Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

IoT Based Smart E-Waste Management System

Authors: Pallavi Bansod, Sonali Shende, Rajat Gajbhiye, Sujata Sardare, Aslam Ghodke, Prof. S. S. Sawwashere

DOI Link: https://doi.org/10.22214/ijraset.2022.45349

Certificate: View Certificate

Abstract

In today\'s busy world time is a vital issue which can\'t be managed by noticing each and every phenomenon with our tight schedule. So now a day\'s Automatic systems are being preferred over manual system to make life simpler and easier in all aspects. To make it a grand success Internet of Things is the latest internet technology developed. The number of users of internet has grown so rapidly that it has become a necessary part of our daily life. Our matter of concern in this project is development of Internet of Things based E-Waste Monitoring System[5]. As the population of world is increasing day by day, the environment should be clean and hygienic for our better life leads. In most of the cities the overflowed E-Waste bins are creating an obnoxious smell and making an unhygienic environment. And this is leading to the rapid growth of bacteria and viruses which are causing different types of diseases. To overcome these situations efficient E-Waste collection systems are getting developed based on IOT. Various designs have already been proposed and have advantages as well as disadvantages. This paper is a review of E-Waste Monitoring System based on IOT[5].

Introduction

I. INTRODUCTION

E-Waste consists of the unwanted materials left over from city, Urban areas, Educational Institutions, Business organizations, home etc. This project will help to understand the developments of research on IOT to eradicate or minimize the E-Waste disposal problem. IOT is a recent communication Technology, in which the objects of everyday life will be equipped with AVR family microcontrollers, GSM for digital communication and suitable protocol stacks, that will make them able to communicate with one another and with the users[5].

We are residing in an age in which responsibilities and structures are fusing collectively with the electricity of IOT to have a extra green gadget of running and to execute jobs quickly! With all of the electricity at our finger pointers that is what we have arise with. The Internet of Things (IOT) will be capable of include transparently and seamlessly big range of various structures, even as supplying information for tens of thousands and thousands of humans to apply and capitalize. Building a trendy structure for the IOT is as a result a totally complicated task, specifically due to the extraordinarily big kind of devices, hyperlink layer technologies, and offerings that can be worried in this type of gadget[7]. One of the principle worries with our surroundings has been strong waste control which influences the fitness and surroundings of our society. The detection, tracking and control of wastes is one of the number one issues of the prevailing era. The conventional manner of manually tracking the wastes in waste packing containers is a bulky procedure and makes use of greater human effort, time and price that may without problems be averted with our gift technologies[10]. This is our solution, a technique wherein waste control is automated. This is our IOT E-Waste Monitoring system, an innovative way that will help to keep the cities clean and healthy.

A. Amount of Electronic Waste Worldwide

- Rapid modifications in technology, modifications in media (tapes, software program, MP3), falling prices, and deliberate obsolescence have ended in a fast-developing surplus of digital waste across the globe.

- Technical answers are available, however in maximum cases, a prison framework, a collection, logistics, and different offerings want to be carried out earlier than a technical answer may be apply. Display devices (CRT, LCD, LED monitors), processors (CPU, GPU, or APU chips), memory (DRAM or SRAM), and audio additives have one-of-a-kind beneficial lives.

- Processors are maximum often out-dated (through software program not being optimized) and are much more likely to end up E-waste" at the same time as show devices are most usually changed at the same time as operating with out restore attempts, because of modifications in rich state appetites for brand spanking new show Technology. This hassle may want to probably be solved with modular clever telephones or phonebook’s. These kinds of telephones are extra long lasting and feature the generation to alternate positive components of the telecall smartphone making them extra environmentally friendly.

- Being capable of certainly update the a part of the telecall smartphone this is damaged will lessen e-waste. An envisioned 50 million lots of E-waste are produced every year. The USA discards 30 million computers each year and 100 million phones are disposed off in Europe each year.

B. E-Waste In India Growth of E-waste and Government Role

- India is one in all the most important manufacturers of e-waste withinside the world. The Global E-waste Monitor 2017, posted with the aid of using the United Nations University, states that India generates approximately 2 million tonnes of E-waste yearly and ranks 5th amongst E-waste generating international locations, after the US, China, Japan and Germany. However, there is no government data on e-waste generated in the country.

- The law says that producers of electronic items should provide postal address, e-mail and toll-free numbers of collection centres—where consumers can drop their equipment—through websites and producer user booklet to facilitate the return of E-waste items.

- The producers have to meet targets, which should be 20 per cent of the waste generated by their sales. This will increase by 10 per cent annually for the next five years. Both the dismantlers and recyclers must file reports to SPCB to certify that they have used scientific methods in their operations.

- E-waste generated by various metros annually

a. Mumbai: 1,20,000 metric tonnes

b. Delhi (NCR): 98,000

c. Bangalore: 92,000

d. Chennai : 67,000

e. Kolkata: 55,000

f. Ahmedabad: 36,000.

C. Environmental Impact

- The approaches of dismantling and removing digital waste in growing nations caused some of environmental impacts..

- Liquid and atmospheric releases end up in bodies of water, groundwater, soil, and air and therefore in land and sea animals – both domesticated and wild, in Environmental impact old keyboards and one mouse.

- When E-waste is warmed up, poisonous chemical compounds are launched into the air negative the atmosphere.

- The harm to the environment is one in all the most important environmental affects from E-waste.

- When digital waste is thrown away in landfills their poisonous substances seep into groundwater, affecting each land and sea animals.

II. PROBLEM STATEMENT

Nowadays, there are tons of Electronics equipment which have been built in the rapid urbanization area. This is due to high demands which have been drastically risen as a result of migration from villages to cities to find work. In order to deal with the developing populace withinside the city area, the authorities has additionally built extra condominium complexes. There are numerous troubles confronted through the citizens of the flats. One of them is disposal of stable waste. Unlike Electronic manufacturing industries use a common dustbin, which tends to fill up very quickly. This overflowing of E-Waste, which is an environmental issue which might cause diseases like cancers. Moreover it is a waste of fuel to travel around a complex or an area to find that some of the E-Waste are filled and some are not. Also, on rare days, problems might arise that there is so much E-Waste that the truck doesn’t have enough capacity. The idea struck us when we observed that the E-Waste truck use to go around the industrial area to collect solid waste twice a day. Although this system was thorough it was very inefficient. For example let's say street A is a busy street and we see that the E-Waste fills up really fast whereas maybe street B even after two days the bin isn't even half full. What our system does is it gives a real time indicator of the E-Waste level in a trashcan at any given time. Using that facts we are able to then optimize waste series routes and in the end lessen gas consumption. It permits trash creditors to plot their daily/weekly select out up schedule. An Ultrasonic Sensor is used for detecting whether the trash can is filled with E-Waste or not. Here Ultrasonic Sensor is installed at the top of Trash Can and will measure the distance of E-Waste from the pinnacle of Trash can and we are able to set a threshold price in keeping with the dimensions of trash can.

If the space can be much less than this threshold value, approach that the Trash can is complete of E-Waste and we will print the message “Trash is Full” on the message and if the distance will be more than this threshold value, then we will print the distance remaining for the E-Waste vat to be full.

III. HARDWARE REQUIREMENTS

We will need the following hardware to accomplish our project.

- HC-SR04 ultrasonic sensor.

- ATMEGA328 Microcontroller.

- GSM module

- Connecting wires.

- Power Supply

IV. BLOCK DIAGRAM

In ‘smart E-WASTE management system’ system, the level of garbage in the dustbins is detected with the assist of Sensor systems, and communicated to the legal manipulate room through GSM system. Microcontroller is used to interface the send message to the higher officials when the dustbin is not cleaned. LCD is used to show the place of the dustbin is complete on the manipulate room. LCD and GSM module. The ultrasonic sensor is act as stage detector .The output of level sensor system with GSM system. In this system, the Ultrasonic sensor is used for e-waste level detection through the use of ultrasonic sound waves. GSM module is used for communication purpose, to detector is connected to the microcontroller.[2] Depending at the microcontroller software in first level the dustbin filled information is displayed on LCD and in second level if the dustbin is filled and not at cleaned then message send to the higher officials. The AT instructions are used to facilitate the messaging provider thru the GSM Module. This program is burned in the microcontroller with the help of Arduino software (IDE). These messages include statistics of rubbish degrees of respective dustbins. Depending on the information sent to control room, the authority informs the concern person of the respective area about garbage level[9]. Then the concerned person makes sure that the garbage of that particular area is collected by sending the collecting vehicles[2].

V. CIRCUIT DIAGRAM

VI. DESCRIPTION OF PROJECT

Waste level detection is the done by ultrasonic sensors (HC-SR04). The ultrasonic sensors is placed on top of the dustbin facing the bottom. The sensors continuously emits the sonic waves, when the sonic waves hit the object and reflect back, the echo in the sensors senses the waves and calculates the distance of the object[8]. Arduino Mega 2560 is used for controlling whole the process detecting garbage in different places and depending on the program first display in LCD to reminding the garbage level in the bin even though the garbage is not take out from the bin then the particular bin information is sent to higher officials through GSM.[1]

VII. SOFTWARE REQUIREMENTS

A. Arduino IDE

The Arduino is open source Integrated Development Environment or Arduino Software (IDE). It includes a textual content editor for writing code, a message area, a textual content console, a toolbar with buttons for not unusual place capabilities and a of menus.[3]

B. Writing Sketches

Programs written the use of Arduino Software (IDE) are knows as sketches. These sketches are written withinside the textual content editor and are stored with the record extension .ino. The message region offers remarks at the same time as saving and exporting and additionally shows errors. The console shows textual content output with the aid of using the Arduino Software (IDE), such as entire mistakes messages and different information. The backside proper hand nook of the window shows the configured board and serial port. The toolbar buttons will let you affirm and add programs, create, open, and save sketches, and open the serial monitor. Arduino Language is user friendly and for programming is merely a set of C/C++ functions that can be called from your code.[3]

VIII. COMPONENT DETAILS

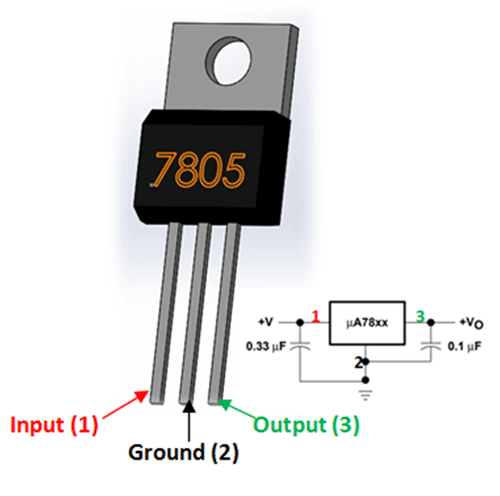

A. Regulator IC 7805

Features

- Minimum Input Voltage is 7V

- 5V Positive Voltage Regulator

- Maximum Input Voltage is 25V

- Operating current(IQ) is 5mA

- Internal Thermal Overload and Short circuit current limiting protection is available.

- Junction Temperature maximum 125 degree Celsius

- Available in TO-220 and KTE package

Voltage regulators are very common in electronic circuits. They provide a constant output voltage for a varied input voltage. In our case the 7805 IC is an iconic regulator IC that finds its application in most of the projects. The name 7805 signifies two meaning, “78” means that it is a positive voltage regulator and “05” means that it provides 5V as output. So our 7805 will provide a +5V output voltage. The output current of this IC can go up to 1.5A. But, the IC suffers from heavy heat loss hence a Heat sink is recommended for projects that consume more current.

For example if the input voltage is 12V and you are consuming 1A, then (12-5) * 1 = 7W. This 7 Watts will be dissipated as heat.

B. Liquid Crystal Display(Lcd)

Features of 16×2 LCD module

- Operating Voltage is 4.7V to 5.3V

- Current consumption is 1mA without backlight

- Alphanumeric LCD display module, meaning can display alphabets and numbers

- Consists of two rows and each row can print 16 characters.

- Each character is build by a 5×8 pixel box

- Can work on both 8-bit and 4-bit mode

- It can also display any custom generated characters

- Available in Green and Blue Backlight

Brief Description on LCD modules

LCD modules are very commonly used in most embedded projects, the reason being its cheap price, availability and programmer friendly. Most of us would have come across these displays in our day to day life, either at PCO’s or calculators. The appearance and the pin outs have already been visualized above now let us get a bit technical.

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. but the most used one is the 16×2 LCD. So, it will have (16×2=32) 32 characters in total and each character will be made of 5×8 Pixel Dots. A Single character with all its Pixels is shown in the below picture.

Now, we know that each character has (5×8=40) 40 Pixels and for 32 Characters we will have (32×40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels. Hence it will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780 is used, which is mounted on the backside of the LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen. You can learn how to interface an LCD using the above mentioned links. If you are an advanced programmer and would like to create your own library for interfacing your Microcontroller with this LCD module then you have to understand the HD44780 IC is working and commands which can be found its datasheet

C. GSM Modem

The SIM900A is a readily available GSM/GPRS module, used in many mobile phones and PDA. The module can also be used for developing IOT (Internet of Things) and Embedded Applications. SIM900A is a dual-band GSM/GPRS engine that works on frequencies EGSM 900MHz and DCS 1800MHz. SIM900A features GPRS multi-slot class 10/ class 8 (optional) and supports the GPRS coding schemes CS-1, CS-2, CS-3 and CS-4.

SIM900A GSM MODULE Features

- Single supply voltage: 3.4V – 4.5V

- Power saving mode: Typical power consumption in SLEEP mode is 1.5mA

- Frequency bands: SIM900A Dual-band: EGSM900, DCS1800. The SIM900A can search the two frequency bands automatically. The frequency bands also can be set by AT command.

- GSM class: Small MS.

- GPRS connectivity: GPRS multi-slot class 10 (default), GPRS multi-slot class 8 (option)

- Transmitting power: Class 4 (2W) at EGSM 900, Class 1 (1W) at DCS 1800

- Operating Temperature: -30ºC to +80ºC

- Storage Temperature: -5ºC to +90ºC

- DATA GPRS: download transfer max is 85.6KBps, Upload transfer max 42.8KBps

- Supports CSD, USSD, SMS, FAX

- Supports MIC and Audio Input

- Speaker Input

- Features keypad interface

- Features display interface

- Features Real Time Clock

- Supports UART interface

- Supports single SIM card

- Firmware upgrade by debug port

- Communication by using AT commands.

D. HC-SR04 Ultrasonic Sensor

Ultrasonic Sensor Pinout Configuration

|

Pin Number |

Pin Name |

Description |

|

1 |

Vcc |

The Vcc pin powers the sensor, typically with +5V |

|

2 |

Trigger |

Trigger pin is an Input pin. This pin has to be kept high for 10us to initialize measurement by sending US wave. |

|

3 |

Echo |

Echo pin is an Output pin. This pin goes high for a period of time which will be equal to the time taken for the US wave to return back to the sensor. |

|

4 |

Ground |

This pin is connected to the Ground of the system. |

E. HC-SR04 Sensor Features

- Operating voltage: +5V

- Theoretical Measuring Distance: 2cm to 450cm

- Practical Measuring Distance: 2cm to 80cm

- Accuracy: 3mm

- Measuring angle covered: <15°

- Operating Current: <15Ma

- Operating Frequency: 40Hz

F. HC-SR04 Ultrasonic Sensor – Working

As shown above the HC-SR04 Ultrasonic (US) sensor is a 4pin module, whose pin names are Vcc, Trigger, Echo and Ground respectively. This sensor is a very popular sensor used in many applications where measuring distance or sensing objects are required. The module has two eyes like projects in the front which forms the Ultrasonic transmitter and Receiver. The sensor works with the simple high school formula that

Distance = Speed × Time

The Ultrasonic transmitter transmits an ultrasonic wave, this wave travels in air and when it gets objected by any material it gets reflected back toward the sensor this reflected wave is observed by the Ultrasonic receiver module as shown in the picture below

Now, to calculate the distance using the above formulae, we should know the Speed and time. Since we are using the Ultrasonic wave we know the universal speed of US wave at room conditions which is 330m/s. The circuitry inbuilt on the module will calculate the time taken for the US wave to come back and turns on the echo pin high for that same particular amount of time, this way we can also know the time taken. Now simply calculate the distance using a microcontroller or microprocessor.

How to use the HC-SR04 Ultrasonic Sensor

HC-SR04 distance sensor is commonly used with both microcontroller and microprocessor platforms like Arduino, ARM, PIC, Raspberry Pie etc. The following guide is universally since it has to be followed irrespective of the type of computational device used.

Power the Sensor using a regulated +5V through the Vcc ad Ground pins of the sensor. The current consumed by the sensor is less than 15mA and hence can be directly powered by the on board 5V pins (If available). The Trigger and the Echo pins are both I/O pins and hence they can be connected to I/O pins of the microcontroller. To start the measurement, the trigger pin has to be made high for 10uS and then turned off. This action will trigger an ultrasonic wave at frequency of 40Hz from the transmitter and the receiver will wait for the wave to return. Once the wave is returned after it getting reflected by any object the Echo pin goes high for a particular amount of time which will be equal to the time taken for the wave to return back to the sensor.

The amount of time during which the Echo pin stays high is measured by the MCU/MPU as it gives the information about the time taken for the wave to return back to the Sensor. Using this information the distance is measured as explained in the above heading.

G. Applications

- Used to avoid and detect obstacles with robots like biped robot, obstacle avoider robot, path finding robot etc.[2]

- Used to measure the distance within a wide range of 2cm to 400cm[2]

- Can be used to map the objects surrounding the sensor by rotating it[2]

- Depth of certain places like wells, pits etc. can be measured since the waves can penetrate through water[2]

There are several basic steps involved in producing a printed circuit board (PCB). Most designs begin with a hand drawn schematic and design plan. With these, the circuit is prototyped and tested to verify that the design works correctly. Then, using software, an electronic version of the schematic is created. A netlist file is created from the electronic schematic and used in other software to create the physical layout of the PCB. Next, the components are placed and routed in the physical layout software and Gerber files are created. These Gerber files are used in a prototyping system to mill, drill, and cut the PCB substrate. The components are then placed and soldered to the substrate. Finally, the board is tested to verify that it works as expected.

The major steps in the PCB design and fabrication process are as follows:

a design and test the prototype circuit— by hand;

b. capture the circuit’s schematic— using OrCAD Capture or similar software;

c. perform the physical layout of the circuit— using OrCAD Layout similar software;

d. fabricate, populate and test the PCB— done by ECE shop personnel or similar personnel.

H. Prototyping

With a basic idea in mind, a circuit schematic is developed and analyzed to ensure the desired functionality and performance. When creating a circuit for PCB production, a designer would also select specific components at this time. Commonly, the next step is to prototype and to test the circuit. IIt is likewise viable to apply the schematic seize software program in conjunction with associated software program to simulate the circuit with out constructing it on a prototyping board.

In the case of the example upto sensor circuit (see Fig. 2), a rough sketched schematic was initially created, along with some design specifications. The important additives had been selected and the circuit become constructed on a prototyping board to confirm that it met the layout criteria. During the prototype board layout phase, thought was given to the best way to arrange the components for the final PCB layout.

I. Schematic Capture

Schematic capture software comes in several forms. In this application note, OrCAD Capture v9.10 will be used. Schematic capture allows the PCB designer to create an electronic schematic. This electronic schematic contains more information than its paper relatives. For example, every part symbol in Capture contains information telling what footprint the symbol is associated with. (Footprints are the symbols used in layout software to define the physical design of each component.) Capture parts symbols are used in a symbolic manner. Thus, the part symbol on Capture’s screen does not show what the actual physical component looks like. It does allow the designer to connect all the components in a circuit and to test the workings of the circuit by exporting files to other software. For our purpose, Capture provides the starting point for creating a physical layout in layout software.

A good way to begin learning Capture is through the Capture menu item Help Learning Capture. This tutorial will do a good job of explaining the basics of Capture. For further help, look in the troubleshooting section found in the appendix of this document and search for your question under Help Help Topics on Capture’s menu bar. In the following section of this application note, we will assume the reader has a basic familiarity with Capture.

One important comment is that every part symbol used in Capture must have a footprint associated with it. The footprint property of the symbol may be edited by double clicking on the part symbol in the schematic and editing the footprint property on the parameter list.[8]

After all the checks are complete, the PCB design can be printed. Unlike other plans, like architectural drawings, PCB plans don’t print out on a regular 8.5 x 11 sheet of paper. Instead A4 SIZE, a special kind of printer, known as a plotter printer, is used. A plotter printer makes a “film” of the PCB. The final product of this “film” looks much like the transparencies that used to be used in colleges for OHP — it’s essentially a photo negative of the board itself. After the film is printed, they’re lined up and a hole, known as a registration hole, is punched through them. The registration hole is used as a guide to align the films later on in the process.

The next stage in the process is that of removing the unwanted copper. Much like the alkaline solution from earlier, another powerful chemical FERRIC CHLORIDE(FeCl3) is used to eat away at the copper that is not covered by photoresist. Once the unprotected copper is removed, the hardened photoresist from earlier needs to be removed with the help of Thinner, as well. Another solvent is used, leaving only the copper necessary for the PCB.

Mix some FeCl3 (ferric chloride) powder in hot water. The reaction is vigorous, so take safety precaution. Put the copper-clad board in the solution and constantly tilt the container from side to side without spilling its contents (Fig). This is done to speed up the reaction. It takes five to six minutes to wash away all the excess copper. In between, keep checking the board. Ensure that the marker or carbon of the impression does not wash away. Take the board out (Fig) and wash it under tap water to remove the permanent marker ink. Remove carbon by using nail polish remover. Use a scrubber to gently scrub the copper surface now our PCB is ready.

IX. FUTURE SCOPE

There is a great scope for the modifications of the e-Waste monitoring system in future. The system can be improved by adding new functionalities like line follower robot to it, when the bin is full directly it is dumping on tipper[2], [3].

A. Advantages

- Very simple circuit.

- The HCSR04 sensor is very rugged.

- Helps monitor E-Waste levels.

- Uses very small amount of electricity.

- Ultimately helps in better planning of E-Waste pickups.

- Can help in reducing overflowing bins.

- Reduces trips to areas where the bins still have a lot of capacity.[2]

B. Disadvantages

- Cannot detect liquid waste.

- Only detects the top of the E-Waste level.

- It wouldn’t realize if there is space left.

- GSM module needs a 12v source.[2]s

Conclusion

We built an efficient E-Waste monitoring system which can be used to monitor the level of E-Waste in the dump. This data can be further used to plan E-Waste collection trips more efficiently, ultimately reducing overflowing bins and helping have better public sanitation.

References

[1] Marian Look, “Trash Plant: India”, earth 911B.National Conference on Product Design (NCPD 2016), July 2016. [2] Sahil Vaidhya, “IOT BASED GARBAGE BIN LEVEL INSPECTION SYSTEM”, International Research Journal of Modernization in Engineering Technology and Science, Volume:04/Issue:05/May-2022, e-ISSN: 2582-5208. [3] P. Ramchandar Rao, “Garbage Monitoring System using Arduino”, International Journal of Trend in Scientific Research and Development(IJTSRD), Volume-1, Issue-6, Sep-Oct:2017, ISSN No:2456-6470. [4] M. Khurrum S. Bhutta, Adnan Omar, and Xiaozhe Yang”Electronic waste:A Growing Concern In Todat’s Environment” Economic Research International , 2011 (), 1-8,DOI:10.1155/2011/474230. [5] Sagnik Kanta, Srinjoy Jash And Himadri Nath Saha,”Internet Of Things Based Garbage Moinitoring System”, 2017 8th Annual Industrial Automation and Electromechanical Engineering Conference (IEMECON)DOI: 10.1109/IEMECON.2017.807957. [6] E.Isa And N.sklevos,”Smart Home Automation: GSM Security System Design And Implementation”, July 2017Journal of Engineering Science and Technology Review 10(3):170-174, DOI:10.25103/jestr.103.22 [7] Mohd Muntjir, Mohd Rahul And Hesham A. Alhumyani, Department of Computer Engineering College of Computers and Information Technology Taif University, Taif, Saudi Arabia,”An Analysis Of Internet Of Things (IOT) Novel Architechtures, Modern Applications, Security Aspects And Future Scope With Latest Case Study”, International Journal of Engineering Research & Technology (IJERT) http://www.ijert.org ISSN: 2278-0181 IJERTV6IS060238 (This work is licensed under a Creative Commons Attribution 4.0 International License.) Published by : www.ijert.org Vol. 6 Issue 06, June – 2017 [8] S. Sanjay Kumar ,Ch. Rajendra Prasad ,\"Garbage Monitoring System using Arduino\",International Journal of Trend in Scientific Research and Development (IJTSRD) ISSN: 2456-6470 ,Volume-1,Issue-6,DOI:10.31142/ijtsrd4602. [9] Kellow Pardini,Joel J.P.C. Rodrigues,ORCID,Ousmane Diallo,Ashok Kumar Das,Victor Hugo C.de Albuquerque and Sergei A. Kozlov,\"A Smart Waste Management Solution Geared towards Citizens,Published: 22 April 2020,Sensors 2020, 20(8), 2380; https://doi.org/10.3390/s20082380. [10] Prof .Mayur Tiwari, Aboli Deshmukh, Kshitija Boke, Netra Deshmukh, Ashwini Dhurve,\"SMART WASTE MONITORING SYSTEM\",Prof. Dept. of Electronics and Telecommunication, Prof. Ram Meghe Institute of Technology and Research, Badnera,Amravati, Maharashtra, India,International Research Journal of Engineering and Technology (IRJET),Volume: 06 Issue: 04 Apr 2019,e-ISSN: 2395-0056,ISO 9001:2008 Certified Journal. [11] Arunkumar, Bhanu Priya, Prof.R.Santhosh Kumar,\"SMART GARBAGE COLLECTING BIN FOR MUNICIPAL SOLID WASTE\", IJMTES | International Journal of Modern Trends in Engineering and Science,Volume: 03 Issue: 03 2016

Copyright

Copyright © 2022 Pallavi Bansod, Sonali Shende, Rajat Gajbhiye, Sujata Sardare, Aslam Ghodke, Prof. S. S. Sawwashere. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET45349

Publish Date : 2022-07-05

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online