Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Industrial Internet of Things (IIOT)

Authors: Prof. M. T. Dangat, Rudra Chandgude, Pravin Kushwaha, Mohammed Champeli, Prathamesh Pardeshi

DOI Link: https://doi.org/10.22214/ijraset.2024.59103

Certificate: View Certificate

Abstract

Industrial Internet of Things (IOT) is a part of IOT (Internet of Things) technology that has provided an opportunity to build powerful industrial system and applications by using different I0T devices like sensors, actuators, Resistance Temperature Detectors, pH analyzers, Level Transmitters, RFIDs, wireless and mobile devices. High-speed internet has given a new hike in development of IOT devices, as it makes remote access facility at ease. Various IOT applications and systems have been developed and deployed in recent years. To understand the development of IO? technology, this study addresses IIOT concepts through a systematic review of various white papers, research papers and online database. This paper will provide an overview of IOT technology, key enabling technologies and their applications in industries. The major objective of IOT is to achieve high operational efficiency, increased productivity, and better management of industrial assets and processes through product customization, intelligent monitoring applications for production floor shops and machine health, and predictive and preventive maintenance of industrial equipment.

Introduction

I. INTRODUCTION

A. History Of Industrial Revolution

- Industrial Revolution 1.0: Occurring from the late 18th to the early 19th century, this period saw the transition from agrarian and handicraft-based economies to machine-driven manufacturing. Key innovations like the steam engine and mechanized textile production led to urbanization, economic growth, and significant social changes.

- Industrial Revolution 2.0: Taking place in the late 19th to early 20th century, also known as the Second Industrial Revolution or Technological Revolution, this era witnessed the widespread adoption of electric power and assembly line manufacturing. Industries such as steel, oil, and automobiles emerged, alongside innovations like the telephone and telegraph, transforming communication and industry.

- Industrial Revolution 3.0: The late 20th century saw the onset of the Digital Revolution or Information Age, characterized by the introduction of electronics, computers, and the internet. This revolutionized communication, information storage, and processing, leading to globalization and the rise of the knowledge economy.

- Industrial Revolution 4.0: In the 21st century, Industry 4.0 or the Fourth Industrial Revolution emerged, marked by the fusion of physical, digital, and biological technologies. Innovations like artificial intelligence, robotics, 3D printing, and the Internet of Things (IoT) aim to create smart interconnected systems across various sectors, enhancing automation, efficiency, and customization.

B. Introduction to Internet of things (IOT)

The Internet of Things (IoT) is the network of physical objects or "things" embedded with electronics, software, sensors, and network connectivity, which enables these objects to collect and exchange data.

IoT allows objects to be sensed and controlled remotely across existing network infrastructure, creating opportunities for more direct integration between the physical world and computer-based systems, and resulting in improved efficiency, accuracy and economic benefit.

Things," in the IoT sense, can refer to a wide variety of devices such as heart monitoring implants, biochip transponders on farm animals, electric clams in coastal waters, automobiles with built-in sensors, DNA analysis devices for environmental/food/pathogen monitoring or field operation devices that assist fire-fighters in search and rescue operations.

These devices collect useful data with the help of various existing technologies and then autonomously flow the data between other devices.

II. WORKING OF INTERNET OF THINGS (IOT)

Internet of Things is not the result of a single novel technology; instead, several complementary technical developments provide capabilities that taken together help to bridge the gap between the virtual and physical world.

The IOT working consist of following 3 main layers:

A. Perception Layer

This is the physical layer of the architecture. This is where the sensors and connected devices come into play as they gather various amounts of data as per the need of the project. These can be the edge devices, sensors, and actuators that interact with their environment.

B. Network Layer

The data that's collected by all of these devices needs to be transmitted and processed. That's the network layer's job. It connects these devices to other smart objects, servers, and network devices. It also handles the transmission of all of the data.

C. Application Layer

The application layer is what the user interacts with. It's what is responsible for delivering application specific services to the user. This can be a smart home implementation, for example, where users tap a button in the app to turn on a coffee maker.

III. INTRODUCTION TO INDUSTRIAL INTERNET OF THINGS (IIOT)

IloT stands for the Industrial Internet of Things or Industrial IoT that initially mainly referred to an industrial framework whereby many devices or machines are connected and synchronized using software tools and third platform technologies in a machine-to-machine and Internet of Things context. The industrial internet of things (IIoT) refers to the extension and use of the internet of things (IoT) in industrial sectors and applications. With a strong focus on machine-to-machine (M2M) communication, big data, and machine learning, the IIoT enables industries and enterprises to have better efficiency and reliability in their operations. The lloT encompasses industrial applications, including robotics, medical devices, and software- defined production processes.

The lloT goes beyond the normal consumer devices and internetworking of physical devices usually associated with the IoT. What makes it distinct is the intersection of information technology (IT) and operational technology (OT). OT refers to the networking of operational processes and industrial control systems (ICSs), including human machine interfaces (HMIs), supervisory control and data acquisition (SCADA) systems, distributed control systems (DCSs), and programmable logic controllers (PLCs).

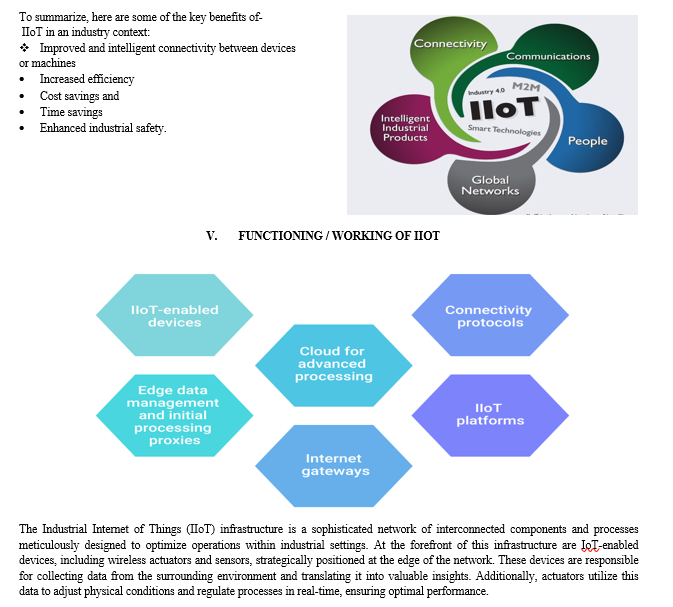

IV. BENEFITS / ADVANTAGES OF IIOT IN MANUFACTURING

One of the greatest benefits of Industrial Internet of Things must be seen in the reduction of human errors and manual labor, the increase in overall efficiency and the reduction of costs, both in terms of time and money. We also cannot forget the possible underpinnings of IIoT in quality control and maintenance.

The goal of the Industrial Internet of Things is also not to fully replace human work, its goal is to enhance and optimize it by, for example, creating new revenue streams and business models with a big role for data (analysis).

The Industrial Internet of Things takes the benefits of the Internet of Things in general to a higher level and to the industries with high-stakes where human error could result in massive risks. The precision level that can be achieved through the IIoT is one of the greatest advantages, that make this discipline one of the most welcome gifts of loT.

Edge data management and initial processing take place directly at the network's edge, where data is locally preprocessed for swift analysis and response. This localized processing significantly reduces the volume of data transmitted to centralized data centers or the cloud, streamlining the overall system efficiency. However, for more extensive and in-depth processing, the cloud comes into play. Here, data from various sources is aggregated and analyzed, providing insights and intelligence that may not be readily available at the edge.

Internet gateways are pivotal components within the IIoT infrastructure, serving as intermediaries between edge devices and the broader internet. These gateways collect, digitize, and transmit sensor data over the internet for further processing. Adherence to connectivity protocols ensures secure and standardized data transfer across the IIoT system, safeguarding the integrity and confidentiality of critical information.

A. Some of the Common Protocols used in IIoT Architecture Include

- Advanced Message Queueing Protocol (AMQP): It is a connection-led, bidirectional, multiplexing, compact data-encoding message transport protocol. AMQP, unlike HTTP, was built for IIoT-oriented cloud connectivity.

- MQ Telemetry Transport (MQTT): This is a compact client-server message transport protocol. MQTT benefits IIoT devices because of its short message frame sizes and minimal code space.

- Constrained Application Protocol (CoAP): This is a datagram-led protocol that may be deployed via a transport layer, including User datagram protocol (UDP), CoAP is a condensed version of HTTP developed for IIoT requirements.

IIoT platforms, guided by the industrial internet reference architecture (IIRA), serve as the backbone of the infrastructure, orchestrating, monitoring, and controlling operations across the entire value chain. These platforms manage device data, analytics, visualization, and AI tasks, facilitating seamless integration and operation of various components within the IIoT ecosystem.

VI. INDUSTRY IOT RESEARCH AND DEVELOPMENTS

Industry loT (Internet of Things) research and development focus on enhancing connectivity and automation in various sectors. This includes optimizing processes, improving efficiency, and exploring innovative applications of loT technology. Researchers often investigate solutions for real-time monitoring, predictive maintenance, and data analytics to drive advancements in industries such as manufacturing, healthcare, energy, and more. It is expected that reporting of Industrial IoT applications and developments will accelerate significantly over the coming few years as the specific opportunities for Industrial IoT become clearer.

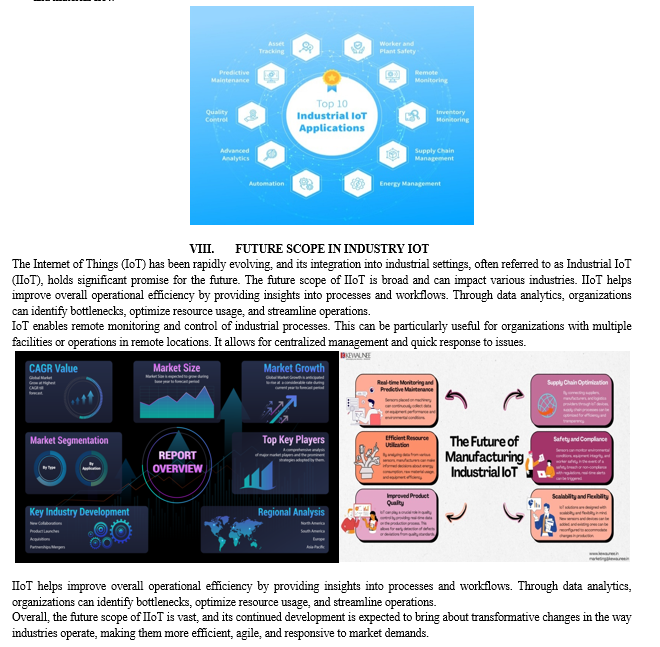

VII. APPLICATION OF IOT IN INDUSTRIES

IoT technology is now being used in industries on large scale. In this section, some major applications of IoT technology are discussed briefly.

- Smart Factories: IIoT enabled equipment can sense the environment and transmit data to managers or field engineers, which enable them to remotely manage their factory units and take advantages of process automation. IloT devices can also transmit data regarding production, losses and inventory to their managers so they can take timely necessary actions.

- Maintenance Management: IIoT sensor enables condition-based maintenance by monitoring critical machines and alerting managers when they deviate from specified parameters like temperature or vibration ranges. This functionality reduces breakdown time, cost and increase operational efficiency of the plant.

- Safety and Security: IIoT devices can work in a hazardous environment like in acid plant or in confined space, thus reducing or eliminating human life intervention. IIoT devices themselves can take immediate actions based on their area of application viz. stopping furnace if the temperature goes beyond the specified limit, honk a siren if the boiler is going to explode or a stack is going to fall etc. Overall workers safety can be enhanced by using big data and IoT technology.

- Quality Control: Uses of IIoT in the production line can improve the overall quality of the final product as they can monitor process and equipment on real-time and maintain plant parameter like temperature, pH, acidity, impurity, densities etc. in a range which results in a quality product. They can also monitor third party raw material quality and can capture customer reviews on final product which can be later analyzed for quality issues.

- Inventory Management: This is best industrial IoT application; through loT systems monitoring of events across a supply chain is done. These systems allow one to track the inventory and trace it globally on a line-item level. This way the users are notified if there are any significant deviations from the plan of action. As a result, this provides a far-reaching and cross-channel visibility into inventories which helps managers in getting realistic estimates of the available material, the work in progress and the estimated arrival time of new materials

- Digital/Connected Factory: The machinery that is embedded with an IoT system can transfer information related to operations to the people such as the original equipment manufacturers and to field engineers. This way process automation and optimization is made advantageous by enabling operation managers and factory heads to remotely manage the factory units.

- Logistics and Supply Chain Optimization: In this industrial IoT application, it provides access to real-time supply chain information by tracking materials in transit, products, and equipment as they move through the supply chain.Througheffective reporting manufacturers can collect and feed the delivery information into systems like ERP, PLM etc. If the plants get to connect to the suppliers, all the concerned parties in the supply chain can trace interdependencies, manufacturing cycle times and material flow

IX. THE FUTURE INDUSTRIES: INDUSTRY 5.0

We are now entering the fifth industrial revolution with a focus on man and machines working together. Based upon personalisation and the use of collaborative robots, workers are free to deliver value-added tasks for customers. This latest iteration goes beyond manufacturing processes to include increased resilience, a human-centric approach, and a focus on sustainability.Industry 5.0 is the creation of higher value jobs that afford greater personalisation for customers and improved design freedom for workers. By allowing manufacturing processes to be handled through automation, human workers are able to focus more of their time on delivering improved, bespoke services and products.

This was already beginning with Industry 4.0, but Industry 5.0 pushes this further through improved automation and feedback to create a service-based model where humans are able to focus on adding value for end-users.

Meanwhile the increased focus on sustainability and resilience means that businesses become more agile and flexible while also having a positive impact on society – rather than simply mitigating any negative effects.

Conclusion

As a result of the benefits IIoT offers, it rapidly became an essential component of the Industry 4.0 revolution. This research provided a complete overview of the challenges and opportunities offered by IloT-enabled technology and applications for industrial growth. The review aimed to contribute to future studies by describing several IoT applications across several fields. Insights from previous IIoT-related research have also been summarized to aid in understanding the progress IIoT has made until now. The ob- servations of this study have led to major findings, such as: 1) lloT technology has been developed to interconnect all industrial equipment, monitoring, and regulating systems, bodily processes, and mechanical controls. These allow manufacturers to work more effectively while reducing errors. 2) It is essential to do additional research to resolve the existing challenges of this technology, as industrial manufacturing processes cannot run smoothly without a well-designed network infrastructure. A more advanced form of industrial IoT infrastructure is expected to contribute to industrial technological advancement in the near future through continuous innovation and experimentation.

References

[1] Accenture. (2015). Driving Unconventional Growth through the Industrial Internet of Things. [2] Industrial Internet of Things (IIoT) in manufacturing- Happiest Minds. (n.d.). Retrieved March 12, 2018, from https://www.happiestminds.com/Insights/industrial-iot/ [3] Reportlinker. (2017, May 30). Industrial Internet of Things (IIoT) Market is expected to reach USD 933.62 billion by 2025. Retrieved March 20, 2018, from https://www.prnewswire.com/news-releases/industrial- internet-of-things-iiot-market-is-expected-to-reach- usd-93362-billion-by-2025-300465783.html [4] Rouse, M. (n.d.). IoTAgenda. Retrieved January 2, 2018, from IoTAgenda website: http://internetofthingsagenda.techtarget.com/definition/ Industrial-Internet-of-Things-IoT.

Copyright

Copyright © 2024 Prof. M. T. Dangat, Rudra Chandgude, Pravin Kushwaha, Mohammed Champeli, Prathamesh Pardeshi. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET59103

Publish Date : 2024-03-18

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online