Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Laboratory Studies on Strength Properties of Concrete using Fly Ash and GGBS

Authors: Suchita Wali, Dr Praveen Kumar P

DOI Link: https://doi.org/10.22214/ijraset.2024.62398

Certificate: View Certificate

Abstract

Cement, fine aggregate, coarse aggregate, and water are the basic raw materials used in the manufacture of concrete. The naturally available aggregates are very precious and need to be conserved. Waste materials such as fly ash and Ground Granulated Blast Furnace Slag (GGBS) which cause disposal problems, and environmental problems can be economically used as a partial replacement for both fine and coarse aggregate. The present research focuses on conducting laboratory studies on the properties of M30 grade concrete by replacing fine and coarse aggregate with fly ash and GGBS. The results show that the optimum percentage of partial replacement of fly ash and GGBS is 30% for both fine and coarse aggregate. The compressive strength of concrete increased by 15% and 24%, respectively, and the tensile strength of concrete nearly increased by 20% in both cases. In addition, the use of waste material helps to reduce the cost of construction while simultaneously solving the disposal and environmental pollution problems.

Introduction

I. INTRODUCTION

In the civil engineering construction field, concrete is the most extensively used materials and it has a wide range of applications. Concrete is used globally to build buildings, bridges, roads, runways, sidewalks, and dams. In India, a developing country, the rate of construction is increasing rapidly. Due to such increased construction, there is a huge demand for cement, in particular Ordinary Portland cement (OPC). However, the rate of manufacture of OPC has decreased due to the limited availability of raw materials like limestone. Since there is a possibility of an acute shortage of natural aggregates in the future, we can explore the use of industrial wastes as an alternative to natural aggregates for concrete production. The production of cement releases greenhouse gas emissions both directly and indirectly: heating limestone releases CO2 directly, while burning fossil fuels to heat the kiln indirectly results in carbon dioxide emissions.

Similarly, India has numerous industries in the areas of hydropower, steel, etc., which produce hundreds and millions tonnes of waste materials every year. The disposal of these materials is a challenging task and causes environmental problems. These materials can be economically used in concrete as a partial replacement for both fine and coarse aggregate. This helps in the preservation of natural resources, and in addition, it reduces the cost of construction.

II. OBJECTIVES OF THE PRESENT RESEARCH

The following are the main objectives of the present research:

- To conduct the basic tests on materials used for concrete, such as fine aggregate, coarse aggregate, and cement as per the code standards.

- To find the optimum percentage of partial replacement of Fly ash and GGBS as fine aggregate and coarse aggregate.

- To design M30 grade concrete as per IS 10262-2019 code provisions.

- To conduct compressive strength and tensile strength tests on the cast concrete specimens.

- Comparison of results.

III. LITERATURE REVIEW

- Sharma R K et al: This study investigates the strength properties of concrete incorporating fly ash and GGBS as partial replacements for cement. Various mix proportions were tested, and compressive strength, split tensile strength, and flexural strength were evaluated. The results indicate that the combination of fly ash and GGBS positively influences the strength of concrete.

- Gupta A, et al: his study investigates the mechanical properties of high-strength concrete incorporating fly ash and GGBS. The effects of various replacement levels on compressive strength, modulus of elasticity, and abrasion resistance were evaluated. The results reveal that the use of fly ash and GGBS enhances the mechanical properties of high-strength concrete.

- Sivapriya V, et al: his study investigates the influence of curing regimes on the properties of concrete containing fly ash and GGBS. Different curing conditions, including water curing, steam curing, and ambient curing, were employed, and compressive strength, permeability, and microstructure were evaluated. The results indicate that proper curing enhances the performance of concrete with fly ash and GGBS.

- Al-AKhras et al: This study presents an economic analysis of concrete containing fly ash and GGBS as partial replacements for cement. Cost-benefit analysis and life cycle cost assessment were performed to evaluate the economic feasibility. The findings indicate that the use of fly ash and GGBS in concrete offers cost savings and economic benefits.

- Wong H, et al: This research presents a microstructural analysis of concrete incorporating fly ash and GGBS using scanning electron microscopy (SEM). The effects of various replacement levels on the hydration products and pore structure were examined. The results reveal significant improvements in microstructure with the addition of fly ash and GGBS.

- Tang W C, et al: This study investigates the influence of temperature exposure on the properties of concrete containing fly ash and GGBS. Thermal conductivity, thermal expansion, and mechanical properties were evaluated under different temperature conditions. The results indicate that the use of fly ash and GGBS mitigates the adverse effects of temperature on concrete.

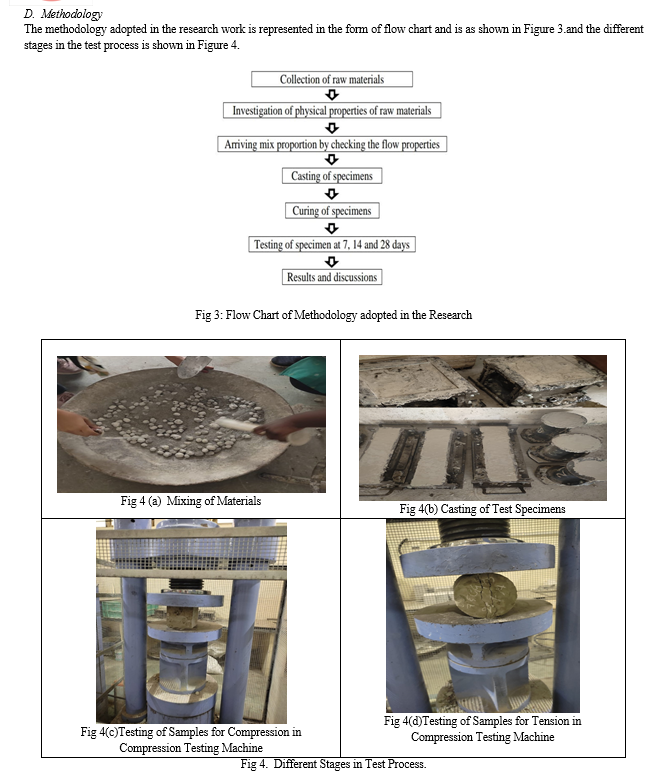

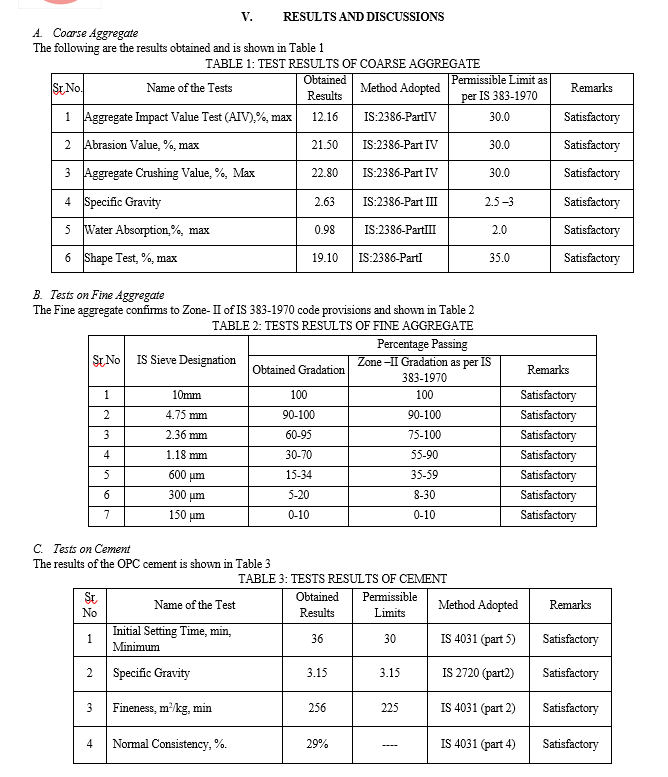

IV. MATERIALS AND METHODOLOGY

A. Materials

The materials used in the present research are

- Natural Fine Aggregate

- Natural Coarse Aggregate

- Cement

- Fly ash

- Coarse Aggregate.

The natural fine and coarse aggregate are obtained from the local quarry and Ordinary Portland cement (OPC) of 53 grade was used in the research.

B. Fly Ash

Fly ash is a by product from thermal power plants. In modern coal-fired power plants, fly ash is generally captured by electrostatic precipitators or other particle filtration equipment before the flue gases reach the chimneys. Depending upon the source and composition of the coal being burned, the components of fly ash vary considerably, but all fly ash includes substantial amounts of silicon dioxide (SiO2) (both amorphous and crystalline), aluminium oxide (Al2O3) and calcium oxide (CaO), the main mineral compounds in coal-bearing rock strata.

The minor constituents of fly ash depend upon the specific coal bed composition but may include one or more of the following elements or compounds found in trace concentrations (up to hundreds ppm): arsenic, beryllium, boron, cadmium, chromium, hexavalent chromium, cobalt, lead, manganese, mercury, molybdenum, selenium, strontium, thallium, and vanadium, along with very small concentrations of dioxins and PAH compounds. It also has unburnt carbon. In the past, fly ash was generally released into the atmosphere, but air pollution control standards now require that it be captured prior to release by fitting pollution control equipment. Fly ash is generally stored at coal power plants or placed in landfills. About 43% is recycled, often used as a pozzolana to produce hydraulic cement or hydraulic plaster and am replacement or partial replacement for Portland cement in concrete production.

Two classes of fly ash are defined by ASTM C618: Class F fly ash and Class C fly ash. The chief difference between these classes is the amount of calcium, silica, alumina, and iron content in the ash. The chemical properties of the fly ash are largely influenced by the chemical content of the coal burned (i.e., anthracite, bituminous, and lignite). The form of fly ash in the form of fine aggregate is shown in Figure1.

???????C. Ground Granulated Blast Furnace Slag (GGBS)

Ground Granulated Blast Furnace Slag (GGBS) is a by product of the iron and steel industry, formed during the production of pig iron in blast furnaces. It is obtained by quenching molten slag from the blast furnace with water, which results in rapid cooling, granulation, and formation of glassy granules. GGBS is then ground to a fine powder, enhancing its reactivity and cementations properties.

- GGBS is widely used as a supplementary cementation material (SCM) in concrete production due to its numerous beneficial characteristics:

- High Compressive Strength: GGBS improves the compressive strength of concrete over time, making it ideal for structural applications.

- Durability Enhancement: It enhances concrete durability by reducing permeability, increasing resistance to chloride ingress, sulphate attack, and alkali-silica reaction (ASR), thus extending the lifespan of structures.

- Workability: GGBS improves the workability of concrete, allowing for easier handling, placement, and compaction during construction.

- Reduced Heat of Hydration: Its slower hydration rate compared to Portland cement reduces the heat generated during concrete curing, minimizing the risk of thermal cracking.

- Environmental Benefits: GGBS reduces carbon dioxide emissions associated with concrete production by substituting a portion of Portland cement, thereby contributing to sustainable construction practices.

- Economic Advantages: While initially, GGBS may incur higher costs than Portland cement, its long-term benefits in terms of durability and reduced maintenance expenses often outweigh the initial investment.

Overall, GGBS is commonly used in various concrete applications such as high-performance concrete, marine structures, bridges, roads, and mass concrete works. Its widespread adoption not only improves the performance and longevity of concrete structures but also promotes sustainable development by utilizing industrial by products effectively. The GGBS in the form of coarse aggregate is shown in Figure 2.

???????

???????

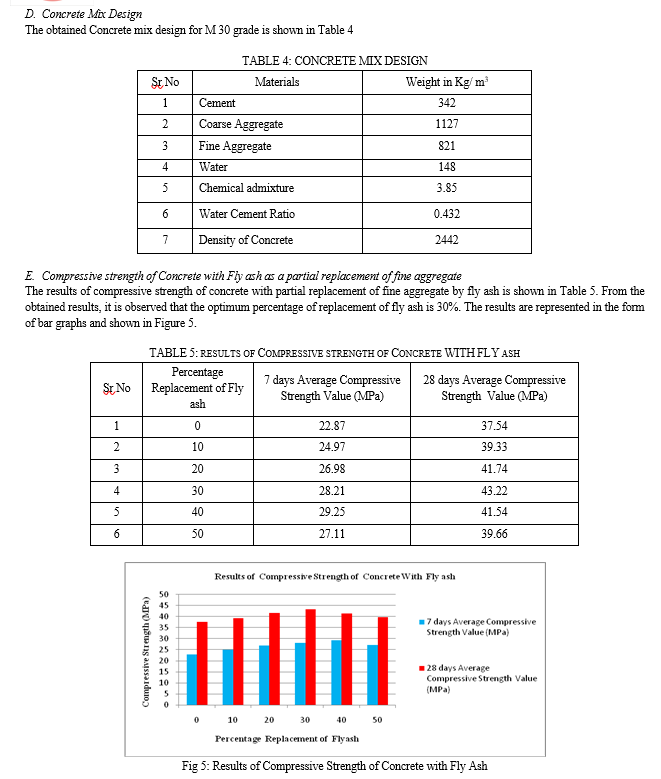

Conclusion

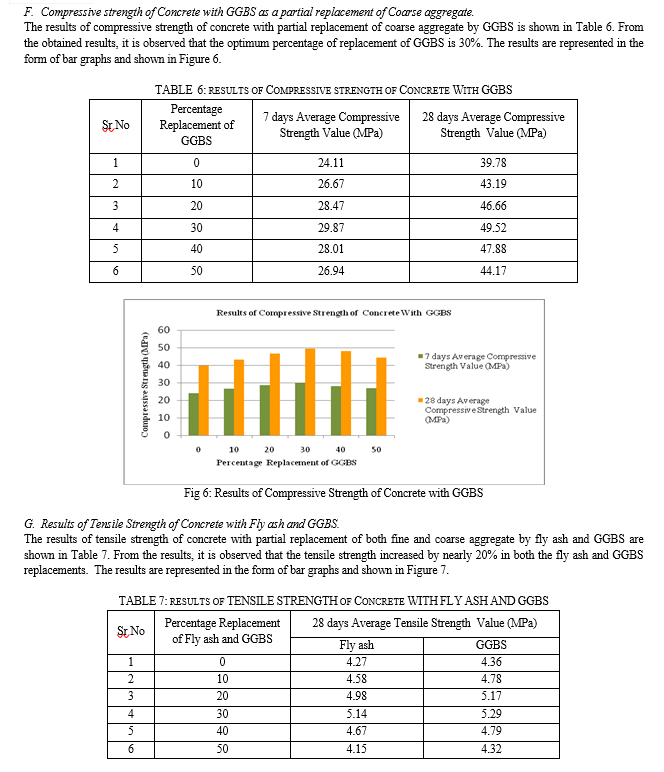

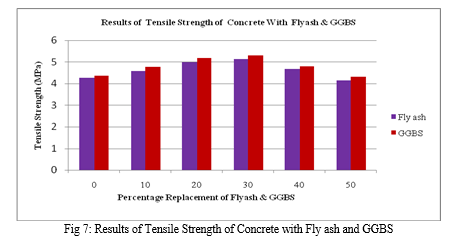

1) The materials used in the present research, namely coarse aggregate, fine aggregate, and cement, satisfy the relevant code specifications. 2) The Mix design for M30 grade concrete is obtained to meet the requirements of Indian Standard (IS) 10262-2019. 3) The compression test results meet the minimum values of strength as per the code requirement. The optimum percentage replacement of both Fly ash and GGBS was obtained at 30%. 4) The 30% replacement of fine aggregate with fly ash and coarse aggregate with GGBS increased the compressive strength of M30 grade concrete by 24.0% and 30%, respectively. 5) The 30% replacement of fine aggregate with fly ash and coarse aggregate with GGBS increased the tensile strength of M30 grade concrete by 20% in both cases. In summary, the research explored the viability of using fly ash and GGBS as a partial replacement for both fine aggregate and coarse aggregate in concrete in an effort to improve the building material\'s sustainability and performance. The use of waste materials in place of conventional materials also reduces the cost of concrete and in turn, the cost of construction. From material characteristics and mix design to testing and analysis of the resulting concrete, the study comprised a comprehensive investigation of numerous aspects. In addition, it demonstrated the prospective advantages, such as environmental sustainability, enhanced concrete properties, and potential cost savings.

References

[1] Sharma, R.K., Kumar, A., & Bhattacharyya, S.K. (2018). \"Strength Characteristics of Concrete with Partial Replacement of Cement by Fly Ash and GGBS.\" International Journal of Engineering and Technology, 7(2), 386-389. [2] Gupta, A., Reddy, S.R., & Rao, P.S. (2017). \"Durability Performance of Concrete with Partial Replacement of Cement by Fly Ash and GGBS.\" Construction and Building Materials, 153, 148-156. [3] Sivapriya, V., & Jayakumar, M. (2019). \"Sustainability Assessment of Concrete Incorporating Fly Ash and GGBS.\" Journal of Cleaner Production, 207, 582-590. [4] Al-Akhras, N.M., & Hasan, M.I. (2019). \"Economic Analysis of Concrete Incorporating Fly Ash and GGBS.\" Journal of Construction Engineering and Management, 145(9), 04019071. [5] Wong, H., & Tan, K.H. (2017). \"Microstructural Analysis of Concrete with Fly Ash and GGBS Using SEM.\" Construction and Building Materials, 152, 144-153. [6] Tang, W.C., & Tam, C.M. (2018). \"Influence of Temperature on Properties of Concrete Incorporating Fly Ash and GGBS.\" Construction and Building Materials, 187, 663-671. [7] Indian Standards IS 12269, Ordinary Portland Cement 53 Grade-Specification, First Revision, Bureau of Indian Standard, New Delhi, India, 2013. [8] Indian Standards IS 10262, Concrete Mix Proportioning-Guidelines, First Revision, Bureau of Indian Standard, New Delhi, India, 2019. [9] Indian Standards IS 2386 (Part-I), Method of Tests for aggregates for Concrete-Particle Size and shape, Bureau of Indian Standard, New Delhi, India, 1963. [10] Indian Standards IS 2386 (Part-III), Method of Tests for aggregates for Concrete-Specific Gravity, Density, Voids, Absorption and Bulking, Bureau of Indian Standard, New Delhi, India, 1963. [11] Indian Standards IS 2386 (Part-IV), Method of Tests for aggregates for concrete- Mechanical Properties, Bureau of Indian Standard, New Delhi, India, 1963.

Copyright

Copyright © 2024 Suchita Wali, Dr Praveen Kumar P. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62398

Publish Date : 2024-05-20

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online