Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

IOT Mining Tracking & Worker Safety Helmet

Authors: Anand Vishwakarma , Animesh Yash, Anshika Singh , Divyanshu Awasthi, Ranjeeta Yadav

DOI Link: https://doi.org/10.22214/ijraset.2024.62778

Certificate: View Certificate

Abstract

The digital revolution in the mining industry is being driven by the growing applications of IoT. In this research, we focus on one of the most important aspects of mine safety – the development of next-gen smart helmet systems. Imagine a smart helmet that is worn by miners and continuously monitors vital environmental parameters such as temperature, humidity and gas levels, but it goes further than simple monitoring. It can also detect if a miner takes the helmet off for any reason or if it becomes damaged due to obstacles inside the mine. This innovative system uses IoT to make a significant improvement in worker safety over traditional methods. With real-time information and hazard alerts, mine operators can proactively prevent accidents and improve overall operations. The collected data can also be used to detect potential hazards and take preventive measures to reduce the risk of accidents and save lives. The development of a smart helmet system marks a paradigm shift for mine safety, ushering in a new era of data-driven decision-making and improved worker protection.

Introduction

I. INTRODUCTION

The mining industry, for centuries, has been a vital source of resources, but one that comes with inherent risks to worker safety. While advancements in technology have improved mining practices, the threat of accidents persists. However, the burgeoning field of the Internet of Things (IoT) offers a transformative opportunity to revolutionize mine safety. This research delves into the development of a next-generation smart helmet system – a wearable sensor network that acts as a digital guardian angel for miners operating in harsh and potentially hazardous environments.

Underground mining operations present a complex web of safety challenges. Workers face constant threats from:

- Toxic Atmospheres: The absence of proper ventilation can lead to a buildup of hazardous gases like methane and carbon monoxide. These pose a serious risk of suffocation and poisoning, potentially causing long-term health problems like silicosis and tuberculosis.

- Ventilation Issues: Inadequate ventilation also contributes to rising temperatures within the mines. This abnormal heat stress can lead to fatigue, dehydration, and heatstroke, further compromising worker safety.

- Unexpected Explosions: The volatile nature of coal and the presence of methane gas create a constant risk of explosions during mining activities. These explosions can cause immediate fatalities and serious injuries.

India, boasting the world's fifth-largest coal reserves, has experienced significant growth in the mining sector. In 2020, the Environment Ministry approved 14 new coal mine projects, aiming to reach a production target of one billion tons by 2024. However, this expansion comes at a cost. Coal mines consistently record the highest number of mining accidents in India, with an average of 549 worker deaths reported annually according to ministry data. Despite significant progress, ensuring miner safety remains a paramount concern. Accidents from factors like gas leaks, falling debris, and equipment malfunctions tragically claim lives. The National Institute for Occupational Safety and Health (NIOSH) reports that in 2020 alone, 29 miners lost their lives in mining accidents within the United States. Globally, the statistics are even more alarming.

Current safety protocols in mines rely heavily on passive measures. Pre-shift inspections aim to identify potential hazards before operations begin. Personal protective equipment (PPE) serves as a physical barrier against dangers encountered during work. Finally, emergency response procedures ensure a rapid and coordinated response to accidents. While these measures are crucial, they have limitations. Inspections may miss hidden dangers, PPE may not provide complete protection in all scenarios, and critical minutes can be lost waiting for emergency response in life-threatening situations.

This research proposes a revolutionary approach to mine safety – the development and implementation of a next-generation smart helmet system. Imagine a helmet equipped with a network of sensors acting as a miner's digital guardian angel. These sensors continuously monitor critical environmental factors like temperature, humidity, and gas levels, ensuring a safe working environment. This system goes beyond simple monitoring – it also detects if a miner removes the helmet for any reason, a vital safety precaution in contaminated environments. Additionally, the helmet can be equipped with sensors to detect impacts or damage sustained from potential collisions within the mine.

This smart helmet system leverages the power of the Internet of Things (IoT). The collected sensor data is transmitted wirelessly in real time to a central monitoring station. This allows mine operators to have a constant and comprehensive view of the environmental conditions within the mine and the status of individual miners. Real-time alerts can be triggered if any sensor reading exceeds pre-defined safety thresholds, enabling immediate intervention to protect workers from potential hazards.

The capabilities of the smart helmet system extend beyond real-time monitoring. The collected data over time becomes a vital resource for proactive risk management. By analyzing this data, patterns and trends can be identified that indicate potential safety risks. This empowers mine operators to take preventative measures, such as improved ventilation systems or modified work practices, to mitigate these risks before accidents occur. This data-driven approach to safety management represents a significant leap forward from traditional methods, where responses are primarily reactive.

The smart helmet system has the potential to save lives. By providing real-time hazard alerts and enabling proactive risk management, this technology can significantly reduce the risk of accidents and fatalities in mines. Additionally, the collected data can be used to identify areas of inefficiency in mining operations, leading to streamlined processes and ultimately, improved operational efficiency. The development of this smart helmet system signifies a paradigm shift in mine safety. It ushers in an era of data-driven decision-making, where real-time information empowers proactive safety measures and minimizes risk. This research delves deeper into the technical aspects of the smart helmet system, exploring the specific sensor technologies, communication protocols, and data analysis methods that will bring this vision to life. The ultimate goal is to create a safer and more efficient future for the mining industry, where worker safety remains the top priority.]

Imagine a world where everyday objects, not just computers and phones, can connect to the internet and share information. That's the core idea behind the Internet of Things (IoT). Regular devices like refrigerators, thermostats, and even wearables can be equipped with sensors and become part of a giant network. The story of IoT actually began in 1982, way ahead of its time! Carnegie Mellon University connected a Coke machine to the internet, allowing it to report when it was low on drinks and if the newly stocked ones were cold. Fast forward to today, there are over 8 billion IoT devices, surpassing the number of people on Earth! By 2030, that number is expected to explode to a staggering 50 billion, connecting everything from kitchen appliances to smartphones. This vast network is built on three main pillars: Devices, Networks, and Applications. One of the key strengths of IoT is its ability to collect data anytime, anywhere. This is often referred to as the "3 A's of IoT" - Always, Anywhere, Anytime.

A. Here's how it Typically Works

- Sensing the World: Tiny sensors embedded in devices gather information about their surroundings. This data can be as simple as temperature or more complex like video footage.

- Connecting to the Cloud: The collected data is then transmitted wirelessly through Wi-Fi, Bluetooth, or other connections to a central data storage system called the cloud.

- Making sense of the Data: Once in the cloud, powerful software analyzes the information, identifying patterns and extracting valuable insights.

- Taking Action: The processed information is then used in various ways. It can be delivered to users through apps, emails, or even trigger automatic actions in other devices.

B. The impact of IoT is vast and Constantly Evolving.

- Smarter Homes and Cities: Imagine controlling your lights remotely, preheating your oven on your way home, or even living in a city that adjusts traffic flow based on real-time data. IoT is making these scenarios a reality.

- Boosting Businesses: Businesses can leverage IoT to improve efficiency in their operations, predict equipment failures before they happen, and provide better customer service.

- A world of Possibilities: From revolutionizing healthcare with remote monitoring to optimizing farming with smart irrigation systems, the potential applications of IoT are endless.

The financial investment in IoT is significant. Global spending on IoT surpassed $700 billion in 2016 and is expected to reach a staggering $6 trillion in the next few years. Cities are also embracing IoT, with Barcelona saving millions of dollars thanks to smart lighting powered by this technology. As the number of connected devices grows, so does the amount of data they generate. By 2019, it's estimated that IoT devices will produce a mind-boggling amount of data - over 500 zettabytes annually! From the voice assistant in your home to your fitness tracker and even a self-driving car, we're already surrounded by devices that are part of the ever-expanding world of IoT.

C. Here's how IoT applies to Smart Helmet Systems for Miners

- Sensors Collect Data: The smart helmet uses various sensors to monitor the miner's environment and well-being. These sensors might detect air quality (gases, dust), temperature, humidity, or even impact (in case of falls).

- Data Transmission: The helmet transmits the sensor data wirelessly via protocols like Bluetooth to a central hub.

- Data analysis: The control center receives data from multiple miners' helmets. This data is analyzed to identify any potential hazards like high methane levels or a miner falling.

- Alerts and Actions: If a hazard is detected, the system can trigger alarms for both the miner (through lights or sounds) and the control room. This allows for a swift response to emergencies.

In essence, IoT creates a connected system where the smart helmet acts as a data collection point, feeding information into a larger network for real-time monitoring and improved safety in mines.

II. LITERATURE REVIEW

In 2023, AKL Sandaruwan and B Hettige [1] presented a worker safety helmet that works on IoT. The importance of safety in the mining industry cannot be overstated, especially in underground operations where the well-being of mine workers is of paramount importance. All mining operations must adhere to fundamental safety regulations and measures to avoid accidents, and collapses are a major risk. While coal mining collapses are not always particularly dangerous, immediate rescues are essential in saving lives. Communication is a key factor in mining, particularly in underground mines. Worn-out wired communication is costly and inefficient, while wireless communication is cost-effective and effective. Wireless communication allows the industry to transmit essential information immediately, thus improving safety measures—furthermore, the integration of sensors (gas and temperature sensors) aids in proactive risk prevention. Miners wear helmets with buzzers that alert them during hazardous conditions, and priority is given to communication so that all mining personnel can confirm their safety before proceeding, thus creating a safe environment for all involved.

To address these issues, a pioneering project has emerged: the creation of smart helmets, which act as intelligent guardians of miners. These helmets are equipped with various sensors to detect potentially hazardous events and keep an eye on the environment around them. By collecting data from various sensors, the helmets can transmit it to the central console, where it can be exchanged in real-time. This allows for the efficient monitoring of miners and the prompt response to emergencies. By utilizing cutting-edge technology, the project improves safety protocols in the mining industry, thus saving lives and preparing the ground for a safer future.

In 2023, Pankaj Kunekar, Prerana Waghmare, Preyas Videkar, Sangharatna Bombarde, Y. D. Satyamedha, V. Khandagale, Yashovardhan U. Wagh [2] presented a solution and a plan for the problem of Miners Security. The issue of safety in the coal mining sector is a major concern due to the frequent occurrence of accidents. This study highlights the need to implement a wireless network connection to transmit real-time data to alert officials in the event of an accident, thus allowing for rapid responses. Accidents resulting from falling rubble onto workers are a major risk in mining. To address this issue, we have launched an IoT-based helmet project to assist the industry. However, the mining sector is lagging in terms of technological progress. To bridge the gap and introduce cutting-edge IoT solutions, we have developed the concept of ‘SMART HELMETS’. These helmets provide a lifeline to workers working in the depths of the mines, acting as an essential safety measure. By incorporating cutting-edge technology in mining practices, we aim to improve worker safety and transform the mining industry. This prototype is composed of an ESP8266, an accelerometer sensor, a gas sensor, and a buzzer which can be used to detect the various dangers present in the mines.

In 2023, Harshal Ramesh Aher, Rupal Vilas Turkane, Gayatri Dattatray Varpe, Namrata Sunil Waghmare, and V. R. Aware [3] proposed the work "Mine Safety System Using IoT." The implementation of a new, innovative approach to mine safety is essential in order to increase mining profitability, reduce costs, and prioritize worker safety. This system is composed of two components: one to monitor the wellbeing of miners, and the other to monitor various environmental factors. Air pollution in mining areas is largely caused by emissions of Sulphur (SO2) oxide, nitrogen dioxide, and CO2. Smoke sensors are used to monitor the levels of these hazardous gases in the mine, with semiconductor gas sensors measuring their concentration levels. If any of the sensor readings exceed the safety threshold, a buzzer is triggered by the microcontroller, which in turn transmits the information to the Monitoring Section Module. The data collected in the Monitoring Section is then uploaded to a webpage using Internet of Things (IoT) technology. This system provides immediate responses to any potential hazards, significantly improving the safety and wellbeing of miners.

In 2022, Suwama Kama, Tanzila Noushin, and Shawana Tabassum [4] conducted a study on the IoT-based Smart Helmet, which involved automated and multi-parametric monitoring of underground miners' health hazards. Making sure workers are safe in underground mines and on construction sites has always been a top priority, but with the rise of IoT technology, it's become even more important. This study focused on creating and deploying an IoT smart helmet that would revolutionize real-time safety monitoring for miners. This smart helmet was designed with specialized body sensors that could capture all sorts of health data. The sensors worked together to wirelessly send important info to the central control room where it was quickly analyzed. The testing process showed how effective the helmet was, but it also showed how it could revolutionize safety in high-risk environments. The most important part of the solution was its immediate response mechanism. This allowed for quick reactions to potential risks, reducing them in real time. Not only did this solve a long-standing safety issue, but it showed how technology could make a huge difference in workplace safety.

This innovative smart helmet is a game-changer in the field of occupational safety, particularly in sectors such as mining and construction where time-critical responses are essential. Its capacity to address safety issues in real time, at the moment they arise, highlights the immense value of real-time tracking technologies. This innovation, which seamlessly integrates IoT capabilities, is a perfect example of what the future holds for workplace safety practices. Implementing such advanced solutions not only protects the health and safety of workers but also establishes a new benchmark for safety in hazardous work environments. Consequently, this development is likely to make a lasting impact in sectors where safety is a priority, creating environments where workers can perform their duties with greater assurance and security.

In 2022, G. Nikhil, T. Shikar, V. Manideep, and G. Radhika [5] conducted a study on developing a Coal Mine Safety System utilizing Wireless Sensor Networks and Arduino technology. The IoT Coal Mine Safety Monitoring and Alerting system solves a critical problem in the inherently hazardous mining industry: worker safety. Mining, particularly in underground settings, presents many risks, and current safety measures often fail, resulting in tragic accidents and the loss of life. This project introduces a revolutionary solution by integrating IoT technology with the help of an Arduino microcontroller. The system uses sensor modules for temperature, smoke, gas, long-range distance, humidity, and more. These sensors collect data and send it to the remote IoT server on a regular basis. If any sensor detects readings that exceed safety limits, it triggers an immediate alert. The system’s rapid response mechanism and real-time data transmission allow for quick interventions and minimize risks to miners’ lives. This project seamlessly integrates IoT capabilities to revolutionize safety protocols in the coal mines. With continuous monitoring and immediate alerts, it provides a strong safety net to protect miners’ well-being.

In 2021, Sowmya Sista Lakshmi, Ayush Dagar, Neeraj Gupta, Manjeet Kaur, and Rashmi Gupta [6] conducted research on the implementation of IoT-based technology in mining tracking and safety helmets. This study focuses on the development and implementation of a smart helmet based on Internet of Things (IoT) technology, which is designed to provide real-time health and safety monitoring of miners working in underground mines or construction sites. The helmet was designed to capture a wide range of health parameters and transmit the data wirelessly. Through rigorous testing, the effectiveness of the helmet was confirmed, demonstrating its potential to transform safety protocols in hazardous environments. The instant response mechanism of the helmet allowed for rapid responses to potential hazards. This innovation addressed long-standing safety issues and highlighted the fundamental importance of technology in improving workplace safety, particularly in industries where time-critical responses are required, such as those in mining and construction.

This smart helmet represents a fundamental shift in occupational safety practices, especially in industries where immediate responses are critical. The ability to respond to safety issues in real time demonstrates the transformative power of real-time monitoring technologies. This innovation seamlessly integrates IoT capabilities, ushering in a new era of workplace safety. Not only will it protect workers, but it will also raise the bar for safety in dangerous workplaces. As a result, this innovation is set to make a difference, creating safer work environments where workers can perform their duties with greater assurance and security.

In 2021, Druvanag P, Eaga Chandralekha, Gatla Niharika, Gavini Pranathi, and Nanda Kishore C V [7] conducted an observation focusing on issues about miners' safety. Worker safety is a top priority in the mining industry, especially in emergencies. There are a lot of hazards out there, like gases, minerals, heavy machinery, and more. Coal mines are enclosed, which means there are more risks, like ventilation issues, so safety is really important. But mining is still important for making important goods and services, and India relies heavily on it. But mining also creates some environmental risks. To make sure worker safety is taken care of, they've come up with a system called Mining Tracking and Safety. It uses RF-based technology to track workers in real time, and it's all thanks to microcontroller-based circuits in workers' helmets.

The helmets have RF transmitters and panic buttons that talk to a central microcontroller that's connected to RF receivers. This interacts with tracker RF systems so that data can be sent over the Internet of Things (IoT). By using this technology, miners can communicate more effectively with each other, which means they can respond more quickly to emergencies. Not only does this help with immediate safety concerns, but it also means they can respond faster in crises, which could save lives. Integrating these advanced solutions can help the mining industry improve worker safety protocols, reduce risks, and create a safer environment for everyone involved.

In 2020, Tarek Eldemerdash, Raed Abdulla, Vikneswary Jayapal, Chandrasekharan Nataraj, and Maythem K. Abbas [8] introduced a program designed to enhance miners' safety through the use of security helmets. The mining industry is a fundamental component of any advanced nation and is responsible for the exploitation and exploration of precious subterranean resources such as metals, metals, minerals, coal, diamonds, and more. The Internet of Things plays an essential role in this context, acting as an essential ICT technology. It enables efficient communication through the use of Wireless Sensor Networks using the IEEE 802.14.5 protocol, which powers Low Rate-WAN communication, using particular modulation techniques to facilitate the smooth exchange of data within the mining industry.

The mining industry has been able to gain access to a range of real-time monitoring capabilities through the integration of Industrial Internet of Things (IoT) technologies, as well as wireless sensor networks. This has enabled the monitoring of the movement of essential resources, the safety of personnel, and the optimization of production processes.

In 2020, Punam S. Tajane, Shrutika B. Shelke, Sonal B. Sadgir, and Archana N. Shelke [9] presented a design concept for a Miners Safety Helmet, which comprises two main segments: the Helmet Unit and the Control Unit. Mining continues to be one of the world’s most dangerous occupations, especially in areas where underground miners don’t have access to proper safety protocols and social assistance. Injuries often leave workers without help, resulting in serious social and economic hardship. The mining industry has one of the highest mortality rates in the world, with accidents such as rock falls, fire, explosions, methane poisoning, electrocution, and more being the leading causes of death. Recent research, including one from China, has highlighted the high mortality rate in underground mining and highlighted the need for improved safety protocols.

To tackle these issues, a powerful communication tech has been created to create an advanced sensing and warning system inside mines. RF technology has been chosen for its efficiency, making it easier to communicate in the mines. Safety is a top priority in the mining industry, so it's important to take the necessary steps to avoid accidents. By using cutting-edge communication tech, the industry can raise its safety standards, making sure miners are better prepared to handle the risks of their jobs.

In 2019, D. Hema [10] conducted a comprehensive observational study specifically centered on the safety concerns related to miners. The consequences of an accident involving a construction worker who does not wear a helmet are extremely serious and can lead to life-altering injuries. In these cases, the availability of emergency medical services quickly can make a significant difference in saving lives. This is why the development of the smart helmet is of paramount importance, as it can help to mitigate the devastating consequences of such accidents. The primary goal of the Smart Helmet is to ensure the safety and well-being of construction workers in their work environments by incorporating advanced features that detect potential hazards from either the workers themselves or their environment. The safety attributes included in the helmet include the detection of alcohol, the tracking of the worker's location, the monitoring of the presence of dangerous gases, the monitoring of oxygen levels, the detection of falls, and the use of an SOS feature to immediately identify an accident. Every worker is required to wear a smart helmet before beginning any work on the construction sites.

This is a proactive way to make sure that workers are wearing the necessary safety gear to reduce the risk of head injuries. The smart helmet is designed to detect various dangers that could affect worker safety. If there is an accident, the prototype will automatically trigger an alert. This alert will immediately relay important information to management about the worker’s current location. This system immediately notifies the management so that they can quickly respond to the situation and provide medical assistance or other necessary interventions. Not only does the incorporation of advanced safety features guarantee the immediate health and safety of construction workers, but it also provides a proactive approach to accident prevention.

In 2018, Rohith Revindran, Hansini Vijayaraghavan, and Mei-Yuan Huang [12] conducted a study on the implementation of Smart Helmets for Safety in the Mining Industry. The mining industry is one of the most important sectors of the global economy. Unfortunately, it is also one of the most dangerous. Miners are constantly facing life-threatening scenarios. This highlights the need for improved safety measures. This project aims to introduce cutting-edge technology to help distressed miners and provide immediate assistance in times of distress. The solution is to augment the miner’s helmet with a Wireless Sensor Mote (WSM) and essential sensors. This will create a network of connected wireless sensors. The WSN is a monitoring system that ensures the health and safety of all the working miners.

The routing protocol designed for this project works on DVR, figuring out the best way to go based on the quickest hop. It's really strong, so it can handle failures without needing to synchronize nodes. It's proactive, so you don't have to wait around for help in case of an emergency. If the force sensor on your helmet detects a load that's over a certain limit, the mote inside your helmet tries to send a distress message to your Room Manager through the route you've chosen. When the Room Manager gets the distress signal, it triggers a coordinated response. Medical teams from the central office can be sent to help the distressed miners. Neighboring miners are also notified, so they can help out if they can. In cases where your mote doesn't have a route to your Room Manager, there's a systematic failure recovery process that makes sure the distress communication system is reliable. Rigorous testing has shown that this project can help improve the safety and well-being of miners in the industry.

In 2017, Jagadeesh R and Dr R. Nagaraja [15] researched an IoT-based Smart Helmet for detecting unsafe events in the mining industry, enhancing safety protocols and minimizing risks. A new smart helmet model designed specifically for the mining industry has been developed to detect and respond to dangerous events in the mining environment. This innovative prototype has several key features that enable it to detect various dangerous situations.

- It can detect the air quality. This is extremely important in mining environments, where the presence of hazardous gases such as carbon monoxide can be a huge risk to workers’ health. The helmet uses sensors to measure saturation levels of these dangerous gases, giving real-time information on the air quality level.

- The smart helmet has an IR (Infrared) sensor, which allows it to detect when a miner removes their helmet. While this may seem like a harmless action, it can be dangerous for the miner’s safety.

- The helmet has a pressure sensor that detects when an object hits the wearer’s head. This is especially important in situations where objects fall or collide with a miner, as it can alert them to potential dangers right away.

The most important feature of this smart helmet is its automatic alert generation. In case of a dangerous accident, the system immediately sends an automated alert email to authorized personnel. The email provides important information about the miner’s situation. Automating this alert process means that response mechanisms are triggered quickly, allowing for immediate action in the event of an emergency. Integrating real-time detection with immediate notification and rapid response improves overall safety procedures in the mining industry and significantly reduces the risks miners face during their work. This cutting-edge smart helmet model is not only a game-changer for safety in the mining industry but also sets a standard for proactive safety solutions at hazardous workplaces. Combining sensors for air quality with IR technology to detect helmet removal and pressure sensors to detect impact, the system provides miners with a comprehensive safety net. The automated alert system further improves the efficiency of the whole safety process, ensuring miners are protected quickly and efficiently.

In 2016, rof. K.S. Ingle and Nisha Dube [16] released a publication titled "Intelligent Mining: A Monitoring and Security System for Coal Mine Workers" in the International Journal of Advanced Research, which introduces a pioneering approach to enhance the safety of coal mine workers. The main goal of this study is to put in place a top-notch monitoring and security system that uses wireless sensor networks. This system is designed to detect and reduce dangerous environmental factors in coal mines, like temperature changes, humidity, and the concentration of gases. Wireless sensor networks are an advanced technology that can be used to monitor different environmental conditions in real-time. By using sensors placed inside the mines, the system can keep an eye on temperature, humidity, gas levels, and more. All this data is then analyzed in real time so that workers can quickly respond to any issues or dangerous conditions. Plus, the helmet-mounted camera is a cool addition to the system - it takes pictures of the worker's environment and sends them to the main control room for detailed analysis.

The importance of this system is clear when we consider that it has the potential to significantly reduce the number of accidents in coal mines. The system provides real-time information on the environment, allowing mine operators and workers to make decisions quickly. Rapid response to hazardous situations is essential for preventing accidents and protecting the health and safety of miners. According to the authors of the paper, “Not only does our proposed monitoring & security system have the potential to minimize accidents, but it also demonstrates the potential of cutting-edge technology to improve worker safety standards in the coal industry.” By utilizing wireless sensor networks as well as the integration of a helmet-mounted camera, our system provides a complete safety net. Real-time monitoring & rapid response mechanisms are essential tools for preventing accidents and safeguarding the safety and health of miners. This research marks a significant step forward in the ongoing effort to improve safety protocols in the coal industry, demonstrating the transformational power of technology to protect lives and promote a safe work environment. In 2016, C. J. Behr, A. Kumar, and G. P. Hancke [18] conducted research on a smart helmet designed to monitor air quality and detect hazardous events within the mining industry. The smart helmet was designed to detect potential hazards in the mining sector. During the development process, we carefully considered three main types of hazards: compromised air, helmet removal and collisions (involving miners being hit by objects).

The system is designed to monitor air quality by detecting hazardous gases such as carbon monoxide (CO), SO2, nitrous oxide (NO2), particulate matter and other pollutants, thus keeping the concentration levels within acceptable limits. As for the risk of miner helmet removal, our first attempt with an internally developed IR sensor was unsuccessful. Consequently, an external IR sensor was incorporated into the helmet, which accurately determines whether the miner is securely wearing the helmet, thus providing optimal safety conditions.

In 2013, Warsha M. Choudhari [20] introduced a proposal for a Coal Mine Security System, aiming to enhance safety and security measures within coal mining operations. The coal mine security system is a key part of mining operations, keeping an eye on important things like gas, CO, temperature, and stop-switch info from the main production equipment. It helps to predict potential safety risks, so you can avoid disasters like gas and dust explosions. This system is more advanced than before, with smart digital sensors inside its control computer, which makes data acquisition more accurate. Plus, it has a powerful MATLAB platform to manage the data, so you can get a better understanding of how the mine is running. And if something goes wrong, the system has the expert system module to come up with solutions. This software plays a vital role in managing and monitoring the entire mining environment. It acts as a central point for processing and analysing the vast amount of data gathered by the system's sensors and equipment. One of its key features is the ability to transmit real-time information to your main control computer's monitoring program via RS232 communication.

This data transmission enables several critical operations, such as real-time displaying, storing, querying and printing of critical parameters related to your mine's environment conditions and the operation status of different electromechanical equipment. Offering this comprehensive approach to monitoring means that not only will you be able to identify potential risks quickly, but also have a full picture of the mine's condition, which will help you make better decisions and significantly enhance safety measures for both miners and equipment. Combining hardware and software to create a powerful and intelligent monitoring solution. Its accuracy, efficiency and proactive problem-solving capabilities help to strengthen the safety protocols in the mining industry and protect both the environment and the miners.

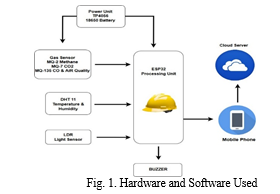

III. SMART TRACKING AND WORKER SAFETY HELMET

The proposed study introduces a cutting-edge solution for protecting underground workers through an Internet of Things (IoT) smart helmet. The helmet is equipped with various sensors to monitor important parameters such as gas levels, temperature, and humidity which are essential for miners’ safety. The transmitter segment of the smart helmet is controlled by the microcontroller and collects information from components like helmet remover detector, collision detector, and gas sensor.

In case of a dangerous situation, the helmet immediately triggers alerts using an application that is deployed across different parts of the mine. The alerts are placed strategically to cover different areas of the mine. When a dangerous situation occurs, the sensors built into the helmet (Helmet remover detector, Gas detector, and Collision detector) immediately detect and send out the relevant parameters. This is an essential safety tool as it provides real time monitoring and timely alerts. This significantly reduces risks and improves the safety protocols for underground workers working underground.

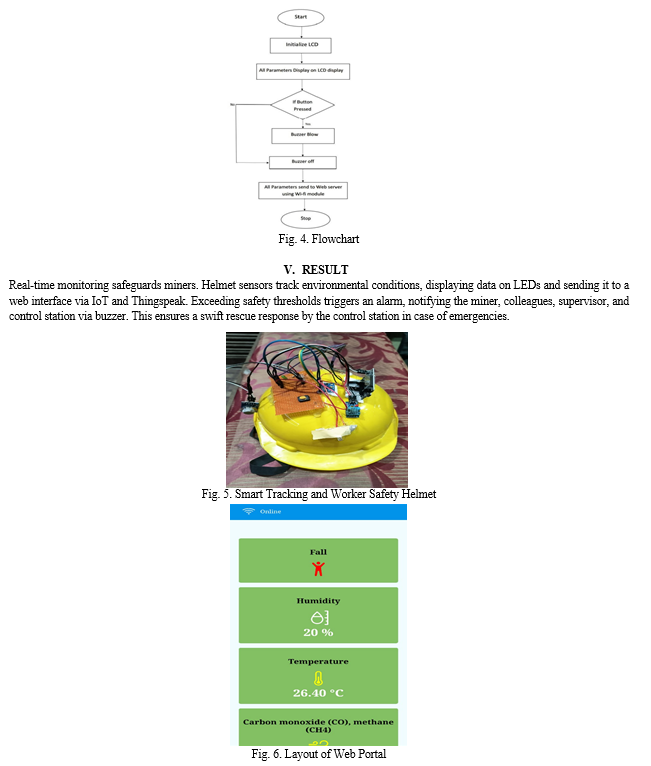

The project is structured in three distinct stages: from hardware design to software design and from there to testing, tuning and debugging. Hardware design is a critical step in the process, as it is used to evaluate the suitability of a transducer and its compatibility with the circuit scheme.

During this stage, the selection of transducer is a rigorous process, with attention paid to experimental attributes such as accuracy, precision and measurement factors, as well as its performance under various conditions. The transducer is carefully evaluated to ensure that it is compatible with the project's requirements. Hardware design serves as a basis, allowing the selected transducer to fit into the circuit framework, and the software design then takes advantage of this compatibility to ensure the project's success. The project is then thoroughly tested, tuning and debugging to refine its performance and address any issues. This thorough approach to hardware and software design ensures a strong foundation and optimal performance, ensuring the successful implementation of the project

The software design stage in this study closely follows the project’s operational flow. The software is divided into two main groups: sequence and interface. To achieve the predefined objectives of the project, these components need to work together seamlessly. Once hardware and software are integrated, there is a critical phase of testing, adjustment and troubleshooting, during which careful attention is paid to every detail. Even small design flaws can be time consuming to rectify, and often require going back to previous stages for validation. This is why testing and adjustment is essential for the success of the project. The integration between hardware and software is a critical juncture, as it requires a detailed assessment of the system’s function and performance. Every component’s interaction needs to be carefully examined to ensure smooth operation. Rigorous testing becomes a crucial part of the design process as it ensures that not only does the software follow the study’s operating flow but also performs flawlessly to meet the approved goals of the project.

The expected outcomes of the proposed work are outlined below:

- Reduced Risks of Mining Incidents: The objective of the project is to reduce the incidence of mining incidents and fatalities through real-time monitoring and emergency response. The system’s capacity to rapidly respond to emergency situations and provide location information can avert or reduce hazardous occurrences.

- Enhanced Safety Culture: Mining companies can promote a safe and responsible workplace culture through the implementation of this cutting-edge safety system. Miners will be assured that their health and safety is a priority, which can result in improved job satisfaction and productivity.

- Emergency Alerts: The IOT web interface displays an emergency signal when a worker presses the panic/emergency button on their helmet. This alerts supervisors and authorities to any critical situations, allowing them to take prompt action to reduce risks and provide assistance.

- Compliance and Reporting: The system is capable of producing comprehensive reports on the movement of workers, emergency occurrences, and safety requirements. The reports can be utilised for regulatory compliance and safety audits, as well as incident investigations, thereby increasing transparency and accountability in the mining sector.

IV. WORKING

An IoT-based worker safety helmet utilizes a network of sensors and wireless communication to create a real-time monitoring system for miners. Here's a breakdown of its operation:

A. The Gear

- Smart Helmet: This helmet houses various components:

- Microcontroller: The central processing unit, managing data and communication.

- Sensors: These monitor critical aspects of the environment and worker well-being. Examples include:

- Gas sensors to detect harmful gases like methane or carbon monoxide.

- Temperature and humidity sensors for monitoring air quality.

- Helmet removal detector to identify if the helmet is taken off in a hazardous zone.

- Collision detector to sense impacts that might injure the worker.

4. Wireless module: This transmits data between the helmet and the control center (e.g., Bluetooth, Wi-Fi).

5. Panic/Emergency Button: A readily accessible button for workers to trigger an emergency signal in case of danger.

6. Power Source: A battery or potentially a self-charging mechanism to ensure continuous operation.

B. The Network

- Central Hub/Control Center: This receives data transmitted from all worker helmets.

- Communication Network: This network carries data between the helmets and the control center (e.g., dedicated network within the mine or existing cellular data).

C. The Process

- Continuous Monitoring: The sensors in the helmet constantly gather data on environmental conditions (gas levels, temperature, humidity) and worker actions (helmet removal, potential collisions).

- Data Transmission: The microcontroller processes the sensor data and transmits it wirelessly to the central hub through the communication network.

- Real-time Monitoring: The control center receives and displays data from all helmets, allowing supervisors to monitor worker locations (if GPS enabled) and environmental conditions.

- Alerts and Response:

- If a sensor detects a dangerous situation (high gas levels, impact), an alarm is triggered in the control center, and the specific worker's location is identified.

- Emergency response protocols are initiated, notifying relevant personnel and potentially even external emergency services.

- In case of a panic button press (if equipped), an immediate emergency signal is sent, prompting a swift response.

Overall, the system creates a connected network for real-time monitoring, immediate emergency response, and data-driven safety improvements in hazardous work environments.

VI. FUTURE SCOPE

In upcoming iterations, this prototype holds promise for advancing current models in identifying diverse hazardous conditions, including the presence of carbon monoxide gases and exhalation in mining zones. Moreover, by integrating sensors such as pressure and IR sensors, this model can be further refined. Furthermore, improvements to the system can be achieved by adjusting signal strength and ranges, and by incorporating equipment to monitor workers' heartbeat and blood pressure.

Conclusion

This project showcases a new mine safety helmet designed to detect various hazardous events. Utilizing a Wi-Fi module and leveraging the power of IoT (Internet of Things), the helmet monitors and transmits crucial data to a base station PC. A. Enhanced Safety Features 1) Gas Detection: Sensors alert miners and supervisors when dangerous gas levels (CO, SO2, NO2, and particulate matter) reach pre-set limits, helping prevent exposure. 2) Environmental Monitoring: Sensors track humidity, temperature, and even the miner\'s location via GPS, providing a comprehensive picture of the work environment. 3) Helmet Removal Detection: An infrared sensor ensures miners wear their helmets in hazardous zones, triggering an alarm if removed. 4) Low Light Warning: The system detects low light levels and alerts miners through a buzzer, promoting better visibility and reducing trip hazards.

References

[1] K. L. Sandaruwan and B. Hettige, \"A Comparative Study on Smart Helmet Systems for Mining Tracking and Worker Safety in the Mining Industry: A Review,\" presented at the KDU FOC Student Symposium, General Sir John Kotelawala Defence University, Rathmalana, Sri Lanka, 28 February 2023. [2] P. Kunekar et al., \"IoT based Smart Security Helmet for Miner’s Safety,\" 2023 5th Biennial International Conference on Nascent Technologies in Engineering (ICNTE), Navi Mumbai, India, 2023, pp. 1-5, doi: 10.1109/ICNTE56631.2023.10146728. [3] A. H. Ramesh, R. V. Turkane, G. D. Varpe, N. S. Waghmare, and V. R. Aware, \"A Review on Mine Safety System Using IoT,\" Innovative Journal for Opportunities and Development in Science & Technology, vol. 3, no. 2, March 2023, Paper ID: IJ2023V3I2-4A-E, ISSN 2582-6026, http://www.ijodst.com/. [4] S. Kama, T. Noushin and S. Tabassum, \"IoT based Smart Helmet for Automated and Multi-parametric Monitoring of Underground Miners’ Health Hazards,\" 2022 IEEE 15th Dallas Circuit and System Conference (DCAS), Dallas, TX, USA, 2022, pp. 1-2, doi: 10.1109/DCAS53974.2022.9845621. [5] G. Nikhil, T. Shikar, V. Manideep, and G. Radhika, \"Coal Mine Safety System Using Wireless Sensor Networks and Arduino,\" International Journal of Innovative Research in Technology, vol. 9, no. 1, June 2022. [6] S. S. Lakshmi, A. Dagar, N. Gupta, M. Kaur, and R. Gupta, \"A Technical Review on IoT Based Mining Tracking and Safety Helmet,\" International Journal of Innovative Research in Computer Science & Technology (IJIRCST), vol. 9, issue 4, pp. 44-47, July 2021. [Online]. Available: https://doi.org/10.21276/ijircst.2021.9.4.11 [7] Druvanag P, Eaga Chandralekha, Gatla Niharika, Gavini Pranathi, and Nanda Kishore, \"IOT Mining Tracking & Worker Safety Helmet,\" International Journal for Research in Applied Science & Engineering Technology (IJRASET), vol. 9, issue 5, May 2021. [Online]. Available: www.ijraset.com [8] T. Eldemerdash, R. Abdulla, V. Jayapal, C. Nataraj, and M. K. Abbas, \"IoT Based Smart Helmet for Mining Industry Application,\" International Journal of Advanced Science and Technology, vol. 29, no. 1, pp. 373-387, 2020. ISSN: 2005-4238. [9] P. S. Tajane, S. B. Shelke, S. B. Sadgir, and A. N. Shelke, \"IoT Mining Tracking & Worker Safety Helmet,\" International Research Journal of Engineering and Technology (IRJET), vol. 07, no. 04, pp. 5587, Apr 2020. e-ISSN: 2395-0056, p-ISSN: 2395-0072. [Online]. Available: www.irjet.net [10] Hema, D. (2019). Smart Helmet for Industrial Workforce - A Review Paper. International Journal for Research in Applied Science and Engineering Technology. [11] Jesudoss, A., Vybhavi, R. and Anusha, B., 2019, April. Design of smart helmet for accident avoidance. In 2019 International Conference on Communication and Signal Processing (ICCSP) (pp. 0774-0778). IEEE. [12] R. Revindran, H. Vijayaraghavan and M. -Y. Huang, \"Smart Helmets for Safety in Mining Industry,\" 2018 International Conference on Advances in Computing, Communications and Informatics (ICACCI), Bangalore, India, 2018, pp. 217-221, doi: 10.1109/ICACCI.2018.8554698. [13] Jeong, M., Lee, H., Bae, M., Shin, D.B., Lim, S.H. and Lee, K.B., 2018, October. Development and application of the smart helmet for disaster and safety. In 2018 International Conference on Information and Communication Technology Convergence (ICTC) (pp. 1084-1089). IEEE. [14] Ghulam E Mustafa Abro, Shoaib Ahmed Shaikh, “PROTOTYPING IOT BASED SMART WEARABLE JACKET DESIGN FOR SECURING THE LIFE OF COAL MINERS”2018 International Conference on Computing, Electronics & Communications Engineering (iCCECE) [15] Jagadeesh R and R. Nagaraja, \"IoT based Smart Helmet for unsafe event detection for mining industry,\" International Research Journal of Engineering and Technology (IRJET), vol. 04, no. 01, pp. 1487, Jan 2017. e-ISSN: 2395-0056, p-ISSN: 2395-0072. [Online]. Available: www.irjet.net [16] Prof. K.S.Ingle 1, Nisha Dube 2 PG Student, Dept. of ECE “Intelligent Mining: A Monitoring and Security System for Coal Mine Workers”, International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering (An ISO 3297: 2007 Certified Organization) Vol. 5, Issue 1, January 2016. [17] Gaidhane, Mahendra Dhame and Prof. Rizwana Qureshi “SMART HELMET FOR COAL MINERS USING ZIGBEE TECHNOLOGY” Imperial Journal of Interdisciplinary Research (IJIR) Vol-2, Issue-6, 2016 ISSN: 2454-1362 [18] C. J. Behr, A. Kumar and G. P. Hancke, \"A smart helmet for air quality and hazardous event detection for the mining industry,\" 2016 IEEE International Conference on Industrial Technology (ICIT), Taipei, Taiwan, 2016, pp. 2026-2031, doi: 10.1109/ICIT.2016.7475079. [19] Yongping Wu, Guo Feng, Zhang Meng,”THE STUDY ON COAL MINE USING THE BLUETOOTH WIRELESS TRANSMISSION” 2014 IEEE Workshop on Electronics, Computer and Applications. [20] Warsha M.Choudhari Professor, Datta Meghe, “Coal Mine Security System ” International Journal of Applied Information Systems (IJAIS) – ISSN : 2249- 0868 Foundation of Computer Science FCS, New York, USA Volume 4– No.10, December 2013. [21] Jiya Tian, Juan Zhu, “POSITIONING SYSTEM FOR MINERS BASED ON RFID” 2011 International Conference on Multimedia Technology [22] CHENG Qiang, SUN Ji-ping, ZHANG Zhe, ZHANG Fan “ZIGBEE BASED INTELLIGENT HELMET FOR COAL MINERS” World Congress on Computer Science and Information Engineering 2009 [23] Ghaith Bader Al-Suwaidi, Mohamed Jamal Zemerly, “LOCATING FRIENDS AND FAMILY USING MOBILE PHONES WITH GLOBAL POSITIONING SYSTEM (GPS),” IEEE/ACS International Conference on Computer Systems and Applications, 2009. [24] D. Kock and J. W. Oberholzer, THE DEVELOPMENT AND APPLICATION OF ELECTRONIC TECHNOLOGY TO INCREASE HEALTH, SAFETY, and productivity in the South African coal mining industry,” IEEE Trans. on Industry Applications, vol. 33, no 1997.

Copyright

Copyright © 2024 Anand Vishwakarma , Animesh Yash, Anshika Singh , Divyanshu Awasthi, Ranjeeta Yadav. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62778

Publish Date : 2024-05-26

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online