Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Improving Worker Safety in Construction A Data-Driven Approach

Authors: Mohammed Nasridin Yousif, Hmouda Ali Amer Salem Massoud, Taher Mohammed Taher Alghusni

DOI Link: https://doi.org/10.22214/ijraset.2024.65736

Certificate: View Certificate

Abstract

Worker safety in the construction industry is a critical concern, given the sector\'s high rates of accidents and fatalities. This paper explores a data-driven approach to enhancing worker safety through the integration of advanced technologies such as Internet of Things (IoT), wearable devices, and Artificial Intelligence (AI). Occupational accidents are frequent in the construction industry, containing significant risks in the working environment. By leveraging real-time data from smart sensors, predictive analytics, and machine learning algorithms, construction sites can identify potential hazards, predict risks, and implement proactive safety measures. The study presents a comprehensive review of existing technologies and their applications in improving workplace safety. It also discusses the challenges in adopting these technologies, including data privacy, system integration, and the need for a safety-centric culture. Through case studies and practical insights, this paper highlights how data-driven approaches can transform traditional safety protocols, significantly reducing accidents and improving overall workforce well-being. The findings underscore the potential of data analytics in fostering a safer, more efficient construction industry.

Introduction

I. INTRODUCTION

Worker safety is a fundamental concern in the construction industry, which consistently reports some of the highest rates of workplace accidents and fatalities globally. Despite advancements in safety standards and regulations, the dynamic and hazardous nature of construction sites presents ongoing challenges for ensuring worker well-being. Falls, electrocutions, and equipment-related incidents are among the most common causes of injuries, emphasizing the need for more effective safety strategies.[1]

Recent advancements in machine learning, computer vision, and increased affordability and processing power of advanced technologies have prompted researchers to work towards the development of data-driven accident prevention systems, adding a technology-driven safety layer to construction sites.[2]

Traditional safety practices, while essential, often rely on reactive measures, addressing incidents after they occur. In contrast, modern technologies offer the potential for proactive interventions by identifying risks and preventing accidents in real time. The advent of data-driven technologies, such as the Internet of Things (IoT), wearable devices, and Artificial Intelligence (AI), has revolutionized workplace safety by enabling continuous monitoring, predictive risk assessments, and automated decision-making.[3]

This paper focuses on leveraging a data-driven approach to improve worker safety in the construction sector. By collecting and analyzing real-time data from IoT-enabled devices, wearable technologies, and advanced analytics tools, construction companies can identify potential hazards, enhance compliance with safety protocols, and foster a safer working environment.[4]

The objectives of this study are threefold: to explore the applications of data-driven technologies in construction safety, to evaluate their effectiveness in mitigating risks, and to identify the challenges associated with their implementation. By doing so, this paper aims to provide a comprehensive understanding of how emerging technologies can transform safety management in construction, reduce accidents, and safeguard the lives of workers.[4]

The construction industry plays a vital role in economic development, but it is also among the most dangerous sectors for workers. According to reports from global labor organizations, construction sites account for a significant proportion of workplace injuries and fatalities. Common risks include falls from heights, exposure to hazardous materials, heavy equipment mishandling, and electrocution. Despite efforts to enhance safety through regulations and training programs, these measures often fall short due to the unpredictable and dynamic nature of construction environments.[5]

Traditional safety measures in construction are primarily reactive, relying on post-incident reporting and manual inspections. While such methods have reduced risks to some extent, they lack the capability to anticipate and prevent hazards proactively. As construction projects become more complex, the need for advanced safety strategies that integrate real-time monitoring, predictive insights, and rapid response mechanisms has become increasingly evident.

Recent advancements in technology provide an opportunity to address these challenges. The emergence of data-driven approaches, powered by the Internet of Things (IoT), wearable devices, Artificial Intelligence (AI), and Big Data analytics, is transforming the safety landscape. IoT sensors can monitor environmental conditions, such as air quality, temperature, and equipment usage, while wearable devices can track workers' physiological data, including heart rate and fatigue levels. AI algorithms analyze this data to predict potential risks and provide actionable insights for accident prevention.[5,6]

The adoption of these technologies offers several advantages. Real-time data collection allows for immediate identification of unsafe conditions, while predictive analytics can foresee hazards and enable preemptive measures. Additionally, these systems support compliance with safety regulations by maintaining detailed records and generating reports automatically. However, implementing data-driven safety solutions is not without challenges. Issues such as high initial costs, data privacy concerns, lack of standardization, and resistance to technological adoption in traditional workflows must be addressed for widespread implementation.[6]

This paper aims to provide a comprehensive exploration of how data-driven technologies can improve worker safety in construction. It examines the current state of safety practices, reviews the latest advancements in technology, and highlights successful case studies from the industry. Furthermore, it identifies the barriers to implementation and proposes strategies to overcome these challenges. By doing so, this study seeks to underscore the transformative potential of a data-driven approach to safety, fostering a culture of prevention and accountability in construction sites.

Construction sites are typically complex and unstructured, consisting of numerous construction resources involved in various activities (as shown in Figure 1), making it extremely difficult to achieve holistic situational awareness. Three main problems and challenges that hinder the achievement of holistic situational awareness have been identified as follows.[6]

Figure 1: Examples of complex and unstructured construction sites

II. RESEARCH CONTRIBUTIONS

A. Proactive Injury Prevention in Construction

Continuous safety monitoring for injury risks is becoming a well-recognized proactive injury prevention approach in construction. The work discussed in this doctoral research is in line with the body of research towards preventive health. MSDs prevention in construction is the targeted application domain. The developed proactive MSDs prevention approach demonstrated effectiveness and applicability for use in detecting risks of MSDs among construction workers as well as triggering timely response for mitigating the chances of developing cumulative injuries in the long term. The developed concept for safety monitoring and assessment approach can also encourage “Prevention through Design” (PtD) practices through identifying and evaluating workers’ ergonomics risks under different workplace design. Furthermore, the proposed concept can be adapted for preventive health through injury prevention in other labor-intensive occupations, such as manufacturing, healthcare, and agriculture.

B. Machine Learning

(ML) and Deep Learning (DL) based Posture Recognition Models. This research also contributes to the body of knowledge for developing and applying the ML-based model for automated human posture recognition. In particular, the developed novel DL-based recognition model has extended the application of DL techniques to wearable sensor signal processing in a way that results in improvement with respect to recognition performance.[7]

C. Wearable Sensing (WS)

The investigation in this research can facilitate applying lowcost wearable sensors as a promising approach for collecting workers’ motion data from real jobsites. The results from experiments and evaluation survey of using the deployed low wearable sensors can guide further WS system design and implementation.[8]

III. SAFETY CHALLENGE FROM MSDS (MUSCULOSKELETAL DISORDERS)

Construction workers have been experiencing a disproportional injury rate. Particularly, MSDs have been repeatedly reported as highly prevalent non-fatal injuries among construction workers calling for special attention in construction (H.-R. Guo et al., 2004; Holmström & Engholm, 2003; Wang et al., 2015). There is a lack of a universally accepted definition of MSDs. This research uses the definition that MSDs are soft-tissue injuries caused by sudden or sustained exposure to repetitive motion, force, vibration, and awkward positions. These disorders can affect the muscles, nerves, tendons, joints, and cartilage in upper and lower limbs, neck, and lower back (Cdc.gov., 2019). They can be categorized based on the causes of the injury, such as sprains, strains, and cumulative trauma disorders (Inyang et al., 2012). The sprains and strains are caused by the tearing of joints or muscles due to physical forces exceeding one’s capability when conducting the activities of lifting and carrying. The cumulative trauma disorders result from tasks involving repetitive actions and prolonged uncomfortable working postures, such as working overhead, bending forward, squatting, and kneeling [9]. Typical MSDs include carpal tunnel syndrome, tendonitis, trigger finger, sciatica, herniated discs, and lower back pains. The common symptoms include pain, aching, numbness, and swelling occurring in areas of the back, shoulder, neck, legs, wrists, and arms [10].

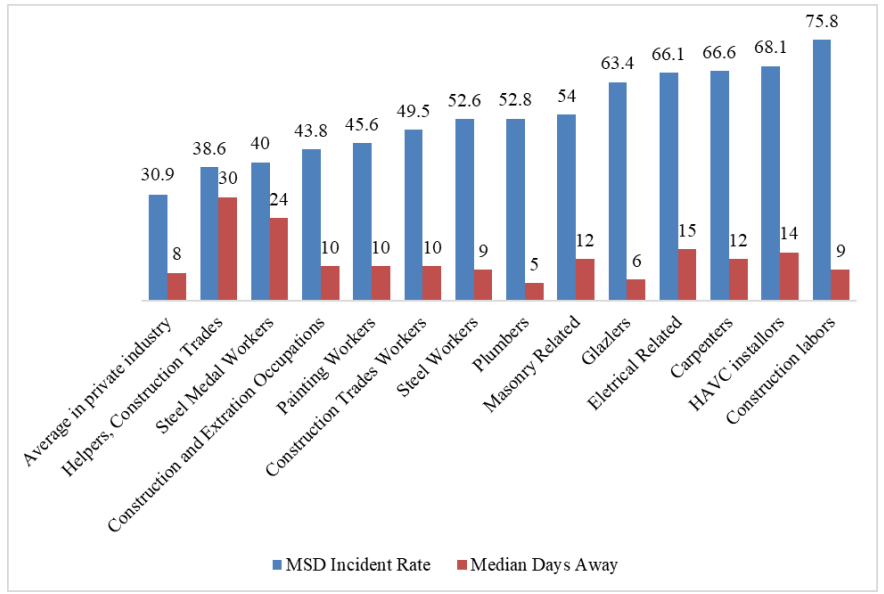

MSDs have a broad influence on various construction trades with multiple influenced body areas. The MSDs rate distribution in selected construction trades with median days away from work is shown in Figure 2. The construction trades highly affected by MSDs are construction laborers and helpers, mechanical equipment installers, carpenters, and steelworkers.

Figure 2: MSDs Injury Rates and Median Days Away from Work

IV. VIRTUAL REALITY AND VIRTUAL PROTOTYPE (VR & VP)

Virtual reality (VR) is a technology that uses computers, software, and peripheral hardware to generate a simulated environment for its user [11]. Applying these technologies in building construction can help to increase the reliability of investors and construction safety training. This research [12] strongly recommended incorporating VR in construction safety training and given the need for improved training and the advantages of using VR.

V. REVIEW OF RELATED STUDIES

Most studies only leverage a single mode of sensor that is bounded by its own limitations. For instance, visual sensors may capture rich contextual information and they do not require attachment to the entities, but they are highly sensitive to illumination and occlusion. Radio-based sensors do not require line of sight, but their accuracy is significantly influenced by the obstacles on the construction site. Inertial sensors are relatively accurate in the short term, but subject to noise and drift errors. It is well acknowledged that a data fusion approach that integrates heterogeneous data obtained from different sensors has the attribute of mutual complementation and can improve the accuracy and confidence of the monitoring results. For instance, [13]. proposed a multisource fusion framework that combines indoor localization results obtained from BLE beacons and inertial measurement unit (IMU). [14] created a novel framework that fuses radio-, inertial-, and vision-based sensors to track construction workers on the jobsite. However, their method used a single camera and cannot provide reliable 3D location information in a large area.

Digital safety in construction management refers to the integrated utilization of digital systems to enhance safety throughout building construction processes [15]. This approach involves transforming operational tasks and processes into a digital environment, aiming to minimize failures and promote a safer construction environment. The automation of construction operations through digital transformation diffusion centers plays a crucial role in streamlining the construction safety process [15, 16]. [17] indicated that a digital safety system as a model is benefit to increase safety in HIB with its conceptual model. This study has tested that approach to other types of buildings and critically interpreted achievable values of data-driven considered approaches. This may shape connectivity in safety for construction management in each period. Additionally, regulatory compliance, stakeholder buy-in, and addressing potential resistance to change are critical factors to consider when shaping automation of digital safety by design in construction projects. Successful implementation requires a comprehensive understanding of project requirements, collaboration among stakeholders, and ongoing evaluation and refinement of automated systems.

VI. DISCUSSION

Worker safety in the construction industry remains a critical concern due to high rates of accidents and fatalities caused by hazards such as falls, electrocutions, and equipment mishandling. Despite advancements in safety regulations and training, traditional reactive safety measures, which rely on post-incident reporting and manual inspections, often fall short in preventing accidents. The advent of data-driven technologies, including the Internet of Things (IoT), wearable devices, Artificial Intelligence (AI), and Big Data analytics, offers transformative potential for improving safety on construction sites [18,19] . These technologies enable real-time monitoring of environmental conditions, tracking of worker health metrics, and predictive risk analysis to identify hazards and prevent accidents proactively. While such advancements promise to revolutionize safety management, challenges such as high implementation costs, data privacy concerns, and resistance to technological adoption persist. This paper explores the applications and benefits of data-driven safety strategies in construction, examines successful case studies, and addresses the challenges of integrating these technologies to foster safer and more efficient construction environments.[20,21]

Conclusion

Enhancing worker safety in the construction industry is both a critical necessity and a challenging endeavor due to the inherently hazardous nature of construction sites. Traditional safety practices, while foundational, lack the capacity to proactively prevent accidents in dynamic and complex environments. Data-driven technologies, such as IoT, wearable devices, and AI-powered analytics, offer a transformative approach to safety management by enabling real-time monitoring, predictive risk assessments, and automated hazard mitigation. The findings of this study demonstrate that leveraging these technologies can significantly reduce workplace incidents, improve compliance with safety regulations, and foster a culture of proactive risk management. Successful case studies highlight how the integration of these systems has enhanced worker safety and operational efficiency across various construction projects. However, widespread adoption is hindered by challenges such as high initial investment, concerns over data privacy and security, and resistance to change in traditional workflows. To overcome these barriers, it is essential to develop cost-effective and scalable solutions, establish clear data governance frameworks, and foster collaboration among stakeholders to promote technological adoption. Future research should focus on refining predictive models, improving the interoperability of systems, and addressing ethical considerations surrounding worker data. By embracing a data-driven approach, the construction industry can achieve significant advancements in worker safety, ensuring a safer and more sustainable future for the workforce.

References

[1] S. Krima, S. Krima, T. Hedberg, A.B. Feeney, Securing the digital threat for smart manufacturing: A reference model for blockchain-based product data traceability, US Department of Commerce, National Institute of Standards and Technology, 2019. https://doi.org/https://doi.org/10.6028/NIST.AMS.300-6. [2] S.M. Semih, G. de S. Borja, Operational Technology on Construction Sites: A Review from the Cybersecurity Perspective, Journal of Construction Engineering and Management. 147 (2021) 4021172. https://doi.org/10.1061/(ASCE)CO.1943-7862.0002193. [3] Y. Halabi, H. Xu, D. Long, Y. Chen, Z. Yu, F. Alhaek, W. Alhaddad, Causal factors and risk assessment of fall accidents in the U.S. construction industry: A comprehensive data analysis (2000– 2020), Safety Science. 146 (2022) 105537. https://doi.org/https://doi.org/10.1016/j.ssci.2021.105537. [4] M. Arslan, C. Cruz, D. Ginhac, Semantic trajectory insights for worker safety in dynamic environments, Automation in Construction. 106 (2019) 102854. https://doi.org/https://doi.org/10.1016/j.autcon.2019.102854. [5] B.R.K. Mantha, B. de Soto, Assessment of the cybersecurity vulnerability of construction networks, Engineering, Construction and Architectural Management. 28 (2021) 3078–3105. https://doi.org/https://doi.org/10.1108/ECAM-06-2020-0400. [6] D. Gracanin, A. D’Amico, M. Manuel, W. Carson, M. Eltoweissy, L. Cheng, Biologically inspired safety and security for smart built environments: Position paper, in: 2018 IEEE Security and Privacy Workshops (SPW), 2018: pp. 293–298. https://doi.org/https://doi.org/10.1109/SPW.2018.00047. [7] H.A. Boyes, Cyber security of intelligent buildings: A review, in: 8th IET International System Safety Conference Incorporating the Cyber Security Conference 2013, 2013: pp. 1–7. https://doi.org/10.1049/cp.2013.1698. [8] M. Safa, S. Baeza, K. Weeks, Incorporating Blockchain technology in construction management, Strategic Direction. (2019). https://doi.org/https://doi.org/10.1108/SD-03-2019-0062. [9] J. Xu, C. Cheung, P. Manu, O. Ejohwomu, J. Too, Implementing safety leading indicators in construction: Toward a proactive approach to safety management, Safety Science. 157 (2023) 105929. https://doi.org/https://doi.org/10.1016/j.ssci.2022.105929. [10] B.R.K. Mantha, B. de Soto, Cybersecurity in Construction: Where Do We Stand and How Do We Get Better Prepared, Frontiers in Built Environment. 7 (2021). https://doi.org/10.3389/fbuil.2021.612668. [11] M. Arslan, C. Cruz, A.-M. Roxin, D. Ginhac, and C. C. Muhammad Arslan Ana-Maria Roxin, Dominique Ginhac, “Spatio-temporal analysis of trajectories for safer construction sites,” Smart Sustain. Built Environ., vol. 7, no. 1, pp. 80–100, 2018. [12] M.-W. M.-W. Park and I. Brilakis, “Continuous localization of construction workers via integration of detection and tracking,” Autom. Constr., vol. 72, pp. 129–142, 2016. [13] E. Konstantinou and I. Brilakis, “Matching Construction Workers across Views for Automated 3D Vision Tracking On-Site,” J. Constr. Eng. Manag., vol. 144, no. 7, 2018. [14] B. Xiao and Z. Zhu, “Two-Dimensional Visual Tracking in Construction Scenarios: A Comparative Study,” J. Comput. Civ. Eng., vol. 32, no. 3, 2018. [15] K. Yang, C. R. Ahn, M. C. Vuran, and H. Kim, “Collective sensing of workers’ gait patterns to identify fall hazards in construction,” Autom. Constr., vol. 82, pp. 166–178, 2017. [16] J. G. E. T.S. Abdelhamid, “Identifying root causes of construction accidents,” J. Constr. Eng. Manag., vol. 126, no. 1, pp. 52–60, 2000. [17] M.-W. M.-W. Park, N. Elsafty, and Z. Zhu, “Hardhat-Wearing Detection for Enhancing OnSite Safety of Construction Workers,” J. Constr. Eng. Manag., vol. 141, no. 9, 2015. [18] Q. Fang, H. Li, X. Luo, L. Ding, H. Luo, and C. Li, “Computer vision aided inspection on falling prevention measures for steeplejacks in an aerial environment,” Autom. Constr., vol. 93, pp. 148– 164, 2018. [19] W. Fang, L. Ding, H. Luo, and P. E. D. Love, “Falls from heights: A computer vision-based approach for safety harness detection,” Autom. Constr., vol. 91, pp. 53–61, 2018. [20] H. Guo, Y. Yu, Q. Ding, and M. Skitmore, “Imageand-Skeleton-Based Parameterized Approach to Real-Time Identification of Construction Workers’. [21] M. M. Soltani, Z. Zhu, and A. Hammad, “Framework for Location Data Fusion and Pose Estimation of Excavators Using Stereo Vision,” J. Comput. Civ. Eng., vol. 32, no. 6, 2018.

Copyright

Copyright © 2024 Mohammed Nasridin Yousif, Hmouda Ali Amer Salem Massoud, Taher Mohammed Taher Alghusni. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65736

Publish Date : 2024-12-03

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online