Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Modifying Expansive Soil Characteristics with Xanthan Biopolymer Integration

Authors: Pragya Gupta, Ushendra Kumar

DOI Link: https://doi.org/10.22214/ijraset.2024.62193

Certificate: View Certificate

Abstract

Expansive soils pose significant challenges in various engineering projects due to their tendency to swell and shrink with changes in moisture content. Traditional stabilization methods often come with environmental and economic drawbacks. This research paper explores the potential of xanthan biopolymer, a polysaccharide of microbial origin (Xanthomonas Campestris), as a sustainable and effective alternative for altering the engineering properties of expansive soils. Through laboratory experiments and analysis, the paper investigates the influence of xanthan biopolymer on key soil properties such as swelling behaviour, shear strength, and permeability. The findings provide insights into the feasibility and efficacy of using xanthan biopolymer for soil stabilization, offering a promising avenue for sustainable geotechnical engineering practices.

Introduction

I. INTRODUCTION

Human population on our planet is ever increasing and so are the number of residential structures. Due to the expansion of urban areas, people are now being forced to construct upon problematic soils, such as the expansive ones which pose a threat to the stability of the structure built on it, hence stabilization of such soils is a concern for the engineers. Improvement in swelling-shrinkage behaviour, compressibility, strength and erosion resistance is the goal of stabilization of soil so that it can be used for construction purposes. Methods of stabilization include physical and chemical methods, of which the physical method involves compacting the soil, heat treatment to the soil, vibratory treatment, etc., compaction being the most used process for densification of soils. Drainage of the soil is also done to remove excess pore water pressure resulting in increased effective stress. Chemical methods use admixtures to help in proper soil compaction or reducing the hydraulic conductivity. Effective chemicals form non-water-soluble precipitates which are hard in nature.

This research work is performed to understand the physical and chemical changes occurring in expansive soils with the addition of Xanthan Bio-polymer in various proportions, to the dry weight of expansive soil.

II. LITERATURE SURVEY

Findings of various researchers and scholars which served as a guide in this research work have been listed below:

Latifi et.al. (2016), The results from both macro and microscale experiments were presented to investigate the behaviour and attributes. The stabilization of cohesive soils using xanthan biopolymer. Soils under examination were mainly montmorillonite and kaolinite clays. Objective of the study involved adjusting the xanthan content within the range of 0.5% to 2.5% relative to the dry soil weight. Significant increase in the Unconfined Compressive Strength was observed for 1% addition of Xanthan.

Chang et.al. (2014) They experimentally demonstrated the variation in characteristics of expansive soil mixed with Xanthan Gum. They evaluated the strengthening characteristics and long-time durability of different soil samples subjected to treatment with the biopolymer xanthan gum, considering factors for example, techniques like blending methodologies, composition of the soil, and the ratio of biopolymer addition. The study concluded that a concentration of 1% to 1.5% of xanthan gum appeared to be the most efficient and economical.

Chen et.al. (October, 2013) have introduced a comprehensive research initiative focused on harnessing biopolymers to enhance the stability and erosion resistance of Mine Tailings. Their study delved deeply into enhancing the undrained. The shear strength (Su) of a mine Tailings by incorporating natural biopolymers such as xanthan gum or guar gum. They demonstrated that increasing the biopolymer content correlates with higher Atterberg limits, and observed that on increasing the guar gum content from 0% to 2% the variation in the undrained shear strength of the mix went from 1.50 to 22.00 kPa whereas an increase from 1.50 to 5.40 kPa was observed on virgin soil and up to 3% xanthan biopolymer variation.

Additionally, the scholars suggested 2 equalities after comparison of their undrained shear strength findings with the earlier established empirical equations from an existing literary source, aimed at predicting the undrained shear strength of Mine Tailings mixed with a biopolymer.

Qureshi et.al. (2017) demonstrated the strength and slake durability characteristics of biopolymer-treated sand from the Al-Sharqia Desert in Oman, comparing it with cement-treated sand. The study showed that achieving peak performance concerning both strength and durability. was achieved with 2-3% xanthan gum content by weight of the soil, leading to increased UCS and resistance to disintegration upon interaction with water.

Chen et.al. (2014) Researched application of naturally occurring biopolymers such as xanthan/guar, for stabilizing mine tailings (MTs) to control dust. They conducted tests to understand the ability to hold water and resist wind erosion in samples treated with biopolymers. Results showed that xanthan gum and guar gum effectively improved the ability to hold water and manage dust, while also providing Significant strength surpassing mere water wetting.

Chang et.al. (2015) He studied the effect of introduction of two thermos-gelation biopolymers for the treatment of soil, which showed promising prospects for enhancing its strength due to clay interacting through hydrogen bonding. They treated sandy and clayey soils with different biopolymer concentrations and found promising results in properties of compressive strength of soil and its durability, both on land and waterfront.

Nakamatsu et.al. (2017) studied the behaviour of foundation soil, treated using biopolymer carrageenan, which caused increased water resistivity, erosion resistance, and mechanical properties of adobe construction.

Chang et al. (2017) illustrated how Jumunjin sand, when treated with gellan gum, showed resilience and usability. They observed that repeated wetting and drying cycles gradually reduced the strength of the sand treated with gellan gum. However, they also noted that the sand exhibited some level of strength restoration even after undergoing multiple cycles of wetting and drying.

Etemadi et.al. (2014) performed experiments in a laboratory setting using soil that had been treated with 5 distinct biopolymers: xanthan, guar gum, chitosan, polyhydroxy butyrate, and poly glutamic acids for stabilization of subsurface heavy metals. These biopolymers were found to improve soil characteristics, decrease permeability, increase shear strength, and enhance metal uptake capacity while reducing leachability.

III. MATERIALS

This section outlines the approach and resources utilized to meet the outlined goals. Laboratory preparation was undertaken to mimic the properties of expansive soil, particularly black soil when treated with a biopolymer (specifically, xanthan gum powder obtained commercially) at different concentrations and curing durations for stabilization. “The process of sample preparation, sampling, and testing techniques employed for material characterization, along with the specifics of the experimental arrangement for investigation will be presented in the coming sections.

A. Expansive Soil

The black soil (expansive soil) utilized for the investigation originates at Sonebhadra, U.P. This soil exhibits a liquid limit of 53%, indicating its significant expansiveness. Subsequently, various quantities of sodium bentonite were incorporated into the soil. The sodium bentonite was sourced from an online store. Through experimentation, it was found that adding 30% bentonite resulted in a liquid limit of 86% for the mixture, signifying a highly expansive soil composition.

B. Xanthan Gum

The biopolymer was procured from an online dealer (India Mart). It typically has a pH range of 6 to 8. This substance, known for its rheology modification capabilities, was first discovered in the 1950s. It's a natural anionic polysaccharide consisting of D-glucuronic acid, D-mannose, pyruvate mannose, 6-O-acetyl D-mannose, and a 1,4-linked glucan (Garcia-Ochoa et al., 2000; Hassler and Doherty, 1990). One of its key characteristics is its pseudoplasticity (Milas & Rinaudo, 1986) and high shear stability (Chen & Sheppard, 1980), even at low concentrations. Additionally, it exhibits desirable properties such as pH stability, storage stability, and compatibility with ionic salts (Hassler & Doherty, 1990). Due to these properties, xanthan gum finds extensive applications across various industries including cosmetics, oil, paper, paint, pharmaceuticals, food, and textiles. It is used as a gel forming, thickening agent, or suspension forming agent, as well as a flocculating agent or for keeping viscosity in check.

IV. METHODOLOGY

Samples of expansive soils with varying percentages of Xanthan Gum (0%, 0.2%,0.5%,0.8% and 1%) were used to prepare samples in this study. Following tests and calculations were conducted on these samples:

- Specific Gravity

- pH

- Distribution of Particle Size

- Limits of Consistency (liquid, plastic and shrinkage limits)

- Linear shrinkage

- Compaction tests (heavy and light compaction as per IS codes)

- Swell Pressure

- Consolidation Test (as per IS 2720-part- 15 1965)

- Unconfined Compressive Strength (UCS)

- Freeze and Thaw Durability Test

- X – Ray Diffraction (XRD)

- Scanning Electron Microscopy

V. RESULTS

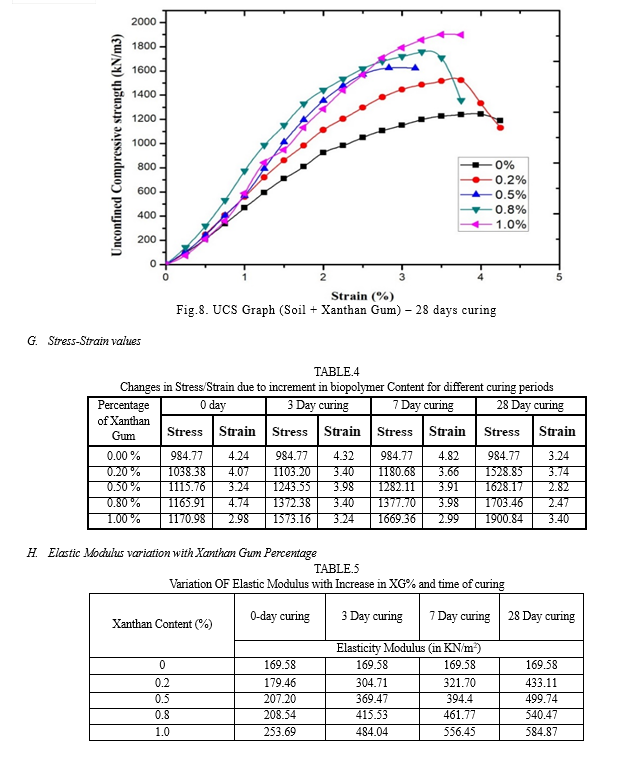

This section discusses the results of an experiment conducted for stabilization of expansive soils by mixing of biopolymer. The sample consisted of expansive soil mixed with different percentages of xanthan gum (0.2%,0.5%,0.8% and 1%) The experiment involved conducting IS light and IS heavy compaction tests for determination of the optimum moisture content along with maximum dry density for both untreated samples and samples treated with biopolymer. Atterberg limits were analysed to observe any changes in plastic behaviour of the treated and untreated expansive soil. Additionally, the study investigated swelling, consolidation, strength, and durability behaviour of the treated soil samples. Each set of results is thoroughly examined to comprehend the relationship between the geotechnical properties enhanced as a result of mixing the Xanthan Gum with soil.

A. Specific Gravity

The table below displays the specific gravity values of various xanthan gum and soil mixtures. It is to be noted that with the concentration of biopolymer increases, the specific gravity decreases.

TABLE. 1

Specific Gravities for Virgin and Soil-Biopolymer Mixes

|

Soil Type |

Specific Gravity (Gs) |

|

Untreated Soil |

2.74 |

|

Soil and Xanthan Gum (0.2%) |

2.68 |

|

Soil and Xanthan Gum (0.5%) |

2.68 |

|

Soil and Xanthan Gum (0.8%) |

2.67 |

|

Soil and Xanthan Gum (1.0%) |

2.27 |

B. pH

The pH level of the soil measures 5.9, indicating a slight acidity. The reaction process of medium and the xanthan gum can get affected due to the pH of the environment (Thakur et al., 2011). when acidic environment is present, xanthan monomer release [H+] from the (RCOOH) groups, (Bueno et al., 2012). Conversely, when the environment is basic, xanthan monomers release hydrogen ions from the ester groups present in them (RCOOR'), which results in a higher tendency to swell in comparison to the acidic groups of the xanthan gum. pH levels of xanthan typically vary from 6 to 8, as indicated on its container. When added to soil, it marginally raises the soil's pH. Further pH test results are provided in Table 6 for detailed information.

TABLE. 2

Result of pH test for Treated and Untreated Soil

|

Soil Type |

pH |

|

Untreated Soil |

5.8 |

|

Soil and Xanthan Biopolymer (0.5 %) |

6.1 |

|

Soil and Xanthan Biopolymer (1.0 %) |

6.1 |

C. Atterberg Limits and related values

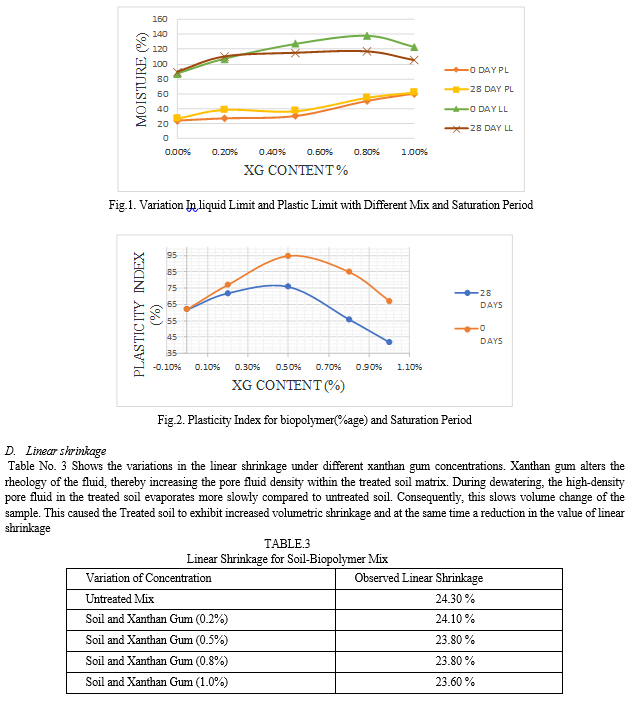

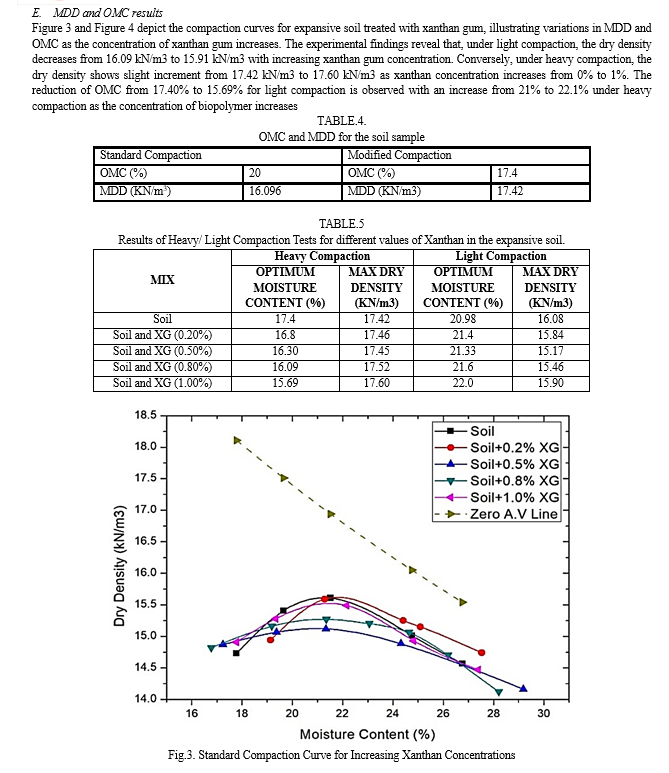

The liquid limit of the soil is a measure of the amount of water which is needed to satisfy demand of the diffuse double layer present around the particles of soil. Figure no. 1 illustrates plastic and liquid limit for the samples at different time intervals and Xanthan Percentage. The increase in both of the limits is attributed to the hydrophilic behaviour of xanthan monomers present in mixture.

Conclusion

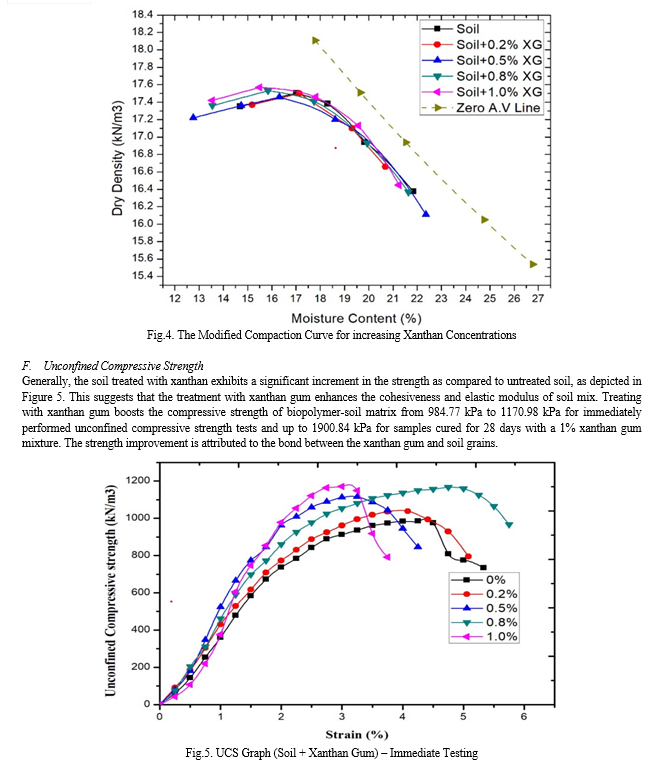

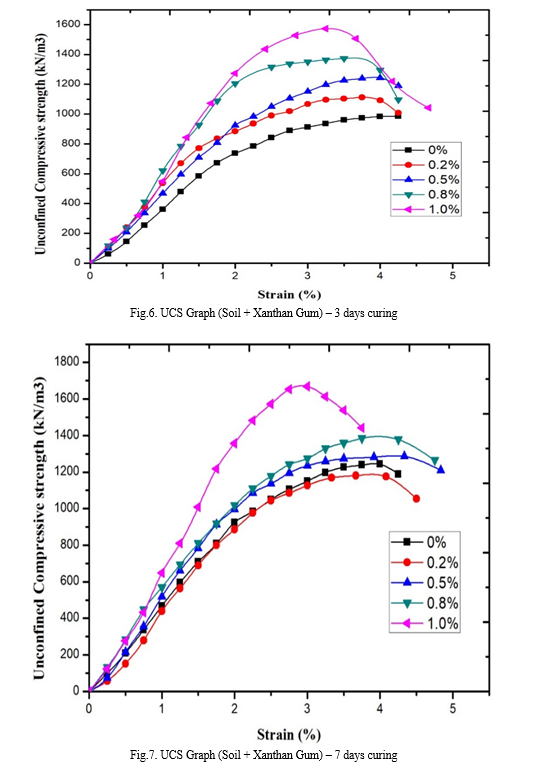

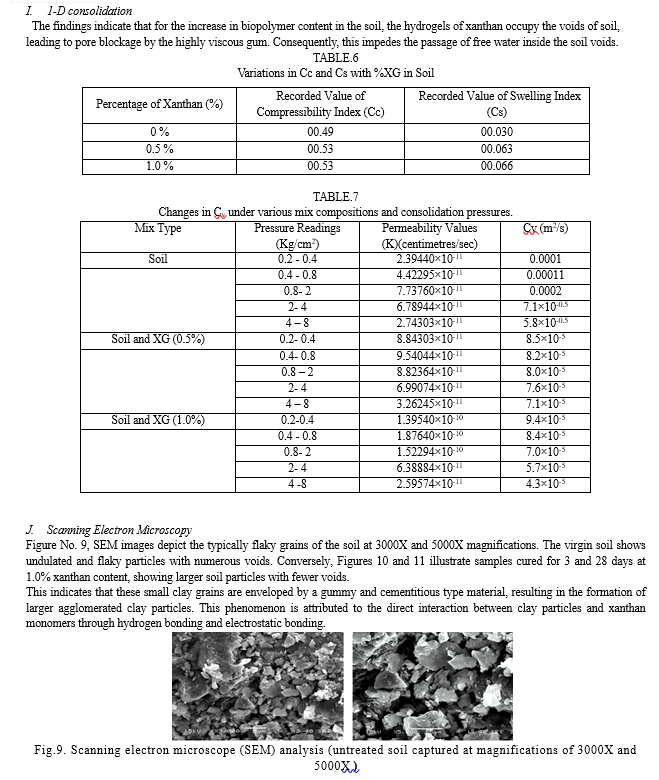

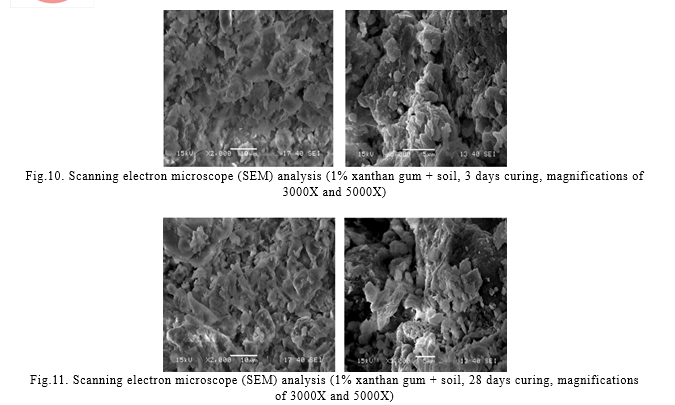

This research investigates about the geotechnical effects of using xanthan gum to stabilize expansive soil. The treatment of black soil with xanthan gum at varying %ages yield significant results, as discussed below based on experimental findings: 1) Increasing the concentration of biopolymer, such as xanthan gum, raises the soil’s liquid limit (LL) due to increased viscosity of pore fluid. However, at concentrations in the range of 0.8% and 1.0%, particle accumulation surpasses the viscosity increase, resulting in a slight decrease in the clay particles\' surface area and consequently a minor decrement in the liquid limit. 2) The same mechanism affects the plastic limit, leading to a consistent increase in plastic limit for both immediate and 28-day tests with rising xanthan gum concentrations. 3) Enhanced pore fluid viscosity from increased xanthan gum content aids in the reduction of the rate of evaporation of liquids from the treated soil, thus causing decreased volumetric change and shrinkage, but increased linear shrinkage. 4) The increased viscosity of the pore fluid due to increased xanthan gum content induces particle flocculation through a high-viscosity diffuse double layer, that resists the impact of standard compaction. This results in an increase in the optimum moisture content (OMC) and maximum dry density (MDD) of the treated soil. However, under heavy compaction, increased energy facilitates lubrication, resulting in a slight increase in MDD. 5) Xanthan gum exhibits a significant strengthening effect on treated soil, with a strength increment of approximately 93% at 1% of xanthan concentration. The strengthening is attributed to the direct interactions between negatively charge on the soil particles and the activity of carboxylic group of the xanthan gum, such as hydrogen bond formation and cation bridging. 6) Initial swelling with slight increase of 7.68% in the DFS is observed, after seven days of curing, particle agglomeration reduces the specific surface area, resulting in reduced water absorption and a decrease in swelling by 29.84% for a xanthan gum substitution of 1%. 7) Swell pressure tests reveal a reduction of 13.51% in swelling pressure for immediately tested samples at 1% xanthan gum concentration, and a reduction of 54.05% after seven days of curing compared to virgin soil. 8) Consolidation tests demonstrate that the mixing of the xanthan biopolymer increases the compressibility index (Cc) by approximately 4.00 % at the xanthan concentrations of 0.5% and 1.0%, while moderately increasing the swelling index (Cs). Additionally, it causes a reduction in the value of hydraulic conductivity but prolongs the period of consolidation settlement with increment in xanthan content. 9) Freezing /thawing durability test shows positive test results for increasing xanthan %. Expansive nature is exhibited by the soil due to its natural affinity for water absorption, causing increased volumetric changes on increasing biopolymer %. The increased pore fluid viscosity causes a decrease in the rate of evaporation, further aiding in reducing the loss of moisture content and providing resistance against the loss of mass in freezing /thawing tests.

References

[1] Abdollahnejad, Z., Kheradmand, M., & Pacheco-Torgal, F. (2017). Evaluation of the Short-Term Compressive Strength of Alkali-Activated Cement-Based Binder Mortars Containing Fly Ash and Waste Glass, Enhanced by Two Biopolymers. Journal of Materials in Civil Engineering, 29(7), 04017045. [2] Aspiras, R. B., Allen, O. N., Harris, R. F., & Chesters, G. (1971). Investigating the Influence of Microorganisms on Soil Aggregate Stabilization. Soil Biology and Biochemistry, 3(4), 347-353. [3] Bueno, V. B., Bentini, R., Catalani, L. H., & Petri, D. F. S. (2013). Synthesis and Swelling Behavior Analysis of Hydrogels Based on Xanthan. Carbohydrate Polymers, 92(2), 1091-1099. [4] Cabalar, A. F., Wiszniewski, M., & Skutnik, Z. (2017). Impact of Xanthan Gum Biopolymer on the Permeability and Mechanical Behavior of Sand. Soil Mechanics and Foundation Engineering, 54(5), 356-361. [5] Chang, I., & Cho, G. C. (2014). Geotechnical Analysis of Residual Soil Treated with Beta-1, 3/1, 6-Glucan Biopolymer. Geomechanics and Engineering, 7(6), 633-647. [6] Chang, I., Im, J., Lee, S. W., & Cho, G. C. (2017). Evaluation of Strength Durability of Korean Sand Treated with Gellan Gum Biopolymer under Cyclic Wetting and Drying. Construction and Building Materials, 143, 210-221. [7] Chen, R., Lee, I., & Zhang, L. (2014). Utilization of Biopolymers for Stabilization of Mine Tailings to Control Dust. Journal of Geotechnical and Geoenvironmental Engineering, 141(2), 04014100. [8] Cole, D. M., Ringelberg, D. B., & Reynolds, C. M. (2011). Investigation of Small-Scale Mechanical Properties of Biopolymers. Journal of Geotechnical and Geoenvironmental Engineering, 138(9), 1063-1074. [9] Etemadi, O., Petrisor, I. G., Kim, D., Wan, M. W., & Yen, T. F. (2003). Metal Stabilization in Subsurface using Biopolymers: Laboratory Drainage Flow Studies. Soil and Sediment Contamination, 12(5), 647-661. [10] Ivanov, V., & Chu, J. (2008). Application of Microorganisms in Geotechnical Engineering for Soil Bioclogging and Biocementation in situ. Reviews in Environmental Science and Bio/Technology, 7(2), 139-153. [11] Nakamatsu et al. (2017) explore the eco-friendly modification of earthen construction with carrageenan [12] Qureshi et al. (2017) study the strength and durability characteristics of biopolymer-treated desert sand. Soltani-Jigheh and Azarnia (2017) examine the effect of liquid polymeric and lime additives on the behaviour of fine-grained soil under unfrozen and freeze-thaw conditions. [13] Tingle and Santoni (2003) explore the stabilization of clay soils with nontraditional additives, and Zohuriaan and Shokrolahi (2004) conduct thermal studies on natural and modified gums. [14] Labille et al. (2005) study the flocculation of colloidal clay by bacterial polysaccharides [15] Martin (1971) discusses the decomposition and binding action of polysaccharides in soil, while Milas and Rinaudo (1986) analyze the properties of xanthan gum in aqueous solutions.

Copyright

Copyright © 2024 Pragya Gupta, Ushendra Kumar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62193

Publish Date : 2024-05-16

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online