Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Generative Landscape Elements: Paving patterns

Authors: Ar. Piyush Pant, Ar. Monica Sharma

DOI Link: https://doi.org/10.22214/ijraset.2023.48901

Certificate: View Certificate

Abstract

One of the basic works which is frequently done in any landscape project is designing a paving pattern. It sounds easy, but to derive a pattern with a set of design goals, requires various hit and trails to get into the final one. There are lot of parameters which we have to cover based on the requirements and context of the site. For Example, Choosing the right proportion of colors, Right Proportion of the material types, Right Sizes of the paving material, Various arrangements and possibility of pattern design, testing various arrangements using different materials of various shapes and sizes and the list goes on. To do all those things manually is a very complex and impossible job, and even if it’s possible the time invested is too high and there is a limitation on the number of design options we can test to achieve our design goal with regular tools. In this article with the help of a test example, we will see how we can solve the above issue by using generative design process, which is very iterative, where we create a parametric model first which has a set of design goals, then using the same data-set we can use optimization engine to go through all alternatives and gives the best filtered results in no time.

Introduction

I. INTRODUCTION

In the field of architecture generative design process is the way to explore the design and also generate High-performance design Alternatives by using a single design idea. When it comes to derive design alternatives manually there is a limitation due to time constraints and other factors, we will not able to generate as many numbers of alternatives as we can do by using generative design process based on single set of design parameter or design idea. As a designer we know what kind of design we want to achieve, we also know various parameters on which we want our design to be tested and get qualified, for example, how will a specific material perform in a given context, we can analyse in advance before using it live on site. There is a wide range of application of generative design in the field of architecture. Be it landscape, or urban design or any other specific field, nothing is left untouched from generative design.

II. ADVANTAGES OF GENERATIVE DESIGN PROCESS

There are various advantages of Generative design and they are increasing with the time, few of the significant advantages can start with generating a large range of design options with one set of design goal in very minimal time, energy and man-power and examining each of those solutions to filter the best with the data to prove it. Another advantage is by using algorithmic designs we can create any kind of complex shapes or products and can optimize the materials used and there manufacturing process. Based on the data the AI engine can also warn us for the critical points in the design, which helps us to resolve the issue faster.

III. GENERATIVE DESIGN PROCESS

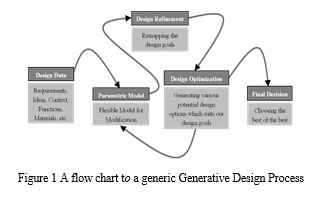

The process of generative design starts when we have a parametric model which is created based on a set of design idea, the requirements of the site and space and various other constraints related to it. As shown in Figure 1, we start with design context, various site requirements, Creative ideas, taking functions and materials into considerations and other factors as well. All the above design data helps us to draft a parametric model. A parametric model gives us the flexibility to check our model on various set of parameters without redoing the model. Once we have a draft parametric model ready, we can move ahead by rechecking or remapping the design goals which we started with as an abstract in the beginning, but once we have a model ready, we can strongly evaluate our design goals based on that. We can now start optimizing our design options on the same design goals by using various optimization engines available, those engines will use the design goals as an input parameter and giving one set of goal output to reach. The engine will simulate and filter various results in the end from which we can manually take final design decisions for execution.

IV. A SAMPLE STUDY: USE OF GENERATIVE DESIGN PROCESS TO EXPLORE PAVING PATTERNS BY USING ONE SET OF DESIGN GOALS

There are so many applications of generative design in various fields of architecture and beyond, by which we can optimize the design process and can come up with high performing design solution in very less time, money, and man power. When it comes to Landscape secondary elements like, paving, flooring, roofing, street furniture’s, public plazas, generative design can do wonders and can help in solving complex design issues in a short time which can’t be imagined without this process. A sample study is done, which follows the same generative design process we will see how it can help in solving the complex design issues to get a High-Performance Design Solution. Sample study shows the layout of rectangular wooden plank in an elevated square lawn with a set a of design goals to fulfill. To do that RHINO and GRASSHOPPER are used as tools.

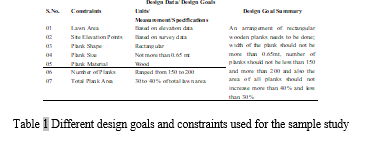

A. Design Data/Design Goals

First Step to create any design is to access the data for various parameters related to our design which acts as a base to our design goals. For Example, in our case we need to know the site area, topography of the site, plank sizes, number of planks we going to use or the total area of planks we need to install from the total site area, width of the planks and others.

B. Generating Parametric Model

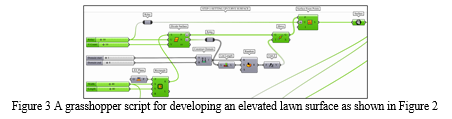

Sing design data and summarized design goal, we get a base on which we can start developing our parametric 3D Model. For generating a parametric 3D Model there are lot of tools available. Advantage of using a parametric model is that it gives flexibility to the optimization engine to check all design alternatives in real time, automatically. In this case we have used Grasshopper & Rhino 3D as tools to develop our parametric model. In grasshopper we can edit the algorithm graphically and see the output in Rhino3D which is tightly integrated with grasshopper.

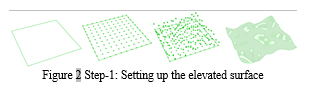

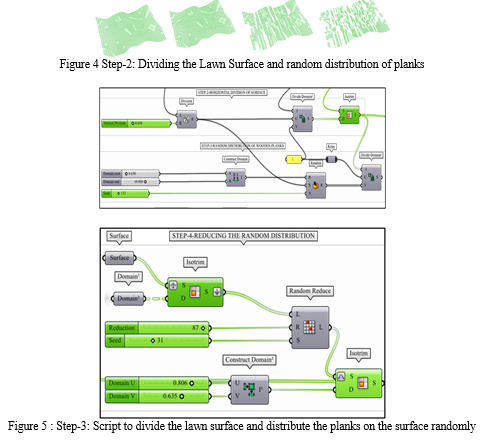

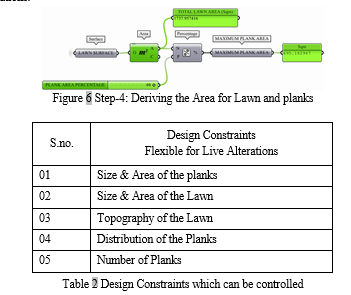

Above four images (Error! Reference source not found.) shows the first few stages of parametric model development which are output in Rhino3D as a result of using a set of components in grasshopper as shown in Error! Reference source not found.. And these components together forms a script in grasshopper which has a set of controllers in the form of number slider attached to give flexibility to model, like we can change the size of the square at any stage of the modelling, Similarly, we can control the grid points which defines the elevation of the lawn surface. Once we have our lawn surface, we will use the same surface to connect to another script as shown in Error! Reference source not found. which will give us the plank divisions and random distribution of them as shown in Figure 4. By doing this we are also giving control to increase or decrease the number of planks and also can control the sizes of the plank by using the number sliders as shown in Figure 5. The seed value gives us different arrangement of paving pattern of same size and area. The reduction value helps us to determine the number of planks to be decreased from the total number now we have our planks ready, our lawn surface is ready. It’s time to optimize this design and choose the best out of it. But before that we need to remap our design goals and identify the parameters which we can use to feed our optimization engine.

V. REFINING DESIGN GOALS

Once our model is ready, we can now remap our design goals. If you refer Error! Reference source not found. for the design data which is tabulated in the beginning, in the summary, it is defined that total plank area should not increase or decrease more than 30 to 40 percent of the total lawn area. So, if you see in Error! Reference source not found., total lawn area is calculated, and for the plank area we can control the percentage range of 30 to 40 percent by providing number slider which starts from 30 and ends on 40. Number of planks can be controlled by reduction controller as shown in Error! Reference source not found. . Finally, we have a parametric model having following flexibility as shown in Error! Reference source not found.. Using these parameters, we can now analyze our design solutions.

VI. DESIGN OPTIMIZATION

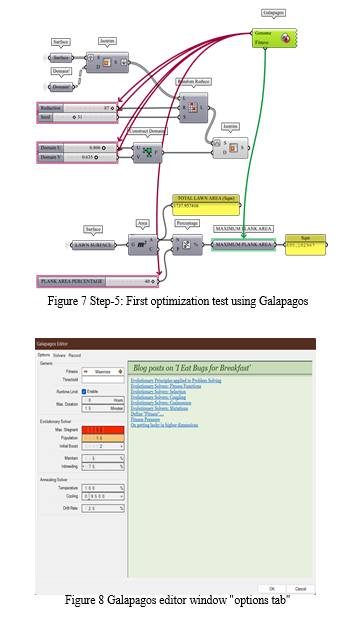

Our script and model all set for the optimization process or design generation process. It evaluates and evolve the design at the same time in very minimal time. This process will automatically simulate and examine all possible alternatives on the design goal given to it, and will filter the best results for the same. More we run the optimization process better result we can get. There are various optimization engine available to perform these task, in this study “Galapagos” is used. Galapagos is an addon inside grasshopper which helps in optimizing the model to achieve our set design goal. Galapagos component have one input as “Genome” which requires the controllers or number slider for our design parameters as stated in Error! Reference source not found.. The red color connections shown in Error! Reference source not found. are the controllers which optimization engine will use to check all possible arrangement one by one, and green connection is the “fitness” which defines the final design goal we want to achieve. Let’s start optimizing our first design goal, we don’t want total plank area to exceed more than 40% and less than 30% of the total lawn area. Total lawn area and 40 % of the lawn area is shown in Error! Reference source not found..

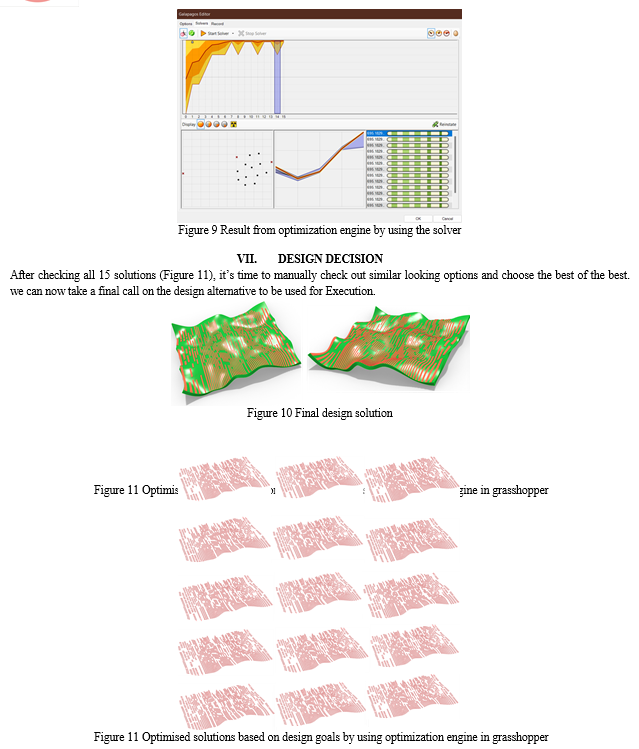

When we go inside the “Galapagos” component (double click to get inside) we will see the interface something as shown in Error! Reference source not found.. In the Galapagos editor window, we can either minimize or maximize our fitness value. Also, in this case we need the area should not exceed 40 % but should be near by 40 % so we will maximize the fitness in Galapagos editor. The number of generation the solver is going to run is 15 and in each generation it will check 15 design solutions so all in total its checking 225 solutions and giving us the best. We can increase the number of generation and population in each generation if we want. Once the solver completes its process it will show us solutions as shown in Error! Reference source not found.. There is a graph in the which shows the filter of solution on every generation the optimization engine runs, below we have different solutions shown in the form of dots, graphs and bars.

Out of 225 arrangement checks it will give 15 best options 1 from each generation, (Error! Reference source not found.) we can reinstate those options one by one in grasshopper and can check them manually. In the same way if we want to limit the number of planks but they should achieve the same area as before we can disconnect the red wire as shown in Error! Reference source not found. from the reduction slider and fix our reduction value, like in this case its 87, and total number of planks are 287 based on current script settings that means after reduction we are left with 200 planks only which are randomly distributed in the lawn achieving the 40 percent area of lawn.

We can also compare different results based on area and based on number of planks and take out the final one. There are other engines which can optimize multiple parameters at same time like we can optimize based on number of planks and area of planks at the same time. But in this case, we are using single optimization system only. We can now check our options on more detailed level by giving them thickness as shown in Error! Reference source not found..

Conclusion

Using Generative design process in developing paving patterns for any space indoor or outdoor is definitely far better than the conventional approach. As we saw in the Examples above that once we have designed a set of parameters which meet our design goals we can test and can generate n-numbers of design solution in no time, which wouldn’t have been possible if it’s done through conventional methods. Not only that we can also test the same design in various site context like in Example-2 above we tested the same paving pattern in an elevated surface instead of the flat one, in an unimaginable time, the application is not limited to that only, we can easily change the paving material (Wooden planks in this case) by doing minimal changes in the overall script. For Example, we want to design an arrangement of Circular stepping stone on the same surface or any other surface with various permutations and combinations in design can be done with minimal effort, this makes designer concentrate more on the design solutions instead of resolving the challenges of the conventional methods and their limitations.

References

[1] https://www.autodesk.com/solutions/generative-design [2] https://www.cimdata.com/en/news/item/8402-generative-design-what-s-that [3] https://www.ptc.com/en/technologies/cad/generative-design [4] https://generativelandscapes.wordpress.com/ [5] https://baharmon.github.io/generative-landscapes [6] https://yazdanistudioresearch.wordpress.com/2014/01/31/optimization-with-galapagos/#:~:text=WHAT%20IS%20GALAPAGOS%3F,defined%20goal%20or%20fitness%20value. [7] https://grasshopperdocs.com/addons/galapagos.html [8] https://www.grasshopper3d.com/ [9] https://www.rhino3d.com/

Copyright

Copyright © 2023 Ar. Piyush Pant, Ar. Monica Sharma. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET48901

Publish Date : 2023-01-29

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online