Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Sustainable E-Waste Management: A Novel Framework Incorporating Circular Economy Principles

Authors: Abhinav Rajpati, Diwakar Pareek, Dr. Gaurav Raj

DOI Link: https://doi.org/10.22214/ijraset.2024.65558

Certificate: View Certificate

Abstract

E-waste management is about taking care of old electronics products. It gathers them, separates the useful parts, safely recycles the hazardous stuff, and fixes or reuses the items for protecting the environment. But e-waste also holds potential benefits for society. Appropriate management and recycling may recover valuable resources, reduce environmental pollution, and provide economic opportunities in recycling industries. We suggest a brand-new comprehensive architecture that includes circular economy principles, emphasizing design for recyclability, product longevity, and closed-loop supply chains. Our research findings will try to suggest that successful e-waste management requires a multi stakeholder approach, involving governments, manufacturers, consumers, and recycling industries.

Introduction

I. INTRODUCTION

The fast development of technology has result in an unprecedented growth in the manufacturing and use of electronic devices. Although many businesses have profited much from these advancements, one major global issue these technologies have also exacerbated is electronic trash, or "e-waste." One of the waste streams in the world today growing quickest is e-waste, which includes abandoned electronics including homes appliances, cell phones, and computers. Electronic waste is among the waste sources with fastest global growth. By 2022, e-waste generated globally would exceed 62 million metric tonnes. These devices have dangerous elements, so improper e-waste disposal seriously jeopardises human health and the surroundings.

Aware of the pressing need to address the e-waste situation, governments and international organisations have instituted many policies and laws to control and lower e-waste. Among this laws are extended producer responsibility (EPR), recycling requirements, public awareness campaigns, and developments of circular economy ideas. Notwithstanding these efforts, the effectiveness of current regulations is still unequal, and the alarming rates of increasing electronic waste generation call for constant improvement.

This study article aims to evaluate the present e-waste management policies across several sites and offer a hybrid or unique policy framework to overcome the inadequacies and restrictions of the current approaches. We want to improve the efficiency and sustainability of worldwide e-waste management by including creative ideas and effective policy components. This project seeks to give data that will help environmentalists, legislators, and business community members handle the growing problem of e-waste and related effects.

II. RELATED WORK

Electronic and electrical equipment waste containing hazardous substances has recently been known as an environmental issue worldwide since, if not checked, ends up posing detrimentality towards ecosystems and human health. In this paper, toxic materials that are contained in e-waste, potential dangers to the environment and health, and approaches taken by other countries to the issue, are analyzed. Tools include use by developing nations of Life Cycle Assessment, analyzing the environmental impact from creation to disposal; Material Flow Analysis, that tracks the movement of materials in order to reduce waste; Multi-Criteria Analysis, in choosing the best option through a multiple criterion for example cost and safety; Extended Producer Responsibility, in which companies are made responsible for their product after its life has run out. For example, studies conducted in Switzerland showed that recycling e-waste has a huge environmental benefit compared to burning. In South America, e-waste management studies showed that technically, refurbished electronics are available, but there are some problems in maintenance and it may cause harm to the environment.

Proper management of e-waste must also involve the designing of environmentally friendly products, proper collection and recycling of e-waste, proper disposal methods, refusing exporting of waste electronics to third world countries, and increased awareness about this whole e-waste problem. Even though no one measure is in itself sufficient, a combination of the above can greatly alleviate the problem. A national policy like Extended Producer Responsibility is envisioned to emerge as an answer to the escalating crisis of e-waste.[1]

Combining both LCA and EPR, well-designed reverse logistics, public awareness, and policy support will greatly help in reducing the risks associated with environmental and health impacts of ewaste, besides offering opportunities for economic benefits in recycling and material recovery.[2]

E-waste management is becoming a relatively fast-developing global issue due to rapid technological advances coupled with high consumer demand on the leading risks from improper electronic disposal on health and the environment. The developed countries implement policies that enforce safe disposal and recycling of such materials using Extended Producer Responsibility (EPR). The developing countries, however, like the Philippines, continue with insufficient policies and rely on the informal recycling sectors, which, in some cases, practice hazardous practices. This would put the Philippines at a disadvantage for failing to have specific laws on e-waste within the existing waste policies of the country, which include the Ecological Solid Waste Management Act of 2000 and the Toxic Substances and Hazardous and Nuclear Wastes Control Act of 1990. There is evidence of enhancement through the adoption of a structured policy modelled after the EU's Waste Electrical and Electronic Equipment (WEEE) Directive, public awareness in the country, and formal recycling infrastructure. The collaboration of the government, industry, and communities must address the ever-increasing e-waste and secure sustainable management practices in the Philippines.[3]

As e-wastes increase with more modernization, waste management around the globe has been a key aspect that prompted the introduction of various policies in the EU and India. The EU established the WEEE and RoHS Directives in setting targets on recycling, banning the materials containing hazardous substances, which include the stakeholders; these are either the manufacturers, sellers, customers, and people selling on e-commerce stores. While India's E-Waste Management Rules focus on Extended Producer Responsibility, in which the entire lifecycle of electronics is laid out with the producers, recyclers, and government agencies, both regions keep the product scope relatively similar but differ in targeting as the EU relies on accountability from the consumer side while India focuses on producer responsibility. Improvements for both suggest India would be the involvement of all stakeholders in the e-commerce industry and customer direct engagement in recycling efforts; the two regions would benefit from global unified standards, cross-border labeling, and universal recycling benchmarks to improve international management of e-waste.[4]

Exploring how to handle electronic waste in developing countries: approaches, factors influencing the situation, and how policies affect the technology sector in India. The paper investigates an emergent trend of e-waste in the Indian ICT sector and sharp differences between large and small-to-medium organizations in managing e-waste. E-waste grows with the spread of ICTs though local firms vary substantially in their management of it, depending on company size and resources. Large firms tend to be proactive towards e-waste mainly because of awareness of government regulations, client pressure, and reputational concerns, whereas smaller firms remain largely indifferent due to financial constraints and negligible regulatory pressure. The authors derive the model based on environmental management literature in developed nations and classify e-waste strategies from being indifferent to innovative, finding key determinants like government regulations, peer influences, client requirements, financial implications, and organizational culture. This research thus points to the requirement of specific policies that could address the challenges being caused by e-waste in developing countries like India.[5]

A circular economy method champions sustainable reuse and recycling to combat the growing threat of e-waste that harbors harmful levels for human and ecosystem exposure. Specifically, resource efficiency for product life extension, aided by bioleaching and green solvents, is a major tenet of CE. International cooperation will be required nonetheless in raising the tide against illicit trade in e-waste, while international treaties like the Basel Convention and the EU's WEEE Directive are crucial. Public awareness and economic incentives probably build more compliance since they can create jobs, reduce dependence on raw materials, and ensure sustainable development.[6]

III. METHODOLOGY

This study adopts a mixed-methods approach, combining qualitative and quantitative research to create a unified e-waste management policy model. This research focuses on analyzing current policy understanding industry specific ewaste challenges, and establishing a decision framework to guide companies on policy implementation based on their production characteristics.

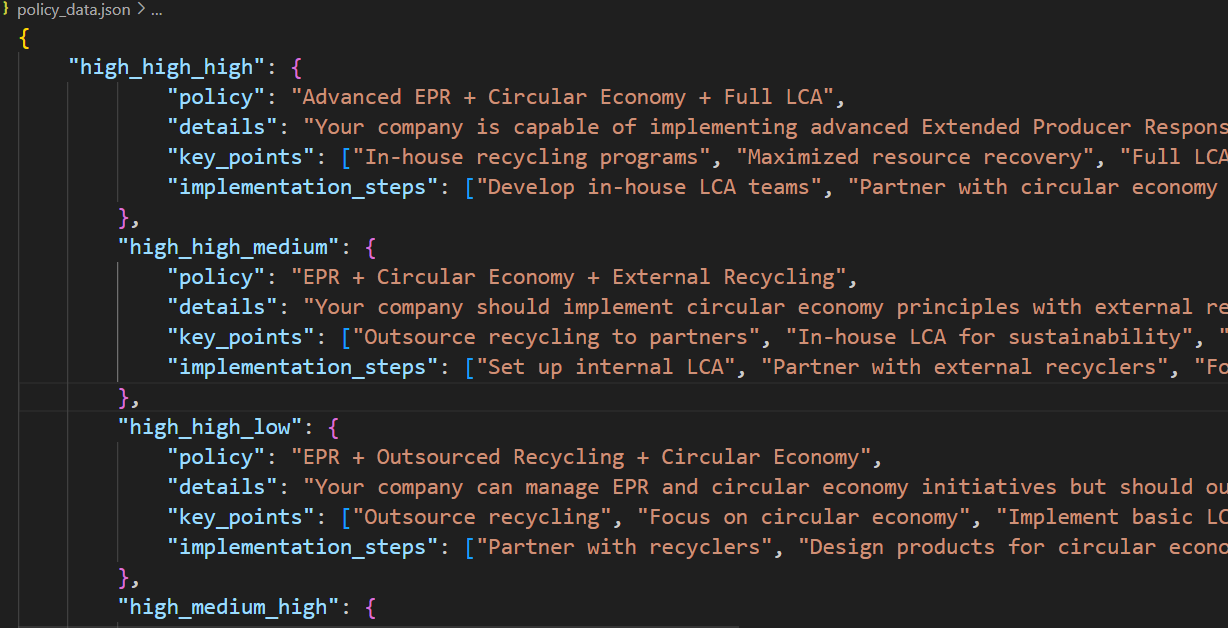

Data collection began with an in-depth literature review, examining e-waste management policies worldwide, such as Extended Producer Responsibility (EPR), Circular economy, full LCA, External Recycling, Out sourced Recycling, Closed loop recycling, and many more. This review was supplemented by an analysis of companies across sectors like electronics, automotive, and appliances to assess production volumes, e-waste generation, and compliance levels.

In this we have studied various policy and created a framework which will help companies to understand what they can do to implement for their e-waste management based on their productivity.

Table 1: Policy Types and Symbol

|

Policy |

Types |

Symbol |

|

EPR |

Advanced EPR |

AEPR |

|

Basic EPR |

BEPR |

|

|

Minimal EPR |

MEPR |

|

|

Circular Economy |

CE0 |

|

|

Third-Party Recycling |

Minimal Third-Party Recycling |

MTPR |

|

LCA |

Full LCA |

FLCA |

|

Basic LCA |

BLCA |

|

|

External LCA |

ELCA |

|

|

Minimal LCA |

MLCA |

|

|

Outsourced LCA |

OLCA |

|

|

External Recycling |

ER0 |

|

|

Outsourced Recycling |

Minimal Outsourced Recycling |

MOR |

|

Outsourced All Recycling |

AOR |

|

|

Minimal Compliance |

MC0 |

|

|

In-House Recycling |

InHR0 |

|

|

Closed-Loop Recycling |

CLR0 |

|

|

Consumer Recycling Incentives |

CRI0 |

Table 2: Policy Explanation

|

Symbol |

Explanation |

|

AEPR |

Comprehensive producer responsibility with advanced recycling and sustainability measures. |

|

BEPR |

Standard compliance with basic recycling obligations. |

|

MEPR |

Bare minimum compliance with regulations. |

|

CE0 |

A system aimed at eliminating waste by reusing, repairing, and recycling resources to maintain their value. |

|

MTPR |

Limited recycling done by third parties. |

|

FLCA |

Comprehensive analysis of all lifecycle stages. |

|

BLCA |

Simplified analysis with limited scope. |

|

ELCA |

Assessment performed by external experts. |

|

MLCA |

Basic compliance-level analysis. |

|

OLCA |

Delegation of LCA to third-party firms. |

|

ER0 |

Recycling activities managed outside the organization. |

|

MOR |

Involves outsourcing only a limited portion of recycling activities. |

|

AOR |

All recycling activities are entirely managed by external agencies or third-party partners. |

|

MC0 |

Meeting only the lowest legal or regulatory requirements. |

|

InHR0 |

Recycling operations managed internally within the organization. |

|

CLR0 |

A system where waste is fully recycled back into the production cycle of the same product. |

|

CRI0 |

Rewards or incentives provided to consumers to encourage recycling behavior. |

Table 3: Policy Decision Table

|

Condition |

Financial |

Technological |

Operational |

Policy |

|

C1 |

High |

High |

High |

AEPR + CE0 + FLCA |

|

C2 |

High |

High |

Medium |

BEPR + CE0 + ER0 |

|

C3 |

High |

High |

Low |

BEPR + OLCA + CE0 |

|

C4 |

High |

Medium |

High |

BEPR + CLR0 + BLCA |

|

C5 |

High |

Medium |

Medium |

BEPR + CE0 + CRI0 |

|

C6 |

High |

Medium |

Low |

BEPR + ELCA + AOR |

|

C7 |

High |

Low |

High |

BEPR + OLCA + InHR0 |

|

C8 |

High |

Low |

Medium |

BEPR + MLCA + AOR |

|

C9 |

High |

Low |

Low |

MEPR + MTPR |

|

C10 |

Medium |

High |

High |

CE0 + FLCA + MTPR |

|

C11 |

Medium |

High |

Medium |

BEPR + CE0 + ER0 |

|

C12 |

Medium |

High |

Low |

BEPR + MLCA + MTPR |

|

C13 |

Medium |

Medium |

High |

FLCA + AOR + BEPR |

|

C14 |

Medium |

Medium |

Medium |

BLCA + MTPR + BEPR |

|

C15 |

Medium |

Medium |

Low |

MEPR + AOR |

|

C16 |

Medium |

Low |

High |

MTPR + BEPR |

|

C17 |

Medium |

Low |

Medium |

MEPR + AOR |

|

C18 |

Medium |

Low |

Low |

MC0 + AOR |

|

C19 |

Low |

High |

High |

MTPR + FLCA |

|

C20 |

Low |

High |

Medium |

MTPR + BEPR |

|

C21 |

Low |

High |

Low |

MEPR + MTPR |

|

C22 |

Low |

Medium |

High |

BEPR + MTPR |

|

C23 |

Low |

Medium |

Medium |

MEPR + AOR |

|

C24 |

Low |

Medium |

Low |

MC0 + AOR |

|

C25 |

Low |

Low |

High |

MEPR + MTPR |

|

C26 |

Low |

Low |

Medium |

MC0 + AOR |

|

C27 |

Low |

Low |

Low |

AOR + MEPR |

Fig: 1

Fig: 2

Fig: 3

Fig: 4

Fig: 5

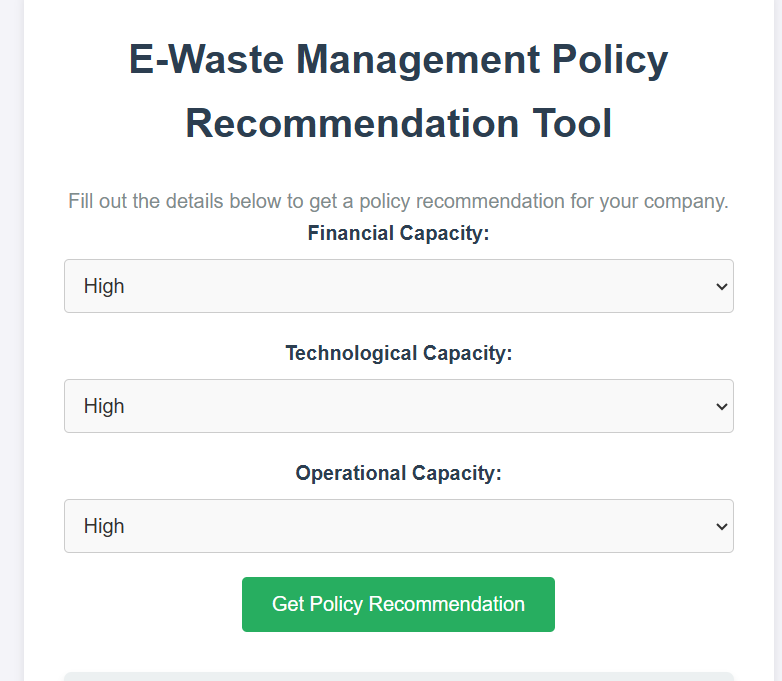

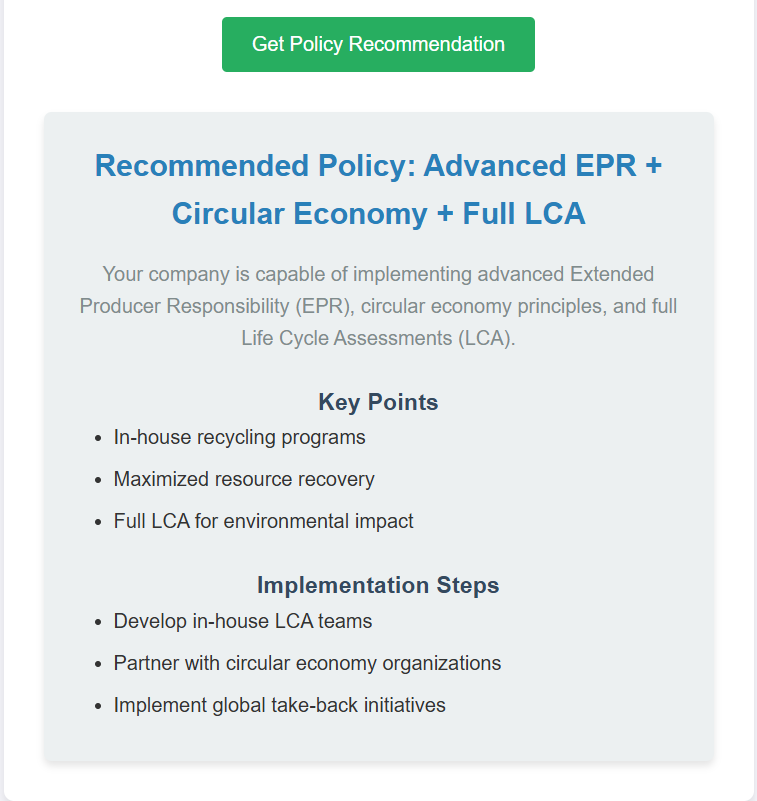

A Policy Recommendation Tool was then developed for this study to guide companies in finding out which policy is best suited for their e-waste management based on their distinct operational capabilities. The companies were rated under three criteria, namely Financial Capacity, Technological Capacity, and Operational Capacity. These capacities rated within the tool give a company a fit policy suggestion that matches its resources and production ability.

- Financial Capacity: This criterion measures the company's financial resources available for implementing e-waste management policies. Companies with high financial capacity are more equipped to invest in comprehensive or advanced waste management systems, while those with limited resources may require more cost-effective, flexible approaches.

- Technological Capacity: Technological capacity reflects the company's access to and proficiency with e-waste management technology. A high technological capacity for a firm means that it can have advanced recycling or disposal processes, thus relying well on policies requiring advanced treatment of waste. Companies with very low technological capacities may need policies oriented towards "back of the house" basic recycling or outsourcing option.

- Operational Capacity: This factor evaluates the infrastructural and logistical capacity of the company in terms of managing e-waste, its storage, transportation, and waste-processing capacities. A company that has a high operational capacity is likely to be better equipped for tougher policy requirements. Company with limited capacities may require less stringent compliance or even progressive approaches.

After a company inputs its self-assessment for each of these criteria, the tool processes the data and provides a tailored policy recommendation. This ensures that the policy for e-waste is implemented in harmony with the abilities of the firm, and the limitations of resources are overcome while the implementation of the policy is practical and effective.

This was validated by case studies and expert feedback, demonstrating its effectiveness in aligning policy recommendations with real company condition. It will prove an effective solution for companies that need guidance on strategies for e-waste management in such a way that each organization can adapt to a sustainable approach given its unique capacities.

IV. CASE STUDY

To enhance practicality applicability of the propose framework, a dedicated case study component is introduced. This involves collecting input from organizations through a structured form, wherein they self-assess their operational capacities across three primary dimensions: High, Medium, and Low for financial, technological, and parameters of operation.

This input is used by the algorithm to assess the replies and dynamically choose the best implementation approach based on the particular capabilities of the organization. We not only suggest the best course of action, but we also provide complete assistance in putting into practice. This entails overseeing every facet of operationalization resource allocation to make sure business can easily implement and use the suggest solution without putting undue burden on their internal resource.

This all encompassing strategy not only make the shift to sustainable ewaste management methods easier but it also give business the ability to successful comply with legal obligations while preserving operational effectiveness.

V. RESULTS AND EXPERIMENTS

The article includes code snippets (Fig 5) showcasing the implementation for policy recommendation tool. Additionally, GUI outputs (Fig 1, Fig 2, Fig 3, Fig 4) are presented.

Conclusion

The research paper outlines e-waste management and, thus, offers a consolidated policy framework as a combination of strengths in prevailing regulations to deliver specific, actionable guidance based on a company\'s production capabilities. Through an analysis of current policies, industry requirements, and stakeholder perspectives, this study developed a flexible model that categorizes companies by financial, technological, and operational capacities to recommend the most suitable e-waste management strategies. The Policy Recommendation Tool introduces further practical application of the framework in that the organizations can have an easy, user-friendly approach to evaluating their capacities that they might have about their company and obtaining recommendations according to their specific policy requirement. For model to be feasible and effective in implementation the alignment of policy requirement with every unique resource constraint of the company improves the rate of compliance and gradually contributes to minimizing e-waste.

References

[1] P. Kiddee, R. Naidu, and M. H. Wong, “Electronic waste management approaches: An overview,” Waste Management, vol. 33, no. 5, pp. 1237–1250, May 2013, doi: 10.1016/j.wasman.2013.01.006. [2] Y. Amer, L. Doan, and S.-H. Lee, “Strategies-for-E-Waste-Management-A-Literature-Review,” 2019, Accessed: Oct. 10, 2024. [Online]. Available: https://www.researchgate.net/publication/334470034 [3] N. Campit, “E-WASTE MANAGEMENT IN THE PHILIPPINES: An Assessment: How effective are the existing environmental governance initiatives in implementing e-waste management in the Philippines?,” Jan. 01, 2017. Accessed: Sep. 15, 2024. [Online]. Available: https://www.academia.edu/42793087/E_WASTE_MANAGEMENT_IN_THE_PHILIPPINES_An_Assessment_How_effective_are_the_existing_environmental_governance_initiatives_in_implementing_e_waste_management_in_the_Philippines [4] K. Mani, “A COMPARATIVE STUDY OF E-WASTE MANAGEMENT POLICIES IN INDIA AND THE EUROPEAN UNION,” Int J Adv Res (Indore), vol. 11, no. 09, pp. 957–969, Sep. 2023, doi: 10.21474/ijar01/17608. [5] R. Heeks, L. Subramanian, and C. Jones, “Understanding e-Waste Management in Developing Countries: Strategies, Determinants, and Policy Implications in the Indian ICT Sector,” Inf Technol Dev, vol. 21, no. 4, pp. 653–667, Oct. 2015, doi: 10.1080/02681102.2014.886547. [6] S. Pouyamanesh, E. Kowsari, S. Ramakrishna, and A. Chinnappan, “A review of various strategies in e-waste management in line with circular economics,” Environmental Science and Pollution Research 2023 30:41, vol. 30, no. 41, pp. 93462–93490, Aug. 2023, doi: 10.1007/S11356-023-29224-Y.

Copyright

Copyright © 2024 Abhinav Rajpati, Diwakar Pareek, Dr. Gaurav Raj. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65558

Publish Date : 2024-11-26

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online