Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Grading and Sorting of Capsicum Using Convolutional Neural Networks (CNN): A Review

Authors: Naiema Firdous Qadri, Ravinder Pal Singh, Jasmeen Gill

DOI Link: https://doi.org/10.22214/ijraset.2024.63813

Certificate: View Certificate

Abstract

Grading and sorting of capsicum, or bell peppers, is a critical task in the agricultural industry to ensure consistent quality control and efficient distribution. In recent years, Grading & Sorting of Capsicum using Convolutional Neural Networks (CNNs), have shown promise in automating this process. The objective is to automate the Grading and Sorting process, which currently done manually and time-consuming. The proposed approach involves the collection of capturing dataset of capsicum images, extracting relevant features, and training a CNN model to classify the capsicum based on their quality criteria such as size, shape, color, and quality levels. These images are pre-processed to enhance their quality and standardize the inputs. A CNN architecture of 85 trained datasets and 33 tested datasets images using for accurate grading and sorting. After the training phase, the model\'s accuracy is evaluated using appropriate metrics such as precision, recall, or F1-score. The performance of the CNN model of grading and sorting system is determined based on the accuracy values, providing an objective measure of its effectiveness. Experimental results of testing datasets obtained an accuracy value of above 90% indicates that the system correctly classified, the capsicum into their respective grades or sorted categories 97.43% accuracy achieved.

Introduction

I. INTRODUCTION

Capsicum, scientifically known as “Capsicum Annuum”. Capsicum, other names such as; Bell-pepper or sweet-pepper in America, Peppers in United Kingdom, and Shimla-mirch in India. It is a genus of flowering plants, belongs to Solanaceae (nightshade) family. Capsicum originated in the Central American & Mexico and first use in food since 6000 BC [20]. Its cultivation started in Spain by Columbus in 1493, however it spread to Mediterranean region and England in 1548. It was brought to India by Portuguese from Brazil prior to 1885, & In China it came under cultivation during the late 1700s, now Capsicums spread all over the world. In India, grown in states like Punjab, Maharashtra, Andhra Pradesh, and Karnataka, & grown in countries like China, Mexico, Spain and the United States [8]. Capsicum obtained various Colors like, Green, Red, Yellow, orange, White, Chocolate, Candy cane striped, Black, and Purple, depending on the variety. But the most common colors of bell peppers are Green, Yellow, Orange and Red. Capsicum is the popular vegetable used in various cuisines around the world, Dishes like, curries, stir-fries, salads, and even stuffed peppers [31]. Capsicum, rich in vitamins C, B6, A, & K, which are essential for healthy immune system. Table.1 Shows the Capsicum nutritional components & its value composition of 100 grams. Capsicums, contains anti-oxidants that help protect against cell damage & inflammation. Also used for weight loss, improve digestion, pain relief, & Anti-cancer properties [10].

Table 1 Capsicum nutritional composition.

|

S. no. |

Nutritional Components |

Value composition of 100 grams |

|

01. |

Calories. |

20 kcal |

|

02. |

Carbohydrates |

4.6 grams |

|

03. |

Dietary fibre. |

1.7 grams |

|

04. |

Sugar. |

2.4 grams |

|

05. |

Fat. |

0.2 grams |

|

06. |

Protein. |

0.9 grams |

|

07. |

Vitamin C. |

127.7 milligrams (213% of the daily recommended intake) |

|

08. |

Vitamin A. |

1577 international units (32% of the daily recommended intake) |

|

09. |

Vitamin B6. |

0.3 milligrams (14% of the daily recommended intake) |

|

10. |

Vitamin K. |

4.9 micrograms (6% of the daily recommended intake) |

|

11. |

Potassium. |

211 milligrams |

|

12. |

Magnesium. |

10 milligrams |

|

13. |

Folate. |

10 micrograms |

Grading & Sorting of Capsicum, is an important process in the agricultural industry. G&S involves evaluating the quality and characteristics of capsicum based on factors like size, shape, color, and texture. Helps ensure that only the highest quality capsicum reaches the market. Manual grading is traditionally done by human inspectors, but advancements in technology have led to development of automated systems that use computer vision and image processing techniques. These systems analyze capsicum images and classify them into different grades based on predetermined criteria. CNN’s is an exciting application that combines the power of computer vision and machine learning techniques. By training a CNN model to recognize and classify dataset images into different quality & grades based on their visual features. The CNN model learns to extract relevant features from the images and make accurate predictions. This automated approach save time, improves accuracy, and efficiency to ensuring consistent quality control in Grading and Sorting process. The Literature reviews of the Research Papers studies that the comparison of the Automated classification shown in Table 2.

Table 2 Comparison table of Automated classification.

|

S. No. |

Authors |

Fruits & Vegetables |

Automated classification |

Accuracy |

|

1 |

H. Ayesha et al. (2022) |

Mangoes |

Classification & Grading using CNN, VGG16, ResNet152, and Inception v3 augmented data. |

96.7% |

|

2 |

Y. A. Azis et al. (2021) |

Dried Chilli |

Digital Image Processing & Artificial Neural Networks (ANN) i.e., Grades, Mean a*, Mean Blue, Mean Contrast. |

94.4% |

|

3 |

et al. (2020) |

Capsicum annuum |

Quality assessment using smartphone camera, i.e., ANN, GUI, MATLAB, red, green, a*, and intensity. |

90.43% |

|

4 |

N. Khuriyati et al. (2019) |

Chilli Peppers |

Sorting & Grading using Digital Image processing, ANN, MATLAB,3 Layers red input, energy, and correlation. |

84.46% |

|

5 |

K. Yadav et al. (2018) |

Real time Fruit |

Sorting using Computer Vision & Machine Learning i.e., KNN, OpenCV, Preprocess, Feature Extraction. |

88% |

|

6 |

Shakshi Jha et al. (2016) |

Tomatoes |

Automated Grading technique, digital Image Processing, system enable the non-destructive gradation. |

84% |

|

7 |

WAN P.N.W.M. Tahir et al. (2015) |

Rice |

Grading using Image processing, RGB color model, histogram, |

46.6% |

|

8 |

Haider et al. (2012) |

Dates |

Nearest Neighbor (Euclidean), LDA, ANN. |

96.7% |

|

9 |

Leiva et al. (2011) |

Blueberries |

LDA, QDA, ANN, SVM, KNN, Image Processing. |

96% |

|

10 |

Yousef Al Ohali et al. (2010) |

Date |

Computer vision grading system, RGB, Extracted features, Neural networks, Hardware; Conveyor, Camera Control and Helm control systems. |

80% |

|

11 |

G. Bernard et al. (2005) |

Apple |

ANN-based segmentation, grading by machine vision, Pixel-wise processing, Linear discriminant, nearest neighbor, Fuzzy, Adaboost & Support vector machines (SVM) classifiers. |

90.3% |

II. MATERIAL & METHODS

A material requires of the capsicum grading and sorting using CNN of the several steps involved:

A. Integration with Hardware

To Integrate Hardware for grading and sorting of capsicum using CNN for used such that, Central Processing Unit (CPU) with a high-performance CPU, such as AMD Ryzen 5000 series 5, or Intel Core i7, with multiple cores for efficient computers. The Graphics Processing Unit (GPU) is used a powerful GPU such as AMD Radeon Graphics from Ryzen series, or other graphics used NVIDIA GPU from GeForce RTX or Tesla series, for accelerated Grades and Sorts of capsicum using CNN. To handle the datasets and implements results during training are sufficient memory used such as Random Access Memory (RAM) is 16 GB or more. The sufficient storage capacity used such as solid-state drive (SSD) is 512 SSD, or 1- 2 TB hard-drive, to store the Capsicum datasets, pre-processed images, and trained models.

B. Software and Frameworks

To implement the grading and sorting of capsicum using CNN, can use software tools such as Python 3.11, OpenCV, Keras, and TensorFlow. Use a suitable Operating System such as Windows 10 or 11, Linux, or macOS. Python provides a flexible programming environment, while OpenCV offers powerful image processing capabilities. TensorFlow or Keras is a popular framework for building and training CNN models. In CNN-model use the Software Anaconda Navigator, Spyder, & PyCharm IDE, which provides the Image Processing APIs supports a wide variety of media types that can be processed and transformed. It supports reading JPEG, PNG, WebP, GIF, JPG, AVIF, TIFF, SVG formats, that perform image processing in Grading and Sorting using CNN techniques and computer vision tasks. Construct a convolutional neural network (CNN) architecture using libraries like OpenCV, TensorFlow or Keras. It can involve using convolutional layers, pooling layers, and fully connected layers. Train the model on the preprocessed capsicum image dataset, adjusting the hyperparameters and optimizing the model's performance.

Use the trained CNN model to classify new capsicum images into multiple angles or different grade & sort categories. Apply image processing techniques, such as color analysis, to extract relevant features for grading.

These steps are high-level overview and the actual implementation may involve more specific details and codes & also needing access to specialized hardware like Cameras and conveyor belts, to make the sorting process more efficient. It can effectively grade and sort capsicum based on desired criteria, contributing to improved efficiency and productivity in the agricultural industry.

III. METHODOLOGY

To develop a system for the grading and sorting of capsicum using CNN involves several critical steps and methodologies. Below is a comprehensive methodology for achieving accurate and efficient capsicum grading and sorting using CNN are:

- Gather a dataset of capsicum images with corresponding grading labels. This dataset should include images of capsicum at different stages of color development, & includes color, size, shape, and the presence of defects scenarios. Preprocess the collected images by resizing them to a consistent size, normalizing pixel values, and applying any necessary image enhancements or filtering techniques. Split the dataset into training and testing datasets. The training set will be used to train the CNN model, while the testing set will be used to evaluate its performance.

- Design the architecture of the CNN model. This typically involves stacking convolutional layers, pooling layers, and fully connected layers. Experiment with different configurations to optimize the model’s performance. Experiment with various CNN architectures, such as VGG, ResNet, or Inception, to find the most suitable architecture for capsicum grading. Train the CNN model using training dataset. This involves feeding the preprocessed capsicum images into the model and adjusting the model’s weights or size through back-propagation and Gradient descent algorithms, and optimization other techniques. Iterate this process until the model achieves satisfactory accuracy. Evaluate the trained model's performance using the testing dataset. Measure metrics such as accuracy, precision, recall, and F1 score to assess its effectiveness in grading and sorting capsicum. Once the model is trained and evaluated, apply it to new, unseen capsicum images for grading and sorting. The model will classify the images based on their color attributes and assign them to the appropriate grade or sort category. Validate the grading and sorting system by testing it on a separate test dataset or real-time images. Make adjustments and refinements as needed to improve the accuracy and reliability of the system.

- Deploy the grading and sorting system in the desired production environment. In CNN to integrate the trained model into a practical system that can process images in real-time. This could involve developing a user-friendly interface, connecting with cameras or image sensors, and implementing the necessary algorithms for grading and sorting based on the CNN model’s predictions. Analyze the performance of the grading and sorting system. Assess its accuracy, efficiency, and any potential limitations or challenges encountered during the process. This methodology can develop a robust and accurate system for grading and sorting capsicum using CNN. Sucessful implementation can lead to highly accurate, efficient, and cost-effective capsicum grading and sorting systems.

IV. IMPLEMENTATION & RESULTS

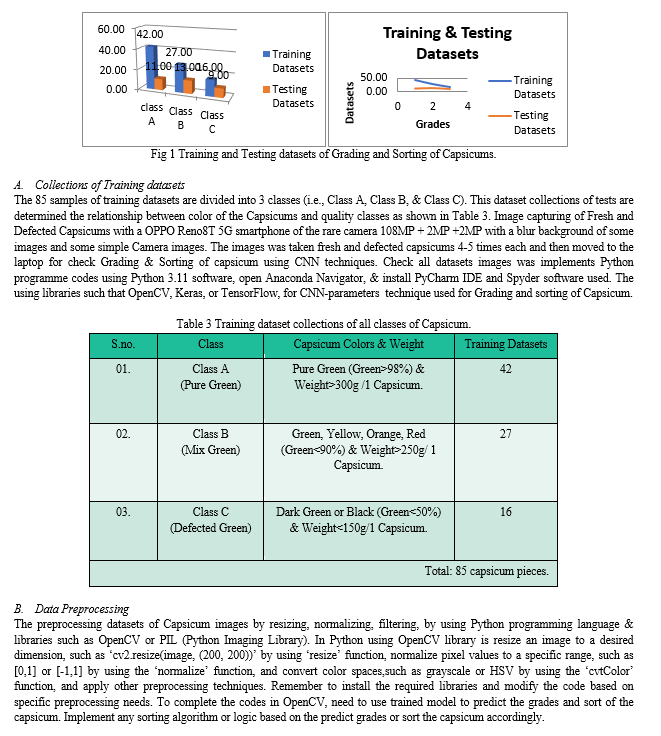

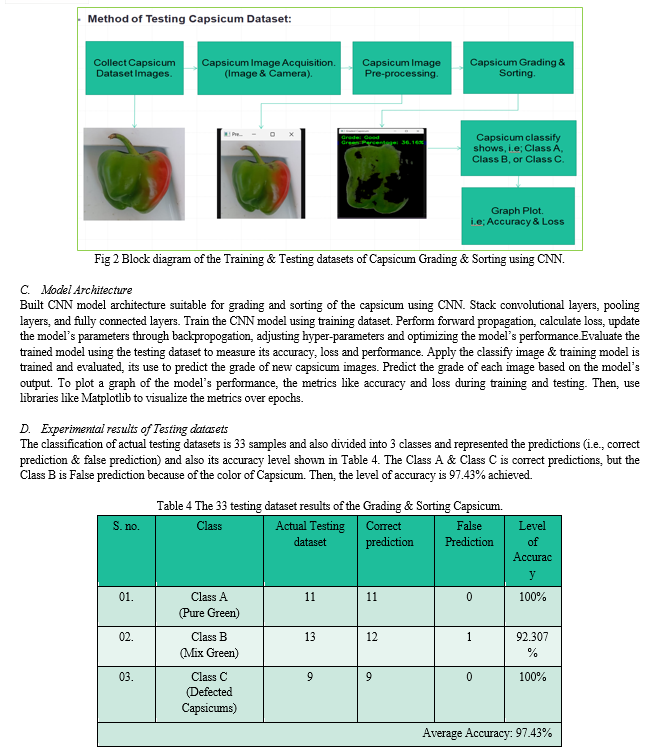

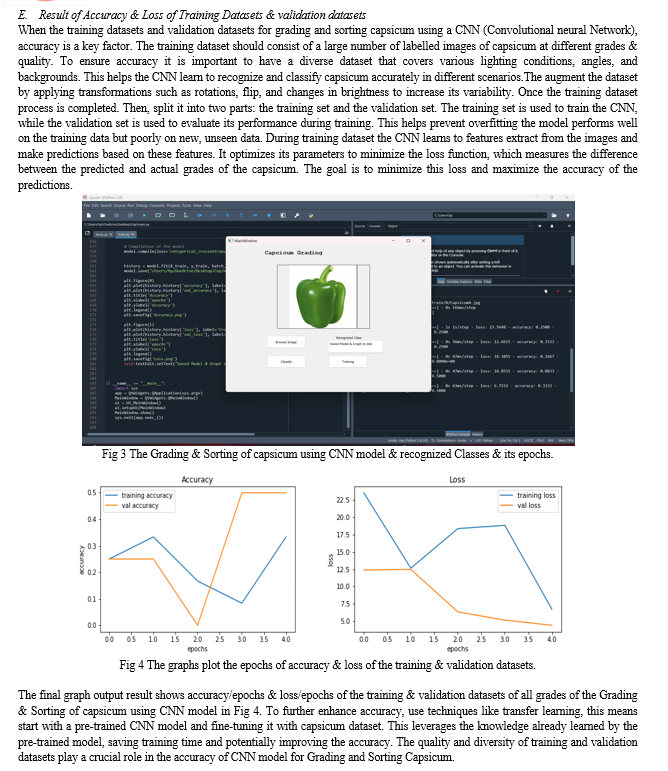

Grading and Sorting capsicum (bell peppers) using CNN (Convolutional Neural Networks) can be a fascinating application. CNNs analyze the visual characteristics of Capsicum such as color, shape, size, and defects, to accurately grade and sort them. To implement this, a dataset of labelled capsicum images is needed for training the CNN model. The model learns from these images to recognize and classify different grades or categories of capsicum based on predetermined criteria. During the grading and sorting process, the capsicum is visually inspected by capturing images from multiple angles. These images are then fed into the trained CNN model, which makes predictions about the grade or category of each capsicum based on its visual features. The CNN model can effectively detect and classify various attributes, such as color uniformity, size consistency, absence of defects, and overall appearance. This automation improves efficiency, reduces human error, and ensures consistent grading and sorting results. Implementing CNN-based grading and sorting systems for capsicum can greatly benefit the agricultural industry by enhancing productivity, optimizing quality control, and reducing manual labor. It’s an exciting application that shows the power of computer vision and machine learning in agriculture. The implement of the grading and sorting of capsicum using CNN, is need a dataset of labelled images of different grades of capsicum (i.e., Class A, Class B, & Class C). Then, the train the CNN model to recognize and classify the capsicum based on their grades. It’s a complex task, but with the right data and training, it can be done! It’s important to have a good understanding of the underlying concepts and access to relevant tools and libraries like TensorFlow, Keras, OpenCV, or PyTorch., etc. Let’s see results, How to implement that training & testing datasets of the Grading and Sorting of Capsicums using CNN model techniques.

Conclusion

Based on the research and experimentation conducted on grading and sorting of capsicum using CNN, It’s concluded that this research paper offers a promising solution by leveraging computer vision techniques, It becomes possible to accurately classify and sort capsicum based on various parameters such as color, size, and shape. This automated process not only improves efficiency, but also reduces human error in the grading and sorting process. Further research and refinement of the CNN models can lead to even more accurate and efficient results. Overall, the integration of Grading and Sorting using CNN model holds great potential for enhancing productivity and quality control in the agricultural industry. The future work, for Grading and Sorting of Capsicum using CNN is quite promising. When Integrating it with hardware, it can develop a Robotics system for automated grading & sorting process, increasing efficiency, reducing human error or enhance accuracy, Real-time processing, and expansion to other agricultural products. The advancements in CNN models, can expect even more precise and automated grading systems in the future. It’s an exciting time ahead for capsicum sorting in agricultural technology.

References

[1] Yuzhen Lu, Jiajun Xu., “Developing A Machine Vision System for Real-time, Automated Quality Grading of Sweetpotatoes.” Department of Biosystems & Agricultural Engineering, Michigan State University, ASABE Omaha, Nebraska., P.1-9, 2023. [2] Mansour Rasekh, Hamed Karami, Sigfredo Fuentes, Mohammad Kaveh, Robert Rusinek, Marek Gancarz., “Preliminary study non-destructive sorting techniques for pepper (Capsicum annuum L.) using odor parameter.” LWT-Food Science and Technology Vol. 164; P.1-11, 2022. [3] Nur-E-Aznin Mimma, Sumon Ahmed, Tahsin Rahman, Riasat Khan, “Fruits Classification and Detection Application Using Deep Learning”, Department of Electrical and Computer Engineering, North South University, Dhaka, Bangladesh., P.1-16, 2022. [4] Hafiz Muhammad Rizwan Iqbal & Ayesha Hakim., “Classification and Grading of Harvested Mangoes Using Convolutional Neural network”, Department of Computer Science, Muhammad Nawaz Shareef University of Agriculture, Multan, Pakistan., vol. 22, no.1, P.95-109, 2022. [5] Marlindia Ike Sari, Rizal Fajar, Tedi Gunawan, Rini Handayani., “The Use of Image Processing and Sensor in Tomato Sorting machine by Color, Size, and Weight.” Diploma of Computer Engineering, Telkom Applied Science, University Telkom, Bandung, Indonesia; JOIV: Vol. 6(1-2), P.244-249, 2022. [6] L. Zu, Y. Zhao, J. Liu, F. Su, Y. Zhang, and P. Liu, \"Detection and Segmentation of Mature Green Tomatoes Based on Mask R-CNN with Automatic Image Acquisition Approach,\" Sensors, vol. 21, no. 23, 2021. [7] Y.A.Azis, N.Khuriyati, A.Suyantohadi., “Classification of Dried Chilli Quality Using Image Processing”, Department of Agroindustrial Technology, Universitas Gadjah Mada, 1st Flora Street, Bulaksumur, Yogyakarta, Indonesia, P.1-9, 2021. [8] Jeediya Gayatri Bhalabhai, Sanjukta Rajhans, Himanshu Pandya, Archana U Mankad, & Chirag Patel. “A Comprehensive review on Capsicum ssp.”, Department of Botany, Bioinformatics, and Climate Change Impacts Management, Gujarat University, Ahmedabad, 380009. (IJRAR); P.581-583, 2021. [9] Gaber El-Saber Batiha, Ali Alqahtani, Oluwafemi Adeleke Ojo, Hazem M. Shaheen, Lamiaa Wasef, Mahmoud Elzeiny, Mahmoud Ismail, mahmoud Shalaby, Toshihiro Murata, Adrian Zaragoza-Bastida, nallely Rivero-Perez, Amany Magdy Beshbishy, Keneth Iceland Kasozi, Philippe Jeandet, and Helal F. Hetta. “Biological Properties, Bioactive Constituents, and Pharmacokinetics of Some capsicum spp. And Capsaicinoids.” International Journal of Molecular Sciences (IJMS 2020. 21(15), 5179); P.1-35, 2020. [10] N Khuriyati, D. A. Nugroho, N.A.Wicaksono. “Quality assessment of chilies (Capsicum annuum L.) by using a smartphone camera.” Department of Agroindustrial Technology, Faculty of Agricultural Technology, universitas Gadjah Mada 1st Flora Street Bulak Sumur Yogyakarta INDONESIA; P.1-7, 2020. [11] Nafis Khuriyati, Agung Putra Pamungkas, Anggraito Agung P. “The Sorting and Grading of Red Chilli Peppers (Capsicum annuum L.) Using Digital Image Processing.” Department of Agroindustrial Technology, Universitas Gadjah Mada Flora Street No. 1 Bulaksumur, Yogyakarta, Indonesia. ISSN: 2394-2568 (SSRG-IJAES); 6, P.19-23, 2019. [12] D. Ireri, E. Belal, C. Okinda, N. Makange, and C. Ji, \"A computer vision system for defect discrimination and grading in tomatoes using machine learning and image processing,\" Artif. Intell. Agric., vol. 2, P. 28–37, 2019. [13] Hosseinpour, S., Ali H. I., Mortaza., A., An Intelegent machine vision-based Smartphone App for Beef Quality. Journal Food Engineering, 248; P.9-22, 2019. [14] M. Haggag, S. Abdelhay, A. Mecheter, S. Gowid, F. Musharavati, and S. Ghani, \"An Intelligent Hybrid Experimental-Based Deep Learning Algorithm for Tomato-Sorting Controllers,\" IEEE Access, vol. 7, P. 106890–106898, 2019. [15] Shamili, M., “The estimation of mango fruit total soluble solids using image processing technique.” Scientia Horticulture, Vol. 294; P.383-389, 2019. [16] G. Liu, S. Mao, and J. H. Kim, \"A mature-tomato detection algorithm using machine learning and color analysis,\" Sensors (Switzerland), vol.19, no. 9, P.1–19, 2019. [17] S. K. Behera, A. Mahapatra, A. K. Rath, and P. K. Sethy, \"Classification & grading of tomatoes using image processing techniques,\" Int. J. Innov. Technol. Explor. Eng., vol. 8, no. 6, P. 545–550, 2019. [18] Juan Pablo Mercol, Juliana Gambini, Juan Miguel Santos, “Automatic classification of oranges using image processing and data mining techniques” Instituto Tecnológico de Buenos Aires, Departamento de Computaci´on, Facultad de Ciencias Exactas y Naturales, UBA, Buenos Aires, Argentina., 2019. [19] F. Putra and T. Rizaldi, \"Application of Color Sensor in the Determination of Tomato Fruit Ripeness (Solanum Lycopersicum, L) in Gravitation Type Fruit Sorting Tool (Gravitation Type),\" Indones. J. Agric. Res., vol. 2, no. 1; P.13–20, 2019. [20] Pasquale Tripodi, & Sanjeet Kumar. “The Capsicum Crop: An Introduction.” CREA Research Centre for Vegetable and ornamental Crops, 84098 Pontecagnano Faiano, Italy; World Vegetable centre, Post Box 42, Shanhua, Tainan 74199, Taiwan; P.1-5, 2019. [21] L. Liu, Z. Li, Y. Lan, Y. Shi, and Y. C. Id, \"Design of a tomato classifier based on machine vision,\" PLoS One, vol. 14, no. 7, P. 1–16, 2019. [22] P. Avalekar and L. S. Admuthe, \"Tomato grading system based on colour models by using neural network,\" Int. Res. J. Eng. Technol., vol.5, no. 7, P.513–522, 2018. [23] Yadav Kadam, Sandip Khansole, Abhijeet Jadhav, Prof. Dr. Arati J. Vyavhare , “Real Time Fruit Sorting Using Computer Vision and Machine Learning”, Department of Electronics & Telecommunication Engineering, P.E.S’s Modern College of engineering, SPPU, Pune., vol. 6, P. 344-349, 2018. [24] “Bell and Chili Peppers” Agricultural Marketing Resource Centre (AMRC), US Department of Agriculture, 2018. [25] Bhargava and A. Bansal, “Fruits and vegetables quality evaluation using computer vision: A review.” J. King Saud Univ. - Computer Info. Sci.; 2018. [26] S. Tamakuwala, J. Lavji, and R. Patel, \"Quality Identification Of Tomato Using Image Processing technique,\" Int. J. Electr. Electron. Data Commun., vol. 6, no. 5, P.67–70, 2018. [27] Adamu and A. Shehu, \"Development of an Automatic Tomato Sorting Machine Based on Color Sensor,\" Int. J. Recent Eng. Res. Dev., vol. 03, no. 11, P.1–7, 2018. [28] Sapan Naik, Bankim Patel, ‘Machine Vision based Fruit Classification and Grading- A Review” IIT Surat University, IMCA University, Uka Tarsadia University, Gujarat, India, IJCA, vol. 170-no.9, P.22-34, 2017. [29] Bairwa D and Sharma G, “Classification of Fruits Based on Shape, Color and Texture using Image Processing Techniques” Int. J. Eng. Res. V6, P.110–114, 2017. [30] Swapnil S. Pawar, M. P. Dale, “Computer Vision Based Fruit Detection and Sorting System” M.E.S. College of Engineering, Pune, ACCET, vol.4 I-2, P.11-15, 2016. [31] Harry Gratte, Margaret Graham, & John Burt. “Growing capsicums and chillies.” Department of Primary Industries and Regional Development; 2016. [32] S. Jha, S. Agrawal, and C. K. Dewangan, \"Grading Of Tomatoes Using Digital Image Processing On The Basis Of Size,\" Int. J. Res. Eng. Technol., vol. 5, no. 10, P. 109-111, 2016. [33] Leo Pauly, Deepa Sankar, “A New Method for Sorting and Grading Of Mangos Based On Computer Vision System” DEC Engineering, School of Engineering, Cochin University of Science and Technology, Kochi -682022, Kerala, India., 2015. [34] Meruliya, T., Dhameliya, P., Patel, J., Panchal, D., Kadam, P., Naik, S., “Image Processing for Fruit Shape and Texture Feature Extraction-Review.” International Journal Comput. Appl. (0975-8887) Vol. 129, No. 8; P.30-33, 2015. [35] Bora D. J., Gupta A. K., and Khan F. A., “Comparing the Performance of L*A*B* and HSV Color Spaces with Respect to Color Image Segmentation International.” Journal of Emerging Technology and Advanced Engineering; 5, P.192-203, 2015. [36] Wan Putri N. W. M. Tahir, Norhaida Hussin, Zaw Zaw Htike and Wai Yan Nyein Naing., “RICE GRADING USING IMAGE PROCESSING” Department of Mechatronics Engineering, Faculty of Engineering, International Islamic University Malaysia, Malaysia., ARPN, vol. 10, no.21, P.10131-10137, 2015. [37] Dattatraya Londhe, Sachin Nalawade, Ganesh Pawar, Vinod Atkari, Sachin Wandkar, “Grader: A review of different methods of grading for fruits and vegetables” Agric Eng Int: CIGR Journal, MPKV, PDKV, MPUAT, Maharashtra, Rajasthan, India., Vol.15, no.3, P.217-230, 2013. [38] Balogun W. A. et al., “Intelligent Technique for Grading Tropical Fruit using Magnetic Resonance Imaging”, International Journal of Scientific & Engineering Research, vol. 4, Issue 7, P. 216-225, 2013. [39] Dubey S. R., Dixit P., Singh N. and Gupta J. P., “Infected Fruit Part Detection using K-Means Clustering Segmentation Technique”, International Journal of Artificial Intelligence and Interactive Multimedia, vol. 2, no. 2, P.65-72, 2013. [40] Khoje S. and Bodhe S., “Comparative Performance Evaluation of Size Metrics and Classifiers in Computer Vision based Automatic Mango Grading”, International Journal of Computer Applications, vol. 61, no. 9, P. 1-7,2013. [41] Leiva G., Mondragón G., Mery D. and Aguilera J.M., “The Automatic Sorting using Image Processing Improves Postharvest Blueberries Storage Quality”, Food Control, vol. 33, Issue 1, P.166-173, 2013. [42] Khoje, S. A., Bodhe, S. K. and Adsul, A., “Automated Skin Defect Identification System for Fruit Grading Based on Discrete Curvelet Transform”, International Journal of Engineering and Technology, vol. 5, no. 4, P. 3251-3256, 2013. [43] Payne, A.B., Walsh, K.B., Subedi, P.P., Jarvis, D., “Estimation of mango crop yield using image analysis – segmentation method.” Computer Electronics Agriculture, Vol. 91, P.57–64, 2013. [44] O. O. Arjenaki, P. A. Moghaddam, and A. M. Motlagh, \"Online tomato sorting based on shape, maturity, size, and surface defects using machine vision,\" Turkish J. Agric. For., vol. 37, no. 1, P. 62–68, 2013. [45] Alipasandi A., Ghaffari H. and Alibeyglu S.Z., “Classification of Three Varieties of Peach Fruit Using Artificial Neural Network Assisted with Image Processing Techniques”, International Journal of Agronomy and Plant Production, vol. 4, no. 9, P. 2179-2186, 2013. [46] Razak, T. R. B. et al., “Mango Grading by using Fuzzy Image Analysis”, International Conference on Agricultural, Environment and Biological Sciences (ICAEBS\'2012) Phuket, P.26-27, 2012. [47] Zhang Y. and Wu L., “Classification of Fruits Using Computer Vision and a Multiclass Support Vector Machine”, Sensors, vol. 12, P.12489-12505, 2012. [48] Khalid, M.A. and Tamer, A.A.A., “Date Fruits Classification using MLP and RBF Neural Networks”, International Journal of Computer Applications, vol. 41, no.10, P.36-41, 2012. [49] Kodagali, J. A. and Balaji, S., “Computer Vision and Image Analysis based Techniques for Automatic Characterization of Fruits – A Review”, International Journal of Food Science and Technology, vol. 2, no. 2, P.1-14, 2012. [50] Rasekhi, R. and Raoufat, M. H., “Sorting Orange Fruit by Machine Vision and Neural Networks Techniques”, CIOSTA CIGR V Conference, 2011. [51] Mahendran, R., Jayashree, G. C. and Alagusundaram, K., “Application of Computer Vision Technique on Sorting and Grading of Fruits and Vegetables”, Journal of Food Processing & Technology, 2011. [52] Ohali, Y. A., “Computer Vision based Date Fruit Grading System: Design and Implementation”, Journal of King Saud University – Computer and Information Science, vol. 23, P.29–36, 2010. [53] Esehaghbeygi A. et al, “Digital Image Processing for Quality Ranking of Saffron Peach”, Int. Agrophysics, vol. 24, P.115-120, 2010. [54] Unay D. et al, “Automatic Grading of Bi-Colored Apples by Multispectral Machine Vision”, Computers & Electronics in Agriculture, 2010. [55] Zaragoza A.V., “Measurement of Colour of Citrus Fruits using an Automatic Computer Vision System”, Thesis: Master in Science and Engineering of Food: Univ. of Politechnica De Valencia, P.1-19, 2010. [56] Kim D.G. et al, “Classification of Grapefruit Peel Diseases using Color Texture Feature Analysis”, International Journal of Agric & Biol Eng., Vol. 2 No.3, 2009. [57] Wang Y.et al,” Study on Fruit Quality Measurement and Evaluation based on Color Identification”, Proc. of SPIE, vol. 7513, 2009. [58] Bennedsen, B. S., D. L. Peterson and A. Tabb. “Identifying apple surface defects using principal components analysis and artificial neural networks.” American Society of Agricultural and Biological Engineers Vol. 50(6): 2257- 2265J; 2007. [59] Mercol, J. P., Gambini, J. and Santos, J.M., “Automatic Classification of Oranges using Image Processing and Data Mining Techniques”, 2007. [60] Bennedsen B. S., Peterson D. L. and Tabb A., “Identifying Apple Surface Defects using Principal Components Analysis and Artificial Neural Networks”, Transactions of American Society of Agricultural and Biological Engineers, vol. 50, no. 6, P.2257-2265, 2007. [61] Bin Z.a., Lu J. a., Yaguang L.b. and Yang T. a., “Gabor Feature-based Apple Quality Inspection using Kernel Principal Component Analysis”, Elsevier: Journal of Food Engineering, vol. 81, pp. 741–749, 2007. [62] Sadrnia H.et al, “Classification and Analysis of Fruit Shapes in Long Type Watermelon using Image Processing”, International Journal of Agriculture & Biology ,1560–8530/2007/09–1–68–70, Iran, 2007. [63] León, K., Mery, D., Pedreschi, F., León, J., “Color measurement in Lab units from RGB digital images.” Food Res. Int. 39, P.1084–1091, 2006. [64] Boonmung S., Chomtee B. and Kanlayasiri K., “Evaluation of Artificial Neural Networks for Pineapple Grading”, Journal of Texture Studies, vol.37, no. 5, P.568–579, 2006. [65] Unay, D. and Gosselin, B., “Artificial Neural Network based Segmentation and Apple Grading by Machine Vision”, IEEE, 2005. [66] D. Unay and B. Gosselin, “A quality sorting method for \'jonagold\' apples” in Proc. Int. Agricultural Engineering Conf. (AgEng), Leuven, Belgium, 2004. [67] O. Kleynen, V. Leemans, and M.-F. Destain, “Selection of the most efficient wavelength bands for \'jonagold\' apple sorting” Postharvest Biology and Technology, vol. 30, no. 3, P. 221-232, December 2003. [68] Antoni Macho, Concepcion Lucena, Racio Sancho, Nives Daddario, Alberto Minassi, Eduardo Munoz, Giovanni Appendino. “Non-pungent capsaicinoids from sweet pepper” (European Journal of Nutrition); P.2-9, 2003. [69] Rao P.S. et al, “New Approaches for Size Determination of Apple Fruits for Automatic Sorting and Grading”, Iranian Journal of Electrical and computer engineering, vol.1, no. 2, 2002. [70] Simões A. S., Costa A.H. R., Hirakawa A. R. and Saraiva A. M., “Applying Neural Networks to Automated Visual Fruit Sorting”, World Congress On Computers in Agriculture and Natural Resources, 2001. [71] G. Rennick, Y. Attikiouzel, and A. Zaknich, “Machine grading and blemish detection in apples” in Proc. 5th Int. Symp. Signal Processing and Appl., Brisbane, Australia, P. 567-570, 1999. [72] Gunasekaran, S. “Computer Vision Technology for Food Quality Assurance.” Trends in Food Science & Technology, 7 (8), P.245-256, 1996.

Copyright

Copyright © 2024 Naiema Firdous Qadri, Ravinder Pal Singh, Jasmeen Gill. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63813

Publish Date : 2024-07-30

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online