Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Fully Automatic Solar Grass cutter

Authors: Mohit Joshi, Harsh Chaurasiya, Prashant Kumar, MS.Upasana Sharma

DOI Link: https://doi.org/10.22214/ijraset.2024.62427

Certificate: View Certificate

Abstract

The term \'Embedded\' signifies the integration of multiple independent devices into a single chip, commonly referred to as a System on Chip (SoC). The advent of VLSI technology has enabled the creation of high-speed, cost-effective, low-power, and co impact integrated circuits. The microcontroller employed for these applications is often referred to as an IBP (Itty Bitty Processor) or an embedded processor. \"Multi-task oriented systems may introduce time delays, which can be inefficient in certain applications. In such scenarios, microcontrollers play a crucial role in embedded system design. In this context, we have developed a versatile embedded system application titled \'PC-controlled pick and place Robot.\' This project serves as a demonstration of the effective utilization of automation and is structured around the integration of a microcontroller and a personal computer (PC). \"The objective of our project is to manage the robot using commands transmitted via Zigbee protocol communication from a personal computer. These commands include F (forward), B (backward), L (left), R (right), U (up), and Down (pick). The wireless control facilitates the manipulation of the robot\'s position through Zigbee interfacing with the PC.\" \"In the receiver section, the Zigbee receiver receives commands transmitted from the Zigbee transmitter, guiding the movements of the robot. This project is powered by a regulated 5V, 750mA power supply, utilizing a 7805 three-terminal voltage regulator for voltage regulation. To rectify the AC output of the secondary 230/18V step-down transformer, a bridge-type full-wave rectifier is employed.\"

Introduction

I. INTRODUCTION

A wireless grass-cutting robot designed to execute specific tasks in unstructured environments without constant human oversight. Various types of robots exhibit a degree of autonomy, each employing distinct methods. High autonomy proves especially beneficial in fields like space exploration, where communication delays and interruptions are inherent challenges."

"In the wireless grass-cutting robot application, two servo motors are employed to govern the robot. The microcontroller utilizes kinematics algorithms to ensure position control over the motors. PWM channels of the microcontroller, along with MOSFET-based power amplifiers and transistors, are employed for motor control. The control of the robotic arm has been successfully achieved using either servo motors or DC motors. The microcontrollers implement inverse kinematics algorithms for precise position control over the motors. Motor actuation is carried out using the internal PWM channels of the microcontroller, alongside MOSFET-based power amplifiers, transistors, or driver circuits. The robotic arm is also equipped for external control, featuring a two-finger gripper as its end effector. With a load-bearing capacity of approximately 500, the device incorporates built-in logic, and all its movements are meticulously controlled by the motors. The operating speed of the pickup arm can be adjusted to meet specific requirements."

"It is crucial for a robot to operate on batteries. Given that the microcontroller functions at 5V, it is imperative that the motors operate within the range of 3-5V. Additionally, it is essential to limit the current consumption to prevent the batteries and control circuit from becoming excessively large and heavy. In this particular design, we incorporate an integrated motor driver chip known as L293D. This motor driver chip can handle peak loads of up to 0.5A. Hence, the motors should ideally require less than 0.5A, even under the most demanding conditions."

The robot is designed with two motors, enhancing its hardware versatility. The entirety of the logic is implemented in the software, allowing for significant flexibility. This implies that through software modifications, nearly every aspect of the robot can be altered according to specific preferences and requirements.

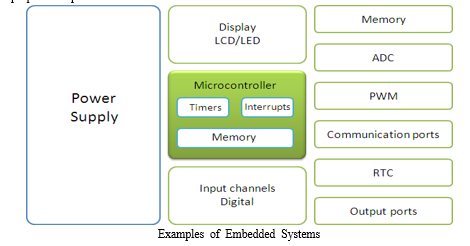

II. INTRODUCTION TO EMBEDDED SYSTEMS

A. Technology Used

An embedded system is a computer system that is engineered to carry out one or several specific functions, often with real-time computing restrictions. It’s usually incorporated into a larger device that includes both hardware and mechanical elements. This is in contrast to a general-purpose computer, such as a personal computer, which has the ability to perform a broad range of tasks based on programming. Embedded systems are vital in controlling a multitude of the devices we use on a daily basis.

Embedded systems, being designed for particular tasks, allow engineers to optimize them. This optimization can lead to a reduction in the product’s size and cost, or an increase in its reliability and performance. Some embedded systems are produced on a large scale, utilizing economies of scale to achieve greater efficiency and cost-effectiveness.

Embedded systems come in a wide variety of physical forms, from small portable devices like digital watches and MP4 players, to large stationary installations like traffic lights, factory controllers, or the systems that control nuclear power plants. The complexity of embedded systems can range from simple setups with a single microcontroller chip, to complex arrangements involving multiple units, peripherals, and networks housed within a large chassis or enclosure.

The term “embedded system” doesn’t have a strict definition, as many systems have some level of programmability. For example, handheld computers have some similarities with embedded systems in terms of their operating systems and microprocessors. However, they are not strictly considered embedded systems because they have the ability to run different applications and connect with peripherals. In addition, embedded systems are often designed to be energy efficient, which is crucial for battery-operated devices. They also typically have robust designs to withstand varying operating conditions and to ensure long-term functionality. Furthermore, due to their dedicated functionality, embedded systems often have user interfaces that are specifically designed for the task at hand, which can make them more intuitive to use than general-purpose computers. Lastly, because embedded systems are typically designed for specific tasks, they can be fine-tuned to ensure optimal performance and efficiency, which is not always possible with general-purpose computers.

III. EXAMPLES OF EMBEDDED SYSTEMS

Embedded systems are omnipresent in all aspects of contemporary life, with numerous instances underscoring their varied applications. Telecommunication systems heavily rely on embedded systems, from telephone switches within the network to mobile phones at the user end. In the realm of computer networking, dedicated routers and network bridges are pivotal in data routing, demonstrating the extensive incorporation of embedded systems in diverse technological fields.

A broad spectrum of devices in consumer electronics, including personal digital assistants (PDAs), MP3 players, mobile phones, video game consoles, digital cameras, DVD players, GPS receivers, printers, and even various household appliances like microwave ovens, washing machines, and dishwashers, fall under the umbrella of embedded systems. These systems augment these devices by providing increased adaptability, efficiency, and additional features, thereby enhancing overall functionality and user experience.

Advanced Heating, Ventilation, and Air Conditioning (HVAC) systems utilize networked thermostats to accurately and efficiently regulate temperature, adapting to changes in time of day and season. Home automation uses both wired and wireless networking to control various aspects such as lighting, climate, security, audio/visual systems, surveillance, and more. Embedded devices are crucial in sensing and controlling these functionalities within the scope of home automation. Transportation systems, from aviation to automobiles, are becoming increasingly dependent on embedded systems. In the aviation industry, new airplanes are equipped with advanced avionics, including inertial guidance systems and GPS receivers, which are essential for navigation and safety compliance. Electric motors, including brushless DC motors, induction motors, and DC motors, utilize electric or electronic motor controllers, underlining the integration of embedded systems.

In the automotive industry, automobiles, electric vehicles, and hybrid vehicles are incorporating embedded systems to improve efficiency and reduce pollution. These systems are crucial in optimizing performance. Advanced automotive safety systems like Anti-Lock Braking System (ABS), Electronic Stability Control (ESC/ESP), Traction Control System (TCS), and automatic four-wheel drive are examples of how embedded systems contribute to enhancing safety and overall vehicle performance, demonstrating the diverse applications of embedded systems in enhancing both vehicle performance and safety.

The medical equipment field continues to evolve, integrating more embedded systems for various applications. In the medical field, embedded systems play a crucial role in monitoring vital signs, enhancing capabilities like electronic stethoscopes for sound amplification, and powering various medical imaging technologies such as PET (Positron Emission Tomography), SPECT (Single Photon Emission Computed Tomography), CT (Computed Tomography), and MRI (Magnetic Resonance Imaging). These systems enable non-invasive internal inspections and significantly contribute to diagnostic procedures and patient care.

Alongside traditional embedded systems built on small computers, there’s a growing trend in miniature wireless devices known as “motes.” These motes are gaining popularity, especially with the growth of wireless sensor networking (WSN). They’re designed to operate wirelessly, often with limited resources, and are integral to the development of interconnected sensor networks for various applications, including environmental monitoring, smart buildings, healthcare systems, and more. Their compact size and wireless capabilities make them versatile for diverse implementations within the realm of sensor networks. WSN utilizes miniaturization enabled by advanced IC design to integrate full wireless subsystems with sophistication.

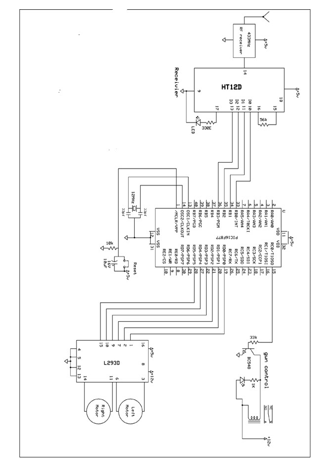

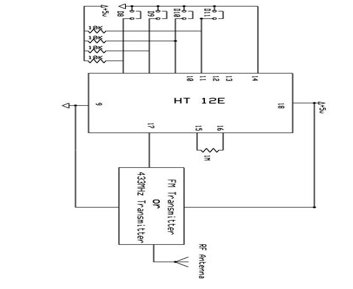

IV. CIRCUIT DIAGRAM

V. RECEIVER

VI. WORKING

For RF tag transmission, an HT12E Decoder IC is used. The 212 encoders, a series of CMOS LSIs, are specifically designed for remote control system applications. They can encode information that includes N address bits and 12-N data bits. Each address/data input can be set to one of two logic states. The programmed addresses/data are transmitted along with header bits via an RF or infrared transmission medium when a trigger signal is received. The versatility of the 212 series of encoders is enhanced by the option to select a TE trigger on the HT12E or a DATA trigger on the HT12A. Additionally, the HT12A provides a 38kHz carrier for infrared systems.

To ensure the local control section functions correctly, a continuous and permanent 5V backup is required. This backup is provided through the following components:

- 230V to 12V Transformer: This transformer steps down the voltage from 230V to 12V.

- Bridge Rectifier: The bridge rectifier converts the AC output from the transformer into DC.

- Capacitor Filter: The capacitor filter smoothens the rectified DC output, reducing ripples and providing a more stable voltage.

- 5V Regulated Power Supply: The voltage-regulated IC 7805 regulates the voltage and delivers a stable 5V output. This regulated 5V source is essential for the proper functioning of integrated circuits (ICs) and relays in the control section.

This 5V source is then connected to all ICs and relays, ensuring a consistent and reliable power supply for the components in the local control section of the system. In addition to these components, the system may also include various sensors and actuators, depending on the specific application. Sensors are used to monitor the environment and provide feedback to the control system, while actuators are used to perform actions based on the control signals. These components are also powered by the 5V source and are controlled by the ICs in the system. Furthermore, the system may also include a communication interface for transmitting data to and from other systems. This could be a wired interface, such as RS-232 or Ethernet, or a wireless interface, such as Bluetooth or Wi-Fi. The communication interface allows the system to interact with other systems and devices, expanding its capabilities and applications. Finally, the system may also include a user interface, such as a display and buttons, for user interaction. The user interface allows users to input commands and receive feedback from the system, making it more user-friendly and accessible. The user interface is also powered by the 5V source and is controlled by the ICs in the system.

Overall, the design and implementation of such a system require a deep understanding of both hardware and software, as well as the specific requirements of the application. Despite the complexity, the benefits of such systems, such as their efficiency, flexibility, and reliability, make them an essential part of many modern technologies.

Conclusion

This project presents a design approach for a solar-powered automated grass cutter. The main goal of this system is to autonomously mow grass without the need for human intervention. The project’s key components and features include: 1) Solar Power Operation: The grass cutter is engineered to run on solar power, highlighting sustainability and eco-friendliness. Solar energy is captured to power the system. 2) Sensor Integration: Sensors are integrated to improve the grass cutter’s functionality. Specifically, an Arduino is used to process sensor data, enabling the system to make informed decisions and navigate its surroundings. 3) Obstacle Avoidance: The project includes an ultrasonic sensor for obstacle avoidance. This sensor assists the grass cutter in identifying obstacles in its path and automatically alters its course to prevent collisions. 4) Power Backup with Inverter: To guarantee uninterrupted operation, the system is equipped with a power backup solution in the form of an inverter. This feature enhances the system’s resilience, allowing it to continue operating even when direct solar power is unavailable. 5) Cost-Efficiency and Reliability: The proposed system is designed to be cost-effective while ensuring a high degree of reliability. By harnessing solar power, implementing obstacle avoidance, and including a power backup system, the project aims to deliver an efficient and reliable solution for mowing grass. In conclusion, this automated grass cutter project merges renewable energy sources, sensor technology, and backup systems to develop an environmentally friendly and dependable solution for lawn maintenance that doesn’t require ongoing human intervention.

References

[1] “Design and Development of a Solar Powered Lawn Mower”: International Journal of Scientific & Engineering Research, Volume 5, Issue 6, June 2014. [2] Hydrogen Powered Lawn Mower”. Int. J. Hydrogen Energy 1993; 18, 345-348. [3] “Simple Design of Self-Powered Lawn Mower”: International Journal of Engineering [4] “Smart Lawn Mower for Grass Trimming”: Volume 3 Issue 3, March 2014/www.ijsr.net. [5] Boyles tad, R., & Mashelsky, l. (1996). Electronics Devices and Circuit Theory. New Jersey, Prentice Hall Inc. [6] Conaster, B., Nastasi, D., & Phipps, K. (2002). Following the Trail of Destruction, Power Quality Magazine, pp 62-66 [7] Brum sickle, W. E., Divan, D. M., Luck jiff, G. A., Freeborg, J. W., & Hayes, R. L. (2003). [8] Operational Experience with a Nationwide Power Quality and Reliability Monitoring System, IEEE-IAS Annual Meeting Conf. Record, Vol 2, pp. 1063 – 1067. [9] Conway, G. A., & Jones, K. I. (2002). Harmonic currents produced by variable speed drives [10] Divan, D., Luck jiff, G. A., Brum sickle, W. E., Freeborg, J., &Bhadkamkar, A. (2004). A grid information resource for nationwide real-time power monitoring. IEEE Transactions on Industry Applications, Volume: 40, Issue: 2, Pages: 699.

Copyright

Copyright © 2024 Mohit Joshi, Harsh Chaurasiya, Prashant Kumar, MS.Upasana Sharma. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62427

Publish Date : 2024-05-21

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online