Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

An Experimental Investigation on Mechanical Properties of Bacterial Concrete Using Bacillus Subtilis

Authors: Anchal Puram, Toshan Singh Rathour

DOI Link: https://doi.org/10.22214/ijraset.2024.62338

Certificate: View Certificate

Abstract

This Concrete is susceptible to micro crack formation and has pores which are highly undesirable because they provide an open pathway for the ingress of water and other deleterious substances. The use of concrete surface treatments with water proofing materials to prevent the access of aggressive substances is a common way of contributing to concrete durability. However, the most common surface treatments use organic polymers (epoxy, acrylics and polyurethanes) all of which have some degree of toxicity. Bio inspired materials can lead to a more sustainable construction industry, especially when providing new low toxic solutions. Hence, there is an urgent need to pay more attention for improving the properties of concrete with respect to strength and durability, especially in aggressive environments. One effective remedy for closure of cracks is the Bacterial Concrete (BC) which will continuously deposit calcite in concrete. This, phenomenon is called as Microbiologically Induced Calcite Precipitation (MICP). The urease enzyme enables the deposition of calcium carbonate (CaCO3) with the help of bacteria. The bacterial remediation technique surpasses other techniques as it is bio-based, eco-friendly and durable. Bacteria need to offer resistance to withstand high pH of concrete and mechanical stresses during mixing. In these present investigations bacterial sample name Bacillus Subtilis (BS) is considered in concentrations of 104, 105 and 106 cells/ml of mixing of water. investigations are carried out on strength-related properties such as compressive strength, splitting tensile strength and flexural strength to assess the quality of concrete. The optimum dosage of cell concentration of bacteria is found to be 105 cells/ml for BS based on compressive strength results. M25 grade concrete is designed and used for embedding Bacillus subtilis bacteria.

Introduction

I. INTRODUCTION

The major shortcoming of Conventional Cement Concrete (CCC) is that it develops cracks under tension. Small cracks formed on the surface of the concrete make the entire structure to lose strength due to permeation of water in the concrete. Therefore, it leads to corrosion of steel and reduction of life span of the structure. It may not be possible to visualize the cracks but they may tend to propagate into fissures in due course and affect the reinforcement of the structure. The deterioration of reinforced concrete results in high maintenance costs. Micro-cracks are therefore precursors to structural failure. The “Bacterial Concrete” is prepared by adding bacteria in the concrete which can constantly precipitate calcite. This process is called Microbiologically Induced Calcite Precipitation (MICP). It helps in enriching strength and durability by filling up voids present in the concrete structure.

A. Bacterial Concrete

The Microbiologically Induced Calcite Precipitation (bio deposition) involves various microorganisms, pathways and environments. MICP can be utilized as an effective alternative repair technique for plugging of micro-cracks and pores in concrete. This bacterial remediation technique surpasses other techniques as it is bio based, eco-friendly, cost effective and durable. Urease positive bacteria have been found to deposit calcium carbonate (calcite) with the help of urease enzyme. The increase of pH value and calcite precipitation are obtained by the enzyme, due to hydrolysis of urea to CO2 and ammonia. Precipitation of calcium carbonate (CaCO3) crystals occurs by heterogeneous nucleation on bacterial cell walls once supersaturation is achieved. With the calcite precipitation in concrete by the bacteria, the formation and propagation of cracks can be reduced and a concrete with dense microstructure can be obtained. Under favourable conditions, calcite formation due to the activation of bacteria and concrete which is insoluble in water. As a result, more durable structural concrete, with reduced maintenance cost can be produced.

B. Self-Healing Mechanism

Recent studies focus attention on crack healing behaviour of concrete. It is to be noted that the microcracks widths in the range of 0.05 and 0.1 mm become completely sealed, during dry and wet cycles. The secondary hydration of unreacted or partially reacted cement particles in the concrete matrix is responsible for healing of concrete. Water seeps into microcracks due to capillarity. The expansion of hydrated cement particles due to the formation of calcium silicate hydrates and calcium hydroxide have been the cause for self-healing. This reaction is also expansive as ingress atmospheric carbon dioxide (CO2) reacts with calcium hydroxide particles present in the concrete matrix to various calcium carbonate minerals. From the perspective of durability, rapid sealing of particularly freshly formed surface cracks is important as this hampers the ingress of water and other aggressive chemicals into the concrete matrix

C. Objective of the study

The objectives of the present work are summarized as follows:

- To produce bacterial concrete by adding bacteria into M25 grade conventional concrete.

- To obtain the optimum dosage of cell concentration of Bacillus Subtilis (BS) bacteria to be added into concrete for better strength characteristics of bacterial concrete.

- To determine the strength properties of conventional and bacterial concrete for M25 grade of concrete.

II. MATERIALS AND METHODS

A. Constituents Materials and their Properties

- Cement

For the present investigation, 43 grade OPC conforming to IS: 8112-2013 was used. The cement sample was tested as per the procedures given in IS: 4031-1988 and IS: 4032-1985. The results of the tests on cement sample are listed in Table 1.

TABLE I

Physical properties of 43 grade Ordinary Portland Cement

|

S. No. |

Physical property |

Results |

Requirements of IS: 8112-2013 |

|

1 |

Fineness, m2/ kg |

320 |

Minimum 225 |

|

2 |

Initial setting time (minutes) |

35 |

Minimum 30 |

|

3 |

Final setting time, (minutes) |

430 |

Maximum 600 |

|

4 |

Standard consistency (%) |

27 |

- |

|

5 |

Compressive strength (MPa) 3-days 7-days 28-days |

27.5 38.0 52.0 |

Minimum 23 Minimum 33 Minimum 43 |

|

6 |

Specific gravity |

3.15 |

- |

2. Fine Aggregate

Locally available river sand was used as fine aggregate. The sand was washed and screened at site to remove deleterious materials and tested as per the procedure given in IS: 2386 - 1963. mechanical properties are presented in Table 2.

TABLE 2

Properties of Fine Aggregate

|

S. No |

Description of test |

Test results obtained |

Permissible limits as Per IS:383-1970 |

|

1 |

Specific gravity (SSD) |

2.60 |

Minimum 2.55 |

|

2 |

Water absorption (%) |

1.48 |

Maximum 3 |

|

3 |

Fineness modulus |

2.87 |

- |

|

4 |

Moisture content |

0 % |

- |

|

5 |

Bulk density |

1570 kg/m3 |

- |

3. Coarse Aggregate

Considering all the aspects, crushed stone aggregates of nominal size 20 mm and of typical particle shape “average and cubic” were used as the coarse aggregates for the present investigation. The aggregates were tested as per the procedure given in IS: 2386 - 1963 and the results are given in Table 3.

TABLE 3

Properties of Course Aggregate

|

S. No |

Description of test |

Test results obtained |

Permissible limits as Per IS:383-1970 |

|

1 |

Deleterious material, % |

NIL |

Maximum 2 |

|

2 |

Specific gravity |

2.84 |

Minimum 2.6 |

|

3 |

Water absorption, % |

0.485 |

Maximum 3 |

|

4 |

Fineness modulus |

5.13 |

- |

|

5 |

Crushing value, % |

33 |

Maximum 30 |

|

6 |

Impact value, % |

14.3 |

Maximum 30 |

|

7 |

Abrasion value, % |

19.4 |

Maximum 30 |

|

8 |

Flaky particles, % |

8 |

Maximum 15 |

|

9 |

Elongated particles, % |

7 |

Maximum 15 |

1. Bacteria

Bacillus Subtilis (BS) was found to thrive in this high-alkaline environment under conditions of high pH value up to 13 of the cement-water mixer. Based on the above criteria, the bacteria used in this study are Bacillus subtilis in three concentrations of 104, 105 and 106 cells/ml each of mixing water.

B. Concrete Mix Design

Since there is no code of reference in existence for bacterial concrete, the mix design procedure for Conventional Cement Concrete (CCC) as per IS: 10262 -2019 was followed. For the present investigation M25 grade concrete was designed and taken as control mix.

The mix proportion was arrived for M25 grade concrete as per IS: 10262 – 2019 and is 1 : 1.698 : 3.088 with water cement ration of 0.50. The design mix proportion was taken as the control mix and the specimen was designated as control specimen (CS). In that proportion, bacteria namely BS was added in three concentrations of 104, 105 and 106 cells/ml each and the specimens were designated as BS1, BS2, and BS3 respectively. The water-cement ratio was similar for all the proposed mix proportions. Totally, four different mixes (one control mix and three bacterial concrete mixes) were prepared.

III. RESULTS AND DISCUSSIONS

All paragraphs must be indented. All paragraphs must be justified, i.e. both left-justified and right-justified.

A. Compressive Strength

From the test results of compressive strength, it is observed that at all ages the compressive strengths of bacterial concrete specimens are found to be greater than those of the control concrete specimen. The maximum compressive strengths was obtained for the bacterial concrete specimen BS2 as 37.48 at the age of 28 days. Hence, the optimum dosage of cell concentration for achieving the maximum compressive strength is found to be 105 cells/ml for Bacillus Subtilis from the experimental results.

The compressive strength of bacterial concrete showed an increase of about 11.00 %, 15.18 % and 11.49 % for 104, 105, and 106 cells/ml respectively at the age of 28 days as compared to control concrete. Moreover, out of all the bacterial concrete specimens, the maximum compressive strength was found to be 15.18 % for Bacillus subtilis having Cell concentration 105 cells/ml.

TABLE 4

Compressive strength of M25 grade bacterial concrete mixes

|

Mix designation |

Type of bacteria |

Cell concentration (cells/ml) |

Average compressive strength in MPa |

||||

|

7 days |

14 days |

28 days |

56 days |

90 days |

|||

|

CS |

Control Specimen |

- |

23.48 |

27.56 |

32.54 |

33.36 |

33.94 |

|

BS1 |

Bacillus Subtilis |

104 |

25.87 |

30.52 |

36.12 |

37.12 |

37.9 |

|

BS2 |

105 |

26.63 |

31.56 |

37.48 |

38.87 |

39.98 |

|

|

BS3 |

106 |

26.02 |

30.65 |

36.28 |

37.64 |

38.72 |

|

B. Splitting tensile strength

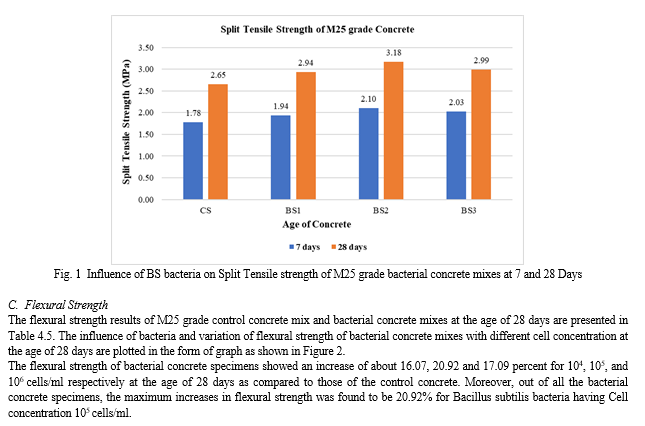

The influence of bacteria and variation of splitting tensile strength of bacterial concrete mixes with different cell concentration at the age of 7 days and 28 days are plotted in the form of graphs as shown in Figures 1. From the test results of splitting tensile strength, it is observed that the splitting tensile strength of bacterial concrete specimens are found to be greater than control concrete specimen. The maximum splitting tensile strengths are obtained for bacterial concrete specimen BS2 as 3.18 at the age of 28 days. Hence, the optimum dosages of cell concentration for achieving the maximum splitting tensile strength at the age of 28 days is found to be 105 cells/ml for Bacillus Subtilis from the experimental results.

V. ACKNOWLEDGMENT

The success and final outcome of this research required a lot of guidance and assistance from many people and I am extremely privileged to have got this all along the completion of this research. All that I have done is only due to such supervision and assistance and I would not forget to thank them.

I owe our deep gratitude to my research guide Mr. Jonty Choudhary (Assistant Professor, Department of Civil Engineering) who took keen interest on my research work and guided us along, till the completion of research by providing all the necessary information for developing a good system.

Conclusion

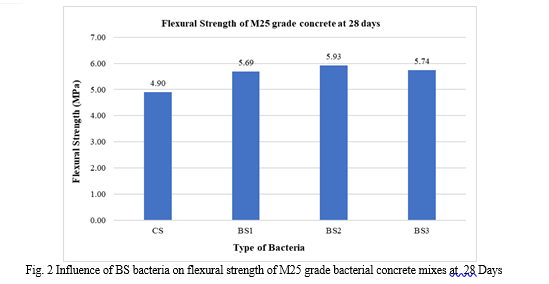

The following conclusions are made based on the experimental investigations carried out on concrete mixes with and without bacteria. 1) At the ages of 7, 14, 28, 56 and 90 days, the compressive strengths of bacterial concrete mixes were more than those of concrete mix without bacteria. This indicates that addition of bacteria into concrete causes an increase in compressive strength. 2) The optimum dosage of cell concentration for BS bacteria is found to be 105 cells /ml for achieving the maximum value of compressive strength. 3) The splitting tensile strengths of all bacterial concrete specimens were found to be greater than those of the control concrete specimen. The maximum splitting tensile strengths are obtained for bacterial concrete specimen BS2 as 3.18 at the age of 28 days. Hence, the optimum dosages of cell concentration for achieving the maximum splitting tensile strength at the age of 28 days is found to be 105 cells/ml for Bacillus Subtilis. 4) The flexural strengths of all bacterial concrete specimens were found to be greater than those of the control concrete specimen. The maximum flexural strength is obtained for bacterial concrete specimen BS2 as 5.93 MPa at the age of 28 days. 5) The optimum dosages of cell concentration for achieving the maximum flexural strength at the age of 28 days is found to be 105 cells/ml for Bacillus Subtilis.

References

[1] Manoli, F & Dalas, E “Spontaneous precipitation of calcium carbonate in the presence of chondroitin sulfate” Journal of Crystal Growth, vol. 217, no. 4, pp. 416-421, 2000. [2] Ramakrishnan V, et al. “Remediation of concrete using Microorganisms” ACI Materials Journal, vol. 98, pp. 3-9, 2001. [3] Hammes F, et. al. “A novel approach to calcium removal from calcium-rich industrial wastewater” Water Research, vol. 37, no. 3, pp. 699-704, 2003. [4] Liang Po, et al. “The effect of carboxymethyl chitosan on the precipitation of calcium carbonate” Journal of Crystal Growth, vol. 261, no. 4, pp. 571-576, 2004. [5] Nemati M, et. al. “Permeability profile modification using bacterially formed calcium carbonate: comparison with enzymic option” Process Biochemistry, vol. 40, no.2, pp. 925- 933, 2005. [6] Muynck WD, et. al. “Bacterial carbonate precipitation as an alternative surface treatment for concrete” Construction and Building Materials’, vol.22, pp. 875-885, 2008. [7] Sunil Pratap Reddy S, et. al. “Performance of standard grade bacterial Bacillus Subtilis concrete” Asian Journal of Civil Engineering Building and Housing, vol. 2, no. 1, pp. 43-55, 2010. [8] Varenyam Achal, et. al. “Corrosion prevention of reinforced concrete with microbial calcite precipitation” ACI Materials Journal, no.109-M16, pp. 01-08, 2012. [9] Wasim Khaliq, et. al. “Crack healing in concrete using various bio influenced self-healing techniques” Construction and Building Materials, vol. 102, pp. 349-357, 2016. [10] Meera, CM & Subha, V “Strength and durability of bacteria based self-healing concrete” International Organization of Scientific Research Journal of Mechanical and Civil Engineering, vol. 03, no. 12, pp.01-07, 2016. [11] Seshagiri Rao, et.al. “Performance of microbial concrete developed using bacillus subtilus JC3” Journal of The Institution of Engineers, Series A - Springer books, 2017. [12] Ramana Reddy, et. al. “An experimental investigation on bacillus subtilis in healing micro-cracks in concrete” international Journal of Advanced Research and Innovative Ideas in Education’, vol. 3, no. 3, pp. 3653-3659, 2017. [13] Kunamineni Vijay, Meena Murmu, and Shirish V. Deo, “Bacteria based self-healing concrete - A review” Construction and Building Materials, Volume 152, pp-1008-1014, 2017. [14] IS 383: 1970, “Specification for coarse and fine aggregates from natural sources for concrete”, Bureau of Indian Standards, New Delhi. [15] IS 516: 1959, “Methods of tests for Strength of concrete”, Bureau of Indian Standards, New Delhi. [16] IS 2386: 1963, “Methods of Test for aggregates for concrete”, Bureau of Indian Standards, New Delhi. [17] IS 456-2000, “plain reinforced concrete code of practice”, Bureau of Indian Standards, New Delhi. [18] IS 10262: 2019, “Concrete Mix Proportioning – Guidelines”, Bureau of Indian Standards, New Delhi.

Copyright

Copyright © 2024 Anchal Puram, Toshan Singh Rathour. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62338

Publish Date : 2024-05-18

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online