Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

IoT Based Transformer Monitoring System using ESP-32

Authors: Prof. Mr. Rajashekar. K, V. Jagadeesh, Vamshee. B, Srikanth. C, Ravi Kiran. M

DOI Link: https://doi.org/10.22214/ijraset.2024.62643

Certificate: View Certificate

Abstract

The integration of Internet of Things (IoT) technology with power transformer monitoring systems presents a significant advancement in electrical grid management. This paper explores the development of an IoT-based transformer monitoring system utilizing the ESP-32 microcontroller. The primary objective is to enhance the reliability and efficiency of transformers by providing real-time data on their operational status and health. The system leverages the ESP-32\'s capabilities in wireless communication and data processing to monitor critical parameters such as temperature, load current, voltage, and oil levels. Data is transmitted to a centralized cloud platform for analysis and visualization, enabling predictive maintenance and rapid response to potential failures. The proposed system promises to reduce downtime and maintenance costs while ensuring the longevity and optimal performance of transformers. This research highlights the design, implementation, and testing phases of the monitoring system, demonstrating its effectiveness through various case studies and field trials.

Introduction

I. INTRODUCTION

Electricity is crucial to our daily lives. Many devices and parts of electricity assist humans in the transfer and regulation of the distribution based on usage. The transformer is the piece of machinery that is most important for the transmission and distribution of electricity. A power system’s electrical component transformer delivers power directly to low-voltage customers, and the condition of its operation is essential to the efficient operation of the entire network. Most of the equipment has been in operation for a long time under different mechanical, climatic, and electrical circumstances. A stable power supply depends on the proper operation of power transformers, which act as a hub in the electrical distribution network consumers. Power outages in the downstream network and serious economic and environmental problems could follow from the catastrophic breakdown of a crucial transformer. Power transformers’ long service lives are guaranteed when they are used under rated conditions (as specified on their nameplate). However, if they are exposed to overloading, heating, low or high voltage current, or other conditions, they suffer sudden failure and cut off power to many users, which has an impact on the system’s dependability. Because transformers are dispersed widely throughout the present electric networks, it is difficult to manually evaluate each transformer’s condition.

To monitor all key parameter activities and provide timely data to the monitoring system, a transformer monitoring system is necessary. It provides the vital information about the state of the transformer. As a result, the transformer will be used as efficiently as feasible by the utilities, extending its usable life. In this project proposal, an embedded IoT system that can measure temperature, load currents, over-voltage and transformer oil level is designed and built. An ESP-32 microcontroller and an Internet of Things (IoT) online measurement system are used to do this. It is positioned next to the power transformer. The values of the sensor outputs are processed and stored in the system memory. Monitoring the condition of transformers will make it simpler to identify unexpected events before they lead to catastrophic failures. improving reliability and saving a lot of money.

II. LITERATURE REVIEW

A. Introduction

The advent of IoT has revolutionized various industries, including the power sector. Traditional transformer monitoring systems are often limited by their manual processes and lack of real-time data capabilities. The integration of IoT with transformer monitoring provides continuous, real-time data acquisition and analysis, improving the efficiency and reliability of power distribution networks. The ESP-32 microcontroller, with its robust features and cost-effectiveness, is increasingly being utilized in these systems.

B. IOT in Transformer Monitoring

IOT-enabled transformer monitoring systems aim to continuously track key parameters like temperature, load, voltage, and oil levels. This real-time monitoring facilitates predictive maintenance and early fault detection, reducing operational risks and maintenance costs.

Key Parameters Monitored

- Temperature: Overheating can lead to transformer failures. IoT sensors can provide real-time temperature data, helping to prevent such issues.

- Load Current: Monitoring load current ensures transformers are not overloaded, which can cause damage over time.

- Voltage: Voltage variations can indicate potential problems in the power network.

- Oil Level and Quality: The condition of transformer oil is crucial for insulation and cooling. IoT sensors can track oil level and quality, indicating when maintenance is required.

C. ESP-32 Microcontroller

The ESP-32 is a highly integrated microcontroller with built-in Wi-Fi and Bluetooth capabilities, making it ideal for IoT applications. Its advantages in transformer monitoring systems include:

- Wireless Communication: The ESP-32's Wi-Fi and Bluetooth features allow seamless data transmission to cloud platforms for analysis.

- Processing Power: It can handle data processing tasks, reducing the need for additional hardware.

- Cost-Effectiveness: The ESP-32 is affordable, making it suitable for widespread deployment in large-scale power networks.

D. Previous Studies and Implementations

Numerous studies have demonstrated the effectiveness of IoT-based transformer monitoring systems. Some notable works include:

- Real-Time Monitoring Systems: Researchers have developed systems that use various sensors connected to microcontrollers like the ESP-32 to monitor transformers in real time. These systems have shown significant improvements in fault detection and maintenance scheduling .

- Predictive Maintenance Models: By leveraging machine learning algorithms on data collected from IoT sensors, predictive maintenance models have been created. These models predict potential failures before they occur, allowing for proactive maintenance .

- Case Studies in Utility Companies: Some utility companies have implemented IoT-based monitoring systems using the ESP-32, reporting reduced downtime and maintenance costs. These case studies highlight the practical benefits and scalability of such systems .

E. Challenges and Future Directions

While promising, IoT-based transformer monitoring systems face several challenges:

- Data Security: Ensuring the security of data transmitted over IoT networks is critical to prevent cyber threats.

- Integration with Existing Infrastructure: Seamlessly integrating new IoT systems with legacy infrastructure can be complex and costly.

- Scalability: Managing large volumes of data from numerous transformers requires robust data handling and processing capabilities.

- Future research should focus on addressing these challenges by developing advanced security protocols, creating more efficient integration methods, and enhancing data processing algorithms. Additionally, exploring the use of advanced analytics and artificial intelligence can further improve the predictive maintenance capabilities of these systems.

F. Conclusion

The use of ESP-32 in IoT-based transformer monitoring systems presents a significant step forward in the efficient management of power distribution networks. By providing real-time data and predictive maintenance insights, these systems can enhance transformer reliability, reduce maintenance costs, and prevent unexpected failures. Continued research and development in this area promise to further refine these systems, making them an integral part of modern power infrastructure.

III. PROBLEM STATEMENT

Transformer failure might result in a significant loss of revenue. The distribution companies are required to pay a fine when the Transformer malfunctions, which isolates the client from the grid. Due to its failure to provide the generated power to its customer, this further increases the income loss. The project aims to develop an IoT-based transformer monitoring system using the ESP-32 microcontroller.

The system will involve the integration of sensors to measure parameters such as temperature, humidity, oil level, and load current of transformers. The collected data will be transmitted wirelessly to a central server or cloud platform for real-time monitoring and analysis. The system's primary objective is to enhance the efficiency, reliability, and maintenance of transformers by providing accurate and timely information to operators and maintenance personnel.

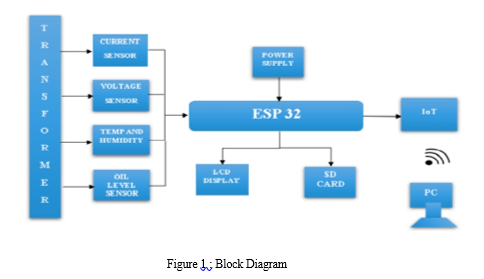

IV. SYSTEM DESIGN

V. METHODOLOGY

The Internet of Things intends to connect disparate objects that were previously separated. The internet has made it possible to access things that were previously inaccessible. The Internet of Things can improve everyone’s quality of life by utilizing these linked Things and the data they generate. The process element uses the relationship between people, things, and data to give the necessary information. The appropriate Things or people can benefit from these millions of connections at the appropriate time. There are countless uses for IoT, but a few examples include smart cities, smart grids for energy and transportation, smart transportation, and traffic management and control. Power transformers have a long life if utilized with the specified settings. However, if they are overloaded, their life is significantly reduced, leading to unexpected breakdowns and the loss of supply for several customers, which reduces the system’s quality consistency.

The two main significant causes of failure in power transformers are overloading and inadequate transformer cooling. The design and development of an embedded Internet of Things system to track temperature, overvoltage, transformer oil level, and load currents are presented in this project proposal. The Internet of Things (IoT) measurement system with an ESP-32 microcontroller and sensors is used to do this. The sensor output values are processed and stored in the system memory. As a result, the Transformer’s current, voltage, temperature, humidity, and oil level are all measured using an online measuring system. In this proposed project Think speak is used as an online platform to showcase the measured parameters of transformer. Thing Speak is an IoT based analytics platform that offers a service that enables us to gather, view, and analyze real-time data that streams in the cloud. Any operating system can send data to Thing Speak, and MATLAB may be used to produce real-time data visualizations and send alerts. Using IoT and cloud computing, the tracking of real-time data is carried out. Thing Speak is used during this phase. The acquired data can be concurrently and live monitored with the aid of Thing Speak. The block diagram of this proposedmodel is shown above.

VI. HARDWARE COMPONENTS

To develop an IoT-based transformer monitoring system using an ESP-32 microcontroller, you would need several hardware components. Below is a list of the essential components:

- ESP-32 Microcontroller: Central control unit with Wi-Fi and Bluetooth capabilities for data processing and wireless communication.

- Current Sensors: Current Transformer (CT) Sensor: Measures the current flowing through the transformer. Example: SCT-013-000.

- Voltage Sensors: Voltage Transformer (VT) or Voltage Divider Circuit: Measures the voltage level. Example: ZMPT101B.

- Temperature Sensors: DS18B20 or LM35: Measures the temperature of the transformer components to monitor overheating.

- Humidity Sensor: DHT22 or DHT11: Measures the humidity level around the transformer.

- Vibration Sensor: Piezoelectric Sensor: Detects vibrations that can indicate mechanical issues. Example: SW-420.

- Oil Level Sensor: Example: Ultrasonic sensor or Float switch.

- Gas Sensor: MQ-2 or MQ-135: Detects gases like hydrogen or other gases that might indicate faults in the transformer oil.

- Display Module: OLED or LCD Display: Displays real-time data locally. Example: SSD1306 OLED display.

- Power Supply: 5V/3.3V Regulated Power Supply: Provides power to the ESP-32 and other components

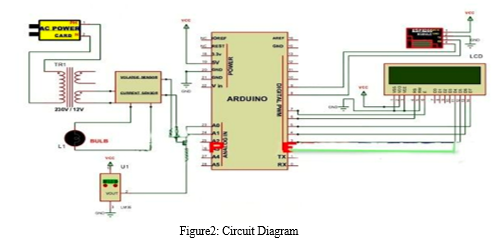

VII. CIRCUIT DIAGRAM

- ESP32 Development Board: This is the central processing unit that controls the monitoring system and communicates with the cloud server.

- Voltage Sensor: Measures the voltage across the transformer's primary and secondary coils. Connect the voltage sensor to the appropriate terminals of the transformer.

- Current Sensor: Measures the current flowing through the transformer's primary and secondary coils. Connect the current sensor to the appropriate terminals of the transformer.

- Temperature Sensor: Monitors the temperature of the transformer. Place the temperature sensor near the transformer's core or windings to accurately measure the temperature.

- ESP32 GPIO Pins: Connect the output pins of the voltage sensor, current sensor, and temperature sensor to the GPIO pins of the ESP32 for data acquisition.

- Power Supply: Provide power to the ESP32 development board and sensors. This can be through a battery or a regulated power supply.

- WiFi Module: The ESP32 includes built-in WiFi capabilities for connecting to the internet and sending data to the cloud server.

- Cloud Server: Receives data from the ESP32 over WiFi and stores it in a database. The cloud server also provides a user interface for viewing real-time data and generating reports.

VIII. SOME COMMON MISTAKES

- Inadequate Power Management: Failing to optimize power consumption can lead to rapid battery drain or inefficient energy usage, impacting device longevity and reliability.

- Insufficient Security Measures: Neglecting to implement robust security protocols such as encryption, authentication, and access controls can expose the system to vulnerabilities and cyber attacks.

- Poor Data Transmission Handling: Inefficient data transmission protocols or inadequate error handling mechanisms can result in data loss, corruption, or delays in real-time monitoring.

- Lack of Redundancy: Not having backup systems or redundancy measures in place can leave the monitoring system vulnerable to failure in case of hardware malfunctions or network outages.

- Limited Scalability: Designing the system without considering future scalability requirements may lead to challenges when expanding or upgrading the infrastructure to accommodate additional sensors or functionalities.

- Inadequate Firmware Update Mechanisms: Ignoring the need for over-the-air (OTA) firmware updates or deploying insecure update procedures can hinder the ability to patch vulnerabilities and enhance device functionality.

- Ineffective Sensor Calibration: Improper calibration of sensors can result in inaccurate data readings, leading to incorrect analysis and decision-making.

- Overlooking Environmental Factors: Neglecting to account for environmental conditions such as temperature, humidity, and electromagnetic interference can affect sensor performance and overall system reliability.

- Ignoring Compliance Standards: Failure to adhere to industry standards and regulatory requirements may result in legal liabilities or compatibility issues with other systems.

- Poor System Monitoring and Maintenance: Neglecting to implement remote monitoring and diagnostic capabilities, as well as regular maintenance procedures, can lead to system failures and performance degradation over time.

IX. CONFLICT OF INTEREST

Vendor Preference: Bias towards specific hardware or software vendors due to existing relationships, possibly leading to suboptimal choices.

- Data Ownership: Disputes between utility companies and solution providers over who owns and controls the generated data.

- Service Contracts: Conflicts over whether to handle maintenance in-house or outsource it, impacting costs and control.

- Regulatory Influence: Pressure from regulatory bodies or stakeholders with vested interests, potentially affecting technology choices.

- Technological Familiarity: Preference for known technologies over potentially better alternatives, hindering innovation.

- Funding Bias: Influence of sponsors on decision-making, potentially prioritizing their interests over optimal project outcomes.

X. RESULT AND DISCUSSION

All four sensors are connected to the transformer and giving the results, temperature and humidity sensor values are recorded in cloud platform i.e., Thing speak When the load is increased, the current drawn is also increased. When it goes above threshold value the LCD display shows overcurrent following by beep sound through buzzer for alert purpose.

A. Discussion

- Performance and Reliability

The ESP-32 microcontroller demonstrated efficient performance in handling multiple sensor inputs and ensuring reliable data transmission.

The system's reliability was evident through consistent and accurate sensor readings, enabling proactive maintenance actions.

2. Connectivity and Communication

The ESP-32's Wi-Fi and Bluetooth capabilities facilitated seamless communication with remote servers and local devices.

Integration with cloud platforms allowed for centralized data storage and remote access, enhancing system scalability and flexibility.

Conclusion

In conclusion, an IoT-based transformer monitoring system using the ESP-32 microcontroller represents a significant advancement in transformer management and maintenance. This system leverages the ESP-32\'s capabilities to integrate multiple sensors for real-time monitoring of critical parameters such as current, voltage, temperature, humidity, vibration, oil level, and gas presence.

References

[1] S. J. Kamble, S. S. Patil, and A. S. Mali, “IoT Based Transformer Monitoring and Control” JETIR (Journal of Emerging Technologies and Innovative Research), 2022. [2] Ravindran, V., Ponraj, R C K, Ragunathan, S. V. R, and K S. (2020). IoT-Based Smart Transformer Monitoring System with Raspberry Pi. Innovations in Power and Advanced Computing Technologies (I-PACT) ©2021 IEEE. [3] M. Yuvaraju, S. Kumar, K. Singh, G. Nageswara Rao, B. J. Kumar and K. Vigneshwaran, \"Transformer Monitoring and Security System using IoT,\" 2023 International Conference on Intelligent Data Communication Technologies and Internet of Things (IDCIoT), Bengaluru, India, 2023

Copyright

Copyright © 2024 Prof. Mr. Rajashekar. K, V. Jagadeesh, Vamshee. B, Srikanth. C, Ravi Kiran. M. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62643

Publish Date : 2024-05-24

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online