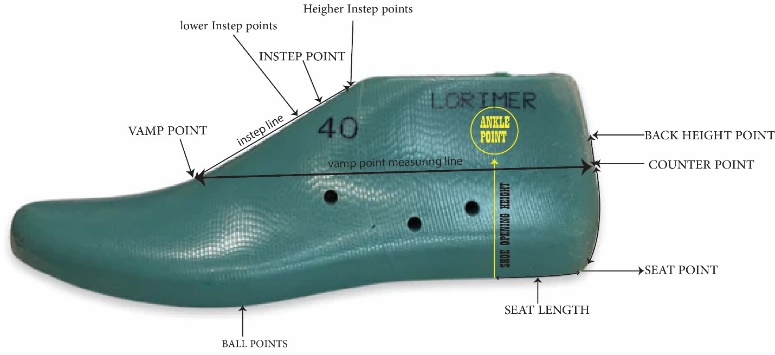

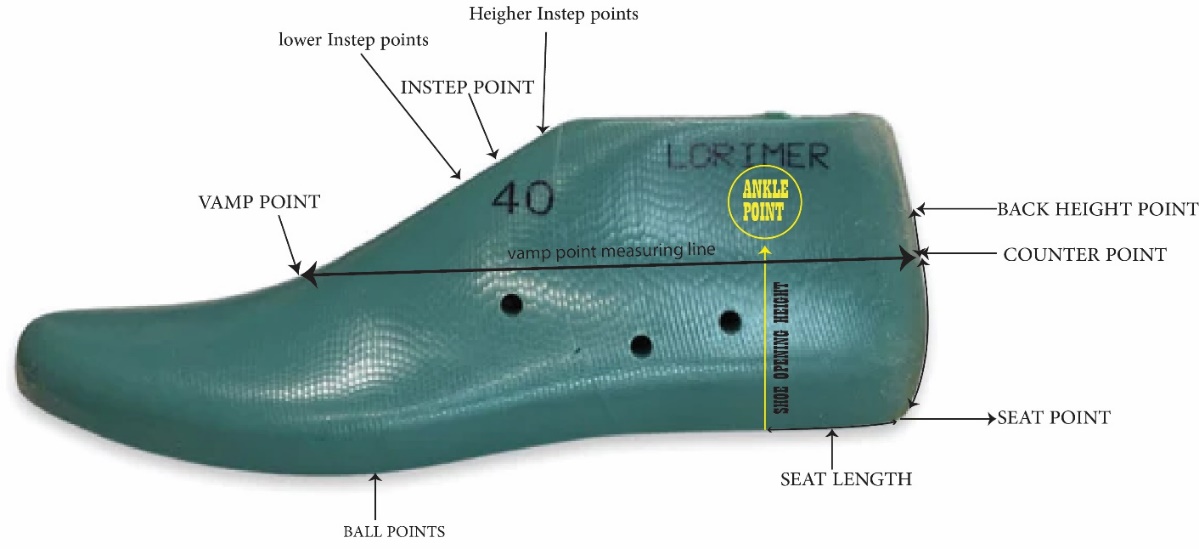

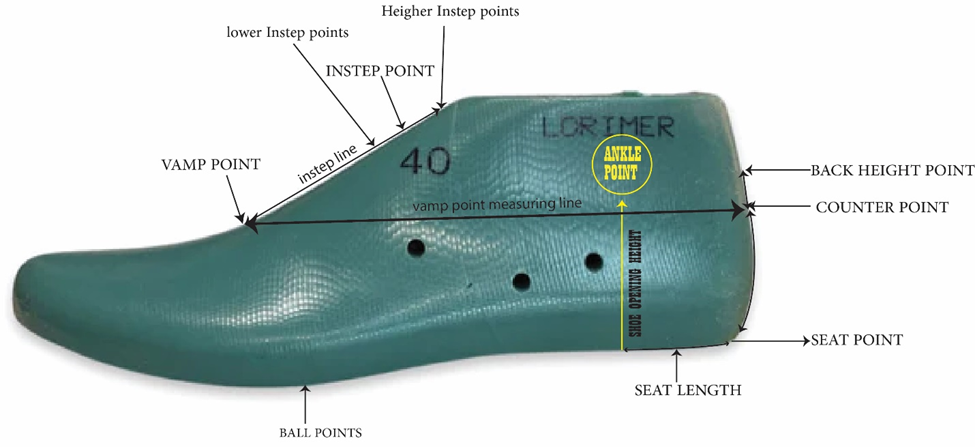

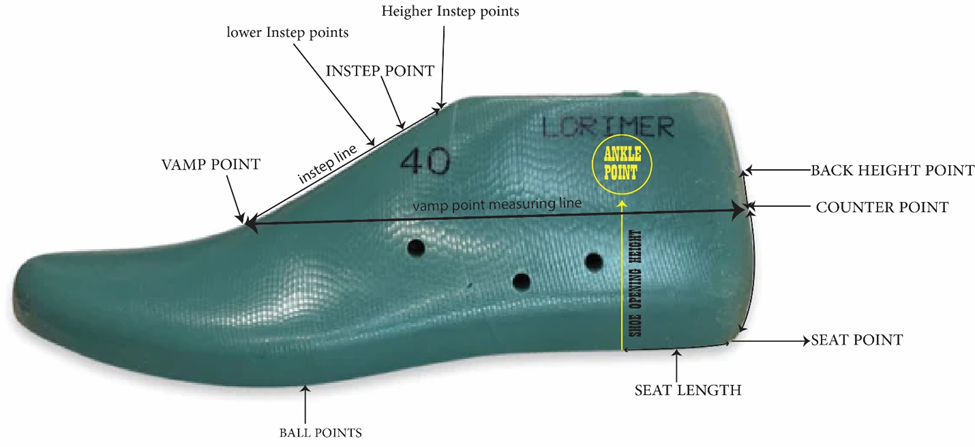

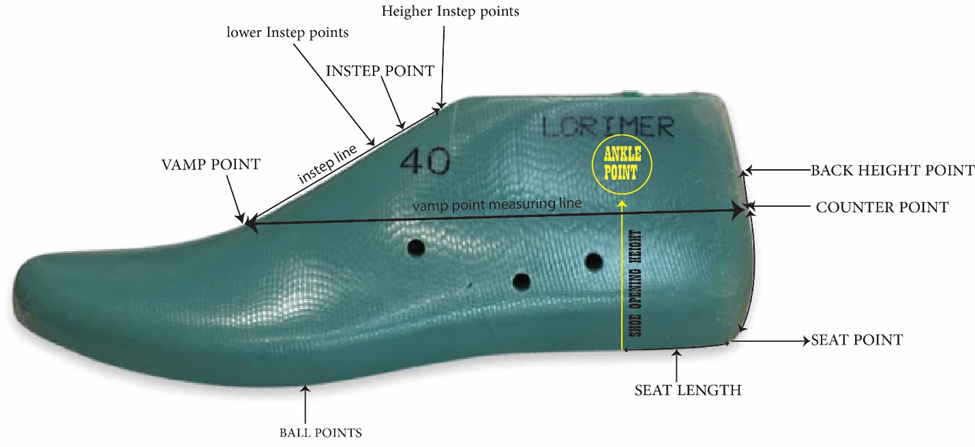

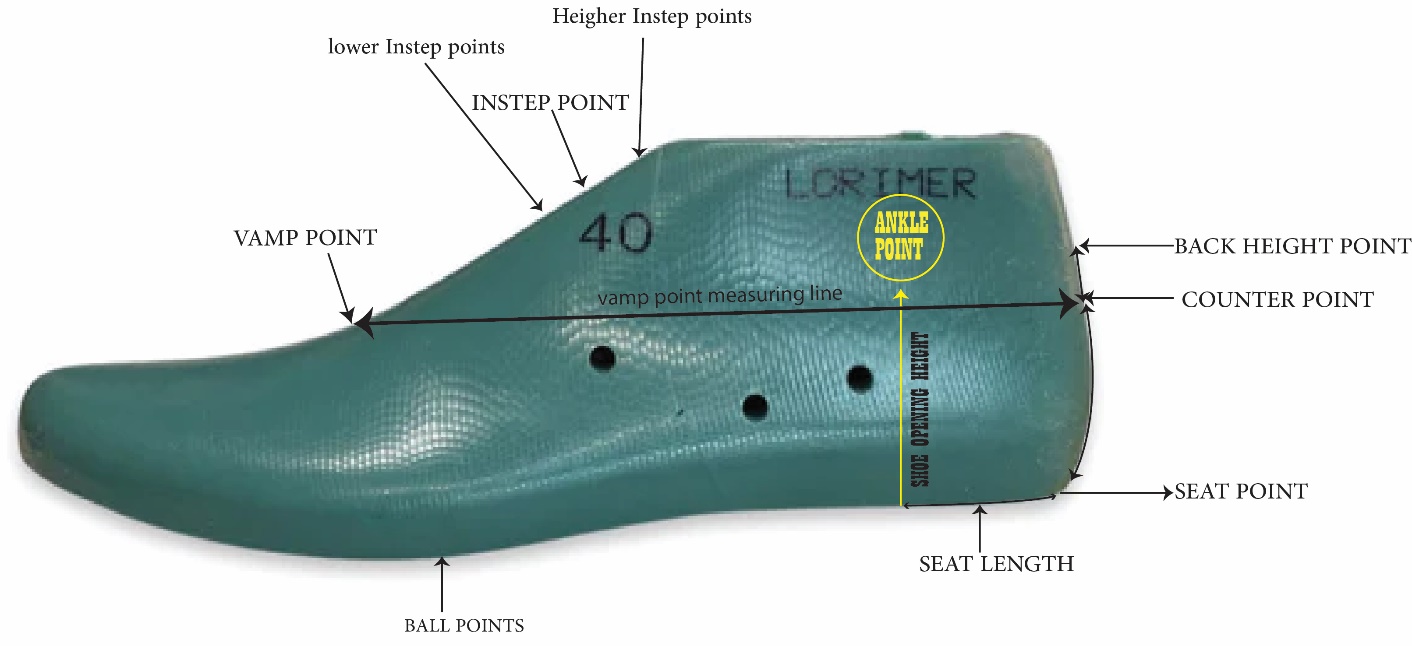

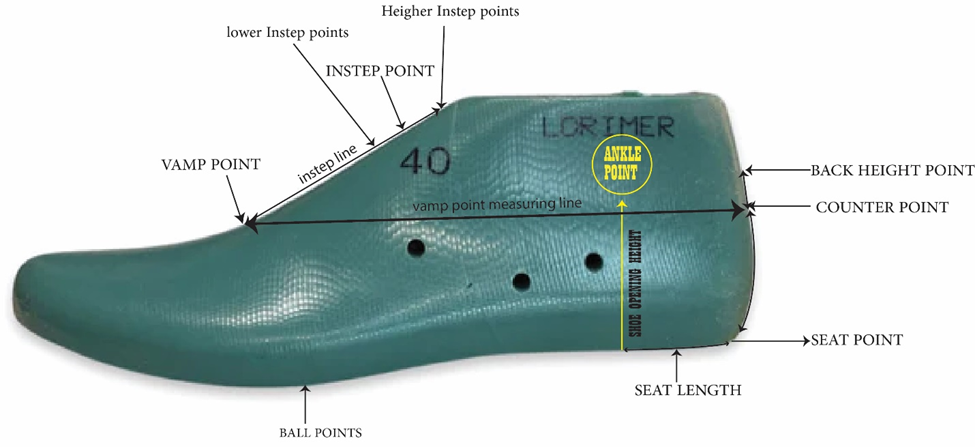

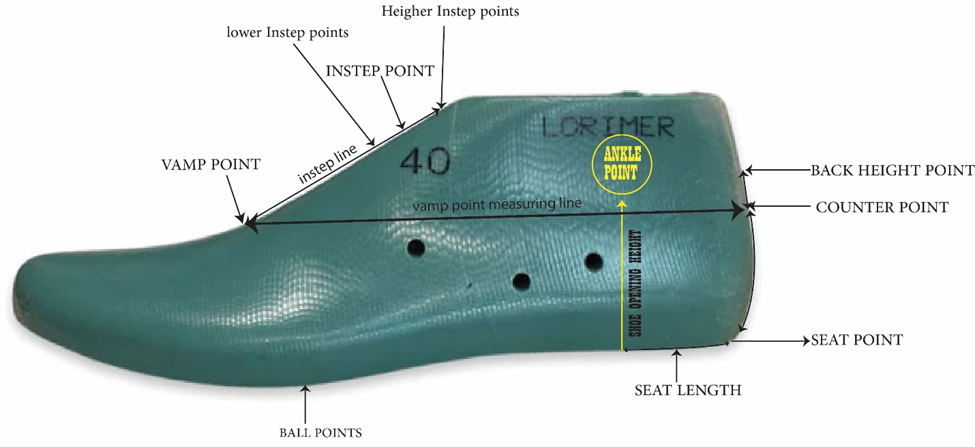

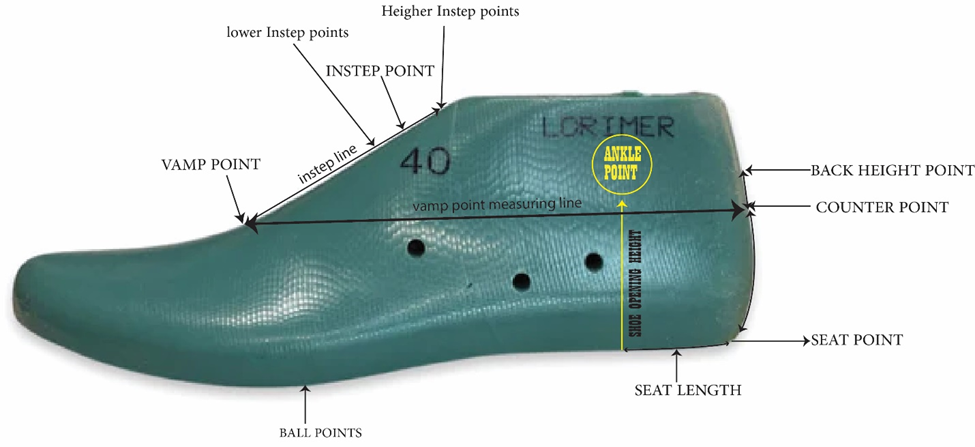

Fig-1(Essential measuring points on last)

Before calculating the essential measuring points for each design style, it is crucial to understand the various types of last lengths.

- Last length:

There are the following kinds of last lengths:

- Absolute Length: The exact length of the foot from seat to toe, also known as the foot length, illustrated in Figure 1.

Absolute Last Length = Foot Length

Figure-2(Foot Length)

Figure-2(Foot Length)

- Standard Last Length: This length is fixed for any shoe style and is derived from the foot length plus an extended allowance due to applied body weight. It is categorized as follows:

- Infant Standard Last Length (ISLL)

- Children Standard Last Length (CSLL)

- Adults Standard Last Length (ASLL)

The Data on foot dimension expansion with body weight application has been collected from various age groups. The average length expansion is 13 mm, and width expansion at the metatarsophalangeal joints/ball girth is 10 mm, illustrated in Figure 2.

Figure-3(Standard Last Length)

Hence, Standard Last Length = Foot Length + Extension Allowance (13 mm)

Another way to calculate the standard last length is:

- Standard Last Length for Least Foot (SLL) = (Size) X 1/3 Here, Size = English Points, 1/3 = the difference between two English sizes

The least foot is the origin of the sizing system, equal to 12 English points. Hence, SLL = Size * 1/3 = 12/3 = 4 Inches = 101.6 mm

- Standard Last Length for Children (CSLL) = (Size) X 1/3” + 4” Here, Size = English Size System, 1/3 = the difference between two English sizes

Children size range is (1-13) English Points.

For example, CSLL for size 1 = (1/3) + 4” = 4.33 Inches = 110 mm CSLL for size 13 = (13/3) + 4” = 8.33 Inches = 211.5 mm

After size 13-1/2 English Points, sizes start again from 1, 2, 3, 4 for Ladies and Men's sizes.

- Standard Last Length for Adults (Women’s and Men’s Sizes) = (13 + Size in EP) * 1/3 + 4” For example, for size 1: (13 + 1) * 1/3 + 4 = 14/3 + 4 = 8.66 Inches = 220.13 mm

All pattern design parameter calculations for any shoe style are based on the standard last length.

- Relative Last Length: This length is variable based on the design style and is directly proportional to the fashion allowance.

Hence, Relative Last Length = Standard Last Length + Fashion Allowance

Figure-4(Relative Last Length)

while the Relative last length is variable.

Now we have to do the calculations of the important measuring points of the last as per the style of the design.it is essential to note that the calculations of the measuring points must be based on the standard last length of the particular size as I have explained in the above last length paragraph.

Figure-5(measuring points on the last for pattern making)

B. Essential Measuring Points for Pattern Making

The essential measuring points on the last for pattern making include:

- Vamp Points

- Lower Instep Points

- Instep Points

- Higher Instep Points

- Counter Points

- Back Height Points

- Seat Point

- Seat Length

- Shoe Opening Height Under Ankle Position

Let us do the calculations of the essential measuring points of the footwear patterns as per the styles of the design.

Here are the following essential measuring points calculation as per the styles of the design.

Sneakers

Figure-6(Sneaker Design)

C. Calculation of Essential Measuring Points

1) Sneakers

- Vamp Point: Vamp Point = ¾ * SLL For Size 6, SLL = (13 + 6) * 1/3 + 4 inches = 19/3 + 4 = 10.33 inches = 262.46 mm Hence, Vamp Point = ¾ * 262 = 196.5 mm

Measure the vamp point from the counter point using a measuring tape, taking the calculated distance of 196.5 mm.

- Instep Point: Instep Point = ¼ * SLL + 19 mm = 84.5 mm

Measure the instep point from the vamp point, taking the calculated distance of 84.5 mm.

- Counter Point: Counter Point = 1/5 * SLL = 52.4 mm

Measure the counter point at a distance of 52.4 mm from the seat point.

- Back Height Point: Back Height Point = Counter Point + 19 mm = 71.4 mm

Measure the back height from the seat point at a distance of 71.4 mm.

- Seat Length: Seat Length = ¼ * SLL = 65.5 mm

Measure the seat length from the seat point at a distance of 65.5 mm.

- Shoe Opening Height: Shoe Opening Height = 1/5 * SLL = 52.4 mm

Measure the shoe opening height from the seat length point at a distance of 52.4 mm.

Calculations:

2) Vamp Point = ¾*SLL

Where SLL for 6 Size = (13+6) *1/3+4 inches

= 19/3+4

= 10.33 inches

= 10.33*25.4

= 262.46 mm

Hence,

Vamp point = ¾*SLL

= ¾*262

= 196.5 mm

Now,

Measure the vamp point with the measuring tape from counter point to vamp point by taking the calculated distance of 196.5 mm. which is the most flexible portion of the foot that is the phalanges and the metatarsals joints.

Figure-7(Sneaker vamp point calculation)

3) Instep point for sneaker = ¼*SLL+3/4th inches / 19 mm

= ¼*262+19 mm

= 84.5 mm

Now,

Measure the sneaker instep point from the vamp point by taking the calculated distance of 84.5 mm. consider the given below diagram for the instep point position.

Figure-8(Sneaker Instep point calculation)

Figure-8(Sneaker Instep point calculation)

4) Counter point = 1/5*SLL

= 1/5*262 mm

= 52.4 mm

Now,

Measure the counter point at a distance of 52.4 mm from seat point as illustrated in the above diagram.

5) Back height point for the sneakers = counter point + 3/4th inches or 19 mm

= 52.4+19 mm

= 71.4 mm

Now,

Measure the back height from the seat point at a distance of 71.4 mm as illustrated in the above diagram.

6) Seat length = ¼*SLL

= ¼*262 mm

= 65.5 mm

Now,

Measure the seat length from the seat point at a distance of 71.4 mm as illustrated in the above diagram.

7) Under ankle position / Shoe opening height = 1/5th *SLL

= 1/5*262 mm

=52.4mm

Now,

Measure the shoe opening height from the seat length point at a distance of 52.4 mm as illustrated in the above diagram

Figure-9(Moccasin Shoes)

Figure-9(Moccasin Shoes)

8) Moccasin

- Vamp Point: Vamp Point = ¾ * SLL = 196.5 mm

Figure-10(Moccasin Vamp Point calculation)

Measure the vamp point with a measuring tape from counter point to vamp point by taking the calculated distance of 196.5 mm.

- Instep Point: Instep Point = 1/5 * SLL = 52.4 mm

Figure-11(Moccasin Instep Point calculation)

Measure the moccasin instep point from the vamp point by taking the calculated distance of 52.4 mm.

- Counter Point: Counter Point = 1/5 * SLL = 52.4 mm

Figure-12(Moccasin Instep Point calculation)

Measure the counter point at a distance of 52.4 mm from the seat point.

- Back Height Point: Back Height Point = Counter Point + 6 mm = 58.4 mm

Figure-13(Moccasin Back Height Point calculation)

Measure the back height from the seat point at a distance of 58.4 mm.

- Seat Length: Seat Length = ¼ * SLL = 65.5 mm

Figure-14(Moccasin Back Height Point calculation)

Measure the seat length from the seat point at a distance of 65.5 mm.

- Shoe Opening Height: Shoe Opening Height = 1/5 * SLL = 52.4 mm

Figure-15(Moccasin Back Height Point calculation)

Measure the shoe opening height from the seat length point at a distance of 52.4 mm.

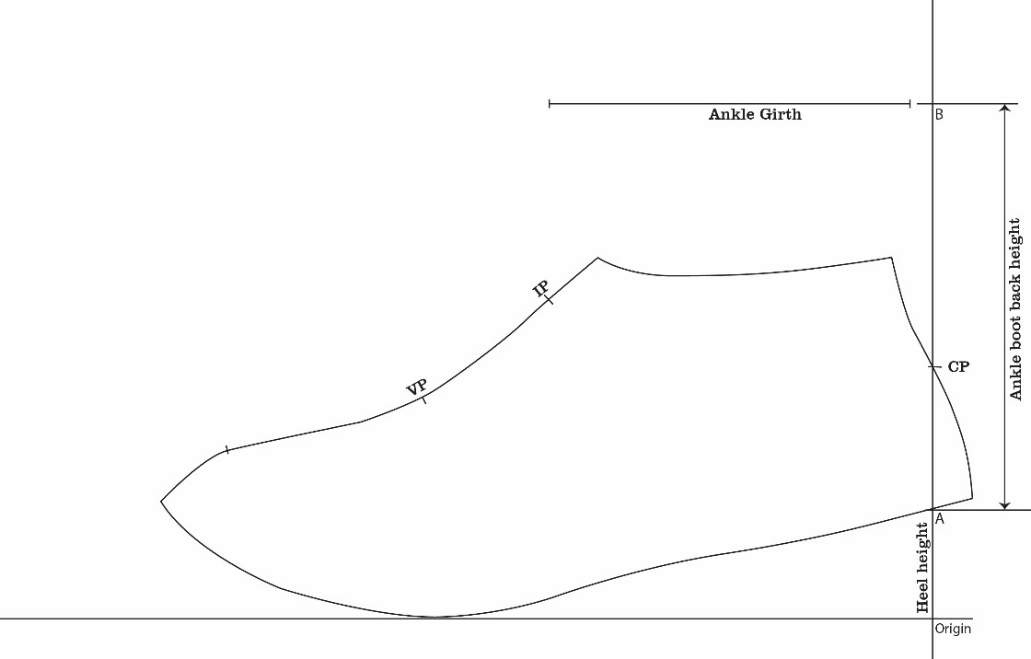

Ankle boot

Figure-16(Ankle boot)

- Vamp Point: Vamp Point = ¾ * SLL = 196.5 mm

Measure the vamp point with a measuring tape from counter point to vamp point by taking the calculated distance of 196.5 mm.

Figure-17(Ankle boot Vamp Point Calculation)

- Instep Point: Instep Point = ¼ * SLL ± 2 = 67.5 mm

Figure-18(Ankle boot Instep Point Calculation)

Measure the ankle boot instep point from the vamp point by taking the calculated distance of 67.5 mm.

- Counter Point: Counter Point = 1/5 * SLL = 52.4 mm

Figure-19(Ankle boot Instep Point Calculation)

Measure the counter point at a distance of 52.4 mm from the seat point.

- Back Height Point: Back Height Point = ½ * SLL + 1 mm = 132 mm

Figure-20(Ankle boot Back Height Point Calculation)

Figure-20(Ankle boot Back Height Point Calculation)

Measure the back height from point A at a distance of 132 mm to point B.

- ½ Ankle Girth: For size 7 = 115 mm Add 3 mm while increasing size and subtract 3 mm while decreasing size. For example, size 8 = 118 mm, size 6 = 112 mm.

Figure-21(Ankle boot Girth Calculation)

Figure-21(Ankle boot Girth Calculation)

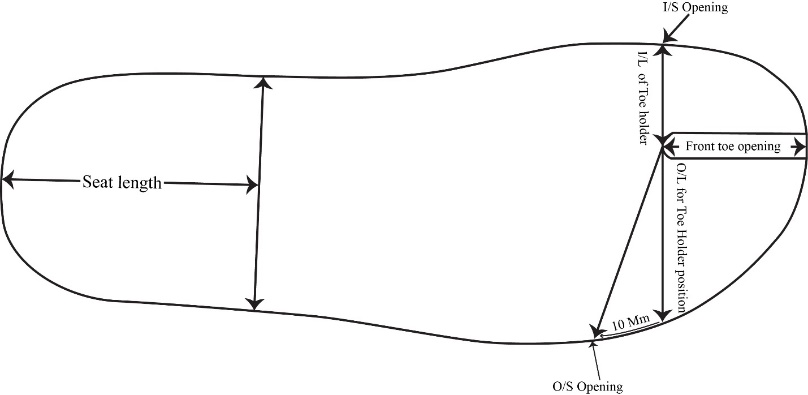

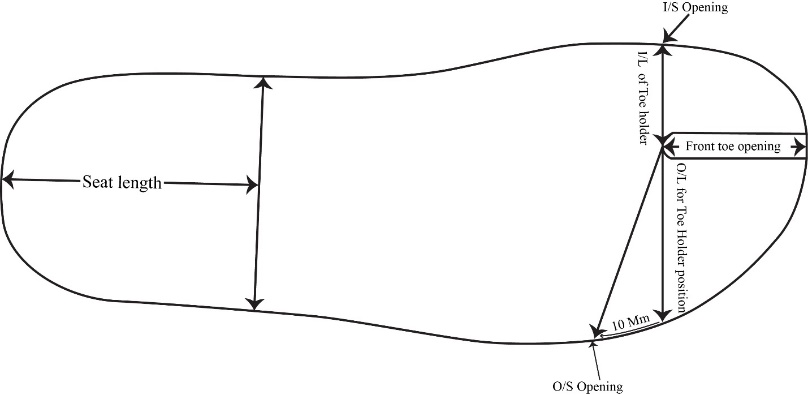

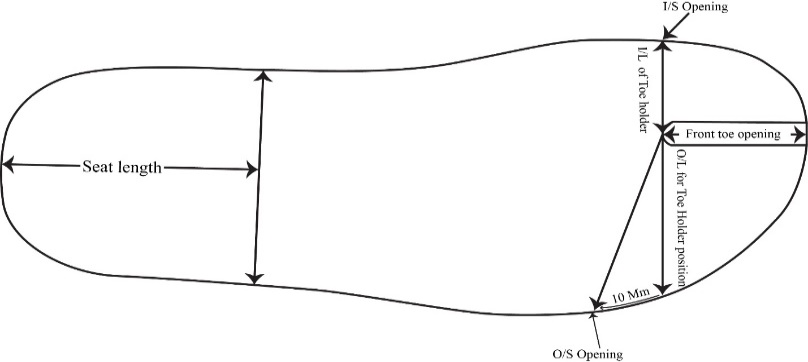

Sandal/ Flip-flop

Figure-22(Sandal/Flip-Flop)

9) Sandal/Flip-Flop

- Vamp Point: Vamp Point = ¾ * SLL = 196.5 mm

Figure-22(Sandal/Flip-Flop Vamp Point Calculation)

Figure-22(Sandal/Flip-Flop Vamp Point Calculation)

Measure the vamp point with a measuring tape from counter point to vamp point by taking the calculated distance of 196.5 mm.

- Higher Instep Point: Higher Instep Point = ¼ * SLL + 12 = 77.5 mm

Measure the higher instep point from the vamp point by taking the calculated distance of 77.5 mm.

Figure-22(Sandal/Flip-Flop Instep Point Calculation)

- Counter Point: Counter Point = 1/5 * SLL = 52.4 mm

Figure-23(Sandal/Flip-Flop Counter Point Calculation)

Figure-23(Sandal/Flip-Flop Counter Point Calculation)

Measure the counter point at a distance of 52.4 mm from the seat point.

- Back Height Point: Back Height Point = 1/5 * SLL + 12 mm = 64 mm

Figure-24(Sandal/Flip-Flop Back Height Point Calculation)

Measure the back height from the seat point at a distance of 64 mm.

- Front Toe Opening: Front Toe Opening = 1/6 * SLL = 44 mm

Figure-25(Sandal/Flip-Flop Front Toe Opening Calculation)

- Seat Length/Back Opening: Seat Length = ¼ * SLL + 5 mm = 70.5 mm

Figure-26(Sandal/Flip-Flop Seat Length Calculation)

Measure the seat length from the seat point by taking the distance of 70.5 mm.

- Inner Length of Toe Holding Position: Inner Length = 1/8 * SLL = 33 mm

Figure-27(Sandal/Flip-Flop Inner Length Calculation)

Measure the inner length for toe holding position by taking the calculated distance of 33 mm.

- Outer Length of Toe Holding Position: Outer Length = 1/6 * SLL + 3 mm = 47 mm

Figure-28(Sandal/Flip-Flop Outer Length Calculation)

Measure the outer length for toe holding position by taking the calculated distance of 47 mm.

IV. FOOTWEAR PATTERN GRADING

Footwear pattern grading is a technique employed within the footwear manufacturing sector to systematically adjust the dimensions of a footwear pattern in order to generate various sizes while preserving the original design proportions and fit characteristics. This process entails either enlarging or reducing a master pattern, typically following a predetermined grading rule or size chart, to produce patterns suitable for different shoe sizes within a given product range.

The grading procedure ensures that each size iteration of the footwear maintains consistent design aesthetics, fit, and functionality akin to the original pattern. This involves precisely scaling the dimensions of the pattern components, such as length, width, and height, in a controlled and uniform manner to achieve precise sizing across a spectrum of shoe sizes.

There are the following types of most popular pattern grading.

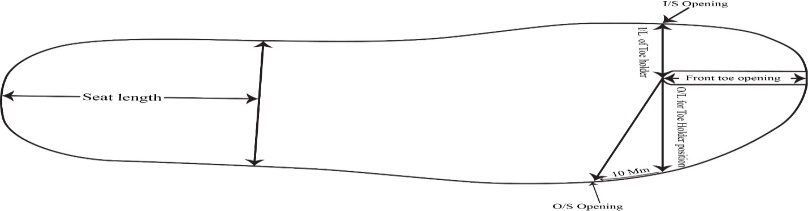

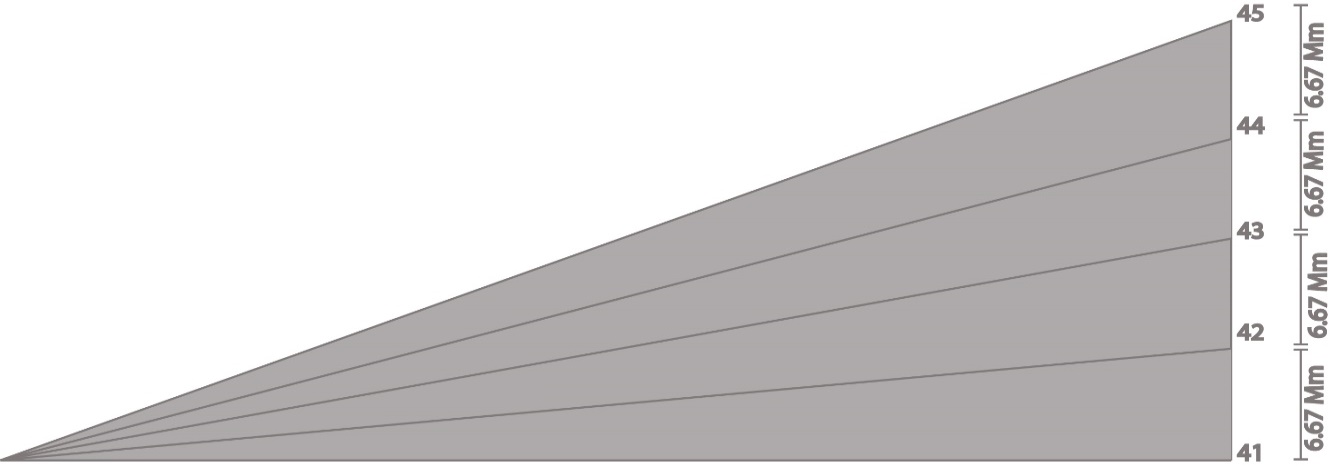

1) French grading system: in this types of the grading system the length and girth increment are as follows:

- Length increase or decrease from one size to another = 6.67 mm

- Girth increase or decrease from one size to another = 4.5 mm

Figure-29(French Grading Length and Girth Calculation)

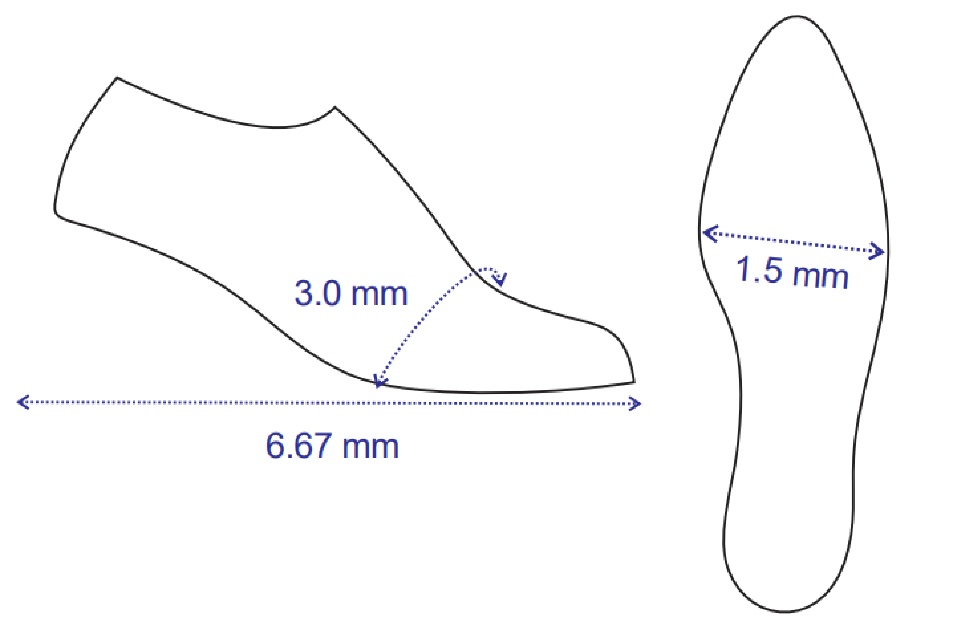

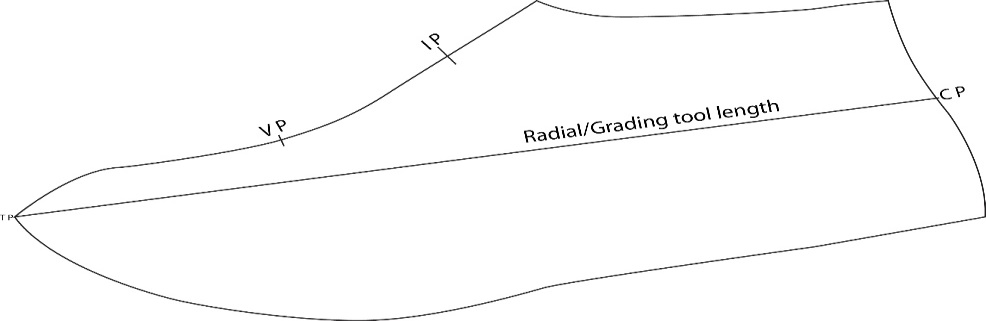

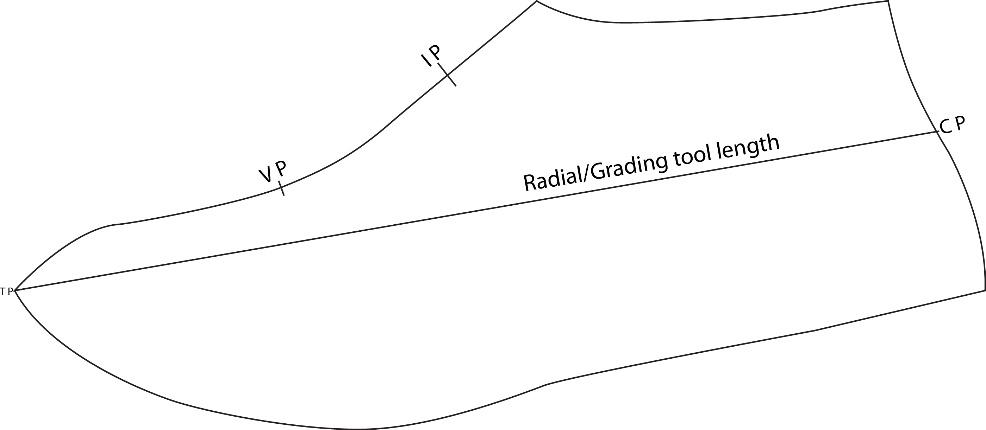

Radial/Grading tool dimension in French size system

This is a tool which is used to do the manual grading of the footwear standard and patterns.

The dimensions of the Radial tools are as follows:

- The length of the radial tools can be achieved by measuring the distance of the mean forms or upper standard from the counter points to toe points. Which has been illustrated in blow diagrams.

Figure-30(Radial Tool Calculation)

- Width side will measure the size increasing or Decreasing dimensions from one size to another

Figure-31(Radial Tool Height Calculation)

Figure-31(Radial Tool Height Calculation)

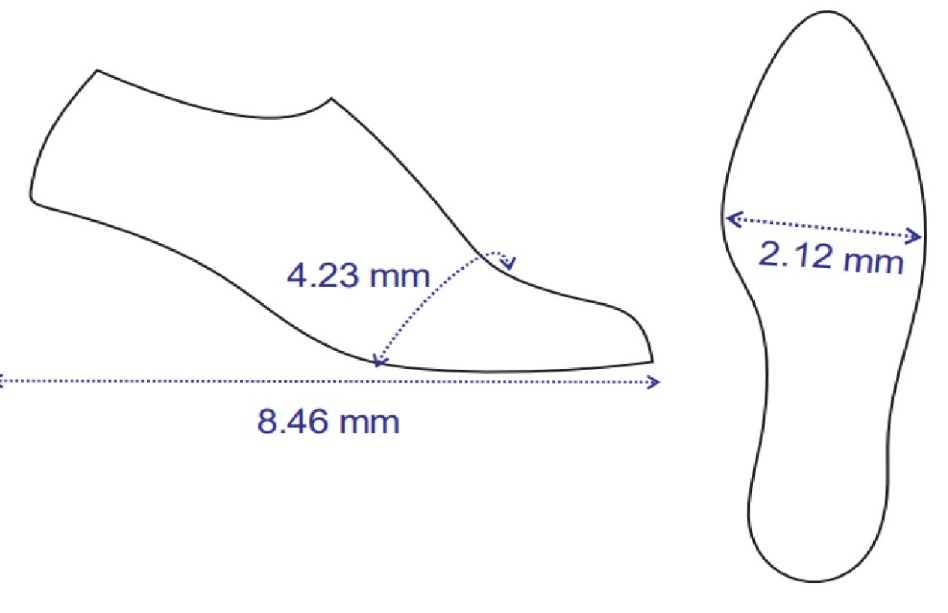

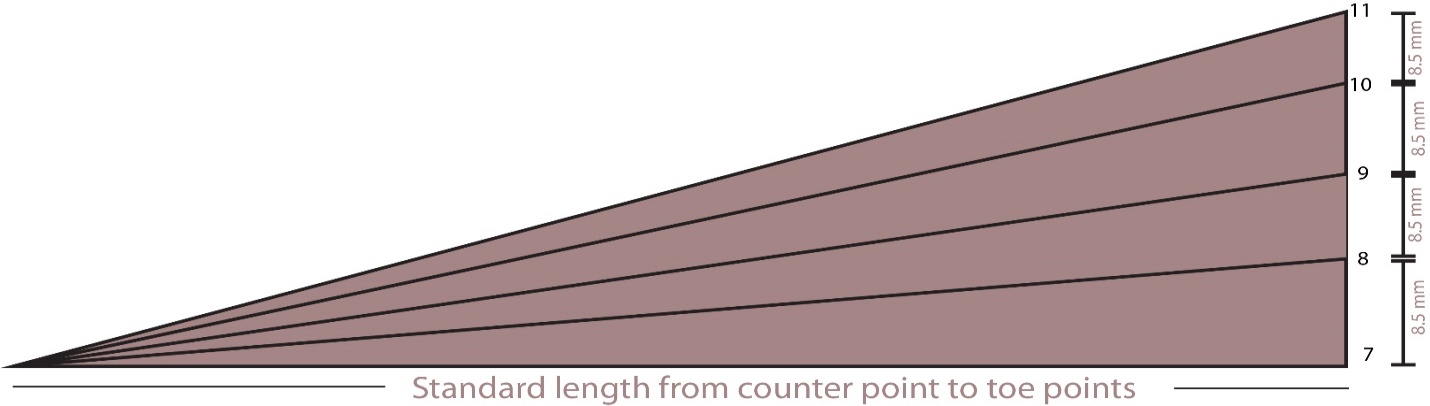

2) English grading system: in this types of the grading system the length and girth increment are as follows:

- Length increase or decrease from one size to another = 8.46 mm

- Girth increase or decrease from one size to another for children ranges (0-10-1/2) =3/16 inch = 4.76 mm

- Girth increase/decrease from one size to another for adults ranging from 1-onword= ¼ inch= 6.35 mm

Figure-32(English Grading Length and Girth Calculation)

Radial/Grading tool dimension in English size system: this is a tool which is used to do the manual grading of the footwear standard and patterns.

The dimensions of the Radial tools are as follows:

- The length of the radial tools can be achieved by measuring the distance of the mean forms or upper standard from the counter points to toe points. Which has been illustrated in blow diagrams.

Figure-33(Radial Tool Calculation)

Figure-33(Radial Tool Calculation)

- Width side will measure the size increasing or Decreasing dimensions from one size to another

Figure-33(Radial tools for English size grading)

Figure-33(Radial tools for English size grading)

V. CASE STUDY

Application of Measurement-Based Pattern Making and Grading

All the above mentioned pattern making and grading calculations has been takin from the industrial experts after doing research and product development practices on the different styles of the design of the variable sizes. The multiple variations of the designs of the footwear made with the application of the above mentioned pattern making and grading calculations and also have been verified the fitting and balancing of the products and launched into the market for the consumer use and got the positive response of the sold products.

Conclusion

This research paper has thoroughly explained the pattern-making and grading calculations based on international standards for all size variations, ranging from infants to adult men and women. Utilizing these researched pattern-making and grading calculations, designers and pattern technicians can easily determine all the necessary parameters for various styles, such as shoes, boots, sandals, and flip-flops in footwear design. Previously, it was challenging to identify exact pattern parameters, such as vamp point, instep point, back height point, etc., for specific sizes and styles to achieve a perfect fit and balance in the final products without creating multiple prototypes. A. Contributions to the Field The pattern-making and grading calculations presented are crucial for footwear last developers and pattern makers in the footwear manufacturing industry. Without knowledge and practice of these calculations, designers, last developers, and pattern technicians cannot create accurate blueprints that translate design imagination into tangible products. These calculations are fundamental for both manual and computerized pattern making and grading processes B. Implications for Practice The pattern-making and grading calculations outlined in this research are vital for achieving a perfect fit and accurate balance in the blueprints of any footwear design style. Implementing these calculations will resolve various imperfections in pattern fit and balance, enabling the creation of multiple size grades without compromising the proportions of the master patterns. This methodology will assist in fixing all pattern parameters across the size range from infants to adult men and women. Additionally, this research is essential for developing specification sheets that preserve pattern parameters for specific design models in the manufacturing industry, aligning with trends observed in the apparel manufacturing sector.

References

[1] Wade, Motavi. (2020) Footwear Pattern Making and Last Design. Chandler: wade’s place. [2] Aki Choklat. (2012) Footwear Design. London: Laurence King Publishing, Ltd.

Copyright

Copyright © 2024 Hafiz Obaidullah. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64002

Publish Date : 2024-08-17

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online