Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

IOT Based Cold Management Chain

Authors: Prof. Dr. Durgaprasad Kamat, Firoz Shaikh, Mahaveer Navalakha, Jaideep Solanki, Abhishek Ghule

DOI Link: https://doi.org/10.22214/ijraset.2024.60986

Certificate: View Certificate

Abstract

The global economy\'s rapid expansion has expedited the supply chain sector, which demands efficient, flexible, and responsive logistics services. To convey information between clients and logistics providers, internet technology has been highly successful. However, the current disconnect between the flow of goods and the flow of information in logistics services has made it difficult for decision-makers to obtain real-time information on products that are sensitive to temperature. A promising approach to managing the cold supply chain is the Internet of Things. In this paper we propose a IOT based cold supply chain management system that helps to enhance the decision support through managing, monitoring the real-time environmental factors like Temperature, Humidity & air quality of the cold chain and predicting the shelf life of temperature-sensitive products.

Introduction

I. INTRODUCTION

The IoT (Internet of Things) is the technology that provides the connections between the different sensing objects or the groups of sensing objects, software, and the other technologies to exchange their data with each other or with other devices over the internet or other communication networks. The four main categories of IoT applications are logistics and transportation, smart environments, personal and social domains, and health care domains. The cloud-based platforms are used for the deployment of all IoT application- based initiatives. In the cold supply chain, using refrigeration and dehumidification systems the designated range of environmental conditions are maintained. The cold supply chain is developed due to the increase of public awareness in product quality and safety. The cold supply chain management handles and tracks a variety of environmentally sustainable products (ESPs).

The cold supply chain has the two roles of storing and transportation of the products to maintain the good quality and safety of the products. In the pandemic (Covid-19), cold supply chain has become the most important management as the vaccine that are transported from places to places requires the stable refrigerated temperature, humidity, and air quality. Due to the lack of development in cold supply chain management in the developing countries the agricultural and the health care products are not maintained properly, and this is a huge economic loss for the country. In this proposed system, the IoT enabled failure detection in the cold supply chain is developed with the help of NodeMcu ESP8266, Temperature sensor, humidity sensor, Gas sensor and GPS senso etc. This system has two sides i.e., administrator side and the driver side. The administrator side has the dashboard which displays the temperature, humidity, and the air quality as well as coordinates of vehicle of the cold supply chain. And the driver’s side has the same dashboard but in the form of the android app.

II. LITERATURE SURVEY

Rahman et.al. summarizes the benefits of the chain in real-time applications by focusing on the RFID- based traceability system in the fisheries supply chain management system to assure fish quality and security. This review's objective is to offer tips and recommendations for strengthening the security and dependability of RFID-based traceability in food SCM systems [1]. [2] In this study, researchers put forth a cold chain logistics system based on the Internet of Things that aids in predicting the shelf life of temperature-sensitive products while tracking real-time cold chain data like temperature.

In the suggested system, RFID is additionally modelled for additional identification-related considerations. The access points developed in the system include WSN, GSM, and RFID. The result of the system shows that IOT supported the cold chain in managing, monitoring, and determining temperature sensitive products. [3] In order to guarantee the functional quality of the complete cold chain management, the researchers in this paper propose an Internet of Things cargo monitoring system that keeps track of environmental changes affecting environmentally sensitive products (ESPs). In this post, an IoT- CMS was created to guarantee product quality in real-time. Information from the sensors in this system can be uploaded to a cloud database that customers can access via the Internet by utilizing IoT technology. According to the findings, the technology can provide full cargo monitoring and offer helpful directions to increase operational effectiveness. A real-time data-centric cold chain monitoring system for ongoing vaccine monitoring is suggested by researchers in this publication. Additionally, it oversees the vaccination's distribution and transportation processes.

The suggested system is distinctive in that it consistently monitors the temperature and humidity for each trip. The hardware and software components are used to track the carrier's location. The entire process of distribution and transportation can be monitored using this system [4]. By fusing IoT and tracking technologies, Luo, Heng, et al. [5] have presented an intelligent tracking system for the cold chain. This system's proposed wireless sensor network, which is based on Zigbee, is its core component. Quickly and effectively, wireless sensors installed in cold storage or refrigerated trucks may collect and transmit real-time data. Remote monitoring centers have the most recent status information on perishable items. The device will produce notifications if the temperature or humidity of the commodities is out of the ordinary. Users of this technology can thus easily keep an eye on the products that are moved in cold chains. The system also allocates servers to save past data for enquiries.Tsang et.al.[6] In this study, they propose an Internet of Things (IoT)-based risk monitoring system (IoTRMS) to control concerns about workplace safety and product quality in cold chains. The suggested IoTRMS makes use of the effective data exchange offered by IoT to investigate the best membership functions and fuzzy rule knowledge, enabling in-the-moment risk assessment for personal occupational safety along the entire cold chain. Therefore, with the use of IoTRMS for the various cold chain parties, risk management in product quality and workplace safety may be carried out effectively and efficiently. [7] In order to ensure that environmentally sensitive products (ESPs) continue to function properly across the whole cold chain operational environment, this paper suggests an Internet of Things-based cargo monitoring system (IoT-CMS) to track any environmental changes. Real-time assurance of product quality is made possible by an IoT-CMS. IoT can be used to monitor the cargo in terms of environmental conditions, with the sensor data being uploaded to a cloud database. Through the Internet, clients can simply access the information. The suggested approach helps cold chain service providers, but it has two significant drawbacks: it depends on subject matter experts and is not widely accessible online. A paper by Tsang, et al. [8] has been proposed and offers a conceptual framework for real-time performance monitoring and improved decision making. With its extremely low cost, simple implementation, interoperability with various networks, low energy consumption, and intelligent data analysis feature, the suggested narrowband Internet of Things (NB-IoT) cold chain solution is a real value enhancer and is perfect for a temperature-sensitive end to end supply chain monitoring. The system's simultaneous data acquisition, processing, communication, and analysis allow for real-time cold chain decision-making. [9] In this, they suggest a cold chain logistics system based on the Internet of Things that improves decision support for all players by controlling, monitoring the cold chain's real-time ambient temperature, and estimating the product's shelf life. For a decision support system to estimate the shelf life of the products, they collect real-time data of environmental parameters using the created wireless sensor network and transfer it to the remote server through a gateway. They additionally simulate Radio Frequency Identification (RFID) for additional issues pertaining to the identification issue of perishable goods inside the cold chain.[10] The authors of this work have conducted a feasibility study on an IOT- enabled solution to reduce the risk of medications being lost owing to temperature fluctuations. The setting for this work is a pharmaceutical firm in a poor nation. Temperature excursions are mostly caused by a combination of human mistake, outdated technology, and faulty temperature monitoring devices. In the study they have identified mainly three challenges for this solution to work in developing countries viz., Technology, Human error, and Temperature control. In the conclusion they conclude that the new emerging IOT technologies like 5G and M2M communications will help in the coming future.[11] In this paper authors have proposed an IOT based solution for tracking and monitoring aquatic products in the cold supply chain. The logical system architecture presented.

It consists of an Arduino board, Zigbee, RFID, sensors, and actuators. The authors claim that the proposed system can provide consumers, transporters, and sellers with a set of smart device tools that give accurate traceability information. The one major issue in this system is that too many people bother to use the system either when they buy the aquatic products as consumers or when they transport or sell them as professionals. Experience shows that a lot of consumers think that these applications are worthless, thinking that they are not able to predict the quality of the products and grade them accordingly.[12] In this paper, an Arduino based wireless sensor network is proposed which offers a real time and innovative solution for storage and logistics for pharmaceutical cold chain management. The paper states that using the IOT in cold supply chain benefits in better management and handling of the products. The system improves the monitoring of the product by using the Arduino sensor network and cloud service infrastructure.

In this paper, researchers have discussed the problems and short comes of the agricultural products logistics cold chain supply based on the Internet of Things techniques in China. The researchers have come forward with optimization suggestions and provided theoretical references. This paper is a literature survey-based paper of the problems in the transportation and distribution of cold supply chain products. Rejeb,et.al[14] have illustrated the deployment of blockchain technology with IOT infrastructure can benefit the modern supply chains and also improve the value chain network. This paper also discusses how blockchain technology affects the key features of the IoT such as security, scalability, information flows, quality, traceability, immutability, and auditing, etc.[15]

In this paper, researchers have proposed a generic framework for defining granularity levels based on products' unique characteristics. The researchers determine the different levels of granularity with the help of smart contracts within a blockchain-enabled supply chain architecture. The proposed framework is demonstrated with the food supply chain by developing a private blocked chain enabled architecture.

III. METHODOLOGY

In this project we propose a system architecture who can measure environmental condition like temperature, Humidity, and air quality and we send all data to the cloud. Simultaneously we fetch data from cloud and display it on website and android application

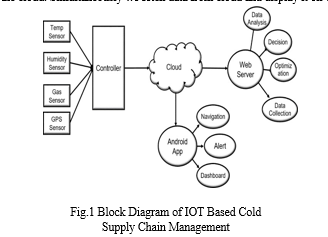

Fig.1 represents the architecture of the proposed system. The entire system can be divided into two parts viz., Hardware and the Software and again in the software there are two parts administers side and driver side. The administrator side software is a website which has the dashboard representing the physical parameters measured from the sensors and the driver’s side has the same dashboard but in the form of an android app.

In hardware, microcontrollers are a central part of the system. ESP8266 microcontroller is used as a microcontroller for the proposed system. Essentially the controller is used for gathering physical data of the reefers using sensors. This gathered information then processed and sent over the cloud. Thingspeak IOT cloud platform is used in this system. This gathered data is accessed in the dashboard of administrator’s server and driver android application. Likewise, the data generated in the transportation is used for supply chain optimization. The hardware consists of ESP8266/NodeMCU microcontroller, DHT11 temperature sensor, MQ-135 gas sensor and Neo 6M GPS.

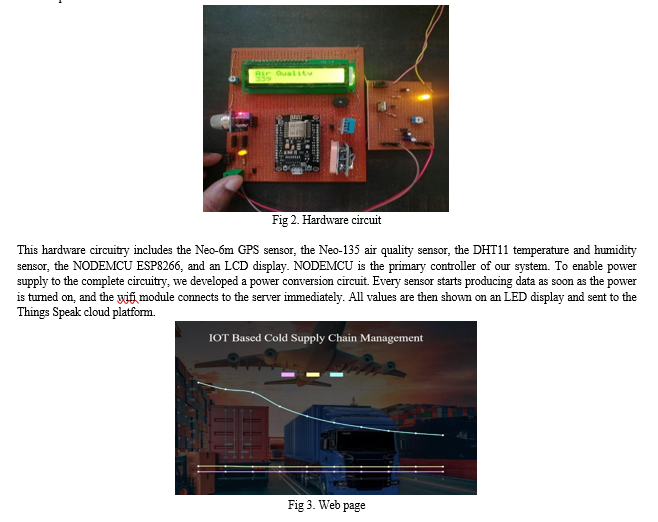

The 12V 2A power adapter is used for powering the entire proposed system. For down conversion of 12V to 5V a well-known linear regulated IC LM7805 is used. By adding battery pack into the system, we can make the system portable. NodeMCU is an open source IoT platform that consists of hardware based on the ESP-12 module for collecting and processing sensor data and firmware that runs on the ESP8266 Wi-Fi SoC from Espressif Systems. The widely used DHT11 temperature and humidity sensor has an exclusive NTC for temperature measurement and an 8-bit microprocessor to output the temperature and humidity measurements as serial data. Like the other gas sensors in the MQ series, the MQ135 sensor has a digital and analogue output pin. When the concentration of these gases in the air exceeds a predetermined threshold, the digital pin rises high. The threshold value may be set using the on-board potentiometer. To assess the concentrations of different gases in the environment, the analogue output pin outputs an analogue signal. It needs to be pre-heated before it can produce reliable findings. We also use a Neo 6 m GPS sensor, which offers real-time coordinates like latitude and longitude, to follow vehicles in the supply chain from the administration side. GPS sensors offer an additional benefit for keeping accurate supply chain track records.

In software, the cloud is a main part of the system. In this system the data is gathered from the controller that gathers the physical data of the using sensors and uploaded on the cloud platform. Thinkspeak cloud platform is used in this proposed system. For tracking we built webpage as well as android application. In webpage HTML and CSS are used for front end and Django framework is used as backend which initializes local server.

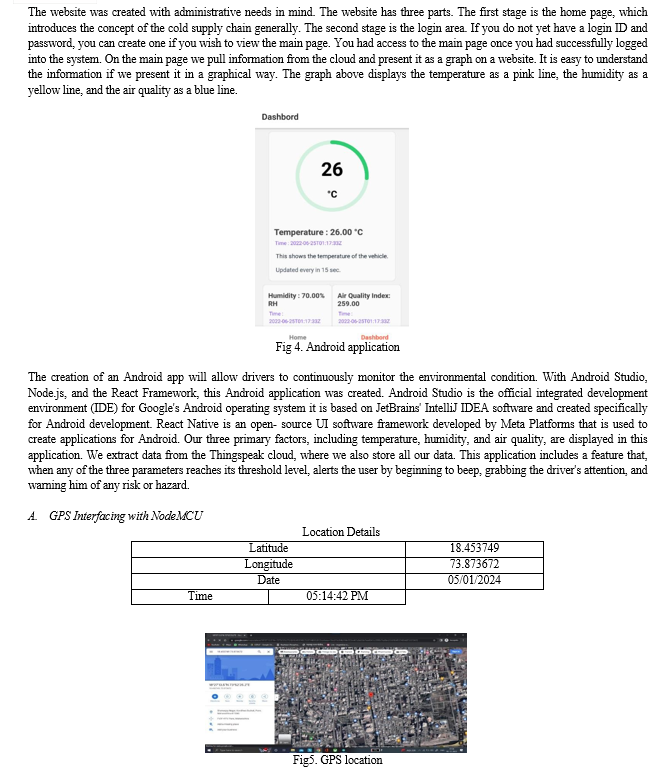

Webpage has three different sections first one Fiigs 7.1 home page who give generalize idea about cold supply chain second section is login party so to access main page we required login id and password after successfully login into system we get access of main page. On main page there is one graph which gives graphical representation of temperature, Humidity and air quality as well as there is one option in dashboard called location after clicking on it we get exact location of vehicle also on dashboard of the website there are many options such as the home, about us, contact us. The Android application is developed using the Android studio and Nodejs, expo,etc. In Application we gather data of temperature, humidity and air quality from cloud and display it in very systematic way.

The proposed system has been developed in Arduino IDE. The programming language used is a combination of Embedded C++. For applications over the internet the Thingspeak IOT platform is used. The hardware consists of ESP8266/NodeMCU microcontroller, DHT11 temperature sensor, MQ-135 gas sensor and Neo 6M GPS. The 12V 2A power adapter is used for powering the entire proposed system. For down conversion of 12V to 5V a well-known linear regulated IC LM7805 is used. By adding battery pack into the system, we can make the system portable.

IV. RESULT

The proposed system shows the failure detection in cold supply chain management. According to the above discussion the hardware is developed with different sensors and the controller

Since the Neo-6M GPS module delivers correct logitute and latitude, it also provides exact location coordination. Therefore, in our system, we use it to monitor the exact location of the vehicle to determine whether it is moving or not. Once we get exat coordinates from sensor. We display the coordinates on a Google map as soon as we receive exact coordinates from the sensor.

Conclusion

An IoT-enabled system that can monitor environmental factors including temperature, humidity, and air quality was introduced in this study. In the complex and temperature-sensitive cold supply chain environment, it aids in decision- making. This system is economically priced and offers a variety of advantages at the application level. On a cloud server, the system\'s collaborative, intelligent monitoring is housed. The results demonstrate the enormous potential of IoT- supported cold chain systems for controlling, monitoring, receiving real-time data and detecting anomalous events involving temperature-sensitive commodities. On a website and an android application, the output of the system which includes temperature, humidity, and air quality is shown. The findings demonstrate the significant potential of IoT-supported cold chain systems for managing, monitoring, receiving real-time data, and identifying abnormal events involving temperature-sensitive goods.

References

[1] Rahman, Labonnah Farzana, Lubna Alam, Mohammad Marufuzzaman, and Ussif Rashid Sumaila. \"Traceability of Sustainability and Safety in Fishery Supply Chain Management Systems Using Radio Frequency Identification Technology.\" Foods 10, no. 10 (2021): 2265. [2] Çeken, Celal, and Dini Abdurahman. \"Simulation modeling of an iot based cold chain logistics management system.\" Sakarya University Journal of Computer and Information Sciences 2, no. 2 (2019): 89-100 [3] Tsang, Y. P., K. L. Choy, Chun-Ho Wu, [4] G. T.S.Ho, H. Y. Lam, and P. S. Koo. \"An IoT-based cargo monitoring system for enhancing operational effectiveness under a cold chain environment.\" International Journal of Engineering Business Management 9 (2017): 1847979017749063. [5] Hasanat, Raisa Tahseen, MD Arifur Rahman, Nafees Mansoor, Nabeel Mohammed, Mohammad Shahriar Rahman, and Mirza Rasheduzzaman. \"An IoT based real-time data-centric monitoring system for vaccine cold chain.\" In 2020 IEEE East-West Design & Test Symposium (EWDTS), pp. 1-5. IEEE, 2020. [6] Luo, Heng, Minjie Zhu, Sengang Ye, Hanping Hou, Yong Chen, and Larissa Bulysheva. \"An intelligent tracking system based on internet ofthings for the cold chain.\" Internet Research (2016). [7] Luo, Heng, Minjie Zhu, Sengang Ye, Hanping Hou, Yong Chen, and Larissa Bulysheva. \"An intelligent tracking system based on internet ofthings for the cold chain.\" Internet Research (2016). [8] Tsang, Yung Po, King Lun Choy, Chun- Ho Wu, George TS Ho, Cathy HY Lam, and P. S. Koo. \"An Internet of Things (IoT)-based risk monitoring system for managing cold supply chain risks.\" Industrial Management & Data Systems (2018). [9] Tsang, Y. P., K. L. Choy, Chun-Ho Wu, [10] G. T.S.Ho, H. Y. Lam, and P. S. Koo. \"An IoT-based cargo monitoring system for enhancing operational effectiveness under a cold chain environment.\" International Journal of Engineering Business Management 9 (2017): 1847979017749063. [11] Wanganoo, Leena, and Vinod Kumar Shukla. \"Real-time data monitoring in cold supply chain through NB-IoT.\" In 2020 11th International Conference on Computing, Communication and Networking Technologies (ICCCNT), pp. 1-6. IEEE, 2020 [12] Çeken, Celal, and Dini Abdurahman. \"Simulation modeling of an iot based cold chain logistics management system.\" Sakarya University Journal of Computer and Information Sciences 2, no. 2 (2019): 89-100. [13] Hernández, Atziri, and Mamoru Yamaura. \"Cold chain management with Internet of Things (IoT) enabled solutions for pharmaceutical industry.\" Malaysia Institute for Supply Chain Innovation (2017): 1-6. [14] Kokkinos, K., A. Exadactylos, D. Vafidis, and M. Hatziioannou. \"Efficient traceability of aquatic products on the cold supply chain management via IoT and artificial neural networks.\" In Proceedings of the 3rd International Congress on Applied Ichthyology & Aquatic Environment, Volos, Greece, pp. 8-11. 2018. [15] Tian, Feng. \"An agri-food supply chain traceability system for China based on RFID & blockchain technology.\" In 2016 13th international conference on service systems and service management (ICSSSM), pp. 1-6. IEEE, 2016 [16] Rejeb, Abderahman, John G. Keogh, and Horst Treiblmaier. \"Leveraging the internet of things and blockchain technology in supply chain management.\" Future Internet 11, no. 7 (2019): 161. [17] Dasaklis, Thomas K., Fran Casino, and Constantinos Patsakis. \"Defining granularity levels for supply chain traceability based on IoT and blockchain.\" In Proceedings of the international conference on omni-layer intelligent systems, pp. 184-190. 2019

Copyright

Copyright © 2024 Prof. Dr. Durgaprasad Kamat, Firoz Shaikh, Mahaveer Navalakha, Jaideep Solanki, Abhishek Ghule. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET60986

Publish Date : 2024-04-25

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online