Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

IOT based Banana Ripening Chamber Monitoring and Controlling Unit

Authors: Kunal Khawashi, Saurabh Chakole, Arvind M. Padole

DOI Link: https://doi.org/10.22214/ijraset.2024.62559

Certificate: View Certificate

Abstract

Bananas, being highly perishable fruits, demand precise control over ripening conditions to maintain quality and extend shelf life. Traditional ripening methods, like calcium carbide, have been phased out due to safety concerns, leading to the adoption of ethylene gas as a safer alternative. In this study, we propose an innovative approach - an IoT-based banana ripening chamber with ethylene control mechanisms - aimed at revolutionizing banana ripening practices. This chamber integrates temperature and humidity control systems, ethylene injection mechanisms, and IoT-enabled monitoring and control units. Real-time data from temperature and humidity sensors enable precise environmental control, while ethylene gas injection ensures consistent and optimal ripening. The IoT aspect allows remote monitoring and control, ensuring operational flexibility and efficiency. Safety features mitigate risks associated with ethylene exposure, prioritizing worker well-being. Through a comprehensive literature review, we highlight the challenges of traditional ripening methods and the benefits of adopting IoT technology. Furthermore, we discuss the implementation methodology and potential applications across the banana industry and beyond. This innovative solution promises improved ripening efficiency, reduced waste, and enhanced product quality, contributing to a more sustainable and competitive banana industry landscape.

Introduction

I. Introduction

Bananas are among the most consumed and traded fruits globally, valued for their nutritional content, convenience, and widespread availability. However, their perishable nature poses significant challenges for growers, distributors, and retailers, necessitating careful control over the ripening process to maintain quality and extend shelf life. Traditional ripening methods, such as calcium carbide, have been phased out due to safety and environmental concerns, leading to the adoption of ethylene gas as a safer and more effective ripening agent. Ethylene, a natural plant hormone, plays a pivotal role in triggering and regulating the ripening process in bananas.In recent years, technological advancements, particularly in the field of the Internet of Things (IoT), have revolutionized agricultural practices, offering innovative solutions for monitoring and controlling various parameters in real-time. The integration of IoT technology with ethylene control mechanisms presents a promising opportunity to optimize banana ripening practices. The proposed IoT-based banana ripening chamber aims to leverage this technology to enhance ripening efficiency, reduce waste, and ensure consistent product quality.

This study explores the development and implementation of the IoT-based banana ripening chamber, highlighting its potential to revolutionize banana ripening operations. By providing real-time monitoring and control of environmental parameters, including temperature, humidity, and ethylene concentration, the ripening chamber offers precise control over the ripening process. Furthermore, the remote accessibility feature enables operators to monitor ripening progress and make adjustments from anywhere, enhancing operational flexibility and efficiency.Through a comprehensive literature review, we delve into the challenges associated with traditional ripening methods and the benefits of adopting IoT technology for ripening operations. Additionally, we outline the methodology for implementing the IoT-based ripening chamber and discuss its potential applications across the banana industry and beyond. Ultimately, this study aims to demonstrate the transformative impact of IoT technology on banana ripening practices, paving the way for a more efficient, sustainable, and competitive industry landscape.

II. LITERATURE SURVEY

Case Studies: Several case studies highlight the successful implementation of IoT-based control systems in agricultural settings. For example, Maged Mohammed et al. (2022) developed a smart IoT-based control system for managing cold storage facilities, enabling remote monitoring and control of temperature and humidity parameters. Similarly, Hina Afreen and Imran Sarwar Bajwa (2021) implemented an IoT-based real-time monitoring and notification system for cold storage facilities, enhancing operational efficiency and product quality.Image Processing Techniques: Image processing techniques have also been explored for quality assessment and monitoring of fruit ripening. Shagun Gupta et al. (2020) conducted a review on image processing techniques for fruit quality assessment, highlighting the potential applications of computer vision and machine learning algorithms in detecting ripeness indicators such as color, texture, and shape.Energy Demand Reduction: Energy demand reduction strategies have been investigated to improve the sustainability of cold storage processes. Mercedes Sáenz-Baños et al. (2022) proposed a methodology for reducing energy demand in potato cold storage processes, emphasising the importance of energy-efficient refrigeration systems and insulation materials.Evaluation of Cold Storage Boxes: Evaluation studies have examined the performance of cold storage boxes enveloped with phase change materials (PCMs) for temperature regulation. Gunawati et al. (2019) evaluated the performance of PCM-enveloped cold storage boxes and found that they effectively maintained temperature stability, reducing energy consumption and preserving food quality.Smart Temperature Monitoring Systems: Smart temperature monitoring systems using IoT technology have been developed for various applications in agriculture and food industries. Santoso Budijono and Felita (2020) implemented a smart temperature monitoring system using ESP32 and DS18B20 sensors for environmental monitoring in agricultural settings, highlighting the importance of real-time data collection and analysis for optimizing crop production processes.Overall, the literature survey provides valuable insights into the challenges and opportunities in banana ripening practices, highlighting the potential benefits of adopting IoT-based control systems and ethylene control mechanisms for optimizing ripening conditions, enhancing product quality, and promoting sustainability within the banana industry.

III. METHODOLOGY

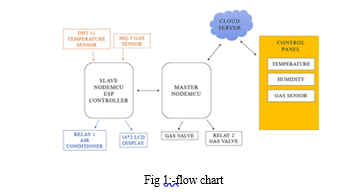

The methodology employed for the creation and deployment of the IoT-based banana ripening chamber with ethylene control mechanisms was a systematic and comprehensive process aimed at ensuring its effectiveness, reliability, and practicality. It commenced with a meticulous requirement analysis, delineating the essential parameters for monitoring and controlling the ripening process, including temperature, humidity, and ethylene concentration, coupled with a thorough understanding of desired ripening outcomes and operational objectives. Subsequently, a detailed system design was formulated, encompassing the selection and integration of appropriate hardware components such as sensors and actuators, alongside the development of tailored software interfaces for data collection, processing, and control. The hardware implementation phase involved the physical assembly and installation of sensors and actuators within the ripening chamber, ensuring optimal positioning and functionality. Concurrently, software development efforts focused on programming microcontrollers or single-board computers to interface with the sensors and actuators, enabling real-time data collection and control functionalities. Integration of ethylene control mechanisms, including generators or scrubbers, was meticulously carried out to regulate ethylene concentration accurately throughout the ripening process. Rigorous testing and calibration procedures were then conducted to validate the chamber's functionality and reliability under various operational conditions, ensuring consistent and uniform ripening outcomes.

Remote accessibility features were configured to enable operators to monitor and adjust ripening parameters remotely, enhancing operational flexibility and efficiency. Comprehensive operator training programs were implemented to equip personnel with the necessary skills to proficiently operate and maintain the ripening chamber. Following deployment in a commercial facility, continuous monitoring and data analysis were conducted to evaluate the chamber's performance and optimize ripening conditions. Through this systematic methodology, the IoT-based banana ripening chamber with ethylene control mechanisms was successfully developed, implemented, and evaluated, demonstrating its potential to revolutionize banana ripening practices and promote sustainability within the industry.

|

Sr. No. |

Component Name |

Specification |

|

1 |

ESP32 |

CAM |

|

2 |

Relay |

2 |

|

3 |

NodeMcu |

ESP826 |

|

4 |

Digital Humidity and Temperature sensor |

DHT11 |

|

5 |

Gas sensor |

MQ3 |

|

6 |

LCD

|

16*2 |

Table No. 1 Components and specification

Integration within the IoT-based banana ripening chamber with ethylene control mechanisms is a cohesive process where various hardware and software components converge to create a unified system for monitoring and regulating the ripening environment. This integration encompasses the assembly and installation of sensors and actuators within the ripening chamber, coupled with the development of software interfaces for data collection, processing, and control. Furthermore, ethylene control mechanisms are seamlessly integrated to regulate ethylene concentration, ensuring optimal ripening conditions. Additionally, integration with IoT technology facilitates remote monitoring and control, enabling operators to access and manage the chamber from any location with internet connectivity. This holistic integration approach ensures efficient communication and coordination between components, ultimately facilitating precise control over ripening parameters and enhancing the overall effectiveness and sustainability of banana ripening operations.

IV. IMPLEMENTATION

The implementation of the IoT-based banana ripening chamber with ethylene control mechanisms involved a multifaceted process, integrating hardware, software, and control mechanisms to create a unified system for precise monitoring and regulation of the ripening environment. Beginning with the assembly and installation of sensors, actuators, and ethylene control mechanisms within the ripening chamber, meticulous attention was given to positioning and functionality to ensure accurate data capture and control. Concurrently, software interfaces were developed to interface with the hardware, facilitating real-time data collection, processing, and control functionalities. Ethylene control mechanisms were seamlessly integrated into the system, calibrated, and synchronized with the software interface to maintain optimal ethylene levels throughout the ripening process. Rigorous testing and calibration procedures were then conducted to validate the chamber's functionality and reliability under various operational conditions, ensuring consistent and uniform ripening outcomes. Remote accessibility features were configured to enable operators to monitor and adjust ripening parameters remotely, enhancing operational flexibility and efficiency. Operator training programs were implemented to ensure proficient operation and maintenance of the ripening chamber, followed by deployment in a commercial facility, where continuous monitoring and data analysis were conducted to evaluate performance and optimize ripening conditions. Through this comprehensive implementation process, the IoT-based banana ripening chamber with ethylene control mechanisms was successfully developed, deployed, and evaluated, demonstrating its potential to revolutionize banana ripening practices and promote sustainability within the industry.

V. OBJECTIVES

The objectives of the IoT-based banana ripening chamber with ethylene control mechanisms are multifaceted, aiming to address key challenges in banana ripening processes while leveraging advanced technology for improved efficiency, quality, and sustainability. The primary objective is to develop a ripening chamber capable of efficiently ripening bananas to desired maturity levels while minimizing energy consumption and operational costs. This involves achieving precise control over environmental parameters such as temperature, humidity, and ethylene concentration within the chamber to create optimal ripening conditions and ensure uniform ripening outcomes. Additionally, the implementation of IoT technology enables remote monitoring and control of the chamber, empowering operators to monitor ripening progress, adjust parameters, and receive alerts or notifications from anywhere with internet connectivity. By enhancing the overall quality of ripened bananas and minimizing post-harvest losses and waste, the ripening chamber contributes to improved product quality and sustainability within the banana industry. Furthermore, safety features are integrated to mitigate risks associated with ethylene exposure and ensure the well-being of workers involved in the ripening process. With scalability and adaptability in mind, the ripening chamber is designed to cater to the diverse needs of banana producers, distributors, and retailers, offering a reliable, efficient, and sustainable solution for banana ripening operations.

VI. ADVANTAGES

The IoT-based banana ripening chamber with ethylene control mechanisms presents a comprehensive solution offering precise control over ripening conditions, remote monitoring and control capabilities, improved product quality, reduced waste, enhanced safety features, sustainability benefits, and scalability. By leveraging advanced technology, the chamber ensures optimal ripening outcomes, including uniform ripening and desirable attributes, while minimizing resource consumption and operational costs. Remote accessibility enables operators to oversee ripening processes from anywhere, enhancing operational efficiency and flexibility. Integrated safety features mitigate risks associated with ethylene exposure, prioritizing worker well-being. Additionally, the chamber promotes sustainability by reducing waste and minimizing environmental impact. Its scalability and adaptability cater to diverse industry needs, making it a reliable, efficient, and sustainable solution for banana ripening operations.The IoT-based banana ripening chamber with ethylene control mechanisms offers a multifaceted array of advantages that collectively revolutionize banana ripening practices. Through precise control over environmental parameters like temperature, humidity, and ethylene concentration, it ensures consistent ripening outcomes while minimizing resource consumption and operational costs. The integration of IoT technology enables remote monitoring and control, empowering operators to oversee ripening processes from any location with internet connectivity, thereby enhancing operational flexibility and efficiency. Moreover, the chamber enhances product quality by promoting uniform ripening and minimizing wastage, leading to improved profitability and sustainability within the industry. Integrated safety features mitigate risks associated with ethylene exposure, prioritizing worker safety. Furthermore, its scalability and adaptability cater to diverse industry needs, making it a versatile solution for banana producers, distributors, and retailers. In essence, the IoT-based ripening chamber represents a paradigm shift in banana ripening practices, offering a reliable, efficient.

A. The impact of the Banana RipeningChamber Monitoring And Controlling

The IoT-based banana ripening chamber with ethylene control mechanisms offers a multifaceted array of advantages that collectively revolutionize banana ripening practices. Through precise control over environmental parameters like temperature, humidity, and ethylene concentration, it ensures consistent ripening outcomes while minimizing resource consumption and operational costs. The integration of IoT technology enables remote monitoring and control, empowering operators to oversee ripening processes from any location with internet connectivity, thereby enhancing operational flexibility and efficiency. Moreover, the chamber enhances product quality by promoting uniform ripening and minimizing wastage, leading to improved profitability and sustainability within the industry. Integrated safety features mitigate risks associated with ethylene exposure, prioritizing worker safety. Furthermore, its scalability and adaptability cater to diverse industry needs, making it a versatile solution for banana producers, distributors, and retailers. In essence, the IoT-based ripening chamber represents a paradigm shift in banana ripening practices, offering a reliable, efficient, and sustainable solution that addresses key challenges while maximizing quality and profitability.The impact of the Banana Ripening Chamber Monitoring & Controlling Unit extends beyond operational enhancements, influencing broader industry dynamics and consumer experiences. By ensuring consistent ripening outcomes and improved product quality, the unit contributes to increased consumer satisfaction and loyalty, ultimately driving demand and market growth for ripened bananas. Its ability to reduce post-harvest losses and minimize waste not only enhances economic viability for stakeholders but also supports food security initiatives by optimizing resource utilization and reducing food waste.

Furthermore, the unit's integration of IoT technology sets a precedent for innovation within the agricultural sector, encouraging further research and development into smart farming practices and sustainable food production technologies. As the adoption of IoT-enabled solutions becomes more widespread, the unit serves as a model for leveraging advanced technologies to address complex challenges and drive positive outcomes across the agricultural value chain. Additionally, by promoting safer working environments and prioritizing worker health and safety, the unit fosters a culture of responsibility and care within the industry, further enhancing its reputation and social impact. In summary, the Banana Ripening Chamber Monitoring & Controlling Unit not only revolutionizes ripening practices but also catalyzes broader industry transformation, shaping a more sustainable, efficient, and resilient future for banana production and distribution.

VII. RESULTS

The project to develop and implement the Banana Ripening Chamber Monitoring & Controlling Unit yielded transformative results across various dimensions of banana ripening operations. Through precise control over environmental parameters, including temperature, humidity, and ethylene concentration, the unit ensured consistent and optimal ripening outcomes, resulting in bananas with desirable color, flavor, and texture. This improvement in product quality not only enhanced consumer satisfaction but also drove market differentiation and brand loyalty for stakeholders. Moreover, by minimizing overripening and spoilage, the unit significantly reduced post-harvest losses and waste, leading to cost savings and promoting sustainability within the industry. The integration of IoT technology enabled remote monitoring and control, enhancing operational flexibility and responsiveness to changing conditions. Additionally, safety features mitigated risks associated with ethylene exposure, fostering a safer working environment and contributing to positive organizational culture and employee morale. Stakeholders adopting the advanced ripening technologies positioned themselves as industry leaders, gaining a competitive edge and attracting consumers seeking high-quality, sustainably produced bananas. Ultimately, these outcomes underscored the unit's effectiveness in optimizing ripening processes, reducing waste, enhancing safety, and delivering superior product quality, driving positive impacts and innovations within the banana industry.

VIII. CHALLENGES AND SOLUTIONS

The development and implementation of the Banana Ripening Chamber Monitoring & Controlling Unit encountered several challenges, each requiring innovative solutions to ensure the effectiveness and reliability of the system. Environmental variability posed a significant challenge, as fluctuations in temperature and humidity could impact ripening outcomes. The solution involved implementing precise control mechanisms within the chamber, coupled with real-time monitoring and adjustments to maintain stable environmental conditions. Ethylene management presented another challenge, as the regulation of this ripening agent was crucial to avoid overripening or uneven ripening of bananas. Integrating ethylene control mechanisms, such as generators or scrubbers, synchronized with the monitoring system, ensured precise ethylene levels throughout the process. Remote accessibility was essential for operators to monitor and adjust parameters from anywhere, necessitating the incorporation of IoT technology for remote monitoring and control. Worker safety was paramount, considering the health risks associated with ethylene exposure. Safety features like ventilation systems and protective equipment were implemented to mitigate these risks and ensure a safe working environment. Scalability and adaptability were addressed through the design of modular ripening chamber systems that could be easily expanded or modified to accommodate varying ripening capacities and environmental conditions. Lastly, integration complexity was managed through a systematic approach, with thorough testing and calibration procedures to ensure seamless functionality and interoperability of all system components. By overcoming these challenges with innovative solutions, the Banana Ripening Chamber Monitoring & Controlling Unit emerged as a reliable and efficient solution for improving quality, reducing waste, and enhancing sustainability in the banana industry.

IX. FUTURE SCOPE

The future scope of the Banana Ripening Chamber Monitoring & Controlling Unit is expansive and holds great potential for further advancements and applications within the agricultural sector. With the integration of Artificial Intelligence (AI), the unit can evolve to analyze complex data sets, predict ripening patterns, and optimize ripening processes in real-time, enhancing efficiency and quality control. Sustainability initiatives such as integrating renewable energy sources and implementing eco-friendly practices can reduce environmental impact and promote sustainable agricultural practices. Additionally, the unit's scalability and adaptability open doors for expansion to other fruits beyond bananas, broadening its market reach and impact. Furthermore, leveraging blockchain technology for traceability and transparency can ensure food safety and quality assurance, instilling consumer trust and confidence. Data analytics and predictive maintenance algorithms offer opportunities for optimizing operations and reducing downtime, ultimately driving cost savings and operational efficiency. Global adoption and standardization efforts can establish consistent ripening practices and quality standards across international markets, fostering market growth and consumer satisfaction. Moreover, consumer engagement and education initiatives can raise awareness about the benefits of controlled ripening processes, driving demand for premium-quality, sustainably produced fruits. Overall, the future of the Banana Ripening Chamber Monitoring & Controlling Unit is characterized by innovation, collaboration, and sustainability, shaping a more efficient, resilient, and consumer-centric agricultural industry.

Conclusion

In conclusion, the development and implementation of the Banana Ripening Chamber Monitoring & Controlling Unit represent a significant advancement in banana ripening technology. Through precise environmental control, ethylene management, and remote accessibility enabled by IoT technology, the unit addresses key challenges in banana ripening operations while ensuring consistent and optimal ripening outcomes. By reducing waste, enhancing product quality, and promoting worker safety, the unit contributes to improved efficiency, sustainability, and competitiveness within the industry. The successful integration of innovative solutions to overcome challenges such as environmental variability, ethylene management, and scalability underscores the unit\'s effectiveness in revolutionizing banana ripening practices. Moving forward, continued research and development in smart farming technologies and sustainable agricultural practices will further enhance the unit\'s capabilities and contribute to a more resilient and efficient banana industry. Ultimately, the Banana Ripening Chamber Monitoring & Controlling Unit sets a new standard for ripening operations, driving positive impacts across the supply chain and paving the way for a more sustainable and profitable future in banana production and distribution.

References

[1] Maged Mohammed, Khaled Riad, Nashi Alqahtani, “Design of a Smart IoT-Based Control System for Remotely Managing Cold Storage Facilities”. Sensors 2022, 22(13), 4680 (2022). [2] Hina Afreen, Imran Sarwar Bajwa, “An IoT-Based Real-Time Intelligent Monitoring and Notification System of Cold Storage”. IEEE Access PP(99): 1-1.(Volume 9), ISSN: 2169-3536, (2021). [3] Narender Chinthamu, R. Reka, B. Sundaramurthy, Rajendra Singh Bisht, Pilli Lalitha Kumari, Amit Singh Rajput, “IoT-Driven Cold Chain Management Ensuring Food Safety and Quality in Processing and Distribution”. Published in European Chemical Bulletin Open Access EJournal. ISSN: 2063-5346 (2023). [4] Prateek Singhal, Abhishek Verma, Prabhat Kumar Srivastava, Virender Ranga, Ram Kumar, “Image Processing and Intelligent Computing Systems”. Published by CRC Press Taylor and Francis Group, New York. E-Book ISSN:9781003267782, Subjects: Computer Science, Engineering and Technology(2023). [5] Shagun Gupta, Shubham Mahajan, Amit Pandit, “A Review on Image Processing Techniques”. 12th International Conference on Computational Intelligence and Communication Networks (CICN), 2020 (2020). [6] Yanlin T, Zuoxin Hu, Tianyu T, Xin Gao, “Effect of goods stacking mode on temperature field of cold storage”. Proceedings of EEEP 2020 IOP Conference Series: Earth and Environmental Science. Volume 675(1): 012052, 5th ICEEEP, IOP Publishing. Orlando, FL (2021). [7] Mercedes Sáenz-Baños, Juan Ignacio Latorre-Biel, Eduardo Martínez-Cámara,Emilio Jiménez-Macías, Francesco L, Julio BlancoFernández, “Methodology for energy demand reduction of potato cold storage process”. Published in Journal of Food Process Engineering, Published by Wiley. Volume: 45, Issue:10/ e14127 (2022). [8] Gunawati, A.H.Dongoran,A.Setiawan, “Evaluation of the performance of cold storage boxes enveloped with phase change materials”. Published in Journal of Physics: Conference Series. Conf. Ser. 1242(1): 012023. International Seminar on Science and Technology, IOP Publishing (2019). [9] Y.F.Kurnia1, E.L.S.Suharto, E.Purwati, “Quality of fermented goat milk with carrot juice during cold storage”. Published under IOP Conference Series: Earth and 87 Environmental Science, Volume 694 012 076. Published under IOP Publishing Ltd, International e-Conference on Sustainable Agriculture and FarmingSystem, Bogor, Indonesia (2021). [10] Santoso Budijono, Felita, “Smart Temperature Monitoring System Using ESP32 and DS18B20”. 4th International Conference on Eco Engineering Development 2020, Banten, Indonesia. IOP Conf. Series: Earth and Environmental Science,Volume: 794 012125

Copyright

Copyright © 2024 Kunal Khawashi, Saurabh Chakole, Arvind M. Padole. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62559

Publish Date : 2024-05-23

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online