Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

IOT Based Food Minitoring System

Authors: Chinmoy Nath, Mohit Singh, Uday Goswami, Sahil Bisht, Ms. Monika Kaushik, Ms. Usha Sharma

DOI Link: https://doi.org/10.22214/ijraset.2024.61907

Certificate: View Certificate

Abstract

The Internet of Things (IoT) has emerged as a transformative technology with wide-ranging applications, and one of its promising domains is in the field of food monitoring systems. This abstract introduces an innovative IoT-based Food Monitoring System designed to enhance food quality assurance and reduce waste in the supply chain. The proposed system integrates various IoT components, including sensors, actuators, and communication devices, to create a comprehensive solution for monitoring the entire lifecycle of food products. Key objectives of the system include real-time tracking of food conditions, ensuring compliance with quality standards, and minimizing the environmental impact associated with food waste. The implementation of this IoT-based Food Monitoring System offers several benefits, including improved food quality, reduced waste, increased operational efficiency, and enhanced consumer satisfaction. By leveraging the capabilities of IoT, this system addresses the challenges associated with maintaining food quality and safety while contributing to the overall sustainability of the food industry.

Introduction

I. INTRODUCTION

Food safety and hygiene is a very important issue in order to prevent the food wastage. The Quality of the food needs to be covered and it must be averted from rotting and decaying by the atmospheric factors like temperature, humidity, moisture and dark. Thus, it is useful to deploy quality monitoring devices at food stores. These quality monitoring sensors always keep a watch on the environmental factors that can cause effect or pace up decaying of the food items. Latterly, the environmental factors can be controlled like by refrigeration, vacuum storage etc.

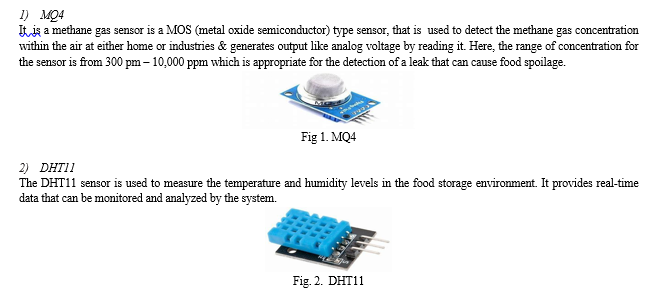

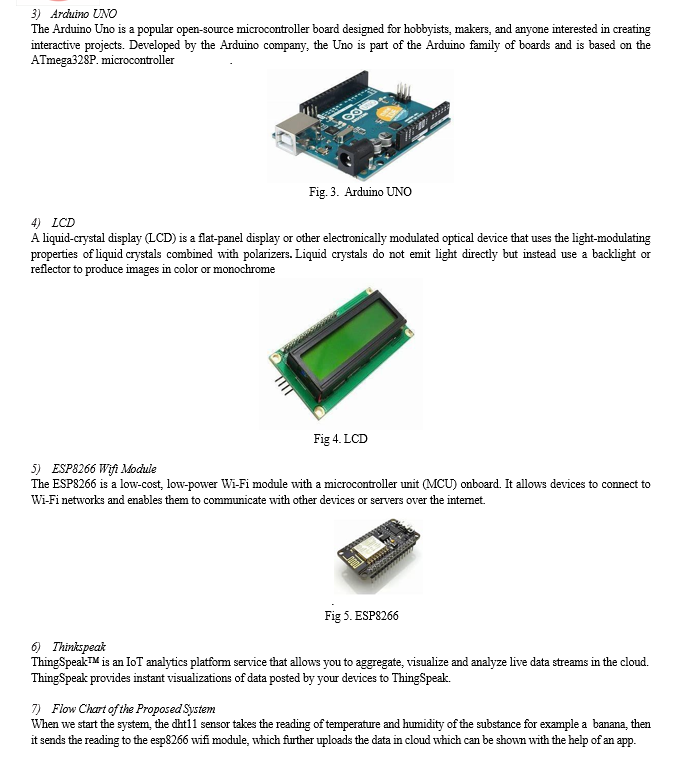

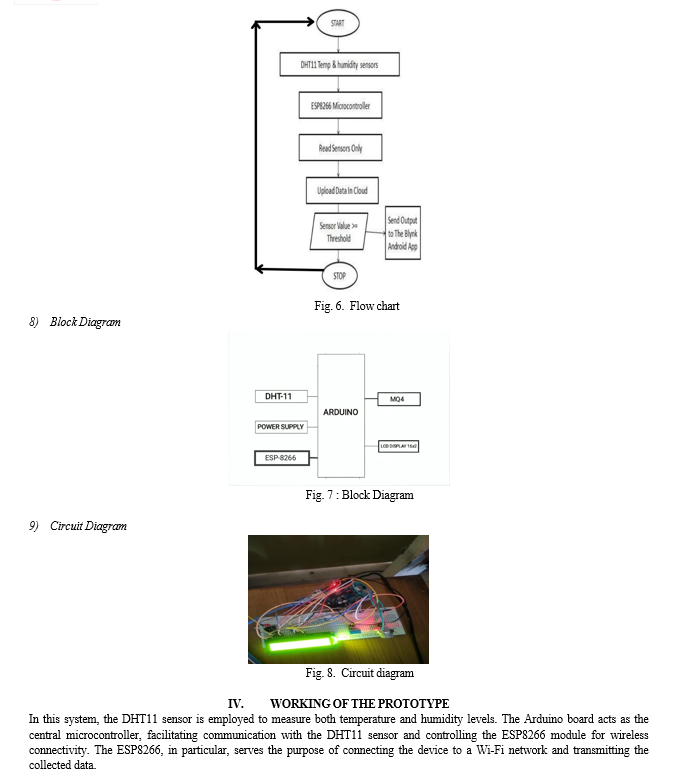

In this project, we are making a food quality monitoring device that will keep watch of various environmental factors like temperature, moisture gas content and exposure to light .The device is assembled on Arduino UNO which is a popular prototyping board. The Arduino board is combined with various sensors like DHT-11 to monitor temperature and moisture, MQ4 to descry gas content to measure exposure to light. This is an IoT device that sends the measured sensor data information to an IoT platform.

The ESP8266 Wi-Fi Modem is connived with the Arduino to connect it to the internet via Wi-Fi router. The sensor data is also displayed on a character LCD connected with the Arduino UNO. The IoT platform that is used for logging and monitoring, measuring of sensor data is Freeboard.io. With the help of Internet of Things, the environmental factors that are affecting the food storage can be monitored from anywhere in the world via internet, anytime and from any device that can access internet. Many such devices can be installed at various location for quality monitoring and quality control. The Arduino running over the device implements the various functionalities in the project like reading the sensor data, converting them into strings that we can use, displaying them on the LCD screen and passing them to the IoT platform.

II. LITERATURE SURVEY

Despite the growing interest in iot based food monitoring system, a comprehensive literature survey encompassing the methodologies, techniques, challenges, and potential applications is lacking. This paper seeks to address this gap by offering a comprehensive overview of existing research in this domain. Through a systematic review of relevant literature, we aim to illuminate the advancements made, highlight the encountered limitations and challenges, and identify potential avenues for future exploration. In this literature survey, we will analyze and synthesize studies that investigate the development and implementation of IOT based systems.

This survey comprehensively covers various aspects, including signal acquisition and processing techniques, cursor control algorithms, user interface designs, usability evaluations, and potential applications across different domains. By consolidating existing knowledge, this survey aims to provide a valuable resource for researchers, practitioners, and developers interested in utilizing IOT based systems to enhance human-computer interaction.

Atkare Prajwal et al. [1] develop a prototype to collect intake sensor data. The required output of the system is displayed on the screen .The system checks the quality of food by using the PH sensor, temperature sensor, and the odor sensor. The objective of this system is to make electronic device that detect food spoilage. The sensor used in this method is an MQ-135 gas sensor. MQ-135 is manufactured by lead oxide (SnO2).Odor is a key point in food quality management, based on the nature of the odor like pleasant and unpleasantness it tells the quality of the food. A thermostat is an instrument runs at full capacity till the particular temperature is reached, it shuts off thermostat is to show the accurate temperature of the food item, the temperature is an important factor in determination of freshness of the food. The temperature sensor is used LM35. The system can be upgraded by using an upcoming and updated sensor such as nutrients sensor. Amrita Srivastava et al. [2] proposed a system to analyze the ambient conditions under which the food item is being stored and transported. The proposed solution senses the temperature, moisture, light parameters of surrounding environment as these parameters affect nutritional values of food items1. The values of these parameters are then compared to standard values serving as threshold values for respective parameters. To ensure food safety it should be monitored at every stage of supply chain. It serves the purpose of preventive consumer health protection by maintaining the required standard ambient conditions needed to preserve the quality of food. However, this model can benefit from further enhancements in certain areas like Integration of the sensors with remote web server. The proposed solution also fail's to incorporate methane or alcohol production in food item to monitor the freshness of food item. Bhargavi Vijendra Sangam et al. [3] proposed uses different array of sensors for monitoring the quality of the food. The temperature and humidity of the food storage is monitored using DHT11 sensors. The gases emitted by different food items are measure during MQ3 and MQ5 sensors. These sensors will detect the gas and if the gas emitted by the food item is above the threshold value will be indicated in LCD and the same will be uploaded in Node MCU and is messaged through Telegram. The array of gas sensors help reducing the chances of inaccurate readings. D. Venkata Lakshmi et al. [4] proposed use of the food nutrition value which is affected due to parameters like temperature, moisture and light the information and values are recorded in sensors. The involvement of the transportation factor the information the shipment location will provide through application. The information and values that are recorded can be retrieved using mobile application.

III. PROPOSED SYSTEM

The proposed system is designed in keeping view of the drawbacks of the existing systems and attempts to make them more productive and easier to use. To know the food nutritional value which is affected due to parameters like temperature, moisture and light, the information and values are recorded in sensors. The involvement of the transportation factor the information the shipment location will provide through application. The information and values that are recorded can be retrieved using mobile application. The web server is used to store the values of data in real time from sensors Hardware and Software Components

The developed system includes the following components:

The first step involves establishing the necessary hardware connections. The DHT11 sensor is connected to the Arduino, while the ESP8266 is interfaced with the Arduino using serial communication through the TX and RX pins. Programming the Arduino is the next crucial step. Using the Arduino IDE, a program is written to read temperature and humidity data from the DHT11 sensor. Simultaneously, the program communicates with the ESP8266, instructing it to transmit this collected data over the Wi-Fi network.

The ESP8266 must be configured to connect to the designated Wi-Fi network. Additionally, its programming should include instructions for receiving data from the Arduino and sending it to a chosen server or cloud platform. Various cloud platforms such as Blynk, ThingSpeak, Firebase, or custom servers can be utilized for data storage and analysis.

Data transmission occurs as the Arduino periodically reads data from the DHT11 sensor. This information is then relayed to the ESP8266, which, in turn, transmits the data to the selected server or cloud platform through HTTP or MQTT protocols. To enhance the functionality of the system, monitoring and alerting mechanisms can be set up on the server or cloud platform. Thresholds for temperature or humidity can be established, triggering alerts if these thresholds are surpassed. This feature ensures that users are promptly informed of any undesirable conditions in the monitored environment.

For a more user-friendly experience, a graphical user interface (GUI) can be developed. This GUI could be a web page, a mobile application, or another platform allowing users to monitor the food conditions conveniently.

In the case of portable or battery-powered systems, implementing power-saving mechanisms is advisable to maximize the operational lifespan. This might involve optimizing the frequency of data transmission or incorporating sleep modes to conserve power when the system is not actively collecting or transmitting data.

Code

const int MQ4Pin = A0; // Analog pin connected to the MQ-4 sensor

const int ledPin = 2; // Digital pin connected to an LED for visual indication #include <DHT.h>

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

#define DHT11_PIN 2

DHT dht11(DHT11_PIN, DHT11); LiquidCrystal_I2C lcd(0x27, 16, 2);

void setup() {

Serial.begin(9600);

lcd.begin();

lcd.backlight();

pinMode(ledPin, OUTPUT);

dht11.begin(); // initialize the sensor

}

void loop() {

lcd.clear();

// Read the analog value from the MQ-4 sensor int sensorValue = analogRead(MQ4Pin); int ppm= pow(10,0.009*(sensorValue-38));

12float voltage = sensorValue * (5.0 / 1023.0);

float humi = dht11.readHumidity();

// read temperature as Celsius

float tempC = dht11.readTemperature();

// read temperature as Fahrenheit

float tempF = dht11.readTemperature(true);

// Print the raw sensor value and voltage

Serial.print("AQI is: ");

Serial.print(ppm);

Serial.print(", Voltage: ");

Serial.println(voltage);

if (sensorValue > 500 ) {

digitalWrite(ledPin, HIGH); // Turn on the LED for visual indication

} else {

digitalWrite(ledPin, LOW); // Turn off the LED

}

// check if any reads failed

if (isnan(humi) || isnan(tempC) || isnan(tempF)) {

Serial.println("Failed to read from DHT11 sensor!");

} else {

Serial.print("DHT11# Humidity: ");

Serial.print(humi);

Serial.print("%");

Serial.print(" | ");

Serial.print("Temperature: ");

Serial.print(tempC);

Serial.print("°C ~ ");

Serial.print(tempF);

Serial.println("°F");

}

delay(1000); //

lcd.print(ppm);

delay(5000);

lcd.clear();

lcd.println("humidity ");

lcd.print(humi);

delay(5000);

lcd.clear();

lcd.print("temperature");

delay(1000);

lcd.clear();

lcd.print(tempC);

lcd.clear();

}

V. COMPARISON TABLE

|

Paper |

Purpose |

Software & Hardware |

Purpose |

Cost |

|

[1] |

Itrack proposed a system to analyze the ambient conditions under which the food item is being stored and transported . The proposed solution senses the temperature, moisture, light parameters of surrounding environment |

DHT-11 Arduino IDE |

Working of DHT-11 is taken from this paper , with the help of DHT-11 temperature and humidity can be measured . |

Low costing around 1.5k-2k |

|

[2] |

IJISTR22 proposed uses different array of sensors for monitoring the quality of the food. The temperature and humidity of the food storage is monitored using DHT11 sensors .The gases emitted by different food items are measured using MQ4 |

MQ4 and DHT-11 Arduino IDE |

Working of MQ4 is taken from this paper, with the help of MQ4 , gases emitted by different food items can be measured. |

Costing around 2k-3k |

|

[3] |

To know the food nutrition value which is affected due to parameters like temperature, moisture and light the information and values are recorded in sensors. |

LDR , DHT-11 Arduino IDE |

Working of LDR is taken from this paper, LDR is a light sensor which measures the amount of light around different food items. |

Costing around 3K-4K |

|

[4] |

The gases emitted by different food items are measured using MQ3 and MQ5 sensors. These sensors will detect the gas and if the gas emitted by the food item is above the threshold value will be indicated in LCD |

MQ3 and MQ5 Arduino IDE |

Instead of MQ3 and MQ5, MQ4 is used to detect gases emitted by the food item, if the gases emitted by the food items are above threshold value , then it will be indicated on the LCD. |

Costing around 2k |

Conclusion

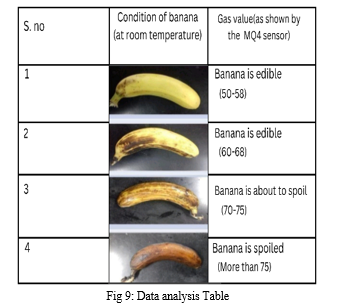

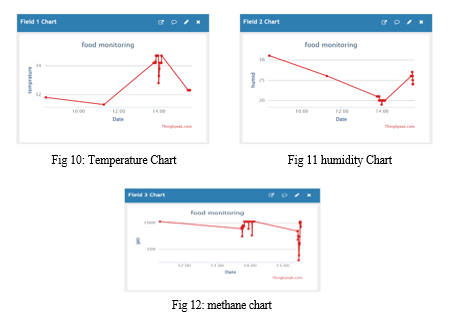

The IoT-based Food Monitoring System is a transformative solution designed to enhance food quality assurance and reduce waste throughout the supply chain. Key components include sensor integration, data analytics, communication infrastructure, actuation mechanisms, user interface, and blockchain technology. This comprehensive system enables real-time monitoring, data-driven decision-making, and dynamic control to maintain optimal conditions for food products. Successful coding efforts have resulted in a robust and adaptive system, addressing challenges and ensuring the security and integrity of the entire process. The integrated internet of things based online monitoring, measuring approach using smart logistics can address, solve the critical needs of reducing food waste in the world, increasing transportation significantly, and tracking food contamination causing food spoilage which can cause many diseases. The experimentation was successful and from this experimentation we can understand how to measure the temperature and moisture, and the ethane gas data given off during the spoilage of food, especially in “BANANAS”. Ethylene is a natural gas that fruit produces as fruit that helps in ripening. Too high a temperature destroys the enzymes that are required, and too low a temperature can break down the cell walls of the fruit so the contents mix and the fruit oxidizes which is bad, it makes the fruit brown and softens abnormally. The optimum temperature and humidity conditions for ripening are 62 to 68 degrees Fahrenheit and 90 to 95 percent relative moisture. The food is monitored at different conditions and evaluated on a daily basis. Many such devices can be installed at various location for better monitoring, measuring and quality control. So in this IoT project, a Food Monitoring device is implemented to monitor, measure the real-time values of the temperature, moisture, and methane gas, which are prime measures in food quality, will be measured and displayed with minimal effort. Therefore, users can adapt to daily life with less difficulty and independently use computers without relying on assistance from others. Person with disabilities or being paralyzed can easily communicate with the people around them. They will not feel much helplessness, bored and alone around other people.

References

[1] Atkare Prajwal, Patil Vaishali, Zade payal, Dhapudkar Sumit, “food quality detection and monitoring system”IEEE 2020. [2] Amrita Srivastava, Ankita Gulati “itrack: iot framework for smart food monitoring system” International Journal of Advanced Research in Science, Communication and Technology 2022. [3] Bhargavi Vijendra Sangam, Jayashree GR, Dr. Girish V. Attimard “food monitoring system using iot” International Journal of Innovative Science and Research Technology 2022. [4] D.Venkata Lakshmi, N.Harshitha , S.V.R.Chaitanya , K.Madhu Babu “food monitoring system using iot in warehouse” International Research Journal of Engineering and Technology (IRJET) 2022.

Copyright

Copyright © 2024 Chinmoy Nath, Mohit Singh, Uday Goswami, Sahil Bisht, Ms. Monika Kaushik, Ms. Usha Sharma. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET61907

Publish Date : 2024-05-10

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online