Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Hydraulic Design Concept of 6.60MLD Water Treatment Plant

Authors: Abhijit Mangaraj, Smrutirekha Sahoo, Ananya P. Parida

DOI Link: https://doi.org/10.22214/ijraset.2024.64395

Certificate: View Certificate

Abstract

The design and construction of a 6.6 million liters per day (MLD) water treatment plant (WTP) in Belpada Village, Odisha, aim to meet the increasing water demand while ensuring public health through effective water treatment processes. The plant, which sources raw water from the Tel River, follows a well-structured treatment process that includes aeration, sedimentation, filtration, and disinfection. This journal outlines the hydraulic design, treatment schemes, and structural components of the WTP. Design calculations, based on CPHEEO standards, are also discussed, focusing on the hydraulic detention times, surface loading, filtration rates, and sludge management techniques.The design of water treatment plants (WTPs) plays a crucial role in delivering safe drinking water, especially in areas with high population density and industrial growth. The 6.6 MLD WTP designed for Belpada Village in Balangir District draws water from Tel River and utilizes a cascade aeration system for the removal of contaminants. This paper discusses the hydraulic and process design, focusing on flow rates, detention times, and surface loading parameters that meet the Central Public Health and Environmental Engineering Organization (CPHEEO) standards.

Introduction

I. INTRODUCTION

A. Background

Access to clean drinking water is a global necessity. India, housing 16% of the world’s population but with only 4% of the water resources, faces unique challenges in managing its water supply. This paper focuses on the 6.6 MLD WTP, designed to meet local water demands while ensuring compliance with safety standards. The design considers the varied quality of raw water, which significantly influences the treatment processes.

Water is a critical resource, and access to clean drinking water is fundamental to public health. Despite India’s vast population, the country possesses only 4% of the world's freshwater resources. The increasing demand due to urbanization, industrialization, and population growth places enormous pressure on water supply systems. To address this issue, the construction of reliable and efficient water treatment plants (WTP) is crucial.

The 6.6 MLD WTP in Belpada Village is designed to cater to both current and future demands, providing potable water that meets Indian Standards (IS 10500:2012). This design is driven by the growing population in the Titilagarh Block, projected to increase from 38,756 in 2011 to over 62,648 by 2054

B. Objective

The main objective is to develop a hydraulic design for a WTP that processes 6.6 million liters per day (MLD), ensuring treated water meets IS 10500:2012 standards.

II. LITERATURE REVIEW

Various studies have been conducted to understand the health impacts of untreated or inadequately treated water. Arsenic contamination in countries like Bangladesh, Chile, and India highlights the importance of well-designed treatment systems?. Hydraulic retention time (HRT), coagulation, and filtration processes have been studied extensively to enhance the efficiency of WTPs. In designing water treatment systems, factors such as surface loading rate, weir overflow rate, and sludge handling are critical.

Studies by the US Geological Survey, for example, have shown that low levels of a number of pharmaceuticals are found in treated drinking water supplies in the United States, but the effects of these substances on health (if any) are unknown.

Arsenic is an environmental contaminant in drinking water that has had profound health impacts. In an attempt to alleviate microbial diseases (e.g., typhus, cholera, and dysentery) from surface drinking water supplies (e.g., hand dug ponds or shallow wells)

In Bangladesh, well-intentioned, charitable organizations drilled numerous wells to tap the groundwater as an alternate and clean drinking water supply. Unfortunately, the sedimentary strata at the depths where the wells were drilled contained high levels of arsenic. Arsenic appears to be released from the sediments by reductive dissolution of arsenic-rich iron ox hydroxides. The sediments containing the arsenic-rich iron ox hydroxides were laid down in the delta area of Bangladesh long ago from the weathering of metal sulfide deposits located upstream.

High sedimentary organic matter content (up to 6% by weight) drives anaerobic microbial degradation processes resulting in reduction of the iron (as Fe3 +) in the ox hydroxides to soluble Fe2 +, releasing arsenic in the process. Chronic exposure to arsenic in drinking water at concentrations of 0.01 mg L− 1 or more can lead to increased risk of skin, lung, bladder, and kidney cancer. Approximately 50% of shallow drill wells in Bangladesh have > 0.01 mg L− 1 and approximately 30% have > 0.05 mg L− 1 of arsenic in groundwater, respectively.

III. PROCESS DESCRIPTION

- Cascade Aerator The cascade aerator is designed to remove dissolved gases, iron, and other contaminants from the raw water by allowing it to cascade down steps. As the water flows over each step, it absorbs oxygen, which oxidizes ferrous iron to ferric iron. The ferric iron precipitates out and is removed downstream in the clariflocculator. The surface loading rate for the aerator is 0.03 m²/m³/hr, and the aerator is designed with six steps, each with a rise of 0.3 meters?Title and Author Details.

- Coagulation and Flocculation Alum and lime are dosed into the water to neutralize the charge on suspended particles, promoting flocculation. A flash mixer is provided for rapid mixing of chemicals, with a retention time of 60 seconds. The clariflocculator combines both flocculation and clarification in one unit, providing 30 minutes for flocculation and 2.5 hours for clarification?.

- Sedimentation and Filtration In the sedimentation process, particles settle by gravity in the clarifier, and the clarified water moves to rapid sand filters. Each filter bed is designed for a filtration rate of 4.8 m³/m²/h, and backwashing is performed regularly to remove accumulated particles. The filters use a dual-media system with sand and gravel?.

IV. DESIGN CRITERIA OF THE WATER TREATMENT PLANT (WTP)

- The design of the WTP is based on understanding water contamination, which primarily arises from untreated industrial wastewater. Effluents from various industrial processes are discharged into water bodies, often carrying high levels of organic and inorganic contaminants. Therefore, the design calculations and assumptions focus on addressing these pollutants effectively.

- Assumptions in Design of Drinking Water Treatment Plant

Design assumptions help in determining the size and capacity of water treatment units. These are crucial for ensuring that the treatment plant meets the water demand and can handle the pollutants effectively.

1) Detention Time (Hydraulic Retention Time, HRT)

This refers to the average time water spends in a treatment unit, allowing contaminants to be removed or neutralized. Sufficient retention time is crucial for water purification.

2) Flow Through Velocity (Horizontal Velocity)

In treatment tanks, raw water particles experience horizontal velocity due to flow and vertical velocity due to gravity. For settling tanks, the horizontal velocity is controlled (1.2 to 1.5 m/min) to prevent the re-suspension of settled solids.

3) Settling Velocity

This measures the speed at which particles settle by gravity, helping in designing the depth of treatment units and ensuring particles are removed before effluent exits the basin.

4) Surface Loading Rate (Overflow Rate)

This is the volume of raw water applied per unit surface area of the treatment basin, expressed as m³/d/m². It helps in determining the appropriate surface area for treatment units.

5) Weir Loading Rate

The weir loading rate is the quantity of water flowing over the weir per unit length, ideally maintained at a maximum of 300 m³/d-m to avoid draw-down currents.

V. DESIGN PARAMETERS

The WTP is designed for a total raw water demand of 6.60 MLD, considering peak day demand. The design complies with the CPHEEO Manual (Third edition, 1999), ensuring appropriate treatment for the analyzed raw water quality.

Raw Water Quality:

The raw water sample was collected from Tel River & Location of Intake for Titilagarh Block (Scheme – 2) is at Belpada Village.

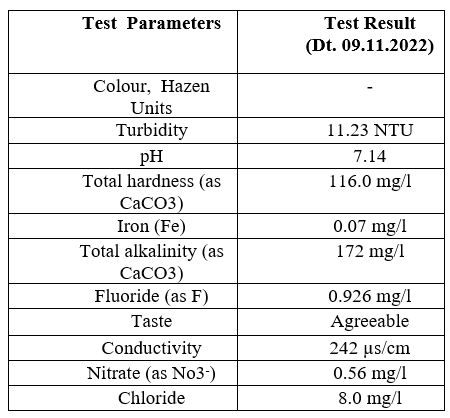

Table 1. Raw Water Quality.

Treated Water Quality: The treated water characteristics shall fulfil requirements of guidelines for potable water in compliance with the Indian standard Specifications for Drinking Water IS 10500:2012.

VI. PROCESS DESCRIPTION

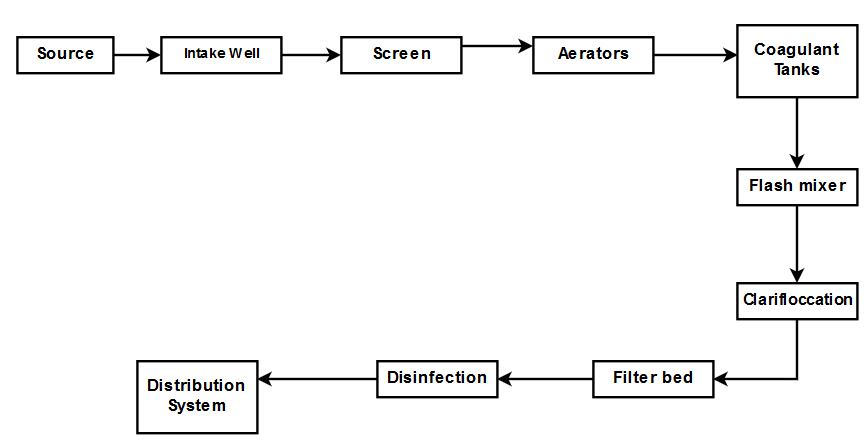

Broadly the process scheme for the WTP described below:

Cascade Aerator:

The cascade aerator is designed to remove iron, color, odor, and dissolved gases from raw water by aerating it as it flows over steps, promoting oxygen absorption. This process converts dissolved ferrous iron to ferric iron, which precipitates and settles downstream in clarifiers. The aerator’s surface loading rate is 0.03 m²/m³/hr.

After the cascade aerator, the water passes through an RCC channel with a Parshall flume to monitor flow, where pre-chlorination, alum, lime, and soda ash are dosed for removing color, odor, hardness, and suspended solids. Lime and soda ash are used when total hardness exceeds 200 ppm.

The treated water then flows to a distribution chamber, which evenly distributes water to clariflocculators. A bypass arrangement is provided to route the water directly to rapid gravity filters if required. The clariflocculators combine flocculation and clarification, allowing particles to settle before the water is filtered.

This aeration process significantly improves the quality of raw water, ensuring the removal of impurities before further treatment steps.

Fig 1. Process flow diagram

VII. PROCESS DESIGN CALCULATION OF 6.60 MLD WTP

PROCESS DESIGN

Basic Data :

Ultimate Flow = 5.48 MLD

(or) 5480.00 cum

Hours of supply (Operation Time) : = 24.00 Hrs

Overall Design Flow for 24 hrs = 6.58 MLD

Say 6.60 MLD

(or) 6600.00 cum

Hours of operation 20.00 hrs

Rate of Design Flow per Hour : (6.6*1000/24) = 275.00 cum/hr

Rate of Design Flow per minute : (275/60) = 4.58 cum/min

Rate of Design Flow per second : (4.58/60) = 0.08 cum/sec

Over Loading for channels & pipes = 50.00%

Overall Design Flow = 9.90 MLD

Rate of Design Flow per Hour : (9.9*1000/24) = 412.50 cum/hr

Rate of Design Flow per second : (412.5/3600) = 0.11 cum/sec

INLET PIPE :

Inlet Pipe Velocity (as per basic piping design) = 1.20 m/Sec

By using the principle

Area : (0.08/1.2) = 0.06 sqm

Pipe Diameter: = 0.28 m

say 300.00 mm

Hence provide intake pipe to Cascade Aerator as 300mm Dia DI Pipe

PROCESS CALCULATIONS

1) CASCADE AERATOR

Hollow Column - Diameter considered = 400.00 mm

Wall Thickness = 200.00 mm

Shaft Over all dia = 800.00 mm

Bell Mouth Diameter with 0.15m height = 600.00 mm

No. of trays (Including 1 no freefall thread) = 6.00 nos

Thread = 600.00 mm

Rise = 300.00 mm

Free fall from last step considered = 0.30 m

Surface Loading for Cascade Aerator = 0.030 m2 /m³ /hr

Ref: CPHEEO -Class 7.2.3.3 -Cascade/ Aerators :pgNo-192 - 0.015 to 0.045m2/m3/hr

Design Flow rate = 275.00 cum/hr

Area of Bell Mouth = 0.79 m2

Area Required for Cascade Aerator = 9.04 m2

Say 9.04 m2

2) Bell Mouth

Cascade Aerator Diameter

A. Dia of first Cascade 2.00 m

B. Dia of second Cascade 3.20 m

C. Dia of third Cascade 4.40 m

D. Dia of Forth Cascade 5.60 m

E. Dia of Fifth Cascade 6.80 m

F. Dia of Free fall Sixth Cascade 8.00 m

Provided Area = 35.81 m2

say 35.81 m2

Required Area .04 H/s OK

Side Circular Launder

Flow rate per second : = 0.11 cum/sec

Considering Half the Flow rate per second = 0.06 cum/sec

Velocity = 0.90 m/sec

Area = 0.06 sqm

Width of Launder Considered = 0.50 m

Depth = 0.12 m

say 0.30 m

Free Board = 0.50 m

Overall diameter considering circular launder excluding thickness of launder = 9000 mm say 9.00 m

Hence provide Cascade Aerator dia as 9m (or) 9000 mm including circular launder of Size 0.5m wide x 0.3m swd launder+0.5m free board +0.3m Free Fall.

Raw Water channel Size: 1.1m wide x 0.4 m SWD +0.5m Free Board

RAW WATER CHANNEL

provide Raw Water channel Size: 1.1m wide x 0.4 m SWD +0.5m Free Board

3) PARSHALL FLUME:

Length of Parshall Flume (L1+L+L2+L4+L5) = 3.845 m

say 3.900 m

Upstream Liquid Depth ha+0.1 = 0.500 m

Submergence ratio ha/hb = 0.600

Downstream liquid depth hb+hp2= 0.310 m

3a FLOW MEASURING / DOWNSTREAM CHANNEL:

provide flow measuring channel size as 1.1 m wide x 0.31 m swd+0.5 m FB

3b BY-PASS CHANNEL:

provide flow measuring and bypass channel size as 0.75 m wide x 0.3 m swd+0.5 m FB

c By-pass gate and arrangement at distribution chamber for filter channel.

Provide manual Stainless Steel Gate of 0.75 wide x 0.8 m height (0.3 m ht + 0.5 m fb)

d IN BYPASS CHANNEL DROP CHAMBER :-

provide distribution chamber size as 1.50 m LG x 1.5m wide x 3.6 m SWD + 0.5 m FB

4) DISTRIBUTION CHAMBER

provide distribution chamber size as 1.0 m LG x 2m wide x 2 m SWD + 0.5 m FB

5) FLASH MIXER

provide flash mixer size as 1.25 m dia x 2 m swd+0.50 m FB - 2No.s

DROP CHAMBER:-

provide drop chamber size as 1 m x 1 m 5.60 m heigth - 2No.s

Flash mixer inlet gate

Provide manual Stainless Steel Gate of 0.3m wide x 0.35 m height

Flash Mixer Motor

Provide 0.75 HP Motor (Size may vary as per actuals)

Design of Flash mixer impeller

Provide impeller of 0.4 m dia with 6 blades of size 0.1 x 0.1 m. (Size may vary as per actuals)

CLARIFLOCCULATOR INLET PIPE - 2 Nos

Provide CLF inlet pipe as 350mm dia DI pipe to clariflocculator from flash mixer

CLARIFLOCCULATOR INLET SHAFT (CENTRE HOLLOW COLUMN)

Provide 900 mm dia (400 + 500 mm) over all size CLF Center Hollow Column.

Conclusion

Research is essential to enhance understanding of the effectiveness of major drinking water disinfection methods—particularly chlorination, chloramination, ozone, and chlorine dioxide—against resistant protozoan cysts and viruses. Investigating key factors influencing disinfection efficacy under actual treatment plant conditions is also crucial. Without this knowledge, future decisions on water treatment methods and the trade-offs regarding chlorination by-products may be disproportionately guided by outdated information on bacterial pathogens that are less of a concern today. Additionally, \"life-cycle\" studies of disinfectants are necessary to assess the broader implications of switching to alternative disinfection practices. For instance, the reliability of ozone disinfection and its potential environmental impact must be thoroughly evaluated before making national and local decisions about such conversions. The study revealed several important conclusions: 1) The microbiological health risk from most tube-well water is low at the supply point. 2) Priming practices may affect bacteriological water quality. 3) Water quality deteriorates significantly at household storage. 4) There is a correlation between the absence of fecal coliforms (FC) at the storage point and the supply point.

References

[1] Boubel, R.W. 1991. Fundamentals of Air Pollution. Academic Press, N.Y. [2] Botbin, D., and Keller, E.1995. Enironmental Science. John Wiley and Sons, USA. [3] Chadha, K.L. and Swaminathan, M.S. 2006. Environment and Agriculture. Malhotra Publishing House, New Delhi. [4] Cunningham, W.P. and Saigo, B.W. 1997. Environment Science. McGraw-Hill, USA. [5] Deswal, S. and Deswal, A. 2005. A Basic Course in Environmental Studies. Dhanpat Rai & Co ltd., Delhi. [6] Lal, R. and Stewart, B.A. 1992. Advances in Science: Soil Restoration Springer Verlag, New York. [7] Manual on Sewerage & Sewage Treatment. 1993. Ministry of Urban Development, Govt. of India. [8] Manual on Water Supply and Treatment. 2000. Ministry of Urban Development, Government of India , New Delhi. [9] Miller, T.G. 2000. Environment Science.Wadsworth Publishing Co., Belmont. Sharma, P.D. 1994. Ecology and Environment. Ashish Publications, Wagner, K.D. 1998. Environment Management. W.B. Saunders Co, Philidelphia, USA.

Copyright

Copyright © 2024 Abhijit Mangaraj, Smrutirekha Sahoo, Ananya P. Parida. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64395

Publish Date : 2024-09-29

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online