Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

An Important Play Role of Polymer in Daily Life and Duration of Covid19

Authors: Suresh Kumar Meena, Rakesh Meena

DOI Link: https://doi.org/10.22214/ijraset.2023.49105

Certificate: View Certificate

Abstract

In this article we are focused on specially application of polymers and what hazards effects will come in future . Because at present time polymer application day by day used in multifunctional work. Here we want to discuss type of polymer. Synthetic polymers having wide applications like as a electronic equipments ,aerospace application, Light equipment , Cardiac heart valves, Polymer base mesh used in prevent of hernia in human body, synthetic polymer rayon useful in textiles industries. Synthetic polymers are vast used in medical sectors ,like as drug delivery, many packing are easily transported from one palace to other palace self-healing, and molecular-recognition materials. Many researchers have synthesized gel materials by designing their molecular and macroscopic structure as well as the constituent materials from the perspective of organic chemistry, physical chemistry, and biochemistry, among others. In addition, the fact that pharmacy, biomedicine, molecular biology, biochemistry, and biophysics are the fields that polymers and polymer chemistry play a significant role in the development of their new areas. It is obvious why the study of giant molecules is one of the most attended and the fastest growing fields of science. Therefore, it seems that polymer is not a specialized interdisciplinary or branch of chemistry. Here I have mention one of the polymers made by me and focused on application of polymers.

Introduction

I. INTRODUCTION

Meaning of the “polymer” refers to large molecules having single repeat unit in their backbones [1-3] . Polymers single unit name is well knowing monomer, that are linked together by covalent bonds to form long chains but in few cases we are found that monomer adding with central atom by coordinated bond. The term was coined in 1833 by Jons Jacob Berzelius [4-5]. The modern concept of polymers as covalently bonded macromolecular structures was proposed in 1920 by Herman Staudinger [6 ]

better selectivity and rapid measurements have been achieved by replacing classical sensor materials with polymers involving nano technology and exploiting either the intrinsic or extrinsic functions of polymers. Semiconductors, semiconducting metal oxides, solid electrolytes, ionic membranes, and organic semiconductors have been the classical materials for sensor devices. The developing role of polymers as gas sensors, pH sensors, ion-selective sensors, humidity sensors, biosensor devices, etc., are reviewed and discussed in this paper. Both intrinsically conducting polymers and non-conducting polymers are used in sensor devices.

II. CLASSIFICATION OF POLYMER

Natural polymers, synthetic polymers and semi-synthetic polymers. Natural polymers are materials of large molecular weights from natural origin such as plants, microorganisms and animals. In comparison to synthetic and semi-synthetic, natural polymers remain attractive primarily because they are inexpensive, readily available, capable of multitude of chemical modifications and potentially biodegradable and compatible due to their origin. Natural polymers possess ample scope in drug, food and cosmetic industries. Natural polymers are biogenic and their biological properties such as cell recognition and interactions, enzymatic degradability, semblance to the extracellular matrix and their chemical flexibility make them materials of choice for drug delivery. Natural polymers These polymers are found in nature generally from plants and animals sources. Such as proteins, cellulose, starch, resins, etc. Semi-synthetic polymers These polymers are obtained from natural polymers by simple chemical treatment to change the physical properties of natural polymers like starch, silicones, etc. Synthetic polymers The fibers which are synthesized in laboratory by polymerization of simple chemical molecules are called synthetic polymers. Synthetic polymers such as Nylon, polyethene, polystyrene, synthetic rubber, PVC, Teflon etc [ 7].

III. EXPERIMENTAL

Methylacrylate (CDH) was shaken two to three times with 5% NaOH to eliminate hydroquinone inhibitor, dried over anhydrous CaCl2 for 6 hours and distilled . The head and tail fractions were discarded. AIBN (2,2_-azobis–isobutironitrile (spectorchem.)) was recrystallized twice from methanol prior to use. BPO (benzoyl peroxide CDH) was used as received. THF was purified by distillation after being refluxed for 2 h in the presence of sodium. Dioxane and DMSO were used after distillation. DMF and methanol used in the present work were of analytical grade and were used as received.

IV. METHODOLOGY OF POLYMERS

A. Condensation Polymerization

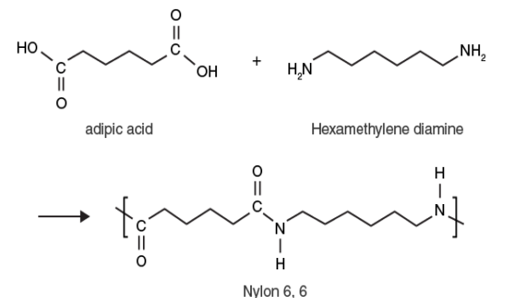

These are the polymers duration of the chemical reaction, water molecule is comes out and such type monomer is having lower molecular weight. Polyamides ,Polyester

Nylon 66

B. Addition Polymerization Methods

These methods are carried out with controlled thermal and catalyst conditions.

In Addition polymerization, or chain reaction polymerization, requires more than two monomer and one monomers to have at least one double bond. In addition polymerization, no molecule is eliminated and no by-product is generated. The molecular weight of the formed polymer is exactly the same as the sum of all monomers included in the polymerization.

The initiation of addition polymerization (in above case, the breaking of a double bond) requires catalysts, pressure, free radical, heat or UV light. The growing polymer chain is a free radical in the polymerization. Terminal radicals are required for ending the reaction. [10]

- There are Three Steps in this Type of Polymerization: Initiation, propagation, and termination. During initiation, the monomer acquires an active site to become a free radical. The addition of initiators or other approaches such as absorption of heat, light or irradiation can trigger the initiation process. In propagation, the initiated monomers add other monomers in rapid succession. This step continues until the active site, which is continuously relocated at the end of the growing chain during propagation, is deactivated by chain termination or chain transfer. The termination step involves the reaction of a polymer chain radical with another free radical. These three steps constitute the normal step-growth polymerization process.

- Bulk Polymerization: This mode of polymerization may be employed to obtain the purest form of polymer, and the greatest yield of polymer per unit volume may be obtained using this method. This method involves only the monomer molecule, an initiator and a chain transfer agent .

- Solution Polymerization: An inert solvent is added to the reacting components in the reaction vessel in this process. The solvent enhances the heat capacity, thereby reducing the viscosity and facilitating heat transfer. Some of the solvent may be refluxed to remove heat from the reaction vessel. But , much of the reactor space is taken up by the solvent. As such , compared to Bulk Polymerization, Solution Polymerization reduces both the reaction rate and the molecular weight of the compounds. Additional batch and continuous processes are used to separate the final polymer product and to recover and store the solvent used.

- Suspension Polymerization: The Suspension Polymerization process cannot be run in a continuous mode , since, such a system has stagnant corners where polymer accumulation may occur. out in jacketed, stainless steel or glass – lined stirred tanks, which may have a capacity of 20,000 gal or 75.5 m3 . Suspension Polymerization produces small, uniform polymer spheres. These are used directly, or may be extruded and chopped to form larger, moulded pellets.

- Emulsion Polymerization: This is the most widely used method of polymerization. This process overcomes the difficulty of heat control and low degree of polymerization. The organic reaction mass is emulsified with soap in a continuous aqueous phase. The dispersed particles are smaller in size than in Suspension Polymerization ( ≤ 0.1 µm) . In addition, due to stabilizing action of soap, the emulsion obtained is stable and agitation may not be necessary. In some methods, a water – soluble initiator may be used. The main product of Emulsion Polymerization is latex, which forms the basis of the popular latex paints. By coagulating the latex with ionic salts and acids, solid rubber may also be obtained.

- Homogeneous Polymerization: Homogeneous bulk polymerization ,the form of the monome is a gas , liquid or solid. No need to initiators . For homogeneous Solution polymerization, the monomer is completely dissolved in a solvent.

- Heterogeneous Polymerization: Emulsion polymerization, the monomer molecules are emulsified in aqueous media in the form of micelles. For heterogeneous Suspension polymerization, the monomer is suspended in a n aqueous or other type of media as large droplets .[ 8-9]

V. APPLICATIONS OF POLYMERS

- Solar Cell: The rapidly growing population and world economy have led to the continuously growing energy demand [10]. The enormous consumption of traditional fossil energy has resulted in the serious resource exhaustion and environmental pollution. One of the most imperative solutions is to look for alternative renewable energies. The solar energy stands out owing to solar is environmentally friendly and free from regional restrictions [11-12]. The solar cell is one of the most effective utilization approaches for solar energy. At present, the research and development of solar cells mainly focus on: (1) Mature silicon-based solar cells. Although the laboratory efficiency can reach more than 25% [13] the development of traditional silicon-based solar cells was limited by the sophisticated manufacturing process, high energy consumption and high cost [14] (2) Thin-film solar cells. The typical thin-film solar cells include the gallium arsenide [15], copper indium gallium selenide [16], and cadmium telluride [17], etc. Although these thin-film solar cells have high efficiency and stability, the abundance of gallium and indium in the crust is low and cadmium is toxic. (3) Emerging solar cells. The emerging solar cells are represented by organic photovoltaics (OPV) [18], dye-sensitized solar cell (DSSC) [19] and perovskite solar cell (PSC) [20]. This kind of solar cells have the advantages of lightweight and low cost.

2. Defence and Aerospace: at present time research of the thermal stable and multi applications of polymers are increased and enhance the research program and right now a lot of utility in defense areas because many equipment are very heavy and due to heavy metals, they are created very difficult for soldiers and many zones like as siyachin, china border areas is very difficult for our soldiers so many equipments, which was prepared by the synthetic polymers and have made many applications .more important application s we know that bullet froop jackets which was made by poly carbonates and recently international seminar arranged and many researchers , scientist were given excellent thought and newly innovation application of polymers [21]. Applications of centrifugal mixing of polyurethane foams, Case studies on coatings for solar radiation abatement, self healing of fiber reinforced polymer composites, and use of shape memory alloys integrated into composites for improved damage tolerance and lightening strike protection were presented. High performance applications of phosphazene elastomers now produced in 15 t/y quantities in Texas were described by Billy Goodwin from Materials Science Inc, pointing to the extreme low Tg (-70°C) and high thermal stabilities in these materials (up to 315ºC for short times). Applications of centrifugal mixing of polyurethane foams were described. Technology with defense related areas ranging from printing adhesives for composites joining, conformal circuitry, flame resistant and camouflage coating, low friction coatings, textured surfaces, flexible displays, integrated electronics and optical engineering. The need for fire resistant alternatives to FR4 substrates for multilayer printed circuit boards in aerospace electronics and the development of new "LuVo" high temperature thermoplastic .A wide range of opportunities for conductive polymers based on chimeric polymerisation of a novel difunctional monomer . The thermo-oxidative stability of there materials and their low moisture uptake point to potential applications including molecular imprinted polymers (MIPs) for nanosensors (explosives sensor), gas sensors, lithographic patterning, solar cells, supercapacitors and batteries and many more. New applications and advantages of fluoropolymers were described in the seminar Coatings applications include those requiring corrosion resistance, low surface tension while high discharge energy density leads to performance benefits for capacitors. This material system also supports electroactive polymer variants which can be engineered to have intrinsic piezo, pyro and ferroelectric properties to address opportunities in sensors, actuators ultrasound imaging and non volatile printed memories. Application in energy applications - notably fuel cells and portable photovoltaic systems were also described. Selective laser sintering (SLS) of syntactic foams based on glass microballoons and nylon in a project running at AWE Aldermarston was described by Anna Walmsley. Highly tailored syntactic foam structures from CAD files having excellent specific properties for composites manufacturing were reported.

3. Application in Medical Science: Synthetic polymers have widely importance role in medical science because without of the polymers we cannot alive our life because in medical field many equipments which are made by the polymers and elastomers which are make easily approach for everyone, here so many application and related articles references given. From past decades, many controlled release technologies were developed for the controlled release of macromolecules, including those based on diffusion-controlled matrices and reservoirs, chemically regulated biodegradable and biodegradable materials, and solvent-activated hydrogels and osmotic pumps [22]. Additional advances introduced “intelligent” materials that release drugs in response to environmental stimuli [23-28]. Pharmaceutical nanotechnology was established49[29] and has expanded to include liposomes, dendrimers, polymeric nano spheres, and polymeric micelles [30-32], Controlled release technologies have even incorporated microelectronics, to engineer remotely triggered and pulsatile therapeutic release [33-34]. Indeed, the field of drug delivery has grown substantially; over 9000 articles on “drug delivery systems” were published in 2014 alone Chemists, chemical engineers, materials scientists, and biomedical engineers are developing DDS with increasing control and sophistication. Many drug delivery products are on the market and helping patients; the estimated sales of DDS was $150 billion in 2013[35]. For example, Doxil, a PE Gylated liposomal doxorubicin, is indicated for several types of cancer, while Lupron Depot, PLGA microspheres releasing leuprolide acetate, is used to treat prostate cancer and endometriosis. Non-durable polymers are often implanted in the body for short-term treatment ( <30 days) or for procedural therapy. These materials include Thermoplastic Polyurethane , Polyamides (Nylon & PEBA) and Polyvinyl Chloride for central venous , diagnostic , interventional and drainage catheters.

4. Application in Smart City Project: Recent scenario is going on smart city formation in our country and one of the smart programs going on in every city having large number of sewerage line and one of the biggest program Gas supply in every house from the pipe lines , all iron pipelines replaced by polymer pipelines and biggest pipe line is made by the highly strength polymer sheet and this is very conventional for utility. Working in smart project every house and colony is connected by the pipe lines and this work very easily made by the polymer . Utility of the pipelines in oil field techniques.

5. Excellent Play Role of the Polymer Duration of Covid-19: Duration of covid -19 many difficulties generate in front of everyone because covid -19 viruses is having very spreading rate in atmosphere ,so how you can protect to Virus from contamination of every humanbeing. So polymer given an important role and protect from covid-19 virus. Considering that many disposable masks for medical use are made of polypropylene ,common name is ppkit and polyamides (PA), and also considering that since February 2020 China – its largest producer in the world – started to produce more than 200 million units of it a day, it is reasonable to expect that the demand for those polymers will also increase. The Japanese government raised investments in mask companies, guaranteeing a supply of more than 600 million masks per month . As if those initiatives were not enough, organizations whose business area is not centered on the production of Personal Protective Equipment kit (PPE) have directed their industrial plants to manufacture masks and other hospital medical equipment. This is the case of SAIC-GM-Wuling, a venture by the General Motors Co, which built 14 production lines for masks, with a daily production of 1.7 million units [36]. Many Italian industries have also dedicated themselves to the production of masks, allocating part of their industrial park for this new application [37]. As Dargaville et al. (2020) well pointed out, the current moment requires coordinated action among doctors, physiotherapists, materials engineers, and the industrial sector to rethink ways of production from already available supplies.

6. Application in Transportation oil Gas Water: Synthetic polymers have more important part in transportation of water, gas ,liquid and cruid oils send by the pipelines and continuous transmission of hydrocarbons across continents satisfying the energy demands of the global economy. Despite the enormous distances and the harsh environments involved, oil and gas pipelines are the most efficient and environmentally safe form of hydrocarbon transportation currently available today. Polymer pipes are easily transported from one place to another.

VI. ACKNOWLEDGEMENT

We are thankful to CDRI Luck now and SICART Vallabh-Vidhyanagar for analysis work. Authors Shiv Narayan Paliwal and Suresh Kumar Meena is thankful to UGC (RGNSF), DST FIST ,New Delhi or financial assistance .

Conclusion

Recently we are highly focused utility of polymers. Polymers are the building blocks of current materials science. Researchers are studying various latest techniques for manufacturing specialized, high-value polymers. Thereby, they are trying to find ways to overcome the long-standing expenses and inefficiencies associated with producing polymers. They are also developing the potential of such processes for sophisticated biomedical and pharmaceutical agents. At current scenario shows the wide application of polymer in daily life, we must be safe environment from the polymer pollution .therefore central Government should be apply one important and strictly prohibited policy to not used lower coast application of polymer and government should be prepared recycling policy.

References

[1] M. N. Belgacem, A. Gandini, Monomers, Polymers and Composites from Renewable Resources, Elsevier, (2011). [2] H-G. Elias, An Introduction to Polymer Science, Weinheim: VCH, (1997). [3] F. W. Billmeyer, Textbook of Polymer Science, New York: Wiley– Interscience, (1971). [4] Jöns Jacob Berzelius, \"Isomeri, dess distinktion från dermed analoga förhållanden,\" Årsberättelse om Framstegen i Fysik och Kemi, (1832) pp. 65–70. [5] William B. Jensen, \"Ask the Historian: The origin of the polymer concept,\" Journal of Chemical Education. 85/5, 624–625 (2008). [6] H. Staudinger, \"Über Polymerisation\" [On polymerization], Berichte der Deutschen Chemischen Gesellschaft (in German). 53/6, 1073–1085 (1920). [7] Rajeswari et al. World Journal of Pharmacy and Pharmaceutical Sciences., Vol 6, Issue 8, 2017. [8] Ullmann F., Encyclopedia of Industrial Chemistry, Wiley – VCH, 1999- 2012 [9] Kirk R. E., Othmer D. F., Encyclopedia of Chemical Technology, John Wiley and Sons, 1999-2012 [10] Min Wang, Haoran Sun, in Encyclopedia of Biomedical Engineering, 2019 [11] Sovacool, B.K. National context derives concrens. Nat. Energy 2018. [12] Quirin, S.; Jeff, T.; Tony, S.; Alexandra, W.; Oliver, M. Energy alternatives: Electricity without carbon. Nature 2008, 454, 816–823. [13] Green, M.A. The path to 25% silicon solar cell efficiency: History of silicon cell evolution. Prog. Photovolt Res. Appl. 2009, 17, 183–189. [14] Razykov, T.M.; Ferekides, C.S.; Morel, D.; Stefanakos, E.; Ullal, H.S.; Upadhyaya, H.M. Solar photovoltaic electricity: Current status and future prospects. Sol. Energy 2011, 85, 1580–1608. [15] Hubbard, S.M.; Cress, C.D.; Bailey, C.G.; Raffaelle, R.P.; Bailey, S.G.; Wilt, D.M. Effect of strain compensation on quantum dot enhanced GaAs solar cells. Appl. Phys. Lett. 2008, 92, 123512. [16] Chiril?, A.; Buecheler, S.; Pianezzi, F.; Bloesch, P.; Gretener, C.; Uh, A.R.; Fella, C.; Kranz, L.; Perrenoud, J.; Seyrling, S.; et al. Highly efficient Cu(In,Ga)Se2 solar cells grown on flexible polymer films. Nat. Mater. 2011, 10, 857–861. [17] Li, W.; Yang, R.L.; Wang, D.L. CdTe solar cell performance under high-intensity light irradiance. Sol. Energy Mater. Sol. Cells 2014, 123, 249–254. [18] Andersen, T.R.; Dam, H.F.; Hosel, M.; Helgesen, M.; Carle, J.E.; Larsen-Olsen, T.T.; Gevorgyan, S.A.; Andreasen, J.W.; Adams, J.; Li, N.; et al. Scalable, ambient atmosphere roll-to-roll manufacture of encapsulated large area, flexible organic tandem solar cell modules. Energy Environ. Sci. 2014, 7, 2925–2933. [19] Freitag, M.; Daniel, Q.; Pazoki, M.; Sveinbjornsson, K.; Zhang, J.B.; Sun, L.C.; Hagfeldt, A.; Boschloo, G. High-efficiency dye-sensitized solar cells with molecular copper phenanthroline as solid hole conductor. Energy Environ. Sci. 2015, 8, 2634–2637. [20] Wu, Y.Z.; Xie, F.X.; Chen, H.; Yang, X.D.; Su, H.M.; Cai, M.L.; Zhou, Z.M.; Noda, T.; Han, L.Y. Thermally stable MAPbI3 perovskite solar cells with efficiency of 19.19% and area over 1 cm2 achieved by additive engineering. Adv. Mater. 2017, 29, 1701073. [21] Polymers in Defence and Aerospace ApplicationsTuesday, 16 March 2010 (Hamburg Conference,10-11th February 2010) [22] Langer, R. S.; Peppas, N. A. Biomaterials 1981, 2 (4), 201. [23] Yoshida, R.; Uchida, K.; Kaneko, Y.; Sakai, K.; Kikuchi, A.; Sakurai, Y.; Okano, T. Nature 1995, 374 (6519), 240. [24] Kopecek, J. ? Eur. J. Pharm. Sci. 2003, 20 (1), 1. [25] Hoffman, A. S.; Stayton, P. S. Macromol. Symp. 2004, 207 (1), 139. [26] Peppas, N. A.; Hilt, J. Z.; Khademhosseini, A.; Langer, R. Adv. Mater. 2006, 18 (11), 1345. [27] Griset, A. P.; Walpole, J.; Liu, R.; Gaffey, A.; Colson, Y. L.; Grinstaff, M. W. J. Am. Chem. Soc. 2009, 131 (7), 2469. [28] Tong, R.; Hemmati, H. D.; Langer, R.; Kohane, D. S. J. Am. Chem. Soc. 2012, 134 (21), 8848. [29] Marty, J. J.; Oppenheim, R. C.; Speiser, P. Pharm. Acta Helv. 1978, 53 (1), 17. [30] Farokhzad, O. C.; Langer, R. ACS Nano 2009, 3 (1), 16. [31] Du, J.-Z.; Du, X.-J.; Mao, C.-Q.; Wang, J. J. Am. Chem. Soc. 2011, 133 (44), 17560. [32] Hu, X.; Hu, J.; Tian, J.; Ge, Z.; Zhang, G.; Luo, K.; Liu, S. J. Am. Chem. Soc. 2013, 135 (46), 17617. [33] Santini, J. T.; Cima, M. J.; Langer, R. Nature 1999, 397 (6717), 335. [34] Farra, R.; Sheppard, N. F.; McCabe, L.; Neer, R. M.; Anderson, J. M.; Santini, J. T.; Cima, M. J.; Langer, R. Sci. Transl. Med. 2012, 4 (122), 122ra21. [35] BCC Research. Global Markets and Technologies for Advanced Drug Delivery, 2014. [36] Harrison Lourenco and Daniela GallonPolymer Applications for Medical Care in the COVID-19 Pandemic Crisis: Will We Still Speak Ill of These Materials? EVIEW article,Front.Mater.,21August2020Sec. Polymeric and Composite Materials Volume 7 - 2020 | [37] Park, C., Kim, K., Roth, S., Beck, S., Kang, J., Tayag, M., et al. (2020). Global Shortage of Personal Protective Equipment Amid Covid-19 [38] Amendola, L., Saurini, M., Di Girolamo, F., and Arduini, F. (2020). A rapid screening method for testing the efficiency of masks in breaking down aerosols. Microchem. J. 157:104928. doi: 10.1016/j.microc.2020.104928 [39] Russell J. Varley, K. H. Leong ,Polymer Coatings for Oilfield Pipelines Chapter, First Online: 02 March 2016

Copyright

Copyright © 2023 Suresh Kumar Meena, Rakesh Meena. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET49105

Publish Date : 2023-02-13

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online