Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experimental Assessment of NSM FRP Systems with Inorganic Adhesives for Concrete Strengthening

Authors: Wajdi Ammar

DOI Link: https://doi.org/10.22214/ijraset.2024.57903

Certificate: View Certificate

Abstract

This study explores the application of various inorganic resins in the Near-Surface Mounted (NSM) strengthening technique, aiming to provide alternatives to traditional organic resins. The research centers on sixty single lap-shear concrete blocks, employing four distinct adhesives—ordinary mortar, Ultra-High-Performance Concrete (UHPC), geopolymer, and polyester-silica—for bonding Carbon Fiber-Reinforced Polymer (CFRP) strips to the concrete blocks. Conducted under monotonic loading, the investigation assesses the bond characteristics between the inorganic resins and both CFRP composites and the concrete substrate. Interfacial behaviour, bond strength, and failure modes are meticulously analyzed, shedding light on the performance of each adhesive. The study reveals insights into the efficiency of the NSM system, emphasizing the significance of the bond between FRP composites and concrete for optimal strengthening. The findings underscore the limited research on NSM systems using inorganic resins, providing a foundation for further exploration in this domain.

Introduction

I. INTRODUCTION

The pursuit of sustainable and resilient structural solutions has fueled ongoing advancements in the field of structural engineering. Fiber-Reinforced Polymer (FRP) composites, with their commendable mechanical properties, have emerged as a transformative material in the domain of structural strengthening [1]. Among the various techniques employed for enhancing the performance of structures, the Near-Surface Mounted (NSM) strengthening method stands out for its potential to optimize the bond between FRP composites and concrete substrates [2].

Traditional NSM applications have primarily relied on organic resins for adhesive purposes. However, this study delves into an innovative approach by exploring the viability of inorganic resins as an alternative adhesive material for NSM strengthening [1]. The motivation behind this exploration is rooted in the need to address the limitations associated with conventional organic adhesives, particularly concerning environmental resistance and long-term durability.

The focal point of this research is a meticulous examination of the performance of different inorganic resins in NSM strengthening applications. To achieve this, sixty single lap-shear concrete blocks were subjected to experimental testing, employing four distinct inorganic adhesives: ordinary mortar, Ultra-High Performance Concrete (UHPC), geopolymer, and polyester-silica [3]. The bond characteristics, interfacial behavior, and resultant bond strength between Carbon Fiber Reinforced Polymer (CFRP) strips and the selected inorganic resins were rigorously evaluated under monotonic loading conditions.

This paper aspires to contribute to the evolving landscape of structural engineering by providing insights into the efficacy of inorganic resins in NSM strengthening [1]. Beyond a mere exploration of materials, the study underscores the pivotal role of the bond between FRP composites and concrete in influencing the overall efficiency of the strengthening system. As society gravitates towards sustainable and durable infrastructural solutions, understanding and harnessing the potential of innovative materials, such as inorganic resins in NSM applications, become integral to advancing the resilience and longevity of reinforced concrete structures.

II. LITERATURE REVIEW

Recent advancements in the field of structural rehabilitation have witnessed a growing interest in the application of near-surface-mounted (NSM) carbon fiber-reinforced polymer (CFRP) strips, particularly when bonded with inorganic resins. This literature review delves into the key findings of two pertinent studies exploring the feasibility and performance of cementitious resins as bonding agents for NSM CFRP applications.

The initial study focused on the utilization of three distinct inorganic resins—polyester-silica, ultra-high-performance concrete (UHPC), and geopolymer—compared to traditional organic matrixes in rehabilitating reinforced concrete beams [4]. The investigation included a thorough analysis of the resins' workability, rheological properties, and their impact on the flexural response of retrofitted beams. Findings revealed that polyester-silica exhibited superior load-carrying capacity, while UHPC showcased stable degradation over an extended period, challenging conventional expectations. In a subsequent study, the emphasis shifted towards understanding the time-dependent interfacial behaviour of NSM CFRP strips using these inorganic resins. The four bonding agents—mortar, polyester-silica, UHPC, and geopolymer—underwent rigorous testing over a 28-day curing period. Notably, the study highlighted the evolving rheological resistance of polyester-silica and UHPC resins, attributing it to an advanced setting process within 30 minutes. The compressive strength of these resins exhibited distinctive patterns, with UHPC rapidly reaching 95.3 MPa at 3 days. Furthermore, the study identified variations in failure modes over time, specifically noting a shift in the plane of failure for mortar-bonded interfaces [5, 6]. This evolving body of research challenges conventional norms and underscores the nuanced interplay between inorganic resins, curing periods, and NSM CFRP interfaces. The findings not only contribute to the understanding of material-level properties but also advocate for a reconsideration of existing design guidelines, proposing modification factors to enhance the acceptance and utilization of cementitious resins in NSM CFRP applications [7, 8].

III. INVESTIGATING THE BOND PERFORMANCE OF NEAR-SURFACE MOUNTED CFRP STRIPS WITH INORGANIC RESINS IN CONCRETE STRENGTHENING APPLICATIONS

This chapter outlines the experimental setup and testing procedures designed to scrutinize the bond performance between near-surface mounted (NSM) CFRP strips and various materials—specifically ordinary mortar, ultra-high-performance concrete (UHPC), geopolymer, and polyester-silica. The primary objective is to evaluate these materials as potential alternatives to conventional bonding agents, with the aim of enhancing the efficacy of the NSM strengthening system.

A total of 60 unreinforced concrete prisms were meticulously prepared, each grooved and categorized based on the type of bond material employed. The selected materials, each possessing unique properties, included ordinary mortar, UHPC, geopolymer, and polyester-silica. These prisms were then subjected to a single-shear lap-test, a method recommended by ACI 440.2R-17.

The concrete mix chosen for this study was Quikrete No. 1101, a pre-blended composition of cement, sand, and aggregate with a compressive strength of 27.6 MPa at 28 days. To assess its performance, cylinders were cast and tested following ASTM C31 / C31M procedures [1]. CFRP strips, supplied by Hughes Brothers and measuring 16 mm wide, 2 mm thick, and 275 mm long, served as the reinforcing material. The bonding agents integral to this study were ordinary Portland cement mortar, UHPC, geopolymer, and polyester-silica. Ordinary Portland cement mortar was meticulously prepared using Quikrete Type I/II cement, local sand, and potable tap water. The mix proportions adhered to the standard mortar mix of cement, water, and sand. Compressive strength tests were conducted at various intervals (1, 3, 7, 14, and 28 days), showcasing a progressive increase in strength [2].

UHPC, ce200™-120G by ceEntek, featuring a nanocarbon fiber-modified formulation, was the material of choice. Three additional components—ce200TM-120G-R premix, cePAA1-93S paste, and ceCA1 admixture—were used in conjunction with potable water. Compressive strength tests demonstrated a steady increase over the curing period, emphasizing its suitability for these experiments.

Geopolymer, known as GeoSprayTM, developed by Milliken Infrastructure Solutions, offered an environmentally advantageous alternative. Comprising post-industrial waste, it promised 80% fewer CO2 emissions. The compressive strength of geopolymer cubes increased steadily until the 28th day, demonstrating its compatibility with the experimental requirements.

Polyester-silica, a composite of silica sand and polyester resin, was utilized. The resin, sourced from Environmental Technology, INC., underwent a chemical hardening process with Castin’ Craft Catalyst. Compressive strength tests revealed a gradual ascent, stabilizing after the 14th day. To assess the workability of the adhesives, rheological properties were gauged through a vane shear test, offering insights into their stiffening behaviour over time. This crucial analysis provided valuable information for the subsequent bonding procedures, ensuring a detailed understanding of the methodology, materials, and testing procedures for the subsequent presentation and analysis of the experimental outcomes.

IV. EXPERIMENTAL RESULTS AND ANALYSIS

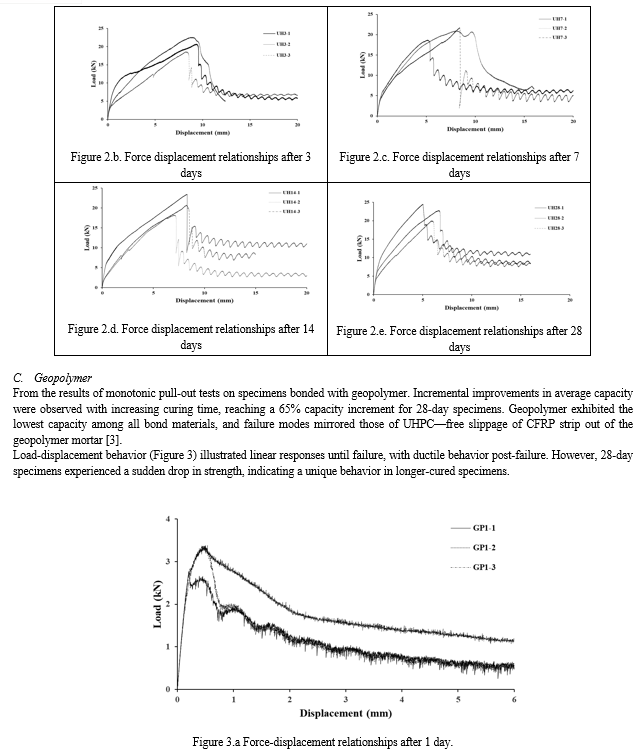

In this chapter, the outcomes of the experiments conducted on 60 concrete blocks, each reinforced with CFRP strips and subjected to different bond materials, are detailed. The specimens were systematically categorized into four series, and each series underwent testing at intervals of 1, 3, 7, 14, and 28 days, with three specimens per specified day. The parameters examined included pull-out capacity, failure modes, and load-displacement behaviour. A comprehensive summary of the results, organized by bond material, is presented below[9, 10].

A. Ordinary Mortar (OM)

The findings from the monotonic pull-out tests on specimens bonded with ordinary mortar. The ultimate loads and average values, along with displacement at ultimate load, reveal noteworthy trends. The ultimate load exhibited a direct correlation with curing time, with a 97% increase observed between the 1-day and 28-day specimens. Two distinct failure modes were identified based on curing time: concrete-adhesive interface failure for 1-day and 3-day tests and interfacial failure between mortar and CFRP strip for 7-day and 28-day tests.

The load-displacement behavior, depicted in Figure 1, demonstrated a linear response until failure for all specimens. Ductile behavior post-failure was attributed to residual frictional stresses between the concrete substrate and mortar, emphasizing the influence of ordinary mortar's compressive strength on bond performance.

Conclusion

This chapter distills the findings from the experimental investigations, offering a comprehensive overview of the study\'s implications and potential avenues for future research. Key observations underscore the influential role of bond material, with ordinary mortar exhibiting a direct correlation between compressive strength and bond performance. Conversely, UHPC, geopolymer, and polyester-silica displayed distinct characteristics in their interactions with CFRP strips. Curing time emerged as a critical factor, showcasing a consistent impact on ultimate loads. The direct relationship between curing time and bond strength emphasizes the significance of considering concrete age in assessing CFRP bond performance. Unique failure modes associated with different curing times and bond materials provide crucial insights for predicting and enhancing the reliability of CFRP-strengthened structures [2,11]. Practical implications of the study extend to material selection, construction scheduling, and failure mode considerations during design. Engineers can leverage this knowledge to optimize project-specific requirements and bolster the long-term efficacy of CFRP-strengthened structures [3,12]. Future research opportunities lie in expanding the scope of bond materials, exploring the influence of environmental conditions, and delving into the long-term durability of CFRP-strengthened structures [13]. As the construction industry evolves, ongoing research in this domain will contribute to advancing the reliability and sustainability of infrastructure.

References

[1] Kim, YJ., Ammar, W. (2023) Time-Dependent Bond of Concrete and Near-Surface-Mounted Carbon-Fiber-Reinforced Polymer with Inorganic Resins. ACI Structural Journal, 120, 137-149. https://doi.org/10.14359/51738720 [2] Kim, YJ., Ammar, W. (2023) Cementitious Resins for Strengthening Reinforced Concrete Beams with Near-Surface-Mounted Carbon Fiber- Reinforced Polymer. ACI Structural Journal, 120, 61-74. https://doi.org/10.14359/51734825 [3] Ammar, W. (2023) Strengthening of concrete structures with NSM, CFRP, and inorganic adhesives [Master’s thesis, University of Colorado Denver]https://digital.auraria.edu/work/ns/cbaa45c7-f9b0-40b8-ba74-654bf6f879d1 [4] ACI. (2017). Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures (ACI 440.2R-17). American Concrete Institute, Farmington Hills, MI. [5] Hamad, S., Ammar, W., Shaniba, S. and Altlomate, A. (2022). Condition Assessment of August A. Busch Bridge Deck Using Portable Seismic Property Analyzer and Ground Penetrating Radar. Open Journal of Civil Engineering, 12, 14-21. https://doi.org/10.4236/ojce.2022.121002 [6] Chellapandian, M., Prakash, S. S., & Sharma, A. (2019). Experimental and finite element studies on the flexural behavior of reinforced concrete elements strengthened with hybrid FRP technique. Composite Structures, 208, 466-478. https://doi.org/10.1016/j.compstruct.2018.10.077. [7] Hamad, S., Ammar, W. and Shaniba, S. (2021) Condition Assessment Using None Destructive Tests at Montauk Bridge Deck. International Journal for Research in Applied Science & Engineering Technology, 9, 581-588. https://doi.org/10.22214/ijraset.2021.39337\\ [8] Samie, H., Abdurraouf, O., Neil, A. and Wajdi, A. (2021) Use of Portable Seismic Property Analyzer and Ground Penetrating Radar to Assess Bridge Decks. Symposium on the Application of Geophysics to Engineering and Environmental Problems Proceedings, Denver, June 2021, 327. https://doi.org/10.4133/sageep.33-179 [9] Zhang, S. S., Yu, T., Chen, G. M. (2017). Reinforced concrete beams strengthened in flexure with near-surface mounted (NSM) CFRP strips: Current status and research needs. Composites Part B: Engineering, 131, 30-42. https://doi.org/10.1016/j.compositesb.2017.08.020. [10] Hamad, S., Ammar, W. and Shaniba, S. (2021) Condition Assessment Using None Destructive Tests at Montauk Bridge Deck. International Journal for Research in Applied Science & Engineering Technology, 9, 581-588. https://doi.org/10.22214/ijraset.2021.39337 [11] Hamad, S., Ammar, W., Shaniba, S. and Altlomate, A. (2022). Bridge Deck Assessment of August a. Busch Using Portable Seismic Property Analyzer and Ground Penetrating Radar. The e-Journal of Nondestructive Testing, 2022-01. https://www.ndt.net/search/docs.php3?id=26507 [12] Alatshan, F., Altlomate, A. and Hamad, S. (2022) Concrete Filled Plastic Stub Columns Strength under Axial Compression. Open Journal of Civil Engineering, 12, 87-100. https://doi.org/10.4236/ojce.2022.121007 [13] Ali, A.A.; Alabbadi, A.M.; Jabbar, F.K.; Alzahrani, H.; Hamad, S. Predicting Soil Erosion Rate at Transboundary Sub-Watersheds in Ali Al-Gharbi, Southern Iraq, Using RUSLE-Based GIS Model. Sustainability 2023, 15, 1776. https://doi.org/10.3390/su15031776

Copyright

Copyright © 2024 Wajdi Ammar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET57903

Publish Date : 2024-01-05

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online