Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Improving Automotive Radiator Performance through Nanofluid-based Heat Transfer Enhancement Coupled with Pipeline Incorporation of Phase Change Materials

Authors: Chandan Kumar, Amit Agrawal

DOI Link: https://doi.org/10.22214/ijraset.2023.57241

Certificate: View Certificate

Abstract

Automotive radiator efficiency plays a pivotal role in the overall performance and sustainability of internal combustion engines. This research explores a novel approach to enhance heat transfer in automotive radiators through the synergistic use of nanofluids and the incorporation of phase change materials (PCMs). The nanofluids, consisting of copper oxide (CuO) or aluminum oxide (Al2O3) nanoparticles dispersed in a paraffin wax matrix, offer a dual mechanism for heat transfer improvement. The first aspect of the study involves the formulation and characterization of nanofluids with optimized ratios of CuO or Al2O3 nanoparticles in paraffin wax. These nanofluids exhibit enhanced thermal conductivity, ensuring efficient heat dissipation in the radiator. The choice of nanoparticles aims to harness their intrinsic thermal properties for improved performance. The second facet involves the integration of phase change materials directly into the radiator pipelines. Paraffin wax, chosen for its phase-change characteristics, acts as a latent heat storage medium. This addition serves a dual purpose: regulating temperature fluctuations within the radiator and absorbing excess heat during high-load conditions, thus preventing overheating. Experimental investigations will include a comprehensive analysis of heat transfer coefficients, pressure drops, and thermal stability of the nanofluid-PCM composite. Computational models will be employed to predict and optimize the fluid flow and heat transfer characteristics within the radiator system. The outcomes of this research hold promising implications for the automotive industry, offering a sustainable and energy-efficient solution to enhance radiator performance. The integration of nanofluids with phase change materials not only contributes to improved heat transfer efficiency but also addresses thermal management challenges in internal combustion engines, ultimately promoting a more environmentally friendly and reliable automotive cooling system.

Introduction

I. INTRODUCTION

Modern automobile engineering relies heavily on efficient heat management as it is essential to achieving the best possible vehicle performance, lifespan, and sustainability. The radiator is a vital part of this thermal control system; its job is to dissipate extra heat that the engine produces. For this reason, water-based engine coolants have been used historically. However, new approaches to improving the heat transfer efficiency of traditional coolants have been made possible by developments in nanotechnology.

Because of their high surface area-to-volume ratio and nanoscale particle size, nanofluids engineered suspensions of nanoparticles in base fluids offer remarkable thermal characteristics. The thermal conductivity and heat capacity of the coolant may be greatly increased by incorporating certain nanoparticles into the fluid. These improvements might completely transform thermal management the radiator's capacities, hence improving the overall effectiveness and performance of vehicle cooling systems.

This graph shows how, while keeping a fixed coolant mass flow rate, cooling capacity and efficacy fluctuate when air flow rate varies at different rpm. The y-axis displays the effectiveness, while the x-axis displays the air flow rate. At 42.7°C, the incoming ambient temperature has been maintained consistently. The plotted graphs show that while cooling capacity rises by 15% when pressure loss drops by 215.75% while keeping constant coolant mass flow rates, effectiveness does not vary when air flow rate increases.This strategy should be further improved and optimised by technology, opening up even more possibilities for automotive applications.

III. FUTURE SCOPE

The innovative approach of enhancing automotive radiator performance through nanofluid-based heat transfer, coupled with the incorporation of phase change materials (CuO or Al2O3 and paraffin wax), sets the stage for multifaceted future research. Further optimization studies, exploring a spectrum of nanoparticle concentrations and varied phase change material compositions, will fine-tune the system for diverse automotive applications. Long-term durability assessments will be pivotal to address potential wear, corrosion, and material stability concerns in real-world conditions. Integrating the proposed system with advanced cooling technologies, assessing its environmental impact, and adapting it for electric vehicles constitute crucial avenues for exploration. Collaborative partnerships with automotive manufacturers, coupled with economic feasibility studies, will ensure the seamless integration of this technology into commercial automotive production. Continuous research into innovative nanomaterials may uncover even more efficient alternatives. The future scope of this research extends beyond immediate improvements, aiming to position the proposed system as an economically viable, environmentally sustainable solution, contributing to the evolution of automotive thermal management and the broader landscape of sustainable transportation technologies.

Conclusion

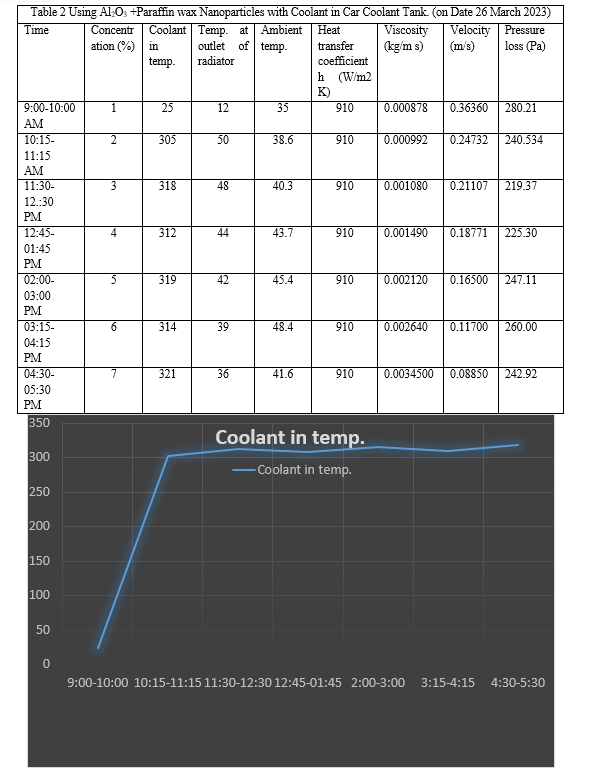

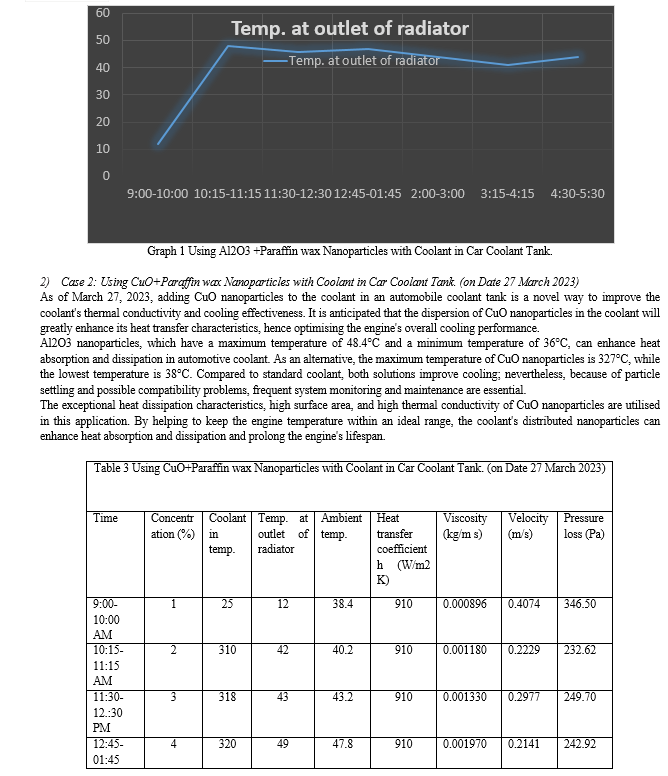

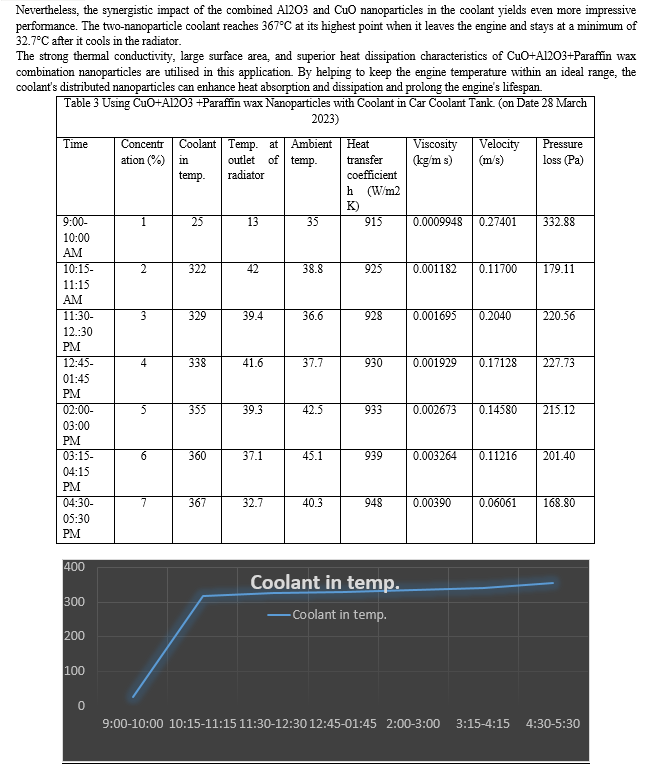

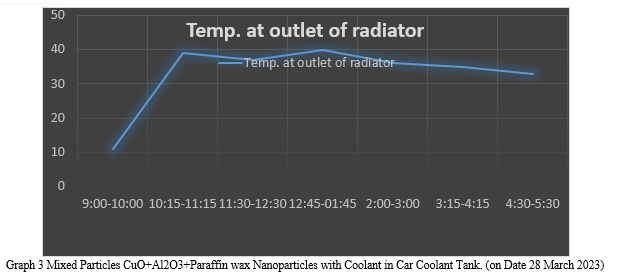

To sum up, employing nanofluids—that is, fluids that include nanoparticles of paraffin wax or oxides of aluminium and copper—in a car\'s cooling system offers a notable improvement over traditional coolants in terms of heat absorption and dissipation. The engine cooling system\'s overall thermal performance is enhanced by these nanoparticles, albeit the precise nanoparticle utilised may cause some temperature range differences. 1) Al2O3 +Paraffin wax Nanoparticles: • 321°C is the maximum temperature that exits the engine. • 36°C is the lowest temperature after the radiator cools. • Al2O3+Paraffin wax nanoparticles show remarkable stability and efficiency in heat transmission. They improve heat removal and successfully boost the coolant\'s boiling point. Particularly in colder climes, the minimum temperature of 36°C after passing through the radiator guarantees protection against freezing. 2) CuO +Paraffin wax Nanoparticles: • 327°C is the maximum temperature that exits the engine. • 38°C is the lowest temperature after the radiator cools. • CuO+ Paraffin wax nanoparticles effectively raise the coolant\'s boiling point and improve heat transmission. They do, however, need to be well maintained and could be more prone to settling. 3) CuO+Al2O3 + Paraffin wax Nanoparticles: • 367°C is the maximum temperature that exits the engine. • 42.7°C is the lowest temperature after the radiator cools. • CuO and Al2O3+ Paraffin wax nanoparticles work together to improve the coolant\'s capacity to absorb and dissipate heat. It is the best option for effectively controlling engine temperature as it reaches the greatest maximum temperature as it exits the engine and keeps the lowest minimum temperature after radiator cooling. Ultimately, the combination of CuO+Al2O3+ Paraffin wax nanoparticles is the best option because it offers exceptional low-temperature protection, a high maximum temperature capacity, and outstanding heat transfer efficiency. The benefits of engine temperature management outweigh the minor compatibility and particle settling concerns, which makes it an appealing alternative for vehicle cooling systems. To completely enjoy these benefits, though, the coolant system must be properly maintained and monitored. a) Case 1: Al2O3 +Paraffin wax Nanoparticles (March 26, 2023) On March 26, 2023, Al2O3+Paraffin wax nanoparticles were added to the automobile coolant, greatly increasing the efficiency of heat transmission. An improved capacity to disperse heat from the engine was demonstrated by the greater heat transfer coefficient (h). The system\'s pressure loss increased somewhat as the concentration of nanoparticles increased, despite a steady drop in viscosity and an increase in velocity. This suggests that whereas Al2O3+Paraffin wax nanoparticles improved heat transmission, managing the resulting pressure loss needs careful thought. b) Case 2: CuO+Paraffin wax Nanoparticles (March 27, 2023) As can be seen by looking at the increase in the heat transfer coefficient (h), the addition of CuO+Paraffin wax nanoparticles to the automobile coolant on March 27, 2023, significantly improved heat transfer efficiency. The fluid flow was aided by the concurrent rise in velocity despite the small increase in viscosity. CuO+Paraffin wax nanoparticles were added, and the system responded well, indicating the possibility of better heat dissipation. For best results, though, viscosity, velocity, and pressure loss must be carefully balanced. c) Case 3: CuO+Al2O3+Paraffin wax Nanoparticles (March 28, 2023) On March 28, 2023, the automobile coolant containing paraffin wax nanoparticles and CuO together showed improved heat transfer capacities. Better heat dissipation was indicated by a greater heat transfer coefficient (h). Pressure loss in the system showed an overall increasing trend, despite a minor drop in viscosity and an increase in velocity. The combination of CuO with Al2O3 or paraffin wax nanoparticles elicited a favourable response from the system, suggesting the possibility of enhanced heat transmission. Optimising the trade-offs between improved thermal characteristics and pressure loss requires striking a careful balance between nanoparticle concentrations. The fundamental component determining the balance between higher viscosity and better thermal conductivity has been identified as optimal nanoparticle concentration. Achieving the proper concentration is essential to avoid excessive viscosity, which might impair flow dynamics and pump performance. The heat transfer coefficient (h), a crucial measure of increased heat dissipation efficiency in the radiator system, significantly increased with the addition of nanoparticles. Furthermore, it was clear that attaining the intended outcomes required careful consideration of operating circumstances and system compatibility. Important procedures included making sure the nanofluid was compatible with radiator materials and other components and evaluating its stability at different operating temperatures. it seems like you\'re looking for recommendations or potential uses for a combination of CuO, Al2O3, and paraffin wax nanoparticles. Here are a few potential applications and suggestions based on the properties of these materials. 1) CuO and Al2O3 nanoparticles are known for their catalytic properties. Combining them with paraffin wax as a matrix could create a catalytic material for specific chemical reactions. 2) Paraffin wax is a phase-change material that can store and release thermal energy. Introducing CuO and Al2O3 nanoparticles into the paraffin wax matrix can enhance its thermal conductivity and efficiency as a heat storage material. 3) Copper oxide (CuO) nanoparticles have antimicrobial properties. Incorporating them with aluminum oxide nanoparticles and paraffin wax could lead to the development of antimicrobial coatings for various surfaces. 4) Paraffin wax nanoparticles can be used for controlled drug delivery. Adding CuO and Al2O3 nanoparticles to the formulation may provide additional functionalities, such as targeted delivery or imaging capabilities. 5) Create composite materials with improved mechanical and thermal properties by dispersing CuO and Al2O3 nanoparticles in a paraffin wax matrix. This can be useful in industries such as aerospace or automotive for lightweight, high-performance materials. 6) Both CuO and Al2O3 nanoparticles have sensing properties. Incorporating them into a paraffin wax matrix could lead to the development of sensors for specific gases or environmental conditions. 7) Explore the use of CuO and Al2O3 nanoparticles in conjunction with paraffin wax for applications in batteries, supercapacitors, or other electrochemical devices. To sum up, the thoughtful use of nanofluids into car radiator systems has the potential to completely transform automotive cooling systems. The enhanced heat transfer efficiency that follows leads directly to improved engine performance, fuel efficiency, and overall vehicle durability. This strategy should be further improved and optimised by future studies and developments in nanofluid technology, opening up even more possibilities for automotive applications.

References

[1] P.K.Trivedi, N.B.Vasava, “Study of the Effect of Mass flow Rate of Air on Heat Transfer Rate in automobile radiator by CFD simulation using CFX”, International Journal of Engineering Research & Technology (IJERT) ISSN: 2278- 0181, august – 2012. [2] P.Gunnasegaran, Shuaib, M. F. Abdul Jalal, and E. Sandhita, “Numerical Study of Fluid Dynamic and Heat Transfer in a Compact Heat Exchanger Using Nanofluids”, International Scholarly Research Network ISRN, Volume 2012, Article ID 585496, doi:10.5402/2012/585496. [3] Chandra Prakash Sahwala,?, Truong Quang Dinhb, Somnath Senguptac “Controller development of thermal management system for electric bikes” 2022 The 5th International Conference on Renewable Energy and Environment Engineering (REEE 2022), 24–26 August, 2022, Brest, France [4] Gogineni. Prudhvi, Gada.Vinay “Cooling Systems in Automobiles & Cars” International Journal of Engineering and Advanced Technology (IJEAT) ISSN: 2249-8958 (Online), Volume-2 Issue-4, April 2013 688 Published By: Blue Eyes Intelligence Engineering and Sciences Publication (BEIESP) © Copyright: All rights reserved. Retrieval Number D1447042413/13©BEIESP Journal Website: www.ijeat.org [5] Ashish Kalra and Sandeep Srivastava, “Gogineni. Prudhvi, Gada.Vinay, G.Suresh Babu Performance of Motorcycle Radiator at High Working Temperatures” International Journal of Engineering Research & Technology (IJERT) http://www.ijert.org ISSN: 2278-0181 Vol. 6 Issue 06, June – 2017 [6] Rafa Krakowski,“Internal Combustion Engine Cooling System With Elevated Cooling Temperature Research On The Model Test Stand”, Journal of KONES Powertrain and Transport, Vol. 20, No. 4 2013. [7] Vinothkumar Sivalingam a 1, Poongavanam Ganesh Kumar “An automotive radiator with multi-walled carbon-based nanofluids: A study on heat transfer optimization using MCDM techniques” Case Studies in Thermal Engineering Volume 29, January 2022, 101724 [8] Filipe Neves a, A.A. Soares a b, Abel Roubo “Forced convection heat transfer of nanofluids in turbulent flow in a flat tube of an automobile radiator” Energy Reports Volume 8, Supplement 9, November 2022, Pages 1185-1195.

Copyright

Copyright © 2023 Chandan Kumar, Amit Agrawal. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET57241

Publish Date : 2023-12-01

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online