Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Effect of Graphene Oxide in Cement Mortar and its Strengthening Mechanism

Authors: P. D. Nemade, Vedant Mogal, Shrikant Kochure, Sarvesh Mahewar

DOI Link: https://doi.org/10.22214/ijraset.2025.66651

Certificate: View Certificate

Abstract

In the present study, the effect of water-dispersed powder Graphene Oxide (GO) nanoparticles on cement mortar and its mechanical Strength after 3, 7 and 28 days of Curing is analysed. These properties were studied by adding 0.00 w/w% ,0.03 w/w%,0.05 w/w%,0.07 w/w% of cement to Obtain Compressive strength and tensile strength of cement mortar. It observed that for 0.03% w/w of cement addition increase in compressive strength is 23.07%, for 0.05% w/w of cement addition increase in compressive strength is 35.59%, and for 0.07% w/w of cement addition increase in compressive strength is 31.52% after 28 Days of curing. Tensile strength analysis for 0.03% w/w of cement addition increase in Tensile strength is 4.46%, for 0.05% w/w of cement addition increase in Tensile strength is 34.70%, that for 0.07% w/w of cement addition increase in Tensile strength is 37.45% after 28 Days of curing. By the addition of different proportions of graphene oxide, the compressive strength increases till the addition of 0.05 % w/w of cement slightly decreases. For tensile strength with addition of graphene oxide the tensile strength is increased.

Introduction

I. INTRODUCTION

The development ecosystem has grown rapidly over the past few years. The construction industry is an evergreen industry that adapts to changing business needs. Cement-based materials have played an important role in the construction industry. However, conventional cement-based products have the disadvantage of hardness and high brittleness and cause cracking, affecting the performance and life of the product.

On the other hand, cement production is encouraged by destroying the environment. The main challenge for sustainable development in the next decade is to design and produce less clinker concrete with lower CO2 emissions, and to be more reliable and durable. Energy consumption and carbon dioxide emissions in cement production constitute 5% of the world's industrial energy consumption and 5% of the world's greenhouse gas emissions, respectively.[1]

Graphene oxide (GO) properties and structure are similar to graphene. A hexagonal network of carbon atoms with hydroxyl and epoxy groups in the fundamental plane and SP2 and SP3 hybrid orbitals consisting of carbonyl and carboxyl groups at the edges.[2]

Graphene oxide (GO) is a graphene derivative with a large surface area and excellent thermal conductivity and mechanical strength, and its surface has a large number of active oxygen groups such as hydroxyl, carboxyl and epoxy groups.[3] Cement mortar composites are widely used in masonry, plastering, repair of damaged stone, patching or filling, plastering, floor levelling and development of prefabricated products. Of all its materials (cementitious materials, water, coarse and fine aggregates), cement has the largest CO2 emissions and energy consumption.[4]

The objective of the present study is to Investigate the effect of graphene oxide (GO) on Mechanical properties (Compressive Strength, Tensile Strength).

II. MATERIALS AND MIX PROPORTION

A. Cement

Cement is a fine aggregate that is often used for bonding in concrete mixes. In this study, UltraTech cement of OPC 53 grade was used. The cement of OPC 53 grade is shown in below Figure 1

Fig.1 UltraTech cement of OPC 53 Grade

B. Fine Aggregate

Use fresh local sand without organic matter as per IS 456-2002. The particles were passed through an IS 4.75 mm sieve. These are used to fill the air spaces in the concrete mix and the quality mix used in the study is shown in Figure 2 below.

Fig.2 Fresh Local Sand

C. Water

The quality of the water is important because impurities can affect the strength of the concrete and cause corrosion of the steel reinforcement. The water used in the production and maintenance of the stone should be very clean and should not contain oil, acid, alkali, salt, sugar, silt, organic matter and other substances that damage the stone. Therefore, drinking water was used for mixing and purification in this study.

D. Graphene Oxide

Graphene oxide (GO) is an oxidized form of graphene. It is an atomic layer produced by the oxidation of graphite and is inexpensive and readily available. Graphene oxide is easy to process because it can disperse in water and other solvents. The graphene oxide used in this study is shown in Figure 3.

Fig.3 Graphene oxide (GO) (brand: vedayukt india private limited)

E. Material Proportion of Mortar

Table 2.4.1: Mix Proportion (1: 3)

|

CEMENT |

SAND |

WATER |

GO % W/W of Cement |

|

3.10 kg |

7.76 kg |

1.302 kg |

0% |

|

3.10 kg |

7.76 kg |

1.302 kg |

0.03% |

|

3.10 kg |

7.76 kg |

1.302 kg |

0.05% |

|

3.10 kg |

7.76 kg |

1.302 kg |

0.07% |

III. EXPERIMENTAL WORK

A. Mixing of Mortar

Fig.4 Mixing of Mortar

In this study, the GO variable was used to create the model. These composites were divided into 0% w/w GO cement, 0.03% w/w GO cement, 0.05% w/w GO cement and 0.07% w/w GO cement. Measure the amount of material needed depending on the particular design and mix them to form the mortar.

B. Casting of the Specimens

For the compression test, a standard cubic mold measuring 70.7 mm x 70.7 mm x 70.7 mm is used for testing purposes. A mold sample is used for the tensile test.

C. Curing of the Test Samples

The test samples are cured for 3 days, 7 days and 28 days in curing tank to check the strength values for cubes.

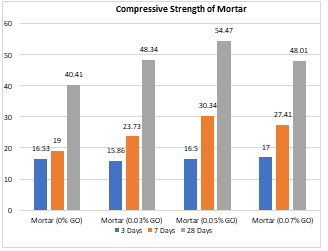

D. Compressive Strength

In this study, the compressive strength of concrete containing 0% GO, 0.03% 3% GO, 0.05% GO and 0.07% GO was measured after 3, 7 and 28 days of curing. Compressive strength is measured using a UTM machine.

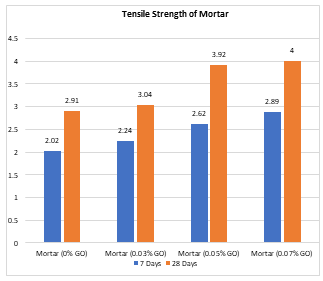

E. Tensile Strength

Tensile strength of 0% GO, 0.03% 3 GO, 0.05% GO and 0.07% GO samples cured for 7 days and 28 days were measured. The tests were done on a tensile testing machine (Vertex Cement Tensile Testing Machine)

IV. RESULTS AND ANALYSIS

A. Compressive Strength

The compressive strength of the mortar is measured in cubes. In the study, 0% 0.03%, 0.05%, 0.07% GO mixture treated on the 3rd, 7th and 28th days was started to be used. Measure compressive strength using a CTM machine.

Table 4.1.1: Compressive strength of cubes at 3 days

|

Sr no. |

Proportion of GO |

Strength (N/mm2) |

|

|

1 |

0% |

17 |

|

|

2 |

0% |

16.6 |

16.53 |

|

3 |

0% |

16 |

|

|

1 |

0.03% |

16.60 |

|

|

2 |

0.03% |

16 |

15.86 |

|

3 |

0.03% |

15.4 |

|

|

1 |

0.05% |

18.20 |

|

|

2 |

0.05% |

16 |

16.5 |

|

3 |

0.05% |

15.40 |

|

|

1 |

0.07% |

17.5 |

|

|

2 |

0.07% |

16 |

17 |

|

3 |

0.07% |

17.5 |

Table 4.1.2: Compressive strength of cubes at 7 days

|

Sr no. |

proportion of GO |

strength (N/ mm2) |

|

|

1 |

0% |

19.6 |

|

|

2 |

0% |

19.2 |

19 |

|

3 |

0% |

18.20 |

|

|

1 |

0.03% |

20.41 |

|

|

2 |

0.03% |

26.60 |

23.73 |

|

3 |

0.03% |

24.21 |

|

|

1 |

0.05% |

32.41 |

|

|

2 |

0.05% |

29.80 |

30.34 |

|

3 |

0.05% |

28.81 |

|

|

1 |

0.07% |

28.01 |

|

|

2 |

0.07% |

24.41 |

27.41 |

|

3 |

0.07% |

29.81 |

Table 4.1.3: Compressive strength of cubes at 28 days

|

Sr no. |

proportion of GO |

strength (N/ mm2) |

|

|

1 |

0% |

40.21 |

|

|

2 |

0% |

37.81 |

40.41 |

|

3 |

0% |

43.21 |

|

|

1 |

0.03% |

48.81 |

|

|

2 |

0.03% |

45.61 |

48.34 |

|

3 |

0.03% |

50.61 |

|

|

1 |

0.05% |

57.81 |

|

|

2 |

0.05% |

51.81 |

54.47 |

|

3 |

0.05% |

53.81 |

|

|

1 |

0.07% |

52.01 |

|

|

2 |

0.07% |

45.01 |

48.01 |

|

3 |

0.07% |

47.01 |

|

Fig. 5 Compressive Strength of mortar

B. Tensile Strength

The tensile strength of the mortars was measured on specimens with 0%, 0.03%, 0.05% and 0.07% GO added and cured for 7 days, 14 days and 28 days.

Table 4.2.1: Tensile strength of cubes at 7 days

|

` |

proportion of GO |

Strength (kg*10) |

KN/mm2 |

|

1 |

0% |

13.54 |

|

|

2 |

0% |

13 |

2.02 |

|

3 |

0% |

13.31 |

|

|

1 |

0.03% |

14 |

|

|

2 |

0.03% |

15 |

2.24 |

|

3 |

0.03% |

15.19 |

|

|

1 |

0.05% |

16.19 |

|

|

2 |

0.05% |

17.5 |

2.62 |

|

3 |

0.05% |

18 |

|

|

1 |

0.07% |

18.75 |

|

|

2 |

0.07% |

19.4 |

2.89 |

|

3 |

0.07% |

18.86 |

Table 4.2.2: Tensile strength of cubes at 28 days

|

Sr no. |

proportion of GO |

Strength (kg*10) |

KN/mm2 |

|

1 |

0% |

19.5 |

|

|

2 |

0% |

18.75 |

2.91 |

|

3 |

0% |

19.16 |

|

|

1 |

0.03% |

19.8 |

|

|

2 |

0.03% |

20 |

3.04 |

|

3 |

0.03% |

20.17 |

|

|

1 |

0.05% |

24.8 |

|

|

2 |

0.05% |

25.7 |

3.92 |

|

3 |

0.05% |

26.84 |

|

|

1 |

0.07% |

25.8 |

|

|

2 |

0.07% |

26.1 |

4 |

|

3 |

0.07% |

27.01 |

Fig. 6 Tensile Strength Of mortar

The effect of GO on the fresh mortar and on the cement, samples was investigated through the methods presented in the previous section. The results are summarized as follows.

C. Compressive Strength

Determining compressive strength after 3, 7 and 28 days of curing. Graphene oxide increases the early compressive strength after 3 and 7 days, but less so after 28 days of treatment. In addition, the compressive strength of 0.05% graphene increased by 35% after 28 days, while the compressive strength of 0.07% graphene increased by 31% after 28 days. This shows that the best improvement in compressive strength is in 0.05% w/w cement.

Henrik et al.,2018 The compressive strength of 0.2% graphene decreased by 8% after 28 days, but the addition of 2% superplasticizer 2.0% increased by 7% after 28 days.

(Chintalapudi et al., 2021) Addition of Graphene Oxide in cement increases compressive strength at optimum dosages. An average increase in compressive strength of 28.5% and 46.4% of GO dosages 0.02%, and 0.03% dosage respectively was observed at 28?days of curing.

D. Tensile Strength

The tensile strength is calculated after 7 and 28 days of curing. Add of 0.05%,0.07% % graphene oxide, the strength gradually increased 34%, 36% after curing for 28 days.

(Li X,2017) Tensile splitting Strength was improved by around 15%. In a microstructural investigation, the interfacial transition zone in cement mortar was found to be denser due to the addition of graphene oxide.

Conclusion

1) In general, graphene oxide can be used as an additive to cement products due to its unique properties. 2) Graphene oxide creates a good relationship with the cement matrix and increases the interaction between graphene oxide and cement products. This increases the compressive strength of the mortar 3) The optimum strength increased is observed at 28 days of curing with 0.05% adding GO by weight of Cement. 4) The addition of graphene oxide also improves the hydration process of the cement, which makes the microstructure denser and improves the overall properties. 5) The nanoscale nature of graphene oxide particles enables them to fill the voids in the cement matrix, thereby reducing porosity and increasing strength 6) Adding graphene oxide to cement mortar is also an acceptable property to affect the tensile strength of materials widely has been researched.

References

[1] Siti 1Aktar Ishak, Haslenda Hashim,Low carbon measures for cement plant – a review,Journal of Cleaner Production,Volume 103,2015,Pages 260-274,ISSN 0959-6526, https://doi.org/10.1016/j.jclepro.2014.11.003. (https://www.sciencedirect.com/science/article/pii/S0959652614011731) [2] T. Naresh Kumar, K. Vishnu Vardhan, M. Hari Krishna, and P. Venkata Nagaraja, ‘Effect of graphene oxide on strength properties of cementitious materials: A review’, Mater. Today Proc., vol. 46, pp. 2157–2160, Jan. 2021, doi: 10.1016/j.matpr.2021.02.637. [3] Senthil Kumar Kandasamy,Chapter 8 - Graphene oxide,Editor(s): Yarub Al-Douri,In Woodhead Publishing Series in Electronic and Optical Materials,Graphene, Nanotubes and Quantum Dots-Based Nanotechnology,Woodhead Publishing,2022,Pages 155-172,ISBN 9780323854573, https://doi.org/10.1016/B978-0-323-85457-3.00024-4. (https://www.sciencedirect.com/science/article/pii/B9780323854573000244) [4] G. Ramakrishna, T. Sundararajan,17 - A novel approach to rheological and impact strength of fibre-reinforced cement/cementitious composites for durability evaluation,Editor(s): Mohammad Jawaid, Mohamed Thariq, Naheed Saba,In Woodhead Publishing Series in Composites Science and Engineering,Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites,Woodhead Publishing,2019,Pages 389-406,ISBN 9780081022900, https://doi.org/10.1016/B978-0-08-102290-0.00017-9. (https://www.sciencedirect.com/science/article/pii/B9780081022900000179) [5] Henrik Kjaernsmo, Samdar Kakay, Kjell T Fossa and John Gronli, The Effect of Graphene Oxide on Cement Mortar, International Conference on Smart Engineering Materials (ICSEM), 2018 [6] K Chintalapudi, R. M. R Pannem, \"Strength properties of graphene oxide cement composites\", Materials Today , Volume 45, Part 4, 2021, Pages 3971-3975 [7] Li, Xiangyu & Lu, Zeyu & Chuah, Samuel & Li, Wengui & Liu, Yanming & Duan, Wen & Li, Zongjin. (2017). Effects of graphene oxide aggregates on hydration degree, sorptivity, and tensile splitting strength of cement paste.

Copyright

Copyright © 2025 P. D. Nemade, Vedant Mogal, Shrikant Kochure, Sarvesh Mahewar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET66651

Publish Date : 2025-01-23

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online