Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Multi Utility Rover with Metal Detection

Authors: Vaishali Rajput, Aashi Mathur, Tejas Abhang, Abhijeet Bharate, Abhijeet Kolhe, Adarsh Pathak, Rudraksh Adhane

DOI Link: https://doi.org/10.22214/ijraset.2024.64692

Certificate: View Certificate

Abstract

Landmines pose a major risk in the battlefield or during operation in remote areas. To reduce the risk of this threat, we have designed a multi-utility rover with metal detection and surveillance. This rover detects the landmine (made of metals) using the principle of electromagnetism and sends a message to a mobile device using ESP32 module. It conveys the level of risk using variable sounds. The rover has 4x4 remote controlled (operated over Wi-Fi) wheels which make it capable of moving in all the directions. It also has an ultra-sonic sensor (for obstacle detection) mounted in front of it to avoid collision with objects. This whole set-up is powered by a 3C 12V rechargeable battery.

Introduction

I. INTRODUCTION

The world is in a war-like situation. Every year at least 5000 people are killed by landmines, most of them being civilians. It is estimated that in 70 countries around the world there are present more than 100 million different kinds of landmines [1]. Talking about India, we have huge security and defense establishments to protect us. Defense agencies carry out operations to deal with such threats. To the personnel taking part in such operations, there is a great risk posed by IEDs and landmines.

The current method of detecting landmines still requires humans to manually carry out search operations to find the presence of mines. Although there are sophisticated vehicles for landmine detection for tanks and armored vehicles. But on a small scale, detection is usually carried out manually.

The focus of this paper is to devise a method for small scale mine detection which does not directly involve humans. We have made a rover equipped with electromagnetic sensors which plays a pivotal role in detecting landmines, serving as a crucial tool in humanitarian efforts and military operations worldwide. By harnessing electromagnetic waves, these rovers can swiftly and accurately identify buried landmines, significantly reducing the risk of accidental detonations and minimizing the threat posed to civilians and military personnel. Its ability to navigate rugged terrain and remotely detect buried explosives not only saves lives but also facilitates the clearance of land for agricultural, residential, and infrastructural developments, fostering stability and progress in conflict-affected regions. Moreover, its non-invasive approach ensures minimal disturbance to the surrounding environment, making them indispensable assets in the ongoing global efforts to eradicate landmines and promote safety and security.

II. ELECTROMAGNETIC INDUCTION

This approach involves the generation of electromagnetic fields by detectors, followed by the analysis of disturbances induced by metallic objects buried beneath the surface. Landmines, upon encountering these electromagnetic fields, disrupt the established patterns, thereby generating discernible signals detectable by specialized equipment. Such precise localization of landmines facilitates their safe removal, markedly enhancing the efficacy and expeditiousness of demining endeavors while concurrently mitigating risks posed to demining personnel. Consequently, this methodology emerges as an indispensable asset in humanitarian mine action and conflict resolution initiatives globally.

A. Capacitance

In our rover, the capacitor plays a vital role in amplifying the electromagnetic field generated by the copper coil, ultimately improving landmine detection sensitivity. It acts as a temporary energy storage unit, accumulating electrical charge during the charging phase. This relationship between capacitance and electromagnetic induction is governed by Faraday's Law of Induction and Lenz's Law.

Faraday's Law states that the electromotive force (EMF), or voltage induced in a closed loop conductor, is directly proportional to the rate of change of magnetic flux through the loop. Mathematically, this can be expressed as [2]

EMF = -ΔΦ/Δt

where EMF is the induced voltage, Φ is the magnetic flux (the strength and direction of the magnetic field through a surface), and Δt is the change in time. Lenz's Law, dictates the direction of the induced current. It states that the induced current will always create a magnetic field that opposes the change in magnetic flux that caused it.

Now, consider the copper coil in our rover. When the capacitor discharges rapidly into the coil, a surge of current flows through it. According to Faraday's Law, this rapid change in current creates a strong magnetic field around the coil. The strength of this magnetic field, crucial for landmine detection, is directly related to the amount of current flowing through the coil. This is where capacitance comes into play.

Capacitance (C), measured in Farads (F), defines the ability of a capacitor to store electrical charge (Q) for a given voltage (V) across its plates. The relationship is expressed as

C = Q/V

A higher capacitance signifies a larger storage capacity for electrical charge.

When the capacitor in the charging circuit has a higher capacitance, it can store a greater amount of charge during the charging phase. This translates to a more significant current surge when the capacitor discharges into the coil. As per Faraday's Law, this larger current generates a stronger magnetic field around the coil, enhancing the ability to detect buried landmines. The stronger magnetic field can penetrate the ground more effectively, inducing larger eddy currents in any metallic objects present, such as landmines. These eddy currents, in turn, generate a secondary magnetic field detectable by the rover's sensors, indicating the presence of a potential threat.

The capacitance of the capacitor directly influences the strength of the electromagnetic field generated by the copper coil. By optimizing the capacitance value, we can maximize the effectiveness of our mine detection rover in locating buried landmines.

B. Induction using a Copper Coil

Our mine detection rover utilizes the principle of electromagnetic induction to unearth buried landmines. This method relies on Faraday's Law of Induction and Lenz's Law to create a powerful magnetic field and detect its interaction with metallic objects.

The rover's copper coil acts as a giant electromagnet. When a current pulse surges through the coil, a strong magnetic field rapidly builds up around it according to Faraday's Law. This magnetic field isn't static; it expands and contracts with each current pulse. Now, Lenz's Law comes into play. If a metal object, like a landmine, lies within the reach of this changing magnetic field, Lenz's Law dictates that the metal object will try to induce its own opposing magnetic field to resist the change.

This resistance isn't passive. The metal object experiences eddy currents, swirling electrical currents within its own body. These eddy currents, in turn, generate their own weak magnetic field. The rover's sensors are tuned to detect these subtle disturbances in the magnetic field caused by the interaction between the coil's field and the metal object. By analyzing these changes, the rover can pinpoint the location of a potential landmine buried beneath the surface.

III. HARDWARE AND ROBOTIC COMPONENTS

The hardware used in this project includes plywood to make it light-weight and mobile. The components of the rover are following:

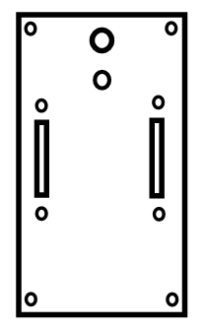

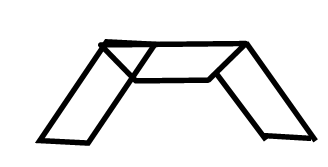

A. Top and Joints

This part includes the top flat portion of the rover in which all the other components except motors are mounted.

Figure 1: Flat-Top Figure 2: Side U Part

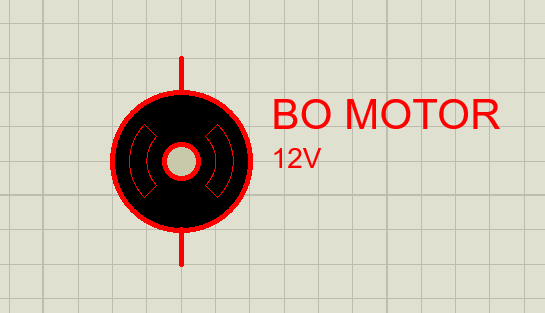

B. Motors and Wheels

The wheel used has a diameter of 20mm. As the rover is 4x4 we have used four such wheels. These wheels are plastic made with rubber tires gives them proper grip.

Figure 3: BO Motor

The motor used here is Dual Shaft BO motor with max speed of 150 RPM on the operating voltage of 3V – 12V. The rover is equipped with 4 BO motors. This gives the rover an approximate speed of 13 km/hr.

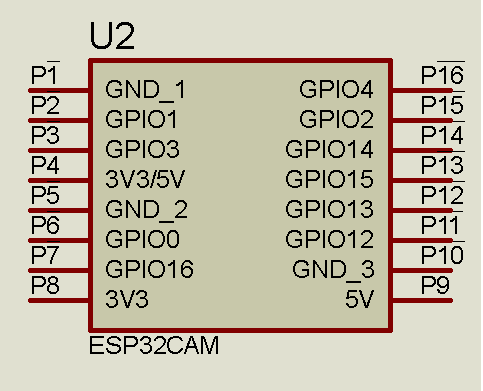

C. ESP 32

The ESP32-CAM module was chosen as the primary visual sensor for our 4x4 rover due to its compact size, low power consumption, and integrated Wi-Fi capabilities. This enables the rover to capture real-time video footage of the minefield and stream it wirelessly for remote monitoring and analysis. The ESP32-CAM's onboard microcontroller allows for on-device image processing tasks if needed, while its microSD card slot facilitates local video storage for later review. These features combined make the ESP32-CAM an ideal solution for the visual data acquisition system in our mine detection rover.

Furthermore, the ESP32-CAM's camera functionality extends beyond mine detection, allowing for real-time camera surveillance of the rover's surroundings, which can be crucial for situational awareness and navigation, particularly in remote or hazardous environments. These features combined make the ESP32-CAM an ideal solution for the visual data acquisition system in our mine detection rover.

The ESP32 also enables Wi-Fi connectivity to the rover. This way the rover can be connected to our mobile device. Upon entering the IP Address provided by the ESP32, a web page opens which displays controls for the rover and the camera feed of the rover. The inclusion of functions such as “esp_http_server.h”, “esp_timer.h”, “Arduino.h” etc. enables users to remotely control the rover using the mobile device.

D. Arduino Uno

While Arduino Uno offers a versatile platform for hobbyist projects, it might not be the most suitable choice for real-world landmine detection due to limitations in processing power and safety considerations. However, it can serve as a valuable tool for initial development and testing purposes.

In a theoretical scenario, the Arduino Uno could be used to control a pulse generation circuit that charges a copper coil. This coil, when pulsed with a specific current, would generate an electromagnetic field. By measuring the induced voltage on the Arduino's analog pins, changes in the magnetic field caused by the presence of metal (potentially a landmine) could be detected. This approach requires careful calibration and experimentation to account for variations in soil composition and environmental factors. It's important to note that this is a simplified concept and wouldn't be effective for real-world landmine detection due to the complexity of landmine types and the need for more sophisticated signal processing techniques.

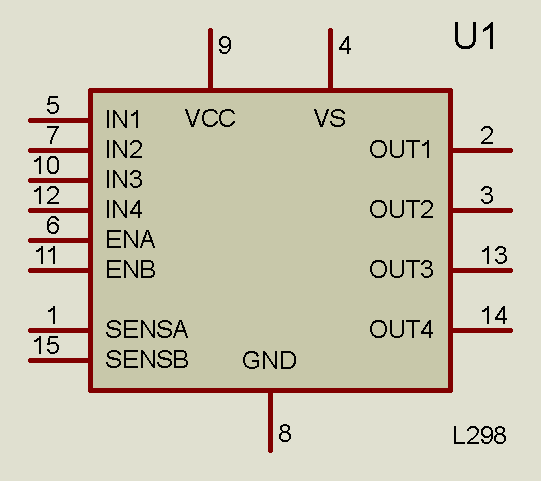

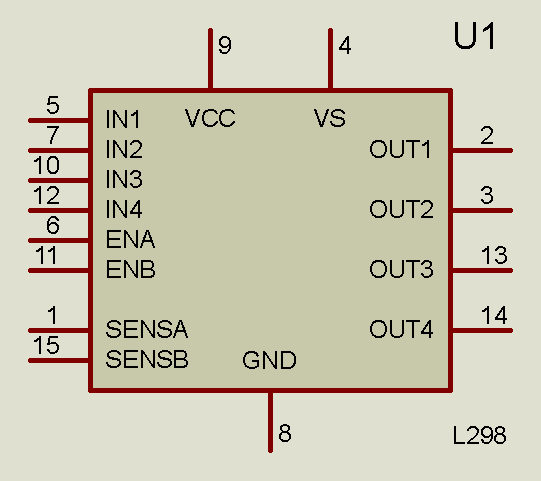

E. Motor Driver

The L298N motor driver acts as the muscle behind our 4x4 rover, providing the necessary control and power to navigate the challenging terrain of a minefield. This versatile integrated circuit (IC) can handle two DC motors simultaneously, perfectly suited for driving each of the rover's four wheels. By controlling the direction and speed of each motor through a series of logic signals, the L298N enables precise maneuvers and allows the rover to adapt to uneven surfaces or obstacles. Furthermore, the L298N boasts a separate power supply input, enabling it to draw power from a dedicated source for the motors, while also incorporating a built-in 5V voltage regulator. This regulated 5V output conveniently powers the ESP32-CAM module, the rover's visual intelligence unit. This eliminates the need for a separate power supply for the camera, streamlining the overall design and power management system of the rover. In essence, the L298N acts as a one-stop shop for motor control and camera power, ensuring the smooth operation of both the rover's mobility and visual data acquisition capabilities.

F. Capacitor

In our mine detection rover, a capacitor plays a crucial role in prepping the copper coil for its electromagnetic search. Imagine the capacitor as a temporary energy reservoir. When the system sends a pulse of electricity, the capacitor stores this charge. Then, when discharged rapidly into the copper coil, it delivers a powerful burst of current. This powerful current surge creates a stronger electromagnetic field around the coil.

Figure 4: 1pF Capacitor

The capacitance, or the capacitor's storage capacity, is important because it determines the intensity of this electromagnetic pulse. A higher capacitance allows for a greater charge to be stored and released, resulting in a more robust electromagnetic field. This stronger field can penetrate the ground more effectively, increasing the chance of detecting any metallic objects like landmines that may be buried beneath the surface.

G. Rectifier Diode

The 1N4007 rectifier diode plays a critical role in the charging circuit of our mine detection rover's copper coil, working alongside the capacitor to ensure efficient energy delivery. Imagine a one-way street for electricity – that's what the rectifier diode is like.

Figure 5: 1n4007

It allows current to flow freely in one direction, towards the capacitor to be stored for the pulse. However, the diode blocks current from flowing back in the opposite direction when the capacitor discharges into the coil. This prevents the capacitor from rapidly draining and ensures a complete discharge, maximizing the current surge delivered to the coil. This powerful surge is essential for generating a strong electromagnetic field for effective metal detection. Without the 1N4007 diode, the current would flow erratically, hindering the capacitor's ability to store energy and ultimately weakening the electromagnetic pulse's effectiveness in detecting buried landmines.

IV. ALGORITHM AND METHODOLOGY

The rover essentially has 2 basic functions to perform – detecting a landmine, rover movements and wireless surveillance over Wi-Fi. We have divided these 2 functions over two systems. System 1 consists of movements and surveillance while System 2 is all about detecting landmines.

A. Let’s understand these Systems

1) Connections & Circuits

a) System 1

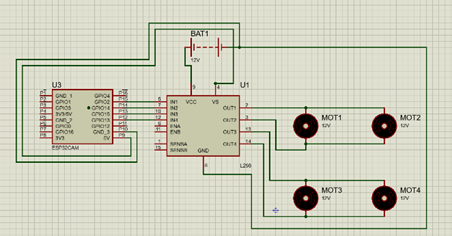

The L298N motor driver serves as the nerve center for the rover's mobility, bridging the gap between the ESP32-CAM module's control and the physical movement of the wheels. To achieve this, the L298N draws power from a separate battery connected to its VCC and ground terminals. This dedicated power source ensures the motors have ample strength to operate without draining the ESP32-CAM module's supply.

Figure 6: Pins connecting ESP 32 Cam and Motors of the rover.

The ESP32-CAM, acting as the rover's brain, transmits control signals via the IN1 and IN2 pins of the L298N. By manipulating these signals, the ESP32-CAM dictates the direction and speed of each motor. Finally, the L298N translates these control messages into action. The OUT1 and OUT2 pins are wired to the left-side motors, while OUT3 and OUT4 manage the right-side motors. This configuration allows the ESP32-CAM to control each wheel independently, granting the rover the ability to navigate diverse terrains and perform precise maneuvers.

Figure 7: Complete Circuit diagram

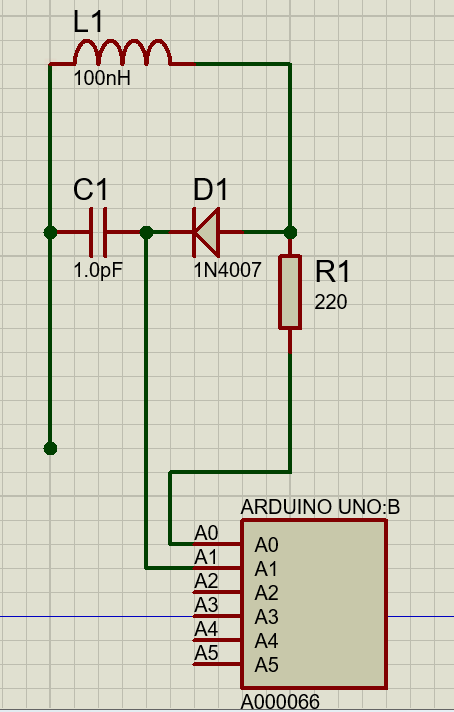

b) System 2

The proposed metal detection circuit for the Arduino Uno utilizes a voltage divider configuration to interface the sensor coil with the microcontroller's analog input pins (A0 and A1). A 220-ohm resistor limits the current flowing from the circuit to A0, protecting the Arduino's sensitive analog circuitry. The other end of the resistor connects to the anode of a 1N4007 diode, ensuring unidirectional current flow towards the Arduino.

Figure 8: Metal detection circuit diagram

A 1 pF capacitor is connected in parallel with the copper coil (inductor) at this shared junction point. The inductor is expected to generate a magnetic field when energized with current. The capacitor's minimal capacitance value might serve a dual purpose: fine-tuning the signal response for optimal sensitivity or filtering out unwanted electrical noise. The remaining terminal of the inductor connects directly to the Arduino's ground pin. Finally, the remaining capacitor terminal also connects to the Arduino's ground, completing the circuit loop. This configuration allows potential changes in the magnetic field, induced by the coil, to influence the voltage measured at the Arduino's A1 pin. It is crucial to acknowledge that this base design might necessitate further calibration and optimization for superior performance. The chosen resistor and capacitor values might require adjustments based on the specific characteristics of the inductor and the desired sensitivity of the metal detection application.

2) Simulation

a) System 1

During the simulation phase of our 4x4 rover, we can virtually test the interaction between the key components: a 12V battery, the L298N motor driver, and the ESP32-CAM module. This simulated environment allows us to refine the system's design and functionality before real-world implementation.

Figure 9: Connections between ESP32-CAM and Motor driver

The simulation will model the 12V battery as a power source, providing the necessary voltage for both the ESP32-CAM module and the L298N motor driver. The motor driver can then be programmed to simulate various motor control scenarios. We can test forward and backward movement, speed variations, and potentially even turning maneuvers. This allows us to assess the motor driver's ability to translate control signals from the ESP32-CAM into the desired motor actions.

Furthermore, the simulation can model the ESP32-CAM module's functionalities. We can test video capturing and processing to ensure the camera delivers clear visuals for remote monitoring and analysis. Additionally, the simulation can model Wi-Fi connectivity, allowing us to virtually test the live video streaming capabilities of the ESP32-CAM. By simulating these aspects, we can identify potential issues and optimize the system for seamless operation before deploying the rover in the field.

Surveillance Function – The ESP 32 Cam module provides real time footage of the surrounding space of the rover. Since the ESP 32 Cam module can connect to Wi-Fi. It hosts a web page on the local IP address which can be accessed by a computer or mobile device, enabling remote monitoring and control of the rover’s movements. This function helps us monitor the surrounding area and avoid any obstacle or detect suspicious activity.

b) System 2

To thoroughly evaluate the functionality of the proposed metal detection circuit interfacing with the Arduino Uno, a computer simulation was implemented. This simulated environment facilitated comprehensive analysis of the circuit's behavior prior to hardware construction.

The simulation software modeled the interaction between the Arduino Uno and the connected components. A digital pulse signal originating from the Arduino was simulated to represent the charging cycle of the physical capacitor. As this virtual capacitor charged within the program, the voltage across it would correspondingly rise. This rising voltage was then virtually transferred to the simulated coil, replicating the current flow that generates a magnetic field in the hardware counterpart.

The final stage of the simulation focused on monitoring the voltage reading at the A1 pin. Ideally, any alterations in the magnetic field induced by nearby metallic objects would be reflected as fluctuations in the simulated voltage measured at A1. By meticulously analyzing these fluctuations, the simulation offered valuable insights into the circuit's sensitivity for metal detection. This simulated environment empowered the refinement of component values and control signals before physical circuit construction, potentially leading to significant time and resource savings during the development phase.

V. FUTURE SCOPE

This project can be further modified with movable 360-degree camera for complete surveillance ensuring complete security. The configuration of the camera can also be changed by adding filters to the images and videos captured by the camera, so that various images such as thermal, dark, etc. images can be clicked. The metal detector sensor can be improved by increasing the number of windings or using a capacitor of greater capacitance. This will enable the rover to detect mines buried deeper into the ground. The wheels of the rover can be modified to operate in dense and rough terrain, this will require an upgrade in the battery and the power output of the wheel too.

Conclusion

This project has successfully developed a prototype mine detection rover and surveillance system with the potential to revolutionize landmine clearance efforts. The 4x4 rover, equipped with an ESP32-CAM module and a capacitor-coil assembly, offers a robust platform for mine detection using electromagnetic induction. The L298N motor driver ensures efficient movement and maneuverability, while the ESP32-CAM\'s Wi-Fi capabilities enable real-time video streaming for remote monitoring and analysis. The simulations conducted during the development phase provided valuable insights into the functionality of the individual components and the overall system. The modular design allows for future improvements, such as incorporating additional sensors for enhanced detection capabilities or integrating more sophisticated algorithms for signal processing. This prototype serves as a steppingstone towards the development of a fully operational mine detection rover. Further research and development efforts can focus on optimizing the system\'s sensitivity, improving its ability to navigate challenging terrains, and ensuring its safety and reliability in real-world deployment scenarios. By combining the power of technology with the ingenuity of engineering, this project has the potential to make a significant contribution to the noble cause of landmine clearance, saving lives and restoring safety to war-torn regions.

References

[1] United States Commitment to Humanitarian Demining, “To walk the earth in safety,” 2002. [2] S. C. Mukhopadhyay and G. Sen Gupta C. P. Gooneratne, “A Review of Sensing Technologies for Landmine Detection: Unmanned Vehicle Based Approach.” 2nd International Conference on Autonomous Robots and Agents, Palmerston North, 2004. [3] United Nations News, Global perspective Human Stories [4] Fundamentals of Physics, Extended by David Halliday, Jearl Walker, and Robert Resnick [5] LT Wood, RM Rottmann, and Regina Barrera. “Faraday’s Law, Lenz’s Law, and conservation of energy”, in American Journal of Physics 72.3 (2004): 376-380. [6] Zerigui, Amel, Xiang Wu, and Zong-Quan Deng. \"A survey of rover control systems.\" IJCSES 1.2 (2007): 106 [7] Kumar, Saurav, and Pallavi Awasthi. \"Navigation architecture for autonomous surveillance rover.\" International Journal of Computer Theory and Engineering 1.3 (2009): 231. [8] Landzettel, Klaus, et al. \"A micro-rover navigation and control system for autonomous planetary exploration.\" Advanced Robotics 18.3 (2004): 285-314.

Copyright

Copyright © 2024 Vaishali Rajput, Aashi Mathur, Tejas Abhang, Abhijeet Bharate, Abhijeet Kolhe, Adarsh Pathak, Rudraksh Adhane. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64692

Publish Date : 2024-10-19

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online