Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Industrial IoT Automation

Authors: Shreyas Navale , Pradnesh Naik , Akshay Lohar, Jai Mulay

DOI Link: https://doi.org/10.22214/ijraset.2024.60368

Certificate: View Certificate

Abstract

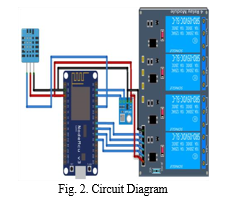

The IoT Industrial Automation System, incorporating a MERN (MongoDB, Express.js, React, Node.js) website with REST API implementation, represents a transformative leap in the realm of industrial automation. This innovative system leverages the power of the internet to remotely monitor and control sensor data and relay actuators. The NodeMCU ESP8266 hardware, complemented by the DHT11 sensor for temperature and humidity measurements, and the BMP180 sensor for atmospheric pressure and altitude data, form the backbone of this comprehensive data acquisition system. In addition, a 4-channel relay actuator enables real-time control and responsiveness within the industrial setting. The heart of the system lies in its web-based dashboard, providing a user-friendly interface for data visualization and remote operation. Furthermore, this platform incorporates machine learning capabilities, facilitating predictive analysis based on historical sensor data. This predictive modelling enhances decision-making processes and augments industrial automation, ushering in a new era of efficiency and productivity. This IoT Industrial Automation System redefines industrial control and monitoring, ushering in a future where technology transforms industry landscapes

Introduction

I. INTRODUCTION

The IoT Industrial Automation System represents a ground breaking convergence of digital technology and industrial processes. At its core, this system harnesses the power of a MERN (MongoDB, Express.js, React, and Node.js) web application with REST API implementation to create a comprehensive and user-friendly dashboard for monitoring and controlling sensor data and relay actuators over the internet. This innovative approach redefines industrial automation, providing real-time insights and remote control at your fingertips The hardware driving this system is centred around the NodeMCU ESP8266, a versatile microcontroller, paired with sensors like the DHT11, which records temperature and humidity, and the BMP180, responsible for capturing atmospheric pressure and altitude data. These sensors form the backbone of data acquisition for the IoT Industrial Automation System, ensuring that environmental parameters are monitored with precision.

In addition to the sensors, a critical aspect of this system is the incorporation of a 4-channel relay actuator, enabling remote control of physical devices or processes. This functionality is seamlessly integrated into the web dashboard, enhancing its utility for industrial applications. Furthermore, the system's web application boasts a predictive analysis component powered by machine learning. It leverages historical sensor data to generate predictions and insights, offering users a deeper understanding of their industrial processes and allowing for data-driven decision making.

In summary, the IoT Industrial Automation System is a gamechanger, offering a comprehensive solution that combines data collection, remote control, and predictive analytics, all accessible through a user-friendly MERN web dashboard. This system promises to revolutionize industrial automation by providing real-time information and intelligent insights to optimize processes and enhance productivity. Industrial automation has been evolving rapidly with the advent of the Internet of Things (IoT). The proposed IoT based industrial automation system aims to enhance productivity, efficiency, and safety in manufacturing and industrial processes. This system integrates various IoT devices and technologies to streamline operations, collect realtime data, and optimize decision-making processes the scope of IoT in industrial automation is broad and dynamic, offering numerous opportunities for enhancing operational efficiency, reducing costs, and improving safety in various industrial sectors. By embracing IoT technologies, industries can position themselves for a more connected and data-driven future, driving innovation and competitiveness in the ever-evolving industrial landscape Although the above encoder–decoder models are promis- ing, some problems still remain. In these works, a decoder uses a fixed target vocabulary to output the corresponding probability distribution at each timestep. This may lead to the incapable to handle rare or out-of- vocabulary (OOV) words. Increasing the size of the target vocabulary could alleviate this problem, but this increases the computational complex- ity in decoding as a softmax function needs to calculate over all possible words. This can be improved by applying a cop y mechanism that dynamically copies the words from the input sequence when decoding without enlarging the size of the vocabulary [10], Another problem with encoder–decoder models is that they often generate unnatural summaries consisting of repeated phrases, especially evident for long text summariza- tion generation.

On a long sentence summarization dataset (e.g., CNN/DailyMail dataset containing multisentence sum- maries of up to 56 tokens on average), a coverage mechanism is used to avoid the repetition problem. It records past atten- tional weights in the decoder and dampens the decoder from attending to the same parts of the input text when decoding in future . Different from this mechanism, an intra-attention mechanism takes the attention at the decoder into account, which is prominently effective for eliminating repetition . However, they consider little about the relations between the input tokens in the encoder and the already generated words by decoder.

II. LITERATURE SURVEY & RELATED WORK

The proposed AIANP provides a huge support to automation industry to control and monitor the industrial environment without any security lacking and delay by means of associating the AI logic in its approach. This is achieved by means of associating the internet enabled services to the industry to operate the machineries accordingly. In literature lots of IoT based automation approaches are available but all are structed up with certain limitations and lacking, so that a new approach is required to resolve the issues over conventional automation technologies. This paper provides a robust industrial automation ability to the users to control and monitor the industry in proper way using proposed Artificial Intelligence Assisted Network Paradigm. And the resulting section provides the proper proof for the proposed approach efficiency and security effectiveness in graphical manner.[1] The concept of the internet of things was introduced by the members of the radio frequency identification development community in 1999.This concept is very popular because of growth of mobile devices, embedded and real time communication, cloud computing and data analytics. The internet of things is a network of physical objects are embedded with electronics, software and sensors having the ability to collect data from the world around us and share data across the internet.[1]The future M2M market will be fuelled by the wide variety of applications that this technology enables . In the proposed system the communication between monitor and industrial plant is achieved using GPRS, the distance barrier is eliminated and automation is achieved from any part of the world. Challenges and Future Directions: Despite the progress made in AI text summarization using LSTM and attention mechanisms, several challenges remain, including handling noisy input data, generating coherent and fluent summaries, and improving the model’s interpretability. Future research directions may involve exploring novel architectures, incorpo- rating external knowledge sources, and enhancing the model’s adaptability to various text genres and languages. By surveying the existing literature, researchers can gain insights into the advancements, challenges, and potential future directions in the field of AI text summarization leveraging LSTM networks and attention mechanisms.

Nandhi et al. [2]. The paper highlights the benefits of IoT integration SCMby using RFID tag tracking methodology to boost the real-time positioning and information pulse updates to avoid anti-counterfeiting by the application of cloud storage and Internet-based online information and data tracking architecture. Tao et al. [ 3]. The paper reports the use of IIoT for smart manufacturing (SM).SM needs smart interconnection among the several attributes of manufacturing. This issue can be solved using IIoT; it compromises access hub (A-Hub), customized access module (CA-Module) and local service pool (LSP).Yang et al. [4]. In this era of globalization, competitions are growing worldwide, and the need of customized products is increasing. To acknowledge this type ofchallenges, and to meet the customer demand, it requires new technologies. Thepaper talks to transform manufacturing sector using IoT which has an enormouspotential connecting all the resources required for the production, based highly onintegrated smart cyberphysical system (CPS).Abdel-Basset et al. [5]. The literature demonstrates and suggests the construction of an intelligent and smart framework for SCM by applying IoT in the various steps ofsupply chain processes so as to collaborate big information data, products, process tracking, etc., which could upscale the infrastructure towards smart and efficient tradition. Chamekh et al. [6]. The paper proposes a secured framework for information sharing and data tracking in the SCM by using Merkel tree architecture which claimsto replace the peer-topeer bases information transfer with additional security and scalable management scheme mechanisms. While not explicitly using LSTM networks, this work demonstrates the effectiveness of attention-based models in sentence selection for summarization tasks. ”Fine-tune BERT for Extractive Summarization” (Liu and Lapata, 2019): Liu and Lapata fine-tune the BERT (Bidi- rectional Encoder Representations from Transformers) model for extractive summarization, demonstrating state-of-the-art performance without relying on LSTM networks. This work showcases the effectiveness of pre-trained language models in summarization tasks. ”Hierarchical Transformers for Multi-Document Summarization” (Cao et al., 2020): Cao et al. propose a hierarchical Transformer model for multi-document summarization, which utilizes self-attention mechanisms to capture hierarchical doc- ument structures. Although not directly related to LSTM-based summarization, this work demonstrates innovative approaches to handle complex summarization tasks. By reviewing these related works, researchers can gain in- sights into different approaches, architectures, and techniques employed in AI text summarization, including those utilizing LSTM networks and attention mechanisms. These studies collectively contribute to the advancement of summarization techniques and provide valuable benchmarks for future re- search.

III. PROPOSED SYSTEM

Industrial automation has been evolving rapidly with the advent of the Internet of Things (IoT). The proposed IoT based industrial automation system aims to enhance productivity, efficiency, and safety in manufacturing and industrial processes. This system integrates various IoT devices and technologies to streamline operations, collect real time data, and optimize decision-making processes. To fulfill the purpose of this thesis, a comprehensive literature study and case study was performed, where important factors affecting the implementation of the IIoT platform were identified. The time constraint and scope for this thesis did not permit comprehensive control and measure of all the affecting factors. In this sense, this thesis will focus on how the OEE can be improved by implementing an IIoT platform in the production cells. The implementation of the IIoT platform is conducted in two production cells

A. Model Architecture

Internet reference architecture provides a standardized framework for designing and implementing internet-based systems. It outlines the key components, their relationships, and how they work together to deliver internet services and applications. The architecture reference model commonly used for IoT is the OSI (Open Systems Interconnection) model. It provides a structured approach for understanding and designing the various layers of communication protocols in IoT systems.

Dataset - The vast amount of data generated by the production process must be stored in a safe and efficient way (Tao et al., 2018). Further, according to Faroukhi et al. (2020a), it is important to bear in mind that storage methods have a big impact on the scalability and the performance of DVC and should therefore allow reliable storage space and powerful data analysis abilities. Data can be stored in three different ways, structured, semi-structured and unstructured. Structured data consists of e.g., digit, symbols and tables etc., semi-structured data consists of trees, graphs and XML documents etc., while unstructured data consists of logs, audio, videos and images etc. (Tao et al., 2018). Traditionally, only structured data has been stored in manufacturing companies since the existing databases have not allowed for handling of semi-structured or unstructured data. Faroukhi et al. (2020b) explains that the reason for this is, on one side related to the historical constraints regarding storage power, and on the other, the limited abilities to create value of semior unstructured data. Further, Tao et al. (2018) describes that object-based storage in manufacturing companies enables data to be stored as objects, thus increasing the flexibility for integrating semi-structured and unstructured data. Tao et al. (2018) argue that cloud computing has large benefits on cost reduction and energy consumption for manufacturing companies and opens for more flexibility.

However, Basir et al. (2019) argues that there exist barriers with cloud in an IIoT-context and suggests fog computing as a faster, more reliable, and safer way of managing data storage in IIoT.

Moreover, Raj et a. (2020) emphasize building cross functionality in the project teams responsible for the IIoT implementation, providing expertise from different domains in the organization. Further, when implementing new technology, Jansen and van der Merwe (2020) and Raj et al. (2020) argue that it is necessary to include training and education early in the implementation of IIoT, and that training, and education is viewed as a key element throughout all steps of the process. Another critical enabler for achieving a successful implementation is to ensure that the company possesses sufficient skills and knowledge. Huarng and Mastur (2016) identified organizational cultural behavior, education, problemsolving-mindset and habits as enablers for the implementation of new 23 technology. Stornelli, Ozcan and Simms (2021) concluded that an important enabler for the implementation of advanced manufacturing technologies is management of human resources policies, corporate structure in terms of culture and size as well as capabilities of technology integration.

B. Evaluation Metrics

ROUGE stands for Recall-Oriented Understudy for Gisting Evaluation. It is essentially a set of metrics for evaluating auto- matic summarization of texts as well as machine translations. It works by comparing an automatically produced summary or translation against a set of reference summaries (typically human- produced). Let’s say that we have the following system and reference summaries: If we consider just the individual words, the number of overlapping words between the system summary and reference summary is 6. This, however, does not tell you much as a metric. To get a good quantitative value, we can actually compute the precision and recall using the overlap. Simply put, recall (in the context of ROUGE) refers to how much of the reference summary the system summary is recovering or capturing.

IV. PROCESS DESIGN

A. Block Diagram

For this thesis, a single case study was chosen as research design. Blomkvist and Hallin (2014)argue that a case study generates more detailed empirical data compared to experiments or surveys and that the complexity of reality can be captured in a more realistic way. Further, according to Blomkvist and Hallin (2014), a case study, correctly executed, enables an analytical generalization of the specific research area and Yin (2018) state that a potential benefit of using a case study design, is to provide a holistic perspective of a real-world scenario. The purpose of this thesis is to investigate how IIoT can be implemented and how an IIoT-based performance measurement can support improvement of OEE for smart production. Therefore, for this thesis, a case study was considered suitable since it enables investigation of a specific phenomenon in a real-world context. This was considered important since it contributed to a deeper understanding of the research area compared to only using existing literature as basis for the analysis. Moreover, a case study was considered suitable since it allows for analysis regarding current situation compared to post-implementation situation regarding OEE. Lastly, the case company showed a promising fit for this study because of its OEE maturity and experience. This enabled a reliable analysis regarding the results of OEE from the implementation of IIoT compared to previous operations. Also, by possession of good understanding of OEE among the production engineers at the company, the collected empirical data at the case company can be described as more nuanced and elaborate. The purpose of this thesis is to investigate how IIoT can be implemented and how an IIoT-based performance measurement can support improvement of OEE for smart production. Therefore, for this thesis, a case study was considered suitable since it enables investigation of a specific phenomenon in a real-world context. This was considered important since it contributed to a deeper understanding of the research area compared to only using existing literature as basis for the analysis.

A. Model Evaluation

According to [9-10], the reliability and efficiency of high performance IIoT systems can be evaluated through four basic fundamental quality metrics: usability, dependability, availability, and maintainability. Corresponding to the IIoT architecture, the model to evaluate the complete reliability of IIoT technological components is shown in Fig. 1, which is adopted in this paper to analyze and investigate the endto-end reliability measurement through the constituent components of IIoT systems.

The developments in the field of data processing, Internet, and electronic communications have enabled the world to easy access to different physical devices. The whole world is covered with different devices embedded with the actuators and sensors. Huge bulk of data is produced from the communication of these heterogeneous devices which need to be researched for mining useful insights. These useful information and insights will play an important role in decision-making and optimum management or services and resources.

The integration of emerging trends, technologies, and applications of IoT in the industrial environment is leading toward the expansion and developments of IIoT. The IIoT is collection of smart devices and objects which sense, collect, process, and communicate real-time occurrences in the industrial setup. IIoT aims to achieve high efficiency of operation to manage industrial assets and increase the productivity of industry with the support of product customization. In the last few years, special attentions were given to the applications of IoT with emerging into the industry. Several IoT devices are brought to facilitate the human life. The applications of IoT technologies in industry of automation have been expended to the IIoT which supports Cyber Physic System in which human and machine interact [1]. Internet of Things has several applications in the daily life and has made life very easy. From industry to education, healthcare, and to other place, the IoT is mostly used. Internet of Medical Things is the advanced version of IoT which has a key role in healthcare. In healthcare, the devices are sometimes connected through heterogeneous environment with the support of different IoT devices.

V. SOFTWARES TO BE USED FOR THE PROJECT

- The NodeMCU (Node Microcontroller Unit) is an opensource software and hardware development environment built around an inexpensive System-on-a-Chip (SoC) called the ESP8266. The ESP8266, designed and manufactured by Espressif Systems, contains the crucial elements of a computer: CPU, RAM, networking (Wi-Fi), and even a modern operating system and SDK. That makes it an excellent choice for Internet of Things (IoT) projects of all kinds. However, as a chip, the ESP8266 is also hard to access and use. You must solder wires, with the appropriate analog voltage, to its pins for the simplest tasks such as powering it on or sending a keystroke to the “computer” on the chip. You also have to program it in low-level machine instructions that can be interpreted by the chip hardware. This level of integration is not a problem using the ESP8266 as an embedded controller chip in mass- produced electronics. It is a huge burden for hobbyists, hackers, or students who want to experiment with it in their own IoT projects.

- GOOGLE COLAB Google is quite aggressive in AI research. Over many years, Google developed AI framework called TensorFlow and a development tool called Colaboratory. Today TensorFlow is open-sourced and since 2017, Google made Colaboratory free for public use. Colaboratory is now known as Google Colab or simply Colab. Another attractive feature that Google offers to the developers is the use of GPU. Colab supports GPU and it is totally free. The reasons for making it free for public could be to make its software a standard in the academics for teaching machine learning and data science. It may also have a long term perspective of building a customer base for Google Cloud APIs which are sold per-use basis. Irrespective of the reasons, the introduction of Colab has eased the learning and develop- ment of machine learning applications.

- VISUAL STUDIO CODE Visual Studio Code is a streamlined code editor with support for development oper- ations like debugging, task running, and version control. It aims to provide just the tools a developer needs for a quick code-build- debug cycle and leaves more complex workflows to fuller featured IDEs, such as Visual Studio IDE . Visual Studio Code is a source-code editor that can be used with a variety of programming languages, including Arduino, MangoDB, JavaScript, Node. js . It is based on the Electron framework, which is used to develop Node.

A. Requirement Analysis

- Hardware Requirements

a. GB RAM.

b. 200 GB HDD.

c. Intel 1.66 GHz Processor Pentium 4

2. Software Requirements

a. Visual Studio Code

b. Windows Operating System

c. Python gt;= 3.6 4

d. Google Colab

e. Windows XP

f. Windows 7,8

VI. STEPS INVOLVED IN THE SYSTEM DEVELOPMENT LIFE:

Below are the steps involved in the System Development Life Cycle. Each phase within the overall cycle may be made up of several steps.

- Step 1: We used the WEKA knowledge analysis platform (Holmes et al., 1994), which is an open-source software that includes tools for data preparation, implementations of several data analytics algorithms, model evaluation and visualization tools. We chose WEKA because it is easy to use, thanks to its graphical user interface (GUI), and because it includes several standard and popular data analysis and predictive modeling algorithms. In addition to the standard algorithms that come with WEKA, there are many extensions and packages offered by the community for other algorithms, such as DeepLearning4J for deep learning algorithms and LibLinear for support vector machines (SVMs). It should be noted that the performance of these algorithms may be less stable than the default ones. For example, we were unable to use LibLinear with Edge-IIoT-2022 due to its large memory footprint.

- Step 2: Requirements Analysis Requirements analysis is the process of analyzing the information needs of the end users, the organizational environment, and any system presently being used, developing the functional requirements of a system that can meet the needs of the users. Also, the requirements should be recorded in a document, email, user interface storyboard, executable prototype, or some other form. The requirements documentation should be referred to throughout the rest of the system development process to ensure the developing project aligns with user needs and requirements. Professionals must involve end users in this process to ensure that the new system will function adequately and meets their needs and expectations.

- Step 3: Architectural Design After the requirements have been determined, the necessary specifications for the hardware, software, people, and data resources, and the information products that will satisfy the functional requirements of the proposed system can be determined. The design will serve as a blueprint for the system and helps detect problems before these errors or problems are built into the final system. Professionals create the system design, but must review their work with the users to ensure the design meets users39; needs.

- Step 4: Coding and Debugging Coding and debugging is the act of creating the final system. This step is done by software developer.

- Step 5: System Testing The system must be tested to evaluate its actual functionality in relation to expected or intended functionality. Some other issues to consider during this stage would be converting old data into the new system and training employees to use the new system. End users will be key in determining whether the developed system meets the intended requirements, and the extent to which the system is actually used.

- Step 6: Maintenance Inevitably the system will need maintenance. Software will definitely undergo change once it is delivered to the customer. There are many reasons for the change. Change could happen because of some unexpected input values into the system. In addition, the changes in the system could directly affect the software operations. The software should be developed to accommodate changes that could happen during the post implementation period. all these process models we’ve used the Iterative model(The Linear Sequential Model) for the development of our project. The Iterative model the waterfall model derives its name due to the cascading effect from one phase to the other as is illustrated in Figure1.1. In this model each phase well defined starting and ending point, with identifiable deliveries to the next phase. This model is sometimes referred to as the linear sequential model or the software life cycle. The model consists of six distinct stages, namely:

a. In the requirements analysis phase (a) The problem is specified along with the desired service objectives (goals) (b) The constraints are identified

b. In the specification phase the system specification is produced from the detailed definitions of (a) and (b) above. This document should clearly define the product function.

c. In the system and software design phase, the system specifications are translated into a software representation. The software engineer at this stage is concerned with: Data structure Software architecture Algorithmic detail Interface representations The hardware requirements are also deter- mined at this stage along with a picture of the overall system architecture. By the end of this stage should the software engineer should be able to identify the relationship between the hardware, software and the associated interfaces. Any faults in the specification should ideally not be passed ‘down stream.

d. In the implementation and testing phase stage the designs are translated into the software domain Detailed documentation from the design phase can significantly reduce the coding effort. Testing at this stage focuses on making sure that any errors are identified and that the software meets its required specification.

e. In the integration and system testing phase all the program units are integrated and tested to ensure that the complete system meets the software requirements. After this stage the software is delivered to the customer [Deliverable – The software product is delivered to the client for acceptance testing.

f. The maintenance phase the usually the longest stage of the software. In this phase the software is updated to: Meet the changing customer needs Adapted to accommodate changes in the external environment Correct errors and oversights previously undetected in the testing phases Enhancing the efficiency of the software Observe that feed back loops allow for corrections to be incorporated into the model. For example a problem/update in the design phase requires a ‘revisit’ to the specifications phase. When changes are made at any phase, the relevant documentation should be updated to reflect that change.

A. Advantages of the Iterative Model

Testing is inherent to every phase of the Iterative model It is an enforced disciplined approach It is documentation driven, that is, documentation is produced at every stage Disadvantages of the Iterative Model:- The waterfall model is the oldest and the most widely used paradigm.

However, many projects rarely follow its sequential flow. This is due to the inherent problems associated with its rigid format. Namely: It only incorporates iteration indirectly, thus changes may cause considerable confusion as the project progresses. As The client usually only has a vague idea of exactly what is required from the software product, this IM has difficulty accommodating the natural uncertainty that exists at the beginning of the project. The customer only sees a working version of the product after it has been coded. This may result in disaster any undetected problems are precipitated to this stage.

VII. RESULTS

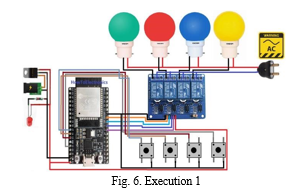

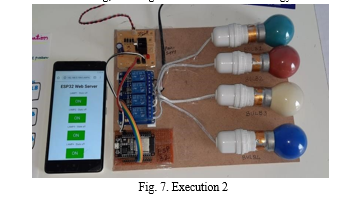

The IoT Industrial Automation System, incorporating a MERN (MongoDB, Express.js, React, Node.js) website with REST API implementation, represents a transformative leap in the realm of industrial automation. This innovative system leverages the power of the internet to remotely monitor and control sensor data and relay actuators. The NodeMCU ESP8266 hardware, complemented by the DHT11 sensor for temperature and humidity measurements, and the BMP180 sensor for atmospheric pressure and altitude data, form the backbone of this comprehensive data acquisition system. In addition, a 4-channel relay actuator enables real-time control and responsiveness within the industrial setting.The heart of the system lies in its web-based dashboard, providing a userfriendly interface for data visualization and remote operation. Furthermore, this platform incorporates machine learning capabilities, facilitating predictive analysis based on historical sensor data. This predictive modelling enhances decisionmaking processes and augments industrial automation, ushering in a new era of efficiency and productivity. This IoT Industrial Automation System redefines industrial control and monitoring, ushering in a future where technology transforms industry landscapes.

VIII. FUTURE WORK

During this thesis it became clear that one of the main advantages of IIoT implementation from an OEE perspective is to support further automation in the production processes. In this view, an 57 interesting area of investigation for future work is how implementation of IIoT with integrated AI such as ML could enable prescriptive maintenance, hence making production self-regulating. This was highlighted by the case company as a goal of the IIoT implementation that would potentially have a great positive impact on the OEE. In this sense, future work in this area could mainly be focused more on the maintenance aspect of production as an enabler for improving the OEE. In addition, this thesis identified a gap in the literature regarding highlighting the importance of human aspects such as domain knowledge and cultural attitude towards the implementation of an IIoT-platform. This is an especially important research area as the literature suggests that Industry 4.0 views data as a main source of value while the literature suggests the transition to Industry 5.0 with a human centric approach. In this sense, this thesis literary contribution is to highlight the crucial role human aspects play in the successful implementation of digital technology, especially IIoT.

Conclusion

In the realm of Industrial Automation, the integration of a MERN-based website with REST API implementation to create a comprehensive IoT system has opened new horizons for efficiency and control. The resulting dashboard not only provides a seamless interface for viewing sensor data but also facilitates the remote control of critical relay actuators, adding a layer of versatility and responsiveness to the system. What sets this IoT Industrial Automation System apart is its predictive capabilities, driven by machine learning. By analysing historical sensor data, the system can forecast trends and provide valuable insights into the industrial environment, aiding in proactive decision-making and maintenance. This amalgamation of hardware, software, and data analytics represents a significant step towards intelligent, data-driven industrial automation. It enhances operational efficiency, reduces downtime, and paves the way for a more sustainable and responsive industrial ecosystem, making it an invaluable asset for businesses looking to embrace the future of automation and data analysis in their operations. Furthermore, we conducted ablation studies and sensitivity analyses to understand the impact of different components and hyperparameters on the model’s performance. This helped us identify key factors contributing to the summarization quality and refine our approach accordingly. The study concluded that challenges and enablers related to the implementation of IIoT to improve OEE can be divided into technical and cultural factors. Technical challenges and enablers mainly consider the achievement of interoperability, compatibility, and cyber security, while cultural factors revolve around digital acceptance, competence, encouragement of digital curiosity, and creating knowledge and understanding towards OEE. Lastly, conclusions can be drawn that implementation of IIoT has a positive effect on OEE since it ensures consistent and accurate data, which lies a solid foundation for production decisions. Also, digitalization of production enhances lean practices which are considered a key element for improving OEE.

References

[1] Nirmala,P.,etal.\"An Artificial Intelligence enabled Smart Industrial Automation System based on Internet of Things Assistance.\" 2022 International Conference on Advances in Computing ,Communication And Applied Informatics (ACCAI).IEEE,2022. [2] Sekar, R. Arun, et al .\"Industrial automation using IoT.\" AIP Conference Proceedings.Vol.2393.No.1.AIP Publishing,2022. [3] Jain, Samyak, and K. Chandrasekaran.\" Industrial automation using Internet of things.\" Research Anthology on Cross-Disciplinary Designs And Applications of Automation.IGIGlobal,2022. [4] Babayigit, Bilal , and Mohammed Abubaker. \"Industrial Internet of Things: A Review of Improvements Over Traditional SCADA Systems for Industrial Automation.\" IEEE Systems Journal (2023). [5] Pandey, Neeraj Kumar, et al. \"Security issues and challenges in cloud of things-based applications for industrial automation.\" Annals of Operations Research (2023). [6] Lesi, Vuk, Zivana Jakovljevic, and Miroslav Pajic. \"Security analysis for distributed IoT-based industrial automation.\" IEEE Transactions on Automation Science and Engineering 19.4(2021). [7] Sundari, V. Kamatchi, et al.\"Comparison analysis of IoT based industrial Automation and improvement of different processes–review.\" Materials Today : Proceedings 45(2021). [8] Ahire, C. P., & Relkar, A. S. (2012). Correlating failure mode effect analysis (FMEA) & overall equipment effectiveness (OEE). Procedia Engineering, 38, 34823486. [9] Ahmad, N., Hossen, J., & Ali, S. M. (2018). Improvement of overall equipment efficiency of ring frame through total productive maintenance: a textile case. The international journal of advanced manufacturing technology, 94(1), 239256. [10] Ahmed, C. M., Ochoa, M., Zhou, J., Mathur, A. P., Qadeer, R., Murguia, C., & Ruths, J. (2018, May). Noiseprint: Attack detection using sensor and process noise fingerprint in cyber physical systems. In Proceedings of the 2018 on Asia Conference on Computer and Communications Security (pp. 483-497). [11] Baker, T., Aldawsari, B., & England, D. (2015). Trusted energy-efficient cloud-based services brokerage platform. International Journal of Intelligent Computing Research (IJICR), 6(4), 630- 639. [12] Banerjee, M., Lee, J., & Choo, K. K. R. (2018). A blockchain future for internet of things security: a position paper. Digital Communications and Networks, 4(3), 149160. [13] Basir, R., Qaisar, S., Ali, M., Aldwairi, M., Ashraf, M. I., Mahmood, A., & Gidlund, M. (2019). Fog computing enabling industrial internet of things: State-of-the-art and research challenges. Sensors, 19(21), 4807. [14] Benjamin, S. J., Murugaiah, U., & Marathamuthu, M. S. (2013). The use of SMED to eliminate small stops in a manufacturing firm. Journal of Manufacturing Technology Management. Blomkvist, P., & Hallin, A. (2014). [15] Metod för teknologer. Examensarbete enligt 4fasmodellen. Studentlitteratur. Botta, A., De Donato, W., Persico, V., & Pescapé, A. (2016). Integration of cloud computing and internet of things: a survey. Future generation computer systems, 56, 684-700. [16] Boyes, H., Hallaq, B., Cunningham, J., & Watson, T. (2018). The industrial internet of things (IIoT): An analysis framework. Computers in industry, 101, 1-12. Braun, V., & Clarke, V. (2006). Using thematic analysis in psychology. Qualitative research in psychology, 3(2), 77101. [17] Bryman, A., & Bell, E. (2011). Företagsekonomiska forskningsmetoder (1: 2 uppl.)(B. Nilsson övers.). Malmö: Liber AB (Originalarbete publicerat 2003) [18] Chen, C. H., Lin, M. Y., & Liu, C. C. (2018). Edge computing gateway of the industrial internet of things using multiple collaborative microcontrollers. IEEE Network, 32(1), 24-32.

Copyright

Copyright © 2024 Shreyas Navale , Pradnesh Naik , Akshay Lohar, Jai Mulay. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET60368

Publish Date : 2024-04-15

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online