Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Load Behaviour of Steel Beam with Opening using Finite Element Approach

Authors: Sandeep M. Shiyekar, Shrikrushna S. Gawade, Harsh K. Rathore, Rohan D. Hendre, Vishal M. Solanke

DOI Link: https://doi.org/10.22214/ijraset.2024.62766

Certificate: View Certificate

Abstract

This project investigates the structural behaviour of castellated steel beams through a combination of Finite Element Analysis (FEA) and software investigation. Castellated beams, known for their web openings, offer improved structural performance with reduced weight. The study focuses on the deflection patterns of these beams under various loading conditions. ANSYS software was used to model and analyse the beams, both with and without stiffeners around the openings. The results indicate that the incorporation of stiffeners significantly enhances the beams\' strength and reduces deflection, optimizing material usage without compromising structural integrity. The strategic placement of stiffeners led to a substantial reduction in steel volume, demonstrating an efficient design approach that balances weight reduction and strength. This work underscores the importance of FEA in optimizing structural designs, providing valuable insights into the behaviour of castellated beams and promoting innovative solutions for industrial applications. The findings contribute to the broader understanding of steel beam behaviour under different loading conditions, highlighting the effectiveness of stiffeners in enhancing performance and efficiency in structural engineering

Introduction

I. INTRODUCTION

The concept of castellated beams has evolved significantly since its inception during the Industrial Revolution, driven by the need for more efficient and economical structural systems. Castellated beams are created by cutting slots along the web of an I-beam and welding additional steel plates, which increases their load-bearing capacity without significantly adding weight. This design innovation has proven invaluable in modern construction, addressing complex architectural and engineering challenges. Recent advancements in manufacturing technologies, such as computer-controlled cutting and welding, have further refined the production of castellated beams, enhancing their precision and expanding their applicability. These beams are widely utilized in contemporary construction projects due to their material efficiency and the ability to integrate utilities within their structure, thus optimizing space and reducing costs. In contemporary construction, castellated beams are favoured for their ability to span large distances with minimal material usage, thus optimizing both cost and structural performance. The integration of web openings allows for the passage of utilities such as electrical conduits, plumbing, and HVAC systems, further enhancing their utility in modern building designs. This paper investigates the structural behaviour of castellated steel beams using a combination of finite element analysis (FEA) and software investigation. The primary focus is on understanding how web openings influence the beams' deflection patterns. A key aspect of this research is the evaluation of beams with and without stiffeners around the web openings. Stiffeners are additional steel plates welded around the openings to enhance the beam's strength and reduce deflection. The study aims to determine the effectiveness of these stiffeners in improving the structural integrity of castellated beams. Through detailed modelling and simulation using ANSYS software, this study examines both unreinforced and reinforced beams, specifically evaluating the impact of stiffeners around the openings. The findings from this research provide critical insights into the optimization of castellated beam designs, balancing material usage with structural integrity. This study aims to contribute to the broader field of structural engineering by offering innovative solutions for enhancing the performance and efficiency of steel beams in various construction applications.

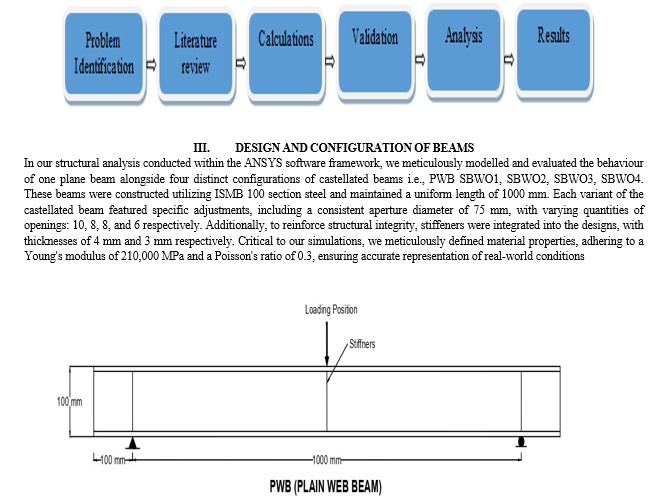

II. OBJECTIVES AND METHODOLOGY

A. jectives

- Analyse Structural Behaviour

- Evaluate the Impact of Web Openings

- Assess the Role of Stiffeners

- Finite Element Modelling

- Optimize Beam Design

- Provide Practical Recommendations

- Cost Efficiency

B. Methodology

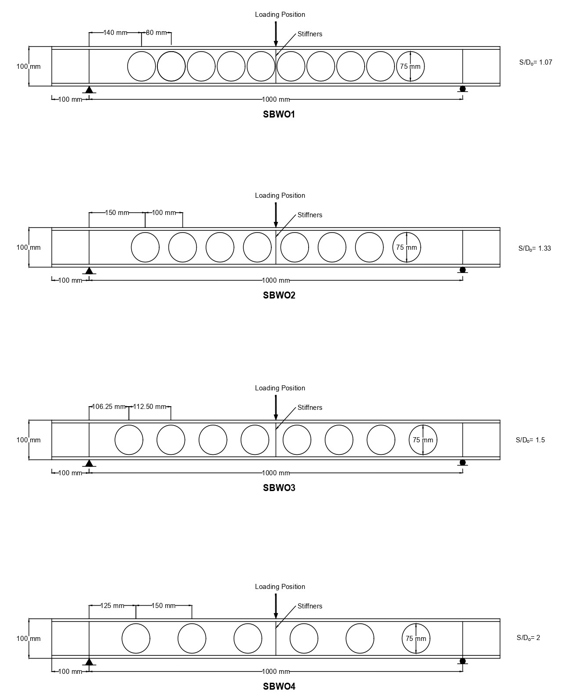

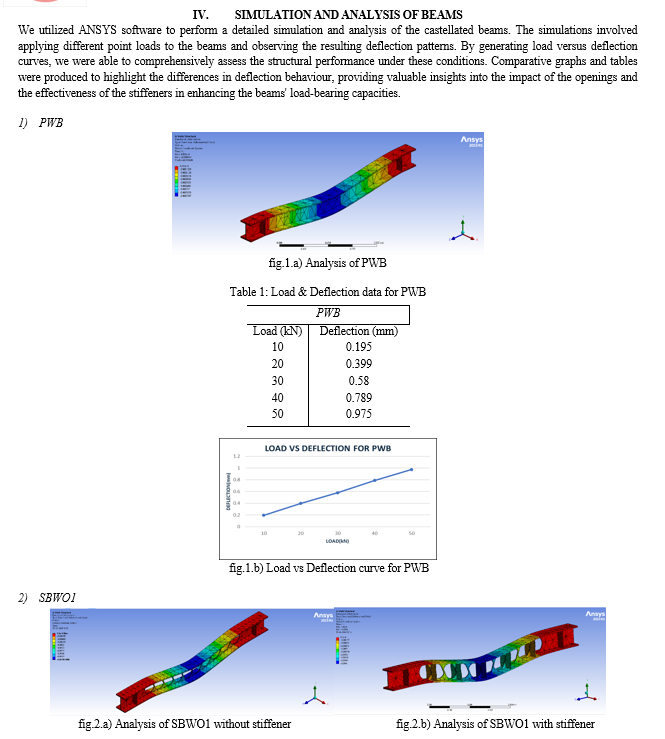

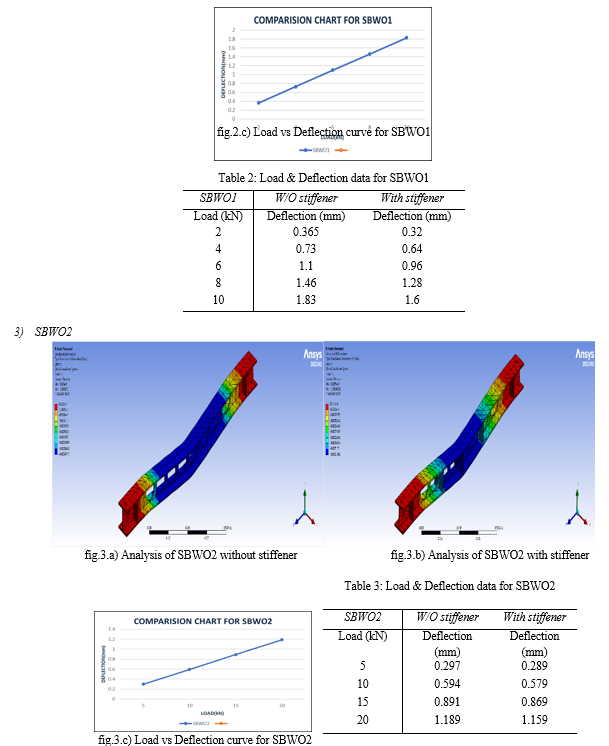

We investigated the deflection patterns of castellated beams using finite element analysis (FEA) in ANSYS software. We fabricated four beams with different numbers of 75mm diameter openings, incorporating stiffeners to enhance load-bearing capacity while reducing material usage. The stiffeners, with a lower volume than the removed material, resulted in a net reduction in steel volume. We subjected the beams to varying loads and documented the deflection patterns, generating load versus deflection curves. The finite element method was used to simulate the beams under different conditions, highlighting the impact of stiffeners on deflection. To ensure accuracy, we validated our simulations through a two-tiered process involving manual calculations based on structural mechanics and equations from the theory of elasticity, followed by comparison with ANSYS results. This validation confirmed the reliability of our simulations, providing a robust foundation for our analysis.

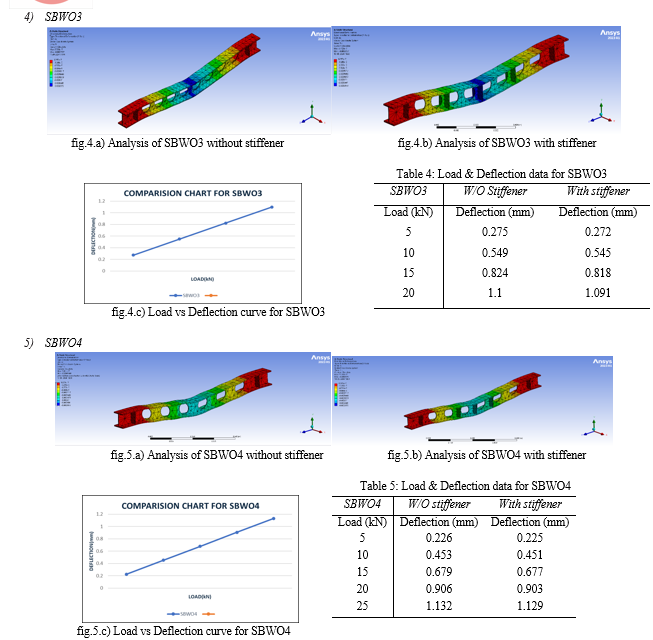

V. RESULTS

The analysis showed that while changes in the spacing of the openings had a minor effect on deflection, increasing the number of openings led to larger deflections. However, the incorporation of stiffeners effectively mitigated this increased deflection, demonstrating their importance in maintaining structural integrity. Additionally, the optimization approach of using stiffeners resulted in a significant reduction in material usage. These findings underscore the potential for cost savings and enhanced structural performance in large-scale construction projects by strategically employing castellated beams with stiffeners. The details of findings are provided below.

- Optimization of quantity of steel

To minimize material usage, we fabricated four castellated beams with varying numbers of 75mm diameter openings, reducing overall beam weight while maintaining strength. We incorporated stiffeners within these openings, designed to have a lower volume than the removed steel, achieving a net reduction in material while enhancing load-bearing capacity. Table 5 shows the decrease in steel volume used across all beams.

Table 6: Percentage of volume saved in each Beam

|

Beam No. |

No. of openings |

No. of Stiffeners |

Volume removed |

Volume Added |

% of volume saved |

|

SBWO1 |

10 |

5 |

176714.59 |

91164 |

48.41 |

|

SBWO2 |

8 |

3 |

141371.67 |

72931.20 |

48.41 |

|

SBWO3 |

8 |

3 |

141371.67 |

72931.20 |

48.41 |

|

SBWO4 |

6 |

3 |

106028.75 |

72931.20 |

31.22 |

2. Observations from deflection patterns

Our analysis revealed that spacing variations in the openings had a minimal impact on deflection patterns. However, increasing the number of openings led to larger deflections. The incorporation of stiffeners effectively reduced these deflections, demonstrating their importance in enhancing structural integrity.

Table 7: Percentage decrease in deflection at highest load analysed

|

Beam No. |

No. of openings |

No. of Stiffeners |

Max. deflection with stiffener |

Max. deflection without stiffener |

% decrease in deflection |

|

SBWO1 |

10 |

5 |

1.6 |

1.83 |

12.57 |

|

SBWO2 |

8 |

3 |

1.159 |

1.189 |

2.52 |

|

SBWO3 |

8 |

3 |

1.091 |

1.1 |

0.82 |

|

SBWO4 |

6 |

3 |

1.129 |

1.132 |

0.27 |

3. Observations for self-weight

The incorporation of stiffeners in the openings of castellated beams reduced self-weight while maintaining strength, as the stiffeners had a lower mass than the removed material. Comparative analyses with plain beams confirmed a reduction in steel usage across all four beams, highlighting our innovative design and material efficiency. Table 7 details the percentage of weight reduction for each beam, underscoring our commitment to sustainable construction techniques.

Table 8: Percentage decrease in weight

|

Beam No. |

No. of openings |

No. of Stiffeners |

Volume of beam (mm3) |

Weight of beam (kg) |

% weight reduced |

|

PWB |

- |

- |

1755500 |

13.78 |

- |

|

SBWO1 |

10 |

5 |

1669950 |

13.11 |

4.87 |

|

SBWO2 |

8 |

3 |

1687060 |

13.24 |

3.90 |

|

SBWO3 |

8 |

3 |

1687060 |

13.24 |

3.90 |

|

SBWO4 |

6 |

3 |

1722403 |

13.52 |

1.89 |

4. Cost Considerations

The reduction in weight, as demonstrated, directly correlates with decreased material requirements, offering substantial cost efficiencies across various infrastructural projects. Our small-scale model analysis revealed an average weight reduction of 4%, which holds significant implications for cost savings, especially in large-scale construction projects characterized by numerous and sizable beams.

With larger beams and a greater quantity of such beams, the cumulative impact of even a modest weight reduction becomes magnified, leading to considerable monetary savings. These savings extend beyond material costs to include transportation, handling, and installation expenses, significantly amplifying the economic benefits of our optimized beam design. By reducing the self-weight of the beams, we not only lower the material costs but also reduce the logistical and labour costs associated with moving, positioning, and securing the beams in place. This comprehensive approach to cost-saving makes our design particularly advantageous for large-scale and resource-intensive construction projects, where efficiency and sustainability are paramount.

Conclusion

This research has significantly advanced our understanding of the structural behaviour of castellated steel beams with web openings, specifically focusing on the role of stiffeners in enhancing performance. Through a comprehensive approach combining experimental investigation and finite element analysis (FEA) using ANSYS software, we have elucidated several critical findings: 1) Structural Performance and Deflection Patterns: The study demonstrated that the incorporation of stiffeners around web openings markedly improves the structural integrity of castellated beams. Beams with stiffeners exhibited significantly reduced deflections under various loading conditions compared to those without stiffeners. For instance, Beam SBWO1 with 10 openings and 5 stiffeners showed a 12.57% decrease in deflection, highlighting the stiffeners\' effectiveness in enhancing rigidity and load-bearing capacity. 2) Material Efficiency and Weight Reduction: The strategic placement of stiffeners led to a notable reduction in the overall weight of the beams. The stiffeners were designed to occupy less volume than the material removed to create the openings, resulting in a net decrease in steel usage. This optimization was quantified with SBWO1 achieving a 48.41% reduction in volume. This not only reduces material costs but also lowers transportation and handling expenses, offering substantial economic benefits for large-scale construction projects. 3) Cost Efficiency: The reduction in beam weight directly correlates with decreased material costs, providing significant cost efficiencies. The research indicated an average weight reduction of 4%, which, when extrapolated to large-scale construction projects, could lead to considerable monetary savings. These savings extend beyond material costs to include logistical and Labor costs associated with the transportation and installation of the beams. 4) Validation and Practical Implications: The FEA results were validated through a rigorous two-tiered process involving manual calculations based on structural mechanics and theoretical elasticity equations. This validation confirmed the accuracy of the ANSYS simulations, ensuring the reliability of our findings. The practical implications of this research are substantial, providing valuable insights for the design and optimization of steel beams in modern construction, particularly in terms of integrating utilities and reducing material usage without compromising structural integrity. 5) Innovative Design Solutions: This study underscores the importance of innovative design solutions in structural engineering. The incorporation of web openings allows for the passage of utilities, optimizing space and reducing overall construction costs. The findings from this research contribute to the broader field of structural engineering by offering a balanced approach to material efficiency and structural performance, making castellated beams with stiffeners a viable and cost-effective option for contemporary construction projects. In conclusion, this research has provided a robust framework for understanding and optimizing the design of castellated steel beams. The insights gained from this study highlight the effectiveness of stiffeners in enhancing beam performance, promoting material efficiency, and achieving cost savings. These contributions are invaluable for advancing structural engineering practices and addressing the evolving demands of modern construction.

References

[1] Samadhan G. Morkhade and Laxmikant M. Gupta, “Experimental investigation for failure analysis of steel beams with web openings”. [2] Samadhan. G. Morkhade & L. M. Gupta, “Ultimate load behavior of steel beams with web openings”. [3] Laxmikant M. Gupta, Ph.D. And Carlos Humberto Martins, Ph.D., “Effect of Web Post Width on Strength Capacity of Steel Beams with Web Openings: Experimental and Analytical Investigation” [4] Samadhan G. Morkhade Rutuja S. Lokhande, Umesh D. Gundal, Ajinkya B. Divate, Saurav S. Deosarkar, Mrunmayi U. Chavan, “Structural behaviour of castellated steel beams with reinforced web openings”. [5] Rujuta A. Bhat, Laxmikant M. Gupta, “Interaction of Buckling Modes for Cellular Steel Beams Under Flexure”. [6] Ferhat Erdal, Mehmet Polat Saka “Ultimate load carrying capacity of optimally designed steel cellular beams”. [7] Konstantinos-Daniel Tsavdaridis, Cedric D’Mello, “Web Buckling Study of the Behaviour and Strength of Perforated Steel Beams with Different Novel Web Opening Shapes” [8] Samadhan G. Morkhade, Manisha Kshirsagar, Radhika Dange, Apurva Patil, “Analytical study of effect of web opening on flexural behaviour of hybrid beams” [9] S.A.L. de Andrade, Luciano Rodrigues Ornelas de Lima, Pedro Cg da s Vellascos, Flavio Rodrigues, “Finite Element Modelling of Steel Beams with Web Openings”

Copyright

Copyright © 2024 Sandeep M. Shiyekar, Shrikrushna S. Gawade, Harsh K. Rathore, Rohan D. Hendre, Vishal M. Solanke. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62766

Publish Date : 2024-05-26

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online