Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

An Investigation into Sugarcane Byproducts Management Practices in Ethiopian Sugar Factory

Authors: Dawit Debela, Devarakonda Harish Kumar

DOI Link: https://doi.org/10.22214/ijraset.2024.65693

Certificate: View Certificate

Abstract

The expansion of sugar factory has played a vital role in transforming the life of the local community through job creation, provision infrastructures such as school, potable water, roads and health institutions. Beside the production of sugar, sugar factory produces different byproducts which are important as a raw material for various industries. In Ethiopia there is big potential to supply molasses, bagasse and cane top as a raw material. Byproducts of the sugarcane industry, if efficiently implemented, has the dual and important advantage of generating reasonable profits, not only for the sugar producers themselves but also for the national economy at large, as exemplified by cheap electricity, imports replacement, the efficient use of local fuels and forest preservation. Ethiopian sugar factory is not utilizing this raw material resource satisfactorily and there is little understanding of these byproducts of sugarcane. The aim of this thesis is to investigate management practices of sugarcane byproducts, utilization and sustainability in case of selected Sugar Factories in particular and the Ethiopian Sugar Factory in general. The collection of reviews was made from various studies undertaken and used as a milestone.

Introduction

I. INTRODUCTION

Ethiopia is a developing country with population of more than 90 million with double digit GDP growth for more than 10 years. Government is investing in economic and social sectors in order to transform the lively hood of the citizens. Among the mega projects that are given top priority by Ethiopian Government is sugar industry. Ethiopia began investment in sugar industry in 1954 with one sugar factory which have been expanded to four small size sugar factories up to 1998. Since then, despite the big potential for cane sugar in the country, the developments of sugar industry have been very stagnant for more than two decades.

The expansion of sugar industries has played a vital role in transforming the life of the local community through job creation, provision infrastructures such as school, potable water, road and health institutions.

According to Shiferaw Jarso(2014), Ethiopia still has potential area where company wants to work with interested partners in the area of animal feed production, dairy farm, fattening, animal product processing up to supply to final consumers both locally and to the world market. There is big potential to supply molasses, bagasses and cane top as a raw material. [18]

The main reasons for involvement of ESC are, the first reason is that raw materials for animal feed are by-products of sugar industry. The second reason is that the sugar projects are located in the areas where pastoralists and farmers with large number of cattle are living. ESC has the responsibility to transform the lively hood of the local community in line with their potential and long time experience. He said, for this end we are working with other ministries such as Federal Democratic Republic of Ethiopia (FDRE) Ministry of Agriculture and Ministry of industry. Therefore, interested partners who have the technology, experience and finance are encouraged to work with us. As Ethiopia is one of the fastest growing countries with peaceful and conducive environment working in the sugar sector with ESC can help as the entry point to other sectors potential investment area. [18] Beside the production of sugar, sugar factory produces different byproducts which are important as a raw material for various industries.

As Srinivasan and Pathak concluded, that the large-scale utilization of byproducts of the sugarcane industry, if efficiently implemented, has the dual and important advantage of generating reasonable profits, not only for the sugar producers themselves but also for the national economy at large, as exemplified by cheap electricity, imports replacement, the efficient use of local fuels and forest preservation.[1] Sustainable production is becoming an increasingly important issue in the process industries. In the cane sugar industry, pressure for sustainable production has come largely from the importers of ethanol from sugarcane. This has focused attention on sustainable production in the sugar industry in general. Some of the major producers of white sugar are aware of the advantages in the market place of sustainable manufacturing processes in terms of brand enhancement and are using the low carbon footprint of sugar to their advantage.

II. LITERATURE REVIEW

A. Introduction

This chapter presents the review of literature relating to the study undertaken. The collection of reviews has been made from various studies undertaken by academicians, practitioners, researchers etc, from time to time. These reviews will enlighten the existing knowledge of the researcher. Besides this, the reviews of empirical studies explore the avenues for the present and future research related to the subject matter in order to understand the research problem. The earlier attempts made by the academicians, economist, socialist, etc, are needed to study.

B. Classification of Byproducts of Cane Sugar Manufacture

Although world prices for sugar and petroleum products have shown spectacular variations since 1973, the long term outlook is very likely to be a gradual increase in the price of all fossil fuels and stagnation, at best, for the price of sugar.

Description Sugar cane was originally from tropical South Asia and Southeast Asia. Different species probably originated in different locations with S. barberi originating in India and S. edule and S. officinarum coming from New Guinea. The thick stalk stores energy as sucrose in the sap. From this juice, sugar is extracted by evaporating the water. Crystallized sugar was reported 5000 years ago in India. [16]

C. Formation process of sugarcane byproducts

Sugar cane coming from the field is weighed first and passed to the juice extraction stage where separation of juice from bagasse is made. Bagasse is the fibrous residue of the cane stalk after crushing and extraction of the juice. This bagasse goes to boiler for steam generation to be used for the sugar factories own consumption. The steam generated is enough to cover the sugar factories thermal energy requirement.

D. Industrial utilization of sugarcane byproducts

Sugarcane occupies a prominent place for high bio-mass fibre production and molasses. Every part of cane plant from tops to bottom is utilized in one form or the other, directly by mankind or in the industry. As a raw material, sugarcane has attained worldwide importance for dozens of industrial derivatives. Main byproducts of cane are known to be the molasses used for alcohol, bagasse utilized for energy production, co-generation, manufacture of particle board and filter press cake used as organic fertilizer.

E. Basic Assumptions and Theoretical Value Considerations

Regardless of the country of origin, maturity, harvesting method, variety of cane and mill efficiency, was considered to have the same compositions of fiber, yield, physical and chemical properties.

A typical sugar cane complex with a capacity of 3,000 tones crushed per day (TCD) can produce.(World Alliance for Decentralized Energy WADE, 2004)

- 345 tones of refined sugar,

- 6,000 liters of alcohol (Ethanol),

- 95 tones of molasses

- 3 tones of yeast,

- 15 tones of potash fertilizer,

- 25 tones of pulp,

- 15 tones of wax,

- 150 tones of press-mud fertilizer and

- 240 MWh of exportable electricity from bagasse.

F. Handling of sugarcane byproducts

A number of factories attempt to store the maximum amount of surplus bagasse for off-crop use. Because of the low bulk density of bagasse, large areas are involved, which usually means storage in the open air. A system will possibly incorporate a long belt conveyor across a concrete slab, with the ability to tip bagasse from the belt at any point, or to a boom stacker moving on rails. In some cases bagasse is transported in large trailers to remote storage areas.

G. Sustainability In case Of Sugar Factory

Sustainability in the sugar industry does not necessarily imply reduced productivity and profits; indeed, measures to address environmental impacts can provide economic benefits for farmers or mills through cost savings from more efficient resource use.

This provides an opportunity to reconcile the needs of the environment and people with the long-term development of the sugar industry. Better Management Practices (BMPs) do just this, addressing environmental concerns such as habitat loss, water overuse and pollution; social needs such as availability of clean water for drinking and sanitation; and economic considerations such as crop yield and maintenance of long-term soil health.

H. Better Management Practices to Reduce the Impacts in Sugar Factory

Sugar produced using Better Management Practices (BMPs) can improve financial returns to farmers and millers – through increased yields, sustained soil health, reduced inputs and enhanced quality of production – as well as providing benefits for businesses that use sugar in their products. [25] Even though there are concerns about the sustainability of the sector, the World Wildlife Fund (WWF), 2004 lists Better Management Practices (BMPs) that can be used to make the process of growing sugarcane more environmentally sustainable.

III. MATERIALS METHODS

Methods and procedures in this study are based on data collected from two complementary sources. The first is documentary sources. The second is site observation and interview to collect data from the selected factory, Arjo Didessa and Finchaa Sugar factory. These two sources could generate both qualitative and quantitative data, which would be used to explore the essence of this paper. To achieve its objective, both qualitative and quantitative data were obtained through the use of interviews, observation, questionnaires and literature review.

A. Sampling and Target population of the study

The study was included about two major target groups. These include Arjo Didessa and Finchaa Sugar factory. The selected sugar factories were expected to be representative of the rest as old and new established sugar factory in the country respectively. The aim was to get mills performance data and to draw conclusions about the sugarcane byproducts generated potential of the country.

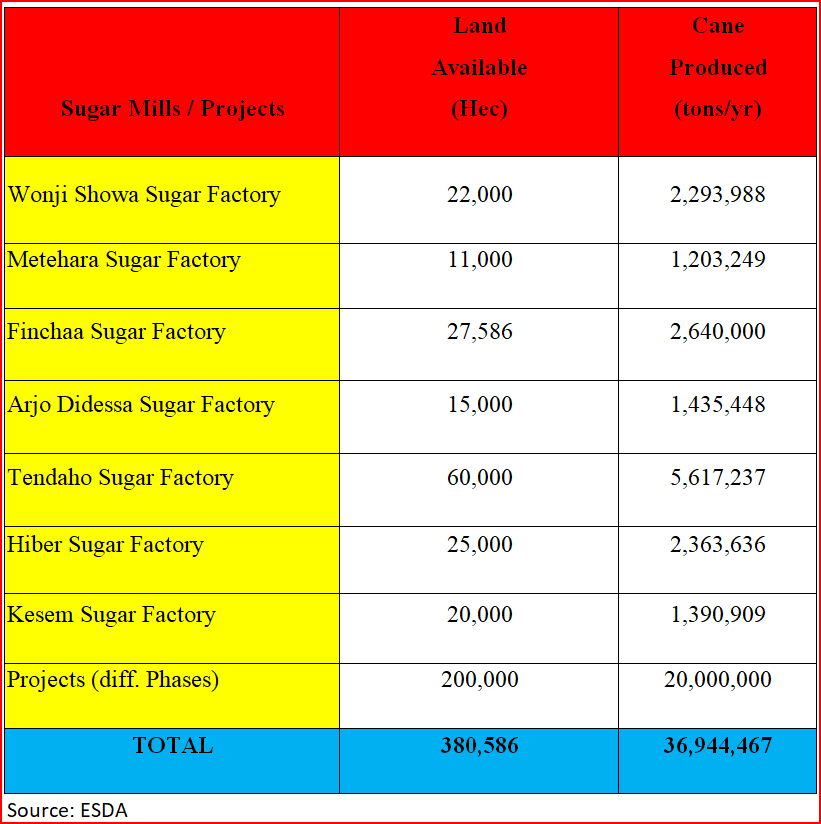

TABLE 3.1 LAND AVAILABLE AND CANE PRODUCED POTENTIALS OF SUGAR FACTORY

Bagasse storage area is observed and the following Figure 3.1 below shows bagasse storage areas.

IV. RESULTS DISCUSSION

By considering Production and operation of generating byproducts in a modernized sugar mill with reasonable daily milling capacity was taken for granted for all other sugar mills regardless of the country where the mills are located, current status and potential uses of the sugarcane byproducts generated were analyzed and assessed. Based on the expandable capacity of the sugar factory expected to be realized in the future, the total bagasse production potential of the country is 14 tons per day; the total molasses production potential of the country is 5,320 tons per day and the total filter cake production potential of the country is 8,400 tons per day.

Current sugarcane byproducts management options in selected number of sugar factory were identified. There is lack of more attention and little understanding of Better Management Practices (BMPs) in sugar factory especially on effective utilization and proper handling of byproducts generated. Sugarcane byproducts generated in sugar factory has its own impact on environment like air pollution, soil degradation and loss in productivity if not properly managed. For example, because of the moisture content and some residual sugars, fresh filter cake ferments, forming acids and often creating unpleasant odors. Pre –harvesting burning of cane can also pollute atmosphere, reduce biodiversity and loss of productivity.

The majority of the respondents agreed that using and managing sugarcane byproducts a strategic issue to Ethiopia for the following four major reasons:

- Effective and economic utilization of available resource.

- Local production of products from which further enhances the development of other strategic sectors.

- Import substitution and foreign currency saving

- Employment opportunity, management know how and transfer of technology

A. Basic Assumptions and Theoretical Value Considerations

Regardless of the country of origin, maturity, harvesting method, variety of cane and mill efficiency, was considered to have the same compositions of fiber, yield, physical and chemical properties.

Production and operation of generating byproducts in a modernized sugar mill with reasonable daily milling capacity was taken for granted for all other sugar mills regardless of the country where the mills are located. Bagasse production potentials for the Ethiopian sugar factory were calculated and summarized in the following table 4.2.

|

TABLE 4.1 Calculated Sugarcane Bagasse Potentials Of Ethiopian Sugar Factory

|

||||

|

Sugar factory / Projects |

Land |

Cane |

Crushing |

Bagasse |

|

Wonji Showa Sugar Factory |

22,000 |

2,293,988 |

12,500 |

1.04 |

|

Metehara Sugar Factory |

11,000 |

1,203,249 |

6,000 |

0.50 |

|

Finchaa Sugar Factory |

27,586 |

2,640,000 |

13,000 |

1.08 |

|

Arjo Didessa Sugar Factory |

15,000 |

1,435,448 |

8,000 |

0.67 |

|

Tendaho Sugar Factory |

60,000 |

5,617,237 |

26,000 |

2.17 |

|

Hiber Sugar Factory |

25,000 |

2,363,636 |

12,500 |

1.04 |

|

Kesem Sugar Factory |

20,000 |

1,390,909 |

10,000 |

0.83 |

|

Projects (diff. Phases) |

200,000 |

20,000,000 |

80,000 |

6.67 |

|

Total |

380,586 |

36,944,467 |

168,000 |

14 |

Note that:

- Bagasse available in tons is calculated and determined based on the assumptions and theoretical value considerations, that is:

Bagasse Prod. Pot. = [Crushing capacity per day (tons) * 0.25]/3000

- All data are based on the expandable capacity of the sugar factory expected to be realized in the future.

As it can be seen from the computation above, the total bagasse production potential of the country is 14 tons per day.

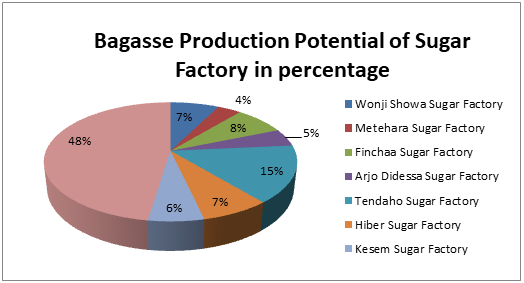

Bagasse Production Potential of Ethiopian Sugar Factory in percentage are given in (figure 4.1) below. In this case Arjo Didessa sugar factory accounts 5%, where as Finchaa sugar factory accounts 8% among selected sugar factory.

Figure 4.1 Bagasse Production Potential of Sugar Factory in percentage

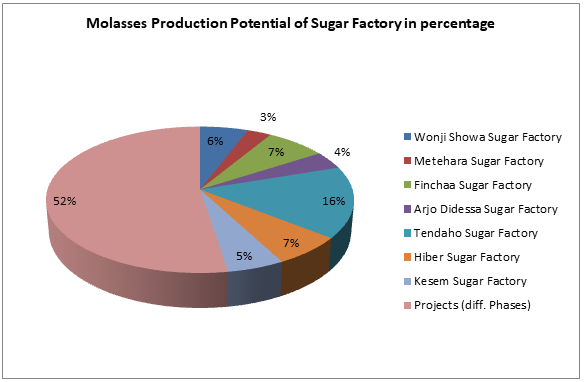

Molasses production potentials for the sugar factory were calculated from the following table 4.2.

Note that:

- Molasses available in tons is calculated and determined based on the assumptions and theoretical value considerations, that is:

Molasses Prod. Pot. = [Crushing capacity per day (tons) * 95]/3000

- All data are based on the expandable capacity of the sugar factory expected to be realized in the future.

As it can be seen from the computation above, the total molasses production potential of the country is 5,320 tons per day.

Molasses Production Potential of Ethiopian Sugar Factory in percentage are given in (Figure 4.2) below. In this case Arjo Didessa sugar factory accounts 4%, where as Finchaa sugar factory accounts 7% among selected sugar factory

Figure 4.2 Molasses Production Potential of Sugar Factory in percentage

|

Sugar Factory/projects |

Land |

Cane |

Crushing |

Filter Cake |

|

Wonji Showa Sugar Factory |

22,000 |

2,293,988 |

12,500 |

625 |

|

Metehara Sugar Factory |

11,000 |

1,203,249 |

6,000 |

300 |

|

Finchaa Sugar Factory |

27,586 |

2,640,000 |

13,000 |

650 |

|

Arjo Didessa Sugar Factory |

15,000 |

1,435,448 |

8,000 |

400 |

|

Tendaho Sugar Factory |

60,000 |

5,617,237 |

26,000 |

1,300 |

|

Hiber Sugar Factory |

25,000 |

2,363,636 |

12,500 |

625 |

|

Kesem Sugar Factory |

20,000 |

1,390,909 |

10,000 |

500 |

|

Projects (diff. Phases) |

200,000 |

20,000,000 |

80,000 |

4,000 |

|

Total |

380,586 |

36,944,467 |

168,000 |

8,400 |

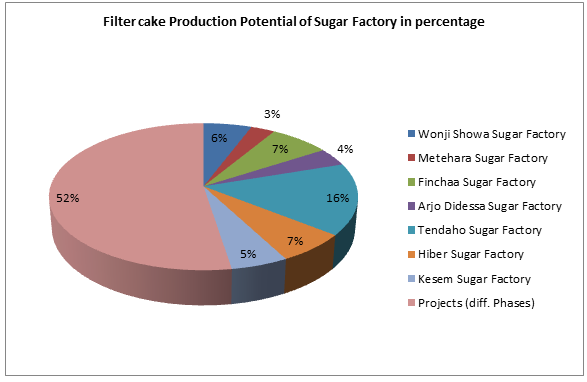

Filter cake Production Potential of Ethiopian Sugar Factory in percentage are given in (figure 4.3) below. In this case Arjo Didessa sugar factory accounts 4%, where as Finchaa sugar factory accounts 7% among selected sugar factory.

Conclusion

Beside the production of sugar, sugar factory produces different byproducts which are important as a raw material for various industries. In Ethiopia there is big potential to supply molasses, bagasses and cane top as a raw material. Byproducts of the sugarcane industry, if efficiently implemented, has the dual and important advantage of generating reasonable profits, not only for the sugar producers themselves but also for the national economy at large, as exemplified by cheap electricity, imports replacement, the efficient use of local fuels and forest preservation. Ethiopian sugar factory is not utilizing this raw material resource satisfactorily and there is little understanding of these byproducts of sugarcane. By counting the number of times a reason (or issue) was given by respondents - so that the one with more counts would be more important than the one with less, the majority of the respondents agreed that using bagasse for pulp and paper manufacturing is a strategic issue to Ethiopia for the following four major reasons: 1) Effective and economic utilization of available resource. 2) Local production of products from which further enhances the development of other strategic sector such as the education, agriculture and chemical. 3) Import substitution and foreign currency saving 4) Employment opportunity, management know how and transfer of technology Generally, the studies shows awareness on creation of more employment opportunities in the rural areas by setting up industries based on sugarcane by-products, judiciously utilizing sugarcane byproducts and industrial effluents to produce value-added products and minimize pollution hazards, and developing knowledge on the byproduct future market in Ethiopia thereby providing an important value to policy makers, academic researchers, business society, industry actors and interested groups. The followings are suggested as a solution depending on the stated problems: • Proper measurement of byproducts generated by implementing flow rate recording mechanism. • Avoid burning cane leaves in the field before harvest. • Assessing the impact of the sugar factory on biodiversity and ecosystems by measuring and reducing effluents entering the environment; and ensuring that the effluents are suitably treated to achieve recognised standards. • Ensuring that workers are appropriately trained to complete their roles, by monitoring skill levels in each department and ensuring that all departmental training needs are identified and rectified as required on byproducts generated. • Implementing Better Management Practices (BMPs) can improve financial returns to sugar factory through increased yields, sustained soil health, reduced environmental pollution and enhanced quality of production. • Suitable technologies could be developed to reduce their voluminous to cheaper concentrated end products. • Using high pressure boiler and high efficiency steam turbine in order to get surplus bagasse. • Giving more attention on the management and monitoring and controlling of sugarcane byproducts by establishing green industry.

References

[1] A Century of Utilization and Fundamental Work of Sugar Cane Bagasse” by Srinivasan and Pathak] http://www.fao.org/docrep/003/s8850e/s8850e03.htm [2] AMAS 98. Food and Agricultural Research Council, Réduit, Mauritius [3] Biofuel Co-Products As Livestock Feed Opportunities And Challenges Editor Harinder P.S. Makkar Food And Agriculture Organization Of The United Nations Rome, 2012 [4] Biruk Hailu, December 2011, \"Bagasse Ash As a Cement Replacing Material\", MSc Thesis, Addis Ababa University [5] C.R. Kothari,2004 , \"Research Methodology\", 2nd Edition [6] Demelash Tebik, November, 2010, \"The Economic Significance of Using Bagasse as An Alternative Source of Raw material for Pulp Manufacturing\": A case of Ethiopia.A Msc Research Report, University of South Africa. [7] Dr Peter W, 2011, ReinSustainable Production Of Raw And Refined Cane Sugar, Paper Presented To Sit Conference, Montreal [8] Ensinas VA, Nebra AS, Lozano AM, Serra L (2006) Analysis of cogeneration systems in sugar cane Factories [9] alternatives of steam and combined cycle Power plants Energy Department [10] Ensinas VA, Nebra AS, Lozano AM, Serra L (2006) Analysis of cogeneration systems in sugar cane Factories – alternatives of steam and combined cycle Power plants Energy Department [10] Home page of International Sugar Organisation(ISO) [11] https://www.bioenergyconsult.com/tag/sugarcane-wastes/ [12] International Finance Corporation IFC (World Bank Group), \"Environmental, Health, And Safety Guidelines Sugar Manufacturing (EHS)\", April 30, 2007 [13] J. Mater. Environ. Sci. 3 (6) (2012) 1Department of Mechanical Engineering, College of Engineering Roorkee, India 2 College of Technology Pantnagar, GBPUAT Pantanagar- 263445, Uttarakhand, India [14] L. R. Holanda and F. S. Ramos, Reuse of Waste Sugarcane Agribusiness and Green Power Generation, Journal of Clean Energy Technologies, Vol. 4, No. 5, September 2016 [15] M. L. Dotaniya1 &S. C. Datta, \"Use of sugarcane industrial by-products for improving sugarcane productivity and soil health\" Int J Recycl Org Waste Agricult , 2016 [16] N. El Bassam, HANDBOOK OF BIOENERGY CROPS A Complete Reference to Species, Development and Applications, London • Washington, DC, 2010 [17] Nov. 2014, 23rd ISO Seminar, The Ethiopian Sugar Industry Current Status & Future Prospect, by Shiferaw Jarso, Addis Ababa [18] Rainey, T. J. 2009. A study in to the Permeability and Compressibility Properties of Australian Bagasse pulp. Thesis for PHD, School of Engineering Systems Queensland University of Technology, Australia. [19] Saylor, Foundation“Sustainability, Innovation and Entrepreneurship”This text was adapted by a Creative Commons Attribution-NonCommercial-ShareA [20] Singh R.V., 1980. “Wealth from Sugarcane Waste”, Yojana, [21] Sugar and the environment. Zeist: WWF. Retrieved July 7, 2016, from file:///C:/Users/april/ Downloads/sugarandtheenvironment_fidq.pdf [22] The Prospects and Challenges of Bio Ethanol Production from Molasses in the Ethiopian Sugar Industry Girma Abebe, 2012 [23] Utilization of molasses and sugar cane bagasse for production of fungal invertase in solid state fermentation using Aspergillus niger , Brazilian Journal of Microbiology , 2004 [24] World Alliance for Decentralized Energy WADE,2004 [25] WWF Global Freshwater Programme, on the topic \"Sugar And The Environment \"] file:///C:/Users/april/Downloads/sugarandtheenvironment_fidq.pdf [26] Y.K. Singh, 2006, Fundamentals of Research Methodology and Statistics

Copyright

Copyright © 2024 Dawit Debela, Devarakonda Harish Kumar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65693

Publish Date : 2024-11-30

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online