Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- References

- Copyright

IoT Enable Grass Cutter Robot - Car

Authors: Mayur S. Shelke, Nikhilkumar P. Chichghare, Shreyash U. Bondre, Ankit M. Maske, Bhavesh R. Pounikar, Sneha M. Panware

DOI Link: https://doi.org/10.22214/ijraset.2024.58021

Certificate: View Certificate

Abstract

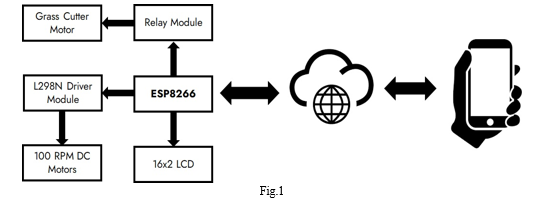

The IoT Enabled Grass Cutter Robo-Car project represents a transformative leap in the realm of lawn maintenance, merging cutting-edge robotics with the expansive capabilities of the Internet of Things (IoT). At its core, this project introduces a state-of-the-art Robo-Car, meticulously engineered to be remotely controlled through an Android application. The crux of the communication infrastructure is a web server, with the ESP8266 serving as the linchpin by receiving signals from the server. These signals orchestrate the nuanced operations of a L298N motor driver, steering the precise movement of 100 RPM motors, and a relay module that commands the activation of the grass cutter motor. With a vision to redefine the landscape of lawn care, this project stands as an exemplar of efficiency, convenience, and remote accessibility in the realm of smart agriculture.

Introduction

I. INTRODUCTION

Traditional lawn maintenance has grappled with challenges stemming from manual exertion and time-intensive processes, hindering overall efficiency in the field. The advent of the IoT Enabled Grass Cutter Robo-Car marks a transformative leap forward, introducing a sophisticated solution that addresses the inherent limitations of traditional practices. Through the utilization of IoT technology, this innovative project not only enhances the effectiveness of grass-cutting operations but also mitigates the physical strain imposed on the workforce.

The primary objective is to usher in a new era of empowerment for users, granting them the ability to exercise remote oversight and control over the intricacies of grass-cutting operations. At the core of this technological marvel is the integration of IoT, which enables seamless communication between the Grass Cutter Robo-Car and an intuitive Android application. This integration allows users to remotely monitor and manage various aspects of the grass-cutting process, providing a level of control unprecedented in traditional lawn maintenance.

The Grass Cutter Robo-Car, equipped with state-of-the-art technology, becomes a reliable and efficient ally in the pursuit of maintaining lush lawns without the drawbacks of manual labour. Efficiency gains are achieved by leveraging real-time data and analytics, optimizing the Grass Cutter Robo-Car's performance based on the specific needs of each lawn. The project envisions a departure from the labor-intensive routines of traditional lawn care, ushering in a future where technology seamlessly integrates with nature. Users can enjoy the convenience of scheduling, monitoring, and adjusting grass-cutting operations through the user-friendly interface of the Android application. The Grass Cutter Robo-Car is designed to adapt to diverse lawn environments, ensuring a precise and tailored approach to grass maintenance.

This innovative solution not only enhances operational efficiency but also contributes to resource conservation by utilizing data-driven decision-making for optimal resource utilization. Through the integration of IoT, the project addresses environmental concerns by minimizing the ecological impact associated with traditional lawn maintenance practices. The Android application serves as a central hub, allowing users to receive real-time updates, set preferences, and even initiate grass-cutting operations from the comfort of their smartphones.

Remote oversight empowers users to make informed decisions, adjusting the Grass Cutter Robo-Car's course or operation parameters based on the real-time feedback received through the IoT platform. The paradigm shift introduced by this project extends beyond mere technological innovation; it signifies a commitment to redefining the relationship between humans and the maintenance of green spaces. By streamlining lawn care processes, the project aims to contribute to a more sustainable and environmentally conscious approach to landscaping. The Grass Cutter Robo-Car's intelligent algorithms ensure that it navigates obstacles, adjusts cutting patterns, and maximizes efficiency without human intervention. As the demand for efficient and eco-friendly lawn maintenance solutions grows, the IoT-enabled Grass Cutter Robo-Car emerges as a pioneering force in reshaping the landscape of traditional practices.

II. PROBLEM IDENTIFICATION

- Manual grass-cutting practices face a myriad of challenges, including significant time investments, strenuous physical labour, and the requirement for direct human presence.

- These longstanding obstacles have historically hindered the scalability and effectiveness of traditional lawn maintenance, prompting the creation of the IoT-enabled Grass Cutter Robo-Car.

- This innovative project, featuring a remotely controlled robotic solution, not only tackles the existing challenges but also introduces a scalable and highly efficient alternative to modernize lawn care practices.

- The impetus for this development lies in the recognition that the traditional methods are no longer sustainable in meeting the demands of contemporary lifestyles and landscaping needs.

- The Grass Cutter Robo-Car addresses the time-intensive nature of manual grass-cutting by leveraging automation and remote-control capabilities, eliminating the need for constant human supervision.

- Moreover, the project aims to redefine the landscape of lawn maintenance, offering a solution that is not only technologically advanced but also adaptable and responsive to the evolving requirements of efficient and scalable green space management.

III. PROBLEM FORMULATION

- The articulation of the problem encapsulates a strategic response to the discerned challenges in conventional grass-cutting methodologies. A targeted approach is adopted with a clear emphasis on reducing manual labor, enabling remote operation through a user-friendly Android application, and providing a scalable solution for efficient lawn maintenance. This project is set on engineering a paradigm-shifting solution by addressing these key facets.

- By framing the objectives within this comprehensive context, the IoT-enabled Grass Cutter Robo-Car aspires to redefine the benchmarks for efficiency and accessibility in grass-cutting operations. The focus on minimizing manual labor aligns with contemporary demands for automation and efficiency in landscaping practices.

- The integration of remote operation through an Android application not only enhances user convenience but also aligns with the evolving landscape of smart technology. Ultimately, this project endeavors to establish a new standard in grass-cutting methodologies, incorporating advanced technologies to create a solution that is not only effective but also adaptable to the changing needs of lawn maintenance.

IV. LITERATURE REVIEW

- Design and Fabrication of Battery-Operated Grass Cutter. (July – 2018) M M Sahu, Manoj ,Kumar Nayak , Sabyasachi Sahu. In this paper , They develop an electric based battery operated grass cutter. An electrical Grass Cutter is more suitable & easy to use than the Grass Cutter with an engine, they select an electrical Grass Cutter with an electric motor, which will provide the high speed rotation to the blades. Cordless electric Cutters are powered by 12-volt rechargeable batteries.

- Design and Fabrication of Hybrid Operating Grass Cutter. Aditya S. Rajmani, Appaji N. Gaonkar, Ajay Darak, Akshay Joshi Prof. Vinay M. Murgod. In this research peper due to the cost of fuel and the effect of emission of gases from the burnt fuel into the atmosphere. This necessited the abundant solar energy from the sun as a source of power to drive a lawn mower. A solar powered lawn mower was designed and development, based on the general principle of moving. The designed solar powered lawnmower comprises of direct current (D.C) motor, a rechargeable battery, solar panel, a stainless steel blade and control switch. Mowing is achieved by the D.C motor which provides the required torque needed to drive the stainless steel blade which is directly coupled to the shaft of the D.C motor. The solar powered lawnmower is operated by the switch on the board which closes the circuit and allows the flow of current to the motor which in turn drive the blade used for mowing. The battery recharges through the solar charging controller. Performance evaluation of the developed machine was carried out with different types of grasses.

- Prof. C. J. Shende: In this paper they have prepared manually handle device which is capable to cut the grass. This device consists of linear blades and it does not affected by climatic conditions. The main objective of this paper is to move the grass cutter is different directions to prepare various designs as per requirements. By using link mechanism the height of the cut can be adjusted. The unskilled labour can easily operate this device.

- C. B. Mills: Today, new technology is bringing us improved mower versions. Low emission gasoline engines with catalytic converters are being manufactured to help reduce air pollution. Improved muffling devices are also being installed to reduce the noise pollution. Battery powered mowers are also becoming practical.

Although slightly smaller with an average cutting swath of only 17-19", these new mowers will quietly cutting lawns without the common cloud of blue smoke hanging in the air, for about an hour per charge. Prices are comparable to a high-end gasoline powered motor.

5. Davidge E D: "I’m planning on moving my entire fleet to propane. Not only is it better for the environment, it also increases my productivity. I’m saving money on fuel, and labor costs as well, since my crew isn’t spending time filling up at the pump. Propane has no additives and is a clean burning system. I save on maintenance since there is no carburetor or fuel filter to maintain.

6. Edwin Beard Budding: Budding obtained the idea of the lawn mower after seeing a machine in a local cloth mill which used a cutting cylinder mounted on a bench to trim cloth to make a smooth finish after weaving. Budding realized that a similar concept would enable the cutting of grass if the mechanism could be mounted in a wheeled frame to make the blades rotate close to the lawn's surface.

7. Ms. Lanka Priyanka: In this paper they have fabricated grass cutting machine with tempered blades are attached to this grass cutter. This grass cutter is manually operated as well as automatic operated. The materials commonly used GI sheet, motor, wheel, Al sheet, switch, wire, square pipe and insulating material.

8. P.Bulski: Bulski identify the sound created by the machine is making noice pollution. He research on sound created by the machine and giving the result how to remove the sound while cutting the grass of lawn or ground. As looking to the petrol engine it make air pollution to environment so from my recommendation it should be implement on electric operated lawn motor.

9. Praful P. Ulhe: In this paper they have prepared manually operated grass cutter with spiral roller blades due to spiral blades increases the efficiency of cutting. For adjusting the height reel cutter is component placed on grass cutter. This grass cutter used to cut the grass uniformly and also it can cut the different types grasses.

V. RESEARCH METHODOLOGY

- The research methodology employed for this project reflects a meticulous and systematic approach, commencing with the discerning selection and integration of each component.

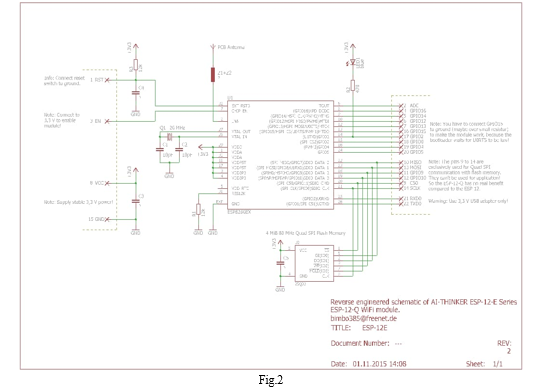

- The core of this methodology revolves around the ESP8266 module, which is intricately programmed to interpret signals emanating from the designated web server.

- By documenting the intricacies of challenges encountered during the development process, the research offers invaluable insights, shedding light on the iterative path traversed to implement effective and innovative solutions.

- This methodical and detail-oriented approach ensures a comprehensive understanding of the project's development, highlighting the significance of each component's selection and integration.

- The ESP8266 module, positioned at the project's epicenter, serves as a linchpin in deciphering signals and facilitating seamless communication with the web server, embodying the precision inherent in the research methodology.

- The documentation of challenges encountered not only provides a transparent account of the development journey but also contributes to the broader knowledge base, fostering continuous improvement and refinement in the field.

VI. CONSTRUCTION & WORKING

- The research methodology employed for this project reflects a meticulous and systematic approach, commencing with the discerning selection and integration of each component. The core of this methodology revolves around the ESP8266 module, which is intricately programmed to interpret signals emanating from the designated web server.

- By documenting the intricacies of challenges encountered during the development process, the research offers invaluable insights, shedding light on the iterative path traversed to implement effective and innovative solutions.

- This methodical and detail-oriented approach ensures a comprehensive understanding of the project's development, highlighting the significance of each component's selection and integration. The ESP8266 module, positioned at the project's epicenter, serves as a linchpin in deciphering signals and facilitating seamless communication with the web server, embodying the precision inherent in the research methodology.

- The documentation of challenges encountered not only provides a transparent account of the development journey but also contributes to the broader knowledge base, fostering continuous improvement and refinement in the field.

VII. DESIGN

- The design considerations at the core of this project span a myriad of facets, commencing with the judicious selection of components. Each choice is grounded in a synthesis of functionality and compatibility, ensuring a harmonious integration within the holistic system.

- The design process extends to the Android application, conceived as the user's gateway to seamless control, undergoing meticulous planning to provide an interface that is not only functional but also intuitive. Safety, recognized as a paramount concern, is intricately embedded within the design through the incorporation of an emergency stop functionality, guaranteeing the secure operation of the entire system.

- At its essence, the design ethos is sculpted to deliver a user-centric, efficient, and safe lawn maintenance solution. This holistic approach ensures that every aspect, from component selection to user interface design and safety features, is carefully considered to create a comprehensive and well-balanced system that aligns with the project's overarching goals.

References

[1] J N Reddy, A course on linear & nonlinear finite element analysis (Great Clarendon Street, Oxford, Oxford University Press, 2004). [2] Egor P. Popov, Engineering mechanics of solids (Englewood Cliffs, New Jersey: Prentice-Hall, 1990). [3] Reidel S. Consideration of grip and push forces for the assessment of vibration exposure. Cent Eur J Public Health. 1995;3:13]. [4] Khurmi, R.S. and Gopta, J.K. (1997). Machine Design, 11th Edition. Eurasia Publishing House Ltd. New Delhi. [5] Khurmi, R.S. and Gopta, J.K. (2003). Machine Design. Eurasa Publishing House, Ltd. New Delhi, India. [6] M. P. Down and R. J. Sands, ?Biometrics: An overview of the technology, challenges and control considerations,? Inf. Syst. Control J., vol. 4, pp. 53–56, 2004. [7] S.Balameenakshi. S.Sumathi,? Biometric Recognition of Newborns: Identification using Footprints?, Proceedings of 2013 IEEE International Conference on Information and Communication Technologies (ICT 2013), 737-742, Tamilnadu, India [8] Hai-Yang Cai, et al ?Newborn Footprint Recognition using Orientation Feature?, Neural Computing & Applications: 1-9, Dec ICIC 2010 [9] Sahoo, Soyuj Kumar, Tarun Choubisa, and Mahadeva Prasanna SR. \"Multimodal biometric person authentication: A review.\" IETE Technical Review29.1 (2012): 54. [10] Anil Jain, Karthik Nandakumar, Arun Ross,? Score normalization in multimodal biometric systems?, Pattern Recognition 38 (2005) 2270 – 228

Copyright

Copyright © 2024 Mayur S. Shelke, Nikhilkumar P. Chichghare, Shreyash U. Bondre, Ankit M. Maske, Bhavesh R. Pounikar, Sneha M. Panware. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET58021

Publish Date : 2024-01-13

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online