Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Load-Bot- Automatic System for Goods Loading and Unloading

Authors: Shruthi B S, Swetha A, Vibhavi R N, Shravya S

DOI Link: https://doi.org/10.22214/ijraset.2024.58010

Certificate: View Certificate

Abstract

The transportation of goods from one point to multiple other points can be carried out manually or automatically using load-bot. In the manual method, human labour is required to load and unload the goods, as well as operate the vehicle to transport them. In contrast, the automatic method involves the use of robotic or autonomous systems to handle the loading and unloading of goods and to drive the vehicle to the desired destinations. Both manual and automatic load-carrying vehicles have their advantages and disadvantages. Manual transportation may be more cost-effective in some cases, particularly for small-scale operations, while automatic transportation offers greater efficiency and speed, particularly for larger operations or those involving heavy loads. Additionally, automatic transportation reduces the need for human labour, potentially improving safety and reducing labour costs. The choice between manual and automatic load-carrying vehicles will depend on factors such as the size of the operation, the nature of the goods being transported, the available resources, and the desired level of efficiency and automation.

Introduction

I. INTRODUCTION

Robots are regarded as the most advanced kind of technology today and have significantly improved a number of industries, including education, the military, and more. They are mechanical or virtual agents that have been programmed to carry out functions autonomously or partially autonomously. They can be used for a variety of tasks, including industrial automation, scientific research, household duties, and entertainment.

Automatic delivery robots, sometimes referred to as autonomous delivery robots or delivery drones, are a particular kind of robot made to move objects from one place to another without the assistance of a person. These robots can sense their surroundings, plan routes, and safely navigate a variety of environments since they are outfitted with sensors, cameras, and navigational systems.

Depending on the environment and the intended delivery type, delivery robots can take various shapes, such as wheeled robots or drones. They usually run on electric motors and use cutting-edge algorithms and artificial intelligence to decide what to do and avoid impediments. While some delivery robots are made for indoor locations or even airborne deliveries, others are built to work on sidewalks.

A load-carrying vehicle called a load-bot is made to move loads of cargo both manually and automatically from one place to many other locations. It is designed to be flexible enough to accommodate a variety of items and load sizes while streamlining and automating the transportation process.

Several industries, including manufacturing, warehousing, logistics, and transportation, find uses for load-bot. It has automation systems, ultrasonic and infrared sensors, and other cutting-edge sensors that let it to move across both interior and outdoor areas. Depending on the preferred mode of operation, the vehicle may be driven manually or automatically. It has the capacity to be adjusted in order to handle various types of cargo, including boxes, pallets, and other load needs. Ultrasonic technology ensures a cost-effective solution.

II. LITERATURE REVIEW

Ashish Verma, Gaurav Mishra, and Ajay Kumar Verma in their research paper - Design and Implementation of a Smart Trolley discusses the development of a smart trolley for material handling in industries. The smart trolley created for this project is intended to move materials from one place to another while navigating an industrial setting. The trolley has sensors and controllers for automatic navigation, but it also has a human control option for emergency situations.[1]

Muhammed Shafi, Amr Elshafiey, and Omar Elsayed in their research paper Development of a low-cost autonomous mobile robot for indoor transportation The robot created for this project is intended to move objects from one place to another while navigating inside spaces on its own. The robot's many parts, including a Raspberry Pi, DC motors, motor drivers, ultrasonic sensors, and an IMU sensor are all described in the paper.[2]

Ritesh Kumar Dubey, Kalyan Kumar Naskar, and Pritam Karmakar -Design and fabrication of a solar-powered autonomous vehicle for smart agriculture, describes the development of a solar-powered autonomous vehicle for smart agriculture. A microcontroller, motor drivers, solar panel, battery, and a number of sensors, including GPS, temperature, humidity, and soil moisture sensors, are among the different parts used in the vehicle. Additionally, the vehicle has a water pump for irrigation and a camera for image processing. The design and construction of the vehicle, including the material choices and component production processes, are also covered in the article.[3]

S. R. Ozcelik and M. S. Karaatli, describes a comprehensive review of the various technologies and systems that can be used for smart material handling, with a focus on their potential benefits and drawback in their paper A review on smart material handling systems. The study discusses a number of areas of intelligent material handling, including conveyor systems, robotics, automated guided vehicles (AGVs), and warehouse management systems. It gives a summary of each system's essential characteristics and draws attention to its advantages, including possible gains in productivity, labour savings, and safety.[4]

Design and development of an autonomous material handling vehicle for industrial applications:- is a research paper written by P. Praveen Kumar, P. Arun, and R. Raghavendra,. The paper presents the design and development of an autonomous material handling vehicle (AMHV) for industrial applications. The study discusses a number of areas of intelligent material handling, including conveyor systems, robotics, automated guided vehicles (AGVs), and warehouse management systems. It gives a summary of each system's essential characteristics and draws attention to its advantages, including possible gains in productivity, labour savings, and safety.[5]

III. DESIGN

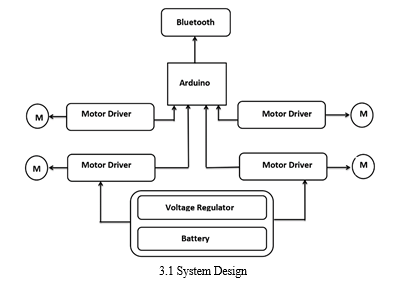

The fundamental element that regulates the Load-bot's movement and behaviour is the Arduino board, which is one of the project's main components and shows how they are connected.

The H-bridge regulates the direction and speed of the motors, which are the Load-bot's main method of propulsion. Data about the distance, load weight, and obstacles in the Load-bot's path are provided by the ultrasonic and infrared sensors.

The Bluetooth module makes it possible for the Load-bot to communicate with a distant device, like a smartphone or tablet.

The battery life, obstacle distance, and status of the Load-bot are all displayed on the LCD screen.

Power Supply is a part of the Load-bot project that powers the other parts. In the Load-bot project, the DC motor is utilized to provide the vehicle's primary means of movement.

IV. IMPLEMENTATION

The process of making a new or updated system design operational is known as implementation. So, it can be said that this is the stage of developing a successful new system, and it's important to give users trust that the new system being suggested won't ever cause problems and will work as intended. If the implementation is not well thought out and managed, anarchy may result.

A. Modules of the Project

A software application's or system's user interface (UI) is the visually appealing and interactive portion that enables user interaction. It consists of the look, feel, and controls that users interact with and see on their screens. The user interface (UI) acts as a conduit between the user and the system, enabling input of commands, system navigation, and output or feedback for users. A Bluetooth terminal is incorporated as part of the user interface for controlling and monitoring the Load-Bot. The Bluetooth terminal allows for wireless communication between a mobile device or computer and the Load-Bot, enabling remote control and real-time status updates.

The implementation of the Bluetooth terminal involves the following key aspects:

- Bluetooth Connectivity: Bluetooth modules are integrated into both the Load-Bot and the mobile device or computer. The Load-Bot is configured as a Bluetooth peripheral device, while the mobile device or computer acts as a Bluetooth central device. This enables them to connect wirelessly and converse with one another.

- Command Interpretation: The Load-Bot's software is configured to understand the instructions sent from the Bluetooth terminal. It comprehends the instructions and carries them out by travelling in a particular route, changing its speed, or starting a delivery process, among other things. Real-Time Feedback: The Load-Bot communicates with the Bluetooth terminal in real-time by sending status updates, sensor readings, or other pertinent information. This enables users to keep track of the Load-Bot's location, battery life, ability to identify obstacles, and any other data required for efficient control and operation.

The implementation of a Bluetooth terminal enhances the usability and flexibility of the Load-Bot, as it enables remote control and monitoring without the need for physical connection or proximity. It provides convenience and ease of use for operators, allowing them to control the Load-Bot from a distance and receive real-time updates on its performance.

B. Modes of Implementations

- Manual Mode

For direct operator control of the Load-Bot in our project, we've added a manual mode. In the manual mode, the Load-Bot can be controlled and moved precisely using manual input devices such joysticks, buttons, or a remote control.

The following essential components are crucial to the manual mode's implementation:

a. Input Devices: We've built joysticks and buttons into the Load-Bot's control system as input devices. These gadgets offer manual control inputs for the Load-Bot's movement, speed, and direction. The control logic of the Load-Bot's software is intended to decipher the signals from the input devices and translate them into the appropriate motor commands. Control logic issues commands to the motor control system, which then modifies the motor's speed and direction in accordance. This enables the Load-Bot to go forward, backward, left or right, or halt depending on the operator's manual inputs.

b. Safety Procedures: are put into place in the manual mode to avoid any potential risks.

c. User Interface: A user interface, such as a control panel device, is often used to access the manual mode. Indicating the current mode, speed, battery level, and any other pertinent details for manual control, the user interface gives the operator unambiguous directions and feedback.

The use of the manual mode gives users complete control over how the Load-Bot moves and behaves. It enables flexibility and precise movement when traveling through difficult or complicated environments. The manual mode provides flexibility and user control in the operation of the Load-Bot, making it a useful feature in situations when personal intervention or fine control is necessary.

2. Automatic Mode

The Load-Bot can be controlled automatically in this mode to follow specified paths. The automatic predefined path mode enables the Load-Bot to independently go along a predefined route, following a series of predetermined waypoints or checkpoints.

The following crucial elements are involved in the automatic predetermined path mode's implementation:

a. Path Planning: To choose the best path or route for the Load-Bot to take, a path planning algorithm or approach is used. This method takes into account things like avoiding obstacles, finding the shortest path, or particular environmental limitations

b. Waypoint Navigation: Using waypoint navigation, the Load-Bot's software may move between waypoints along a predetermined course. In order to achieve precise positioning and trajectory tracking, it makes use of sensors and control algorithms. In order to follow the preset path, the Load-Bot modifies its movement and direction in response to feedback from sensors like encoders or GPS.

c. Obstacle Detection and Avoidance: The Load-Bot is fitted with obstacle detection sensors, such as ultrasonic or infrared sensors, to ensure safe navigation. These sensors continuously monitor the area to look for potential collisions or impediments. The software of the Load-Bot uses obstacle avoidance algorithms to navigate around obstacles and modify its course as necessary.

d. Real-Time path Correction: While following the predetermined course, the Load-Bot's software continuously assesses its position and contrasts it with the predetermined waypoints. The Load-Bot's software performs the required changes to correct the path and guarantee accurate navigation if there are any deviations or faults in the path execution.

e. Feedback and Reporting: The Load-Bot's software gives feedback and keeps track of how well the path is being followed. Information on the current waypoint, the distance to the next waypoint, the anticipated time of arrival, or any potential problems discovered throughout the navigation process may be included in this feedback. It allows operators to keep an eye on and follow the Load-Bot's progress in real time.

The automatic predefined path mode's installation enables the Load-Bot to travel independently along predetermined paths, minimizing the need for human interaction and boosting operational effectiveness. The automatic predefined path mode expands and streamlines the capabilities of the Load-Bot, boosting output and freeing up operator resources for more crucial tasks.

V. EXPERIMENTAL RESULTS

We have created a load-carrying vehicle that can securely and effectively move huge loads from one path to several others. The main input given are rotor speeds, most control laws control combinations of commanded rotor speeds. The movement of drone is captured by live video streaming in web interface and drone can be controlled by transmitter The Load-bot's movement and behaviour are mostly managed by the Arduino board. The motors, which are the Load-bot's main method of propulsion, are directed and speeded by the H-bridge. The distance, weight of the load, and any obstructions in the Load-bot's path are all determined by the ultrasonic and IR sensors. The Load-bot can communicate with a distant device, like a smartphone or tablet, thanks to the Bluetooth module. The Load-bot's status, battery life, and obstacle distance are all displayed on the LCD screen. The Load-bot project's power supply component powers the other components. In the Load-bot project, the DC motor serves as the main source of propulsion for the machine. It is managed, through the Arduino.

Conclusion

We have created a load-carrying vehicle that can securely and effectively move huge loads from one path to several others. The vehicle is able to effortlessly navigate twists, corners, and obstacles while navigating tight places and uneven terrain. It includes simple manual controls that make it possible for the operator to steer the vehicle smoothly and effectively. Additionally, it includes safety features like sensors to recognize obstructions and avoid collisions that safeguard the operator and stop mishaps. It is also built for automatic operation, allowing it to travel along a predetermined route and discharge the load several times without the need for human input.

References

[1] Ashish Verma, Gaurav Mishra, and Ajay Kumar Verma Design and Implementation of a Smart Trolley For Material Handling International Journal of Scientific and Research Publications in 2017. [2] Muhammed Shafi, Amr Elshafiey, and Omar Elsayed Development of a low-cost autonomous mobile robot for indoor transportation, Journal of Intelligent & Robotic Systems in 2020. [3] Ritesh Kumar Dubey, Kalyan Kumar Naskar, and Pritam Karmaka - Design and fabrication of a solar-powered autonomous vehicle for smart agriculture Journal of Renewable and Sustainable Energy Reviews in 2020. [4] S. R. Ozcelik and M. S. Karaatli, A review on smart material handling systems in the journal of Procedia Manufacturing in 2018. [5] P. Praveen Kumar, P. Arun, and R. Raghavendra, Design and development of an autonomous material handling vehicle for industrial applications in the journal of Procedia Technology in 2016 [6] ArkaSain, JanardanDattani and Dhara M Mehta, “Design and Implementation of Wireless Control of Pick and Place Robot Arm”, International Journal of Advanced Research in Engineering and Technology (IJARET), p-ISSN: 0976-6480 and e-ISSN: 0976-6499, Volume 9, Issue 3, May – June 2018. [7] M.J.Sawarkar, TruptiR.Raut, Nutan P. Nemad, Sonal C. Meshram, Pournima P. Tabhane, Pick and Place Robotic Arm Using Android Device”, International Research Journal of Engineering and Technology (IRJET), e-ISSN: 2395-0056 and p-ISSN: 2395-0072, Volume: 04, Issue: 03, Mar-2017.

Copyright

Copyright © 2024 Shruthi B S, Swetha A, Vibhavi R N, Shravya S. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET58010

Publish Date : 2024-01-12

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online