Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

IOT Based Mining, Tracking and Worker Safety Helmet

Authors: Anjali Rameshwar Katkar, Renuka Prabhakar Shete, Dipali Macchindra Tajane, Prof. Umesh Balkishan Phiske, Dr. B. E. Shinde

DOI Link: https://doi.org/10.22214/ijraset.2024.64538

Certificate: View Certificate

Abstract

This project addresses a cost-effective, flexible solution of underground mine workers safety. A module of MEMS and temperature-based sensors are used for underground environment monitoring and automating progression of measurement data through IOT communication technique is proposed with high accuracy, smooth control and reliability. Arduino microcontroller is used for collecting data and making decision, based on which the mine worker is informed through server. Sensor data transforms into digital signal and effectively communicate wirelessly with the ground control centre computer.

Introduction

I. INTRODUCTION

Safety of workers should always be of major consideration in any form of mining. Underground operations prove to be a risky venture as far as the safety and health of workers are concerned. These risks are due to different techniques used for extracting different minerals. The deeper the mine, the greater is the risk. These safety issues are of grave concern especially in case of coal industries. Thus, safety of workers should always be of major consideration in any form of mining, whether it is coal or any other minerals. Underground coal mining involves a higher risk than open pit mining due to the problems of ventilation and potential for collapse. However, the utilization of heavy machinery and the methods performed during excavations result into safety risks in all types of mining. Modern mines often implement several safety procedures, education and training of workers, health and safety standards, which lead to substantial changes and improvements in opencast and underground mining. Coal has always been the primary resource of energy in India, which has significantly contributed to the rapid industrial development of the country. II

II. LITERATURURE REVIEW

In 2023, AKL Sandaruwan and B Hettige [1] presented a worker safety helmet that works on IoT. The importance of safety in the mining industry cannot be overstated, especially in underground operations where the well-being of mine workers is of paramount importance. All mining operations must adhere to fundamental safety regulations and measures to avoid accidents, and collapses are a major risk. While coal mining collapses are not always particularly dangerous, immediate rescues are essential in saving lives. Communication is a key factor in mining, particularly in underground mines. Worn-out wired communication is costly and inefficient, while wireless communication is cost- effective and effective. Wireless communication allows the industry to transmit essential information immediately, thus improving safety measures—furthermore, the integration of sensors (gas and temperature sensors) aids in proactive risk prevention. Miners wear helmets with buzzers that alert them during hazardous conditions, and priority is given to communication so that all mining personnel can confirm their safety before proceeding, thus creating a safe environment for all involved.

To address these issues, a pioneering project has emerged: the creation of smart helmets, which act as intelligent guardians of miners. These helmets are equipped with various sensors to detect potentially hazardous events and keep an eye on the environment around them. By collecting data from various sensors, the helmets can transmit it to the central console, where it can be exchanged in real-time. This allows for the efficient monitoring of miners and the prompt response to emergencies. By utilizing cutting-edge technology, the project improves safety protocols in the mining industry, thus saving lives and preparing the ground for a safer future.

In 2023, Pankaj Kunekar, Prerana Waghmare, Preyas Videkar, Sangharatna Bombarde, Y. D. Satyamedha, V. Khandagale, Yashovardhan U.Wagh [2] presented a solution and a plan for the problem of Miners Security.

The issue of safety in the coal mining sector is a major concern due to the frequent occurrence of accidents. This study highlights the need to implement a wireless network connection to transmit real-time data to alert officials in the event of an accident, thus allowing for rapid responses. Accidents resulting from falling rubble onto workers are a major risk in mining. To address this issue, we have launched an IoT- based helmet project to assist the industry. However, the mining sector is lagging in terms of technological progress. To bridge the gap and introduce cutting-edge IoT solutions, we have developed the concept of ?SMART HELMETS‘. These helmets provide a lifeline to workers working in the depths of the mines, acting as an essential safety measure. By incorporating cutting-edge technology in mining practices, we aim to improve worker safety and transform the mining industry. This prototype is composed of an ESP8266, an accelerometer sensor, a gas sensor, and a buzzer which can be used to detect the various dangers present in the mines.

In 2023, Harshal Ramesh Aher, Rupal Vilas Turkane, Gayatri Dattatray Varpe, Namrata Sunil Waghmare, and V.

R. Aware [3] proposed the work "Mine Safety System Using IoT." The implementation of a new, innovative approach to mine safety is essential in order to increase mining profitability, reduce costs, and prioritize worker safety. This system is composed of two components: one to monitor the wellbeing of miners, and the other to monitor various environmental factors. Air pollution in mining areas is largely caused by emissions of Sulphur (SO2) oxide, nitrogen dioxide, and CO2. Smoke sensors are used to monitor the levels of these hazardous gases in the mine, with semiconductor gas sensors measuring their concentration levels. If any of the sensor readings exceed the safety threshold, a buzzer is triggered by the microcontroller, which in turn transmits the information to the Monitoring Section Module. The data collected in the Monitoring Section is then uploaded to a webpage using Internet of Things (IoT) technology. This system provides immediate responses to any potential hazards, significantly improving the safety and wellbeing of miners.

In 2022, Suwama Kama, Tanzila Noushin, and Shawana Tabassum [4] conducted a study on the IoT-based Smart Helmet, which involved automated and multi-parametric monitoring of underground miners' health hazards. Making sure workers are safe in underground mines and on construction sites have always been a top priority, but with the rise of IoT technology, it's become even more important. This study focused on creating and deploying an IoT smart helmet that would revolutionize real-time safety monitoring for miners. This smart helmet was designed with specialized body sensors that could capture all sorts of health data. The sensors worked together to wirelessly send important info to the central control room where it was quickly analyzed. The testing process showed how effective the helmet was, but it also showed how it could revolutionize safety in high-risk environments. The most important part of the solution was its immediate response mechanism. This allowed for quick reactions to potential risks, reducing them in real time. Not only did this solve a long-standing safety issue, but it showed how technology could make a huge difference in workplace safety.

This innovative smart helmet is a game-changer in the field of occupational safety, particularly in sectors such as mining and construction where time-critical responses are essential. Its capacity to address safety issues in real time, at the moment they arise, highlights the immense value of real- time tracking technologies. This innovation, which seamlessly integrates IoT capabilities, is a perfect example of what the future holds for workplace safety practices. Implementing such advanced solutions not only protects the health and safety of workers but also establishes a new benchmark for safety in hazardous work environments.

Consequently, this development is likely to make a lasting impact in sectors where safety is a priority, creating environments where workers can perform their duties with greater assurance and security.

III. WORKING MECHANISM

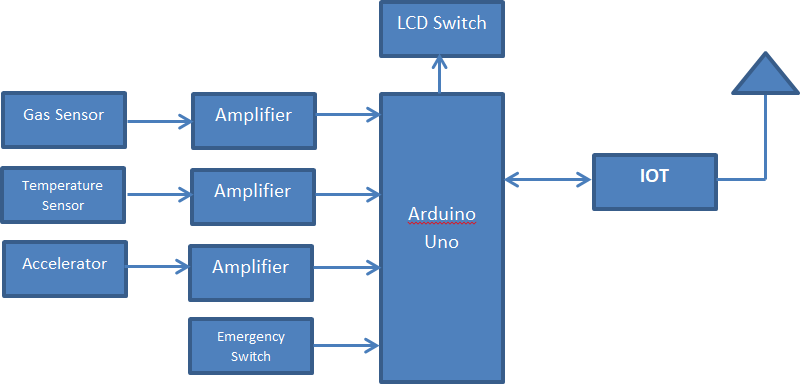

Fig 1- user interface through dataset

In this project, we have gas sensor and temperature sensor. When the temperature is high, the sensor sends immediate notification to the main communication area. This work has to be by the Internet Of Things (IOT). Similarly the temperature has to notify the changes in the temperature and it will send alert messages to the user.

IV. PROPOSED METHODOLOGY

The proposed study introduces a cutting-edge solution for protecting underground workers through an Internet of Things (IoT) smart helmet. The helmet is equipped with various sensors to monitor important parameters such as gas levels, temperature, and humidity which are essential for miners‘ safety. The transmitter segment of the smart helmet is controlled by the microcontroller and collects information from components like helmet remover detector, collision detector, and gas sensor. In case of a dangerous situation, the helmet immediately triggers alerts using an application that is deployed across different parts of the mine. The alerts are placed strategically to cover different areas of the mine. When a dangerous situation occurs, the sensors built into the helmet (Helmet remover detector, Gas detector, and Collision detector) immediately detect and send out the relevant parameters. This is an essential safety tool as it provides real time monitoring and timely alerts. This significantly reduces risks and improves the safety protocols for underground workers working underground.

The project is structured in three distinct stages: from hardware design to software design and from there to testing, tuning and debugging. Hardware design is a critical step in the process, as it is used to evaluate the suitability of a transducer and its compatibility with the circuit scheme. During this stage, the selection of transducer is a rigorous process, with attention paid to experimental attributes such as accuracy, precision and measurement factors, as well as its performance under various conditions. The transducer is carefully evaluated to ensure that it is compatible with the project's requirements.

V. ADVANTAGES

- Improved safety: Real-time monitoring and alerts can help reduce the risk of accidents and health issues.

- Enhanced efficiency: Data-driven decision-making and better coordination can help reduce downtime and increase productivity.

- Data-driven insights: Detailed data collection and analysis can help improve safety protocols.

- Compliance assurance: The system can help mining companies adhere to safety regulations and standards.

- Increased worker confidence: Miners can feel more secure knowing that their safety is being monitored.

VI. SCOPE OF PROJECT

- Tracking: The project uses radio frequency (RF) technology to track the location of workers in a mine in real time.

- Emergency response: The helmet has a panic button that sends an alert to an IoT web interface when pressed. This allows supervisors and authorities to respond quickly to emergencies.

- Data Analaytics: The system collects data on worker movement and safety incidents. This can be used to improve safety practices and emergency response.

- Gas Detection: The helmet can detect dangerous gases and alert the worker.

- Communication: The helmet can communicate with other miners using the Internet of Things.

- Real- time monitoring: The helmet can provide a real-time perspective of the underground mine system.

- LCD Display: The helmet can display readings from sensors using a liquid crystal display (LCD).

VII. ACKNOWLEGEMENT

We extend our sincere gratitude to the Department Head, Prof. Prachi Deshpande, project guide, Prof.Umesh Balkishan Phiske for their constant support and valuable guidance during the course of our project. We are also grateful to Dr. Bhausaheb Shinde, the project coordinator, and Principal Dr. Omprakash Rajankar for their unwavering encouragement and assistance.

Furthermore, we would like to express our appreciation to the entire staff and our fellow classmates who played a significant role in our achievements. Their availability and continuous encouragement have been invaluable to our success.

Conclusion

A real time monitoring system is developed to provide clearer and more point to point perspective of the underground mine system and also provide reliable communication using IOT between mine workers. In this way it will be helpful to all miners present inside the mine to save their life before any casualty occurs. The implementation of IOT technology in a safety helmets is a major development in the field of workplace safety. By incorporating IOT technology into the helmets, ral-time environmental monitoring and immediate response to potential hazards are achived.

References

[1] Nisha Dube1, Prof. K.S.Ingle 2 PG Student, Dept. of ECE ?Intelligent Mining: A Monitoring and Security System for Coal Mine Workers?, International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering (An ISO 3297: 2007 Certified Organization) Vol. 5, Issue 1, January 2016. [2] Huping Xu, Feng Li, Yancheng Ma, A ZigBee- based miner Localization System‘, IEEE, 2012, [3] C. Qiang, S. Ji-ping, Z. Zhe and Z. Fan, ?ZigBee Based Intelligent Helmet for Coal Miners,? IEEE World Congress on Computer Science and Information Engineering (WRI 2009), 31 Mar. -2 April 2009, vol. 3, pp. 433–435, 2009. It was unable to detect the location of the miner. [4] Pranjal Hazarika, ?Implementation of safety helmet for coal mine workers?, 1st IEEE International Conference on Power Electronics Intelligent Control and Energy Systems, pp. 1-3, 2016. It did not have panic button and pressure sensor. [5] C. j. Behr, A. Kumar and G. P. Hancke, A Smart Helmet for Air Quality and Hazardous Event Detection for the Mining Industry, IEEE, PP. 2028- 2031, 2016. It only had temperature and air quality sensor.

Copyright

Copyright © 2024 Anjali Rameshwar Katkar, Renuka Prabhakar Katkar, Dipali Macchindra Tajane, Prof. Umesh Balkishan Phiske, Dr. B. E. Shinde. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64538

Publish Date : 2024-10-10

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online