Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- References

- Copyright

Measurement of Blast Induced Ground Vibration using Arduino based SW-420 Vibration Sensor their Comparison with the Existing Vibration Monitoring Instrument

Authors: Pankaj Kumar Mahto, Dr. Sunil Kumar Singh

DOI Link: https://doi.org/10.22214/ijraset.2024.62813

Certificate: View Certificate

Abstract

When blasting is exposed to vibration or shock, those can be damaged partially or fully depending on the vibration energy. Therefore, quantitative analysis of blasting vibration has become popular among researchers. In this research, vibration sensor was developed. The SW-420 vibration sensor, manufactured by Scriptronics, is utilized in the context of monitoring seismic activities generated by mines blasts. Mines, whether for extraction or demolition purposes, often produce significant vibrations that can pose risks to nearby infrastructure, environment, and personnel safety. The SW-420 sensor provides a compact and sensitive solution for detecting these vibrations in real-time. In mining operations, precise monitoring of blast-induced vibrations is crucial for ensuring the safety of workers, nearby communities, and structures. The SW-420 vibration sensor is designed to detect and measure these vibrations accurately. Its compact size and robust construction make it suitable for deployment in harsh mining environments. The sensor operates on the principle of a spring-based switch mechanism. When subjected to vibrations exceeding a predetermined threshold, the sensor triggers an electrical signal, indicating the occurrence of a vibration event. This signal can be transmitted to a monitoring station where it is analyzed to assess the intensity and impact of the blast. Integration of SW-420 sensors into a comprehensive monitoring system allows mine operators to: 1) Monitor blast-induced vibrations in real-time. 2) Set customizable thresholds for triggering alarms or safety protocols. 3) Collect data for analysis to optimize blast design and mitigate potential risks. 4) Ensure compliance with regulatory standards regarding vibration levels.

Introduction

I. INTRODUCTION

In the mining industry, safety is paramount, and monitoring potential hazards such as blasts is crucial for preventing accidents and ensuring worker well-being. One essential tool for this purpose is the SW-420 vibration sensor, manufactured by Scriptronics. These innovative sensors are specifically design to detect vibrations, making it invaluable in mining operations where blasts are common occurrences.

A. Overview of SW-420 Vibration Sensor

- Purpose-built Design: The SW-420 sensor is engineered to detect even the slightest vibrations, providing early warning of potentially hazardous conditions resulting from blasts in mining environments.

- Sensitivity: With high sensitivity, the SW-420 can pick up vibrations across a wide range of frequencies, allowing for early detection of blasts and other seismic events.

- Robust Construction: Recognizing the harsh conditions present in mining operations, Scriptronics has designed the SW-420 sensor to be rugged and durable, capable of withstanding the demanding environments commonly found in mines.

- Ease of Installation: The sensor is designed for easy integration into existing monitoring systems, allowing mining operators to quickly deploy it in critical areas without significant downtime.

- Real-time Monitoring: By providing real-time data on vibration levels, the SW-420 enables mining operators to take immediate action in response to detected blasts, such as initiating safety protocols or evacuations if necessary.

- Compatibility: The SW-420 sensor is compatible with various data logging and monitoring systems commonly used in the mining industry, ensuring seamless integration into existing infrastructure.

- Cost-effective Solution: Despite its advanced capabilities, the SW-420 sensor offers a cost-effective solution for blast monitoring, helping mining companies enhance safety measures without breaking the budget.

B. Benefits of Using SW-420 Vibration Sensor

- Enhanced Safety: By detecting blasts promptly, the SW-420 sensor helps minimize the risk of accidents and injuries to workers in mining operations.

- Preventive Maintenance: Early detection of vibrations can also aid in identifying potential equipment failures or structural weaknesses, allowing for proactive maintenance to prevent costly downtime.

- Regulatory Compliance: Many mining operations are subject to strict regulations regarding safety and environmental protection. By using the SW-420 sensor, companies can demonstrate compliance with these regulations and avoid fines or penalties.

- Peace of Mind: With the SW-420 sensor in place, mining operators can have peace of mind knowing that they have a reliable system in place to monitor blasts and other seismic activities, safeguarding both personnel and assets.

II. LITERATURE SURVEY

|

YEAR |

TITLE |

AUTHOR NAME |

TECHNIQUE USED |

|

2016 |

Low-Cost Plate-Type MOEMS Uniaxial Vibration Sensor Based on Metal Etching and Fiber Collimator Technique |

Jing Wang |

One novel low-cost plate-type MOEMS uniaxial vibration sensor based on metal etching and fiber collimator technique is proposed and studied in this paper. |

|

2014 |

Power Modulation-Based Optical Sensor for High-Sensitivity Vibration Measurements |

Kevin Chen |

An intensity modulation-based curved waveguide sensor is developed in this paper for vibration measurements.

|

|

2019 |

A Novel Miniaturized Fiber Bragg Grating Vibration Sensor

|

LingLing Yu |

A novel miniaturized fiber Bragg grating (FBG) vibration sensor is proposed |

|

2012 |

Present Situation and Prospects of Vibration Sensors |

Xiao Long Rong |

Vibration measurement has become an important method in mechanical structural product's research, design, produce, apply and maintenance.

|

|

2015 |

A Low-Frequency Resonant Electromagnetic Vibration Energy Harvester Employing the Halbach Arrays for Intelligent Wireless Sensor Networks |

Hin Liu |

An electromagnetic (EM) vibration energy harvester (VEH) employing the Halbach arrays magnetic circuits to convert a low-frequency vibration energy into an electrical energy is presented |

III. MOTIVATION AND OBJECTIVE

The objective of measuring blast-induced ground vibration using an Arduino-based SW-420 vibration sensor and comparing it with existing vibration monitoring instruments can be multifaceted:

- Accuracy Evaluation: One objective could be to assess the accuracy and reliability of the Arduino-based SW-420 vibration sensor in capturing blast-induced ground vibrations compared to established monitoring instruments. This involves analyzing whether the sensor can provide measurements that are consistent and comparable to those obtained from traditional monitoring devices.

- Cost-Effectiveness: Another objective might be to evaluate the cost-effectiveness of using the Arduino-based sensor for this purpose. This involves comparing the cost of the sensor and associated Arduino setup with that of conventional vibration monitoring instruments. If the Arduino-based solution proves to be significantly more cost-effective without compromising accuracy, it could be a viable alternative for certain applications.

- Ease of Deployment and Maintenance: Assessing the ease of deployment and maintenance of the Arduino-based system compared to existing instruments could be another objective. This includes factors such as setup complexity, calibration requirements, data retrieval and processing, and overall system reliability over time.

- Data Analysis and Interpretation: Analyzing the data collected from both the Arduino-based sensor and existing instruments to understand the characteristics of blast-induced ground vibrations is a crucial objective. This involves examining parameters such as vibration amplitude, frequency spectrum, duration, and their variations under different blasting conditions.

- Performance Comparison: Finally, the comparison aims to determine whether the Arduino-based system can provide comparable or even superior performance in terms of accuracy, reliability, and cost-effectiveness compared to traditional vibration monitoring instruments.

As for motivation, this project addresses several important aspects:

a. Technological Advancement: It explores the potential of using modern, low-cost hardware like Arduino-based sensors for specialized applications traditionally dominated by expensive monitoring equipment.

b. Accessibility: By potentially offering a more affordable solution, it could make ground vibration monitoring more accessible to smaller organizations or projects with limited budgets.

c. Educational Value: For students and educators, working on such a project provides hands-on experience with sensor technology, data acquisition, analysis, and comparison, enhancing their skills and understanding in these areas.

d. Environmental Impact: Understanding blast-induced ground vibrations is critical for assessing their impact on nearby structures, the environment, and human safety. Improved monitoring can lead to better mitigation strategies and reduced environmental impact from blasting activities.

Top of Form

IV. THEORY OF SW-420 VIBRATION SENSOR

To measure blast-induced ground vibration using an Arduino-based SW-420 vibration sensor and compare it with existing vibration monitoring instruments, you need to follow these steps:

A. Learn about the principles of blast-induced ground vibration, including its causes, propagation, and effects on structures and the environment.

B. Sensor Selection

Choose the SW-420 vibration sensor for your Arduino-based system. Understand its specifications, such as sensitivity, frequency range, and output format.

C. Arduino Setup

Set up your Arduino board with the necessary components, including the SW-420 sensor and any additional circuitry required for power and signal conditioning.

D. Calibration

Calibrate your SW-420 sensor to ensure accurate measurements. This may involve determining its sensitivity and adjusting any scaling factors in your Arduino code.

E. Data Acquisition

Develop code for your Arduino board to read data from the SW-420 sensor. This code should include sampling techniques, data storage, and possibly real-time monitoring capabilities.

F. Field Testing

Conduct field tests where blasts are induced. Place your sensor at strategic locations to capture ground vibrations accurately.

G. Data Analysis

Analyze the data collected by your Arduino-based system. Calculate parameters such as peak particle velocity (PPV), frequency content, and duration of vibration events.

H. Comparison with Existing Instruments

Obtain data from existing vibration monitoring instruments used in similar scenarios.

Compare the results obtained from your Arduino-based system with those from the existing instruments. Look for correlations, differences in accuracy, and any limitations or advantages of each method.

I. Documentation and Reporting

Document your methodology, including sensor specifications, calibration procedures, data acquisition techniques, and analysis methods.

Prepare a report or presentation detailing your findings, including the comparison between the Arduino-based system and existing instruments. Discuss the strengths and weaknesses of each approach and make recommendations for future improvements or applications.

This process involves a combination of theoretical understanding, practical implementation, data analysis, and critical evaluation of results. It's essential to ensure the accuracy and reliability of your measurements and interpretations when comparing many measurement systems.

V. PROBLEMS

When measuring blast-induced ground vibration using an Arduino-based SW-420 vibration sensor and comparing it with existing vibration monitoring instruments, you might encounter several challenges:

- Sensor Calibration: Ensuring the SW-420 sensor is accurately calibrated can be tricky. Factors such as temperature variations and sensor aging can affect calibration over time, leading to measurement inaccuracies.

- Signal Processing: Processing raw vibration data from the sensor may require advanced signal processing techniques to extract meaningful information such as peak particle velocity (PPV) and frequency content.

- Noise Interference: External noise sources, including electrical interference and environmental vibrations unrelated to the blast, can introduce noise into your measurements, affecting data accuracy.

- Data Synchronization: If you're comparing data from multiple sensors or instruments, synchronizing the data timestamps can be challenging but is crucial for meaningful comparisons.

- Field Conditions: Field testing in real blast environments introduces practical challenges such as sensor placement, weather conditions, and safety considerations.

- Instrument Limitations: Existing vibration monitoring instruments may have limitations in terms of their frequency range, sensitivity, or data resolution, which can impact the accuracy of comparisons.

- Data Analysis Complexity: Analyzing and interpreting vibration data, especially from multiple sources, requires expertise in data analysis techniques and statistical methods to draw valid conclusions.

- Reporting and Documentation: Documenting your methodology, including sensor specifications, calibration procedures, and data analysis techniques, is essential for making the result transparency and reproducibility.

To address these challenges, consider some of the following strategies:

- Conduct thorough sensor calibration and quality checks before field testing.

- Implement noise filtering and signal processing algorithms in your Arduino code to improve data quality.

- Use synchronized time-stamping methods for data collection from multiple sensors or instruments.

- Perform comprehensive data validation and statistical analysis to account for uncertainties and variability.

- Collaborate with experts in signal processing and data analysis for complex data interpretation.

- Document your procedures, challenges faced, and solutions implemented in your final report or presentation.

By addressing these challenges proactively and employing rigorous methodologies, you can enhance the reliability and validity of your measurement and comparison efforts.

VI. METHODOLOGY

To measure blast-induced ground vibration using an Arduino-based SW-420 vibration sensor and compare it with existing vibration monitoring instruments, you can follow these steps:

A. ose the Arduino-based SW-420 vibration sensor for your project. Ensure it's compatible with your Arduino board and capable of detecting the range of vibrations you expect from the blasting activities.

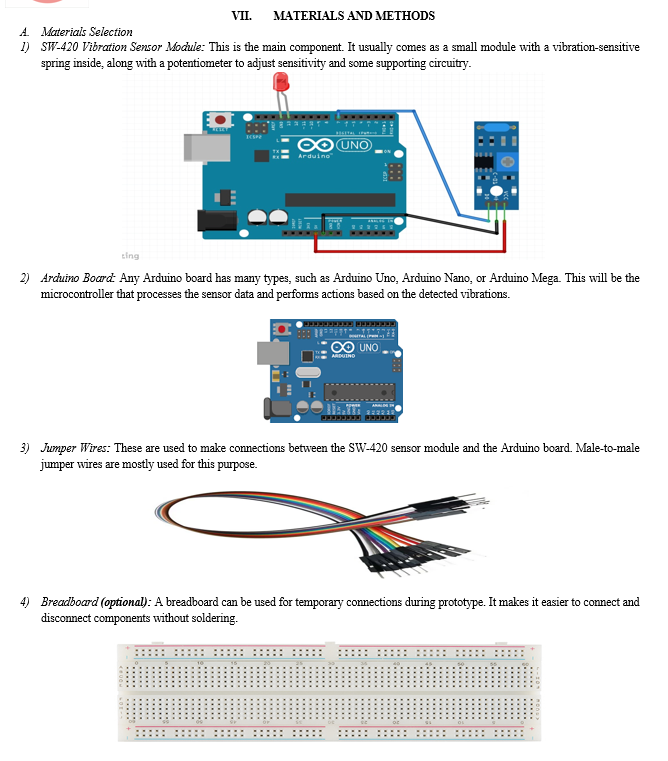

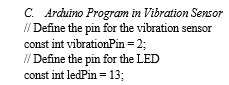

B. Setting Up Arduino and Sensor

Connect the SW-420 sensor to your Arduino board according to its datasheet or pinout instructions.

Write a program (using Arduino IDE or any compatible software) to initialize the sensor and read vibration data from it.

C. Calibration

Calibrate your SW-420 sensor to ensure accurate readings. This may involve setting thresholds for what constitutes a vibration event of interest and what is background noise.

D. Data Collection

Place the sensor at the desired location where you want to measure blast-induced ground vibration.

Run your Arduino program to start collecting vibration data during blasting activities.

E. Data Analysis

Collect data from the SW-420 sensor during blasting events and store it in a suitable format (e.g., CSV files).

Use data analysis tools (Python, MATLAB, Excel, etc.) to process and analyze the collected data. Calculate parameters such as peak acceleration, frequency spectrum, and duration of vibrations.

F. Comparison with Existing Instruments

Obtain data from existing vibration monitoring instruments used in your field or location.

Compare the data collected from the SW-420 sensor with data from these instruments. Look for correlations, discrepancies, and any differences in measurement accuracy or sensitivity.

G. Evaluation and Validation

Evaluate the performance of the SW-420 sensor by comparing its measurements with those of established instruments.

Validate the sensor's accuracy, precision, and reliability for blast-induced ground vibration monitoring applications.

H. Reporting and Conclusions

Document your methodology, including sensor setup, calibration procedures, data collection, analysis techniques, and comparison results.

Draw conclusions about the effectiveness and suitability of the SW-420 sensor for blast-induced ground vibration monitoring compared to existing instruments.

Discuss any limitations, challenges faced, and recommendations for future improvements or research in this area.

- Understand the Sensor: First, make sure you understand how the SW-420 vibration sensor works. Read the datasheet or any available documentation to understand its specifications, pinout, and how it communicates with the Arduino.

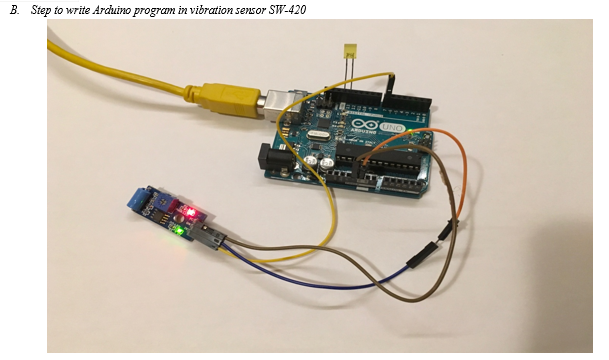

- Gather Materials: Collect all the necessary materials as mentioned earlier: Arduino board, SW-420 vibration sensor module, jumper wires, breadboard (optional), resistors (if needed), LEDs or other output devices (if needed), power source, and a computer with the Arduino IDE installed.

- Set Up Hardware: Connect the SW-420 vibration sensor module to your Arduino board according to its pinout. Typically, you'll connect the sensor's output pin to one of the digital pins on the Arduino.

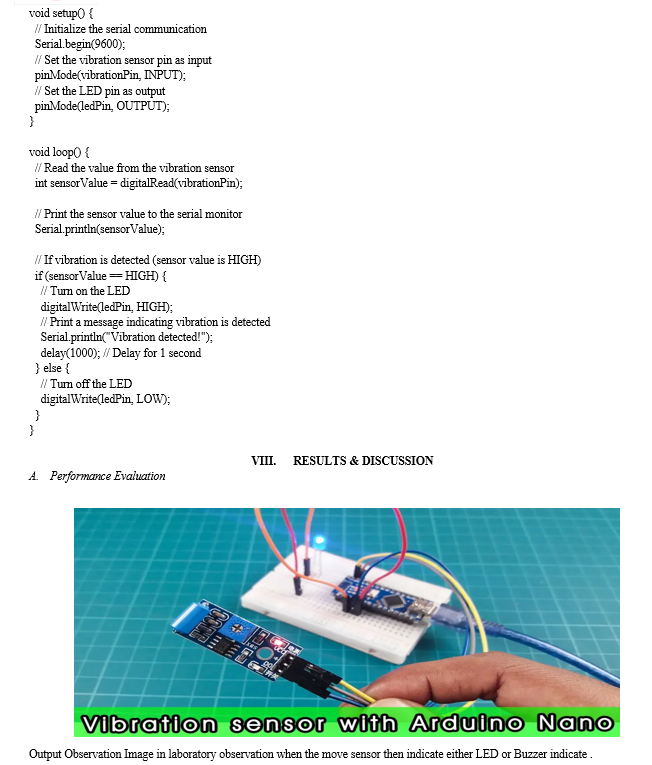

- Write the Code: Open the Arduino IDE on your computer and start a new sketch. Write the code to read data from the vibration sensor and respond accordingly. This could involve using functions like pinMode(), digitalRead(), and digitalWrite().

- Test and Debug: Verify that the code is working as expected by uploading it to your Arduino board. Use the serial monitor to debug and print sensor values or any other relevant information for troubleshooting.

- Refine the Code: Refine your code as needed based on testing results. You might need to adjust sensor sensitivity, add additional functionality, or optimize the code for better performance.

- Document Your Project: Document your project by adding comments to the code, creating a wiring diagram, and writing a brief description of how the project works. This documentation is helpful for future reference or if you decide to share your project with others.

- Deploy and Enjoy: Once everything is working correctly, deploy your Arduino project in its intended environment and enjoy its functionality!

IX. FUTURE WORK

- Data Analysis Techniques: Explore advanced data analysis techniques such as signal processing algorithms (like Fourier transforms or wavelet analysis) to extract meaningful information from the vibration data collected by your sensors.

- Integration with Geographic Information Systems (GIS): Integrate your vibration monitoring system with GIS software to map and visualize the spatial distribution of blast-induced ground vibrations. This can help in understanding how vibrations propagate through different geological formations.

- Machine Learning for Predictive Modeling: Use machine learning algorithms to develop predictive models for blast-induced ground vibrations. Train the model using historical vibration data along with other relevant parameters such as blast design parameters, geological characteristics, and weather conditions.

- Remote Monitoring and Control: Implementation of remote monitoring and control capabilities for your vibration monitoring system. This involve in developing a web-based interface or a mobile app to remotely access real-time vibration data and adjust the monitoring settings.

- Comparative Studies with Different Blast Scenarios: Conduct comparative studies by varying blast parameters such as charge size, distance from the blast site, and geological conditions. Analyze how these variations impact ground vibrations and compare the results with your existing data and literature findings.

- Validation and Calibration: Validate and calibrate your Arduino-based SW-420 vibration sensor against standard vibration monitoring instruments to ensure accuracy and reliability of all the measurements.

- Environmental Impact Assessment: Expand your study to include an environmental impact assessment of blast-induced ground vibrations. Evaluate the potential effects on nearby structures, ecosystems, and human activities, and propose mitigation measures if necessary.

X. ACKNOWLEDGEMENT

We would like to articulate our deep gratitude towards our project guide Dr. Sunil Kumar Singh and under co-supervision of Dr. Nirupama who has always been a source of motivation and firm support for carrying out the project, through his invaluable suggestions and constant encouragement all through the dissertation work. We would like to convey our sincere gratitude to Dr. Amit Gupta, Head of the Department, for his kind and constant encouragement throughout the work. We would like to express our sincere thanks to all the faculty members of the Chemical Engineering department for their kind cooperation. We would like to acknowledge the assistance of all our friends in the process of completing this work. An assemblage of this nature could never have been attempted without reference to and inspiration from the works of others whose details are mentioned in the reference section. We acknowledge our indebtedness to all of them. Further we would like to express our feelings towards our family members who directly or indirectly encouraged and motivated us during this project.

References

[1] Y. Sang, X. Huang, H. Liu, and P. Jin, “A vibration-based hybrid energy harvester for wireless sensor systems,” IEEE Trans. Magn., vol. 48, no. 11, pp. 4495–4498, Nov. 2012. [2] E. Halvorsen, “Fundamental issues in nonlinear wideband-vibration energy harvesting,” Phys. Rev. E, vol. 87, p. 042129, Apr. 2013. [3] J. Qiu, Y. M. Wen, P. Li, and H. J. Chen, “Magnetoelectric coupling characteristics of five-phase laminate composite transducers based on nanocrystalline soft magnetic alloy,” Appl. Phys. Lett., vol. 104, pp. 112401, Mar. 2014. [4] A. Bibo, and M. F. Daqaq, “Investigation of concurrent energy harvesting from ambient vibrations and wind using a single piezoelectric generator,” Appl. Phys. Lett., vol. 102, pp. 243904, Jun. 2013. [5] B. Rezaeealam, T. Ueno, and S. Yamada, “Finite element analysis of galfenol unimorph vibration energy harvester,” IEEE Trans. Magn., vol. 48, no. 11, pp. 3977–3980, Nov. 2012. [6] J. Qiu, Y. M. Wen, P. Li, and J. Yang, “Design and testing of piezoelectric energy harvester of powering wireless sensors of electric line monitoring system,” J. Appl. Phys., vol. 111, pp. 07E510, Mar. 2012. [7] T. Sato, K. Watanabe, and H. Igarashi, “Coupled analysis of electromagnetic vibration energy harvester with nonlinear oscillation,” IEEE Trans.Magn., vol. 50, no. 2, pp. 7007604, Feb. 2014. [8] J. Qiu, Y. M. Wen, P. Li, X. Liu, H. J. Chen, and J. Yang, “A resonant electromagnetic vibration energy harvester for intelligent wireless sensor.

Copyright

Copyright © 2024 Pankaj Kumar Mahto, Dr. Sunil Kumar Singh. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62813

Publish Date : 2024-05-27

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online