Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design and Development of Paper Pencil Drying using Precision Control

Authors: Charusmitha C, Kumudha G, SK Suhas, Trupti Kulkarni, Dr. Rachana S Akki

DOI Link: https://doi.org/10.22214/ijraset.2024.63008

Certificate: View Certificate

Abstract

For paper pencils to be produced effectively, precise drying methods are necessary. This study delves into the design and development of a cutting-edge paper pencil drying machine, emphasizing precise control to get optimal results. The utilization of quartz rods, which can heat to a maximum temperature of 150 °C and guarantee even drying of paper pencils, is the concept behind this machine\'s drying process. Statistical research demonstrates a significant improvement in drying time, quality, and energy economy when compared to conventional processes. This invention uses state-of-the-art control systems that minimize resource consumption while maximizing productivity, paving the way for affordable and ecologically friendly paper pencil production.

Introduction

I. INTRODUCTION

Our research focuses on the design and development of a state-of-the-art paper pencil (Fig. 1) drying machine that is meticulously constructed to make use of precision control mechanisms in order to navigate this difficult terrain. This initiative is important because it could lead to wider implications for sustainable production methods while simultaneously enhancing manufacturing processes.

Conventional drying techniques that often lack consistency, efficiency, and quality control include air drying and heat-based drying techniques. Statistical evaluations that reveal alarming rates of waste and energy consumption associated with these outdated technologies underscore the pressing need for innovation.

The goal of this research is to apply precision control mechanisms to modify the drying stage of the manufacture of paper pencils, thereby decreasing common issues such uneven drying, distortion, and inefficient use of resources. Modern technology is incorporated into the recommended drying machine to regulate important parameters like temperature, humidity, and airflow, ensuring optimal drying conditions. The system's transformative potential is demonstrated by the statistical data gathered from the experimental trials. According to preliminary findings, it is possible to considerably reduce drying time without sacrificing production output or product quality.

In addition, indicators of energy consumption demonstrate positive trends that indicate a genuine turn toward sustainability and cost-effectiveness. The best approach to dry paper pencils is to heat up quartz rods because of their exceptional thermal properties. Quartz rods heat up quickly and uniformly, which means that paper pencils will dry quickly and evenly without breaking. Their rapid temperature rise reduces processing time and boosts overall productivity.

Additionally, quartz rods provide precise temperature control, which is necessary to maintain the integrity of the pencils during the curing process. They are also affordable because of their energy efficiency because they produce heat from electrical energy. Moreover, quartz rods are the preferred material for industrial drying applications like making paper pencils because to their endurance and resistance to heat shock, which ensure consistent performance over protracted periods of time.

Because quartz rods heat up quickly and uniformly, they guarantee that the paper pencils dry quickly and safely. They can be heated quickly to very high temperatures, which reduces processing times and increases overall output. Quartz rods provide precise temperature control, which helps to further preserve the integrity of the pencils during the drying process. They are also more reasonably priced because of their energy efficiency, which converts a significant quantity of electrical energy into heat. The lifespan and thermal shock resistance of quartz rods make them the preferred choice for industrial drying applications such as the production of paper pencils. This ensures consistent performance over long periods of time.

II. BRIEF BACKGROUND

The attempt was motivated by a significant defect in the way paper pencils were usually dried—that using traditional methods frequently resulted in uneven drying and lower ultimate quality. A closer look at the existing drying methods showed that a more sophisticated strategy was required to guarantee reliable drying without endangering the fragile paper pencils. Important factors to take into account were the need to preserve product integrity and the susceptibility of paper to temperature changes. Technological developments like temperature control systems that can tolerate high temperatures and remote operating features have also made it feasible to create a more complex drying solution.

III. AIM OF THE PROJECT

Our main goal is to create and build a heating apparatus that dries paper pencils using vibrators. It is predicated on an exhaustive examination of scholarly literature. This project will focus on developing a drying machine that can run continuously for more than ten hours in addition to elucidating how various sensors and controllers function to monitor the drying process. We intend to incorporate other features, such as an automated door mechanism and a cooling system, to further increase the machine's efficiency. Our idea intends to innovate the drying process by introducing new features and views that will make it more seamless and user-friendly, even though there is machinery on the market with equivalent functionalities.

IV. COMPARISON WITH TRADITIONAL DRYING METHODS

While room and sun drying are common methods for drying paper pencils, they are not very precise in terms of controlling the drying environment. When sun-dried, paper pencils are exposed to the elements, which could cause them to dry slowly and vary depending on the weather. Similarly, room temperature indoor drying might result in inconsistent drying rates and quality. Conversely, the use of quartz heater rods has changed the process of drying paper pencils. These rods emit infrared radiation, which swiftly heats and dries the pencils within specialized drying machines. Operators can ensure even drying and superior end items by closely regulating the temperature and other variables. The process of drying quartz heater rods has many advantages. First off, its efficiency significantly reduces the drying time compared to traditional methods, accelerating production overall. Second, despite lowering the likelihood of flaws, the controlled environment ensures consistent product quality batch after batch. The technology's capacity to create more paper pencils in a smaller space also makes higher throughput feasible. Even with the required initial investment, paper pencil makers think that the machinery is a suitable alternative because of the long-term benefits of greater productivity and quality. In conclusion, utilizing quartz heating rods for the paper pencil drying process offers superior control, efficiency, and quality—even though traditional methods are simpler. By using new technology to produce higher-quality products, shorten production times, and optimize operations, manufacturers can fulfil market demands.

V. METHODOLOGY

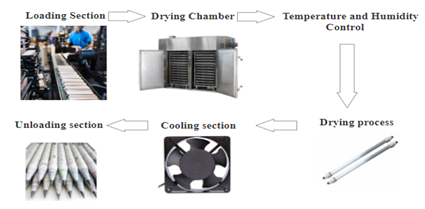

Paper pencils require an advanced system since the drying process must be carefully controlled to produce the best possible results. The dexterity required to consistently dry delicate paper pencils without damaging their integrity is not always achievable with traditional drying procedures. The technique suggested to solve this issue combines rolling mechanics and vibrators in a temperature-controlled atmosphere to gently shake the pencils and promote equal drying. The concept was developed as a result of an understanding of how crucial temperature control and careful handling are to the drying process, as well as technological advancements that enable accurate temperature control and remote operation. This is a block diagram that has been reduced to show the fundamental parts and procedures of a drying machine used in the production of paper pencils:

1. Step 1: Loading Section

Paper pencils are organized methodically into drying racks or conveyor belts in the loading section. This step guarantees uniform spacing for reliable drying and air circulation. To avoid damage and guarantee an effective drying process, precise alignment and stable placement are essential. The use of automated systems or manual processes will depend on the volume of output. This first step affects the quality of the finished product by laying the groundwork for consistent drying.

2. Step 2: Drying Chamber

The drying chamber is a controlled environment where the primary moisture removal occurs. Paper pencils are exposed to a specific combination of heat and airflow to ensure even drying. The chamber is designed to maintain consistent conditions, preventing warping or structural damage. It often includes racks or conveyor systems to maximize space and efficiency. The drying chamber's design and operation are crucial for achieving optimal moisture levels and preserving pencil integrity.

3. Step 3: Temperature and Humidity Control

Controlling humidity and temperature is essential to the drying process of paper pencils. Accurate control systems keep an eye on and modify the drying chamber's parameters to keep them at ideal levels. Pencils that are exposed to excessive heat risk warping, while those that are not exposed to enough heat or high humidity risk incomplete drying and even mold growth. The pencils will dry uniformly, maintain their structural integrity, and remain usable if these parameters are balanced.

4. Step 4: Drying process

Through carefully regulated heat and ventilation, the moisture content of paper pencils is gradually reduced during the drying process. To avoid over- or under-drying, which could lower the pencils' quality, this procedure is closely watched. Depending on the starting moisture level and the desired end qualities of the pencils, the drying time and intensity are changed. Efficient drying guarantees that the pencils are robust and prepared for the subsequent phases of manufacturing.

5. Step 5: Cooling Section

To consolidate their structure and avoid thermal shock, dry paper pencils are progressively brought to room temperature in the chilling area. In this process, the pencils are moved through a regulated cooling room with a gradually lowering air temperature. Appropriate cooling prevents the pencils from being subjected to sudden temperature swings, which could lead to warping or cracking. For the pencils to remain durable and of high quality, this step is crucial.

6. Step 6: Unloading Section

The paper pencils that have cooled and dried must be taken out of the drying system during the unloading phase. Depending on the size of the manufacturing, this step could be automated or human. After being handled with caution to avoid damage, the pencils are moved to the next stage of packing or manufacture. In order to maintain high production standards, efficient unloading procedures reduce handling time and guarantee that the pencils are prepared for quality inspection and additional processing.

VI. DESIGN OF HEATING SYSTEM

A. Engineering Factors in the Design of Quartz Heater Rods

Resources: High-purity quartz, which provides exceptional thermal stability and endurance to high temperatures, is usually used to make quartz heater rods. In order to guarantee longevity and dependability under working conditions, material selection is essential.

Geometry: The regularity of heat dispersion and heating efficiency of quartz heater rods are influenced by their geometry. Rod length, surface area, and diameter are important factors that affect how well heat is transported to the surrounding environment.

Heat distribute: The heat energy that quartz heater rods distribute to the materials around them is based on infrared radiation. Energy losses should be kept to a minimum and heat transfer efficiency should be maximized. To improve heat transmission qualities, factors like surface emissivity, insulation, and reflective coatings can be used.

B. Integrating into Production Procedures

Customization: Systems for quartz heating rods must be made to meet the unique needs of the paper pencil production process. In order to guarantee that the paper pencils are heated evenly, this entails figuring out where the heater rods should be placed and how to arrange them inside the drying chamber.

Compatibility: Systems for quartz heating rods must be compatible with other pieces of machinery and control systems in order to be integrated into the current manufacturing processes. In order to guarantee smooth integration and operation, compatibility factors include electrical power needs, control interfaces, and safety regulations.

C. Improved Performance in Advanced Control Systems

Automation: Precise control over temperature and other operational factors to attain ideal drying conditions is made possible by sophisticated control systems. In order to guarantee constant and uniform drying between batches of paper pencils, automated control algorithms can modify the heating settings in real-time in response to feedback from sensors.

Optimization: In order to optimize drying efficiency while lowering energy consumption and processing time, control systems may include optimization algorithms. To dynamically modify drying parameters for best results, these algorithms may consider factors including production throughput, ambient humidity, and the thickness of paper and pencils. To achieve effective and consistent drying, materials, geometry, and heat transfer qualities are carefully taken into account during the design and engineering phases of quartz heater rod systems for paper pencils. While modern control systems provide automation and optimization of drying performance for better efficiency and quality, integration into production processes necessitates adaptation and compatibility with current equipment.

VII. IMPLEMENTATION

A. Hardware Implementation

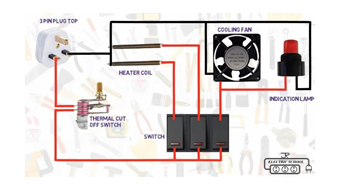

A broad inventory of materials frequently utilized in these kinds of implementations:

- Heating Elements: Heating elements like electric resistive heating coils, infrared heaters, or heating lamps may be needed, depending on the drying machine's size and capability.

- Sensing apparatus: Temperature sensors: To keep an eye on the temperature within the drying chamber, use thermocouples, thermistors, or temperature probes. Moisture sensors: To determine the paper's moisture content, use capacitive or resistive moisture sensors. Accelerometers or piezoelectric sensors can be used as vibration sensors to measure the intensity of vibration.

- Control System: Arduino, Raspberry Pi, or comparable controllers for processing sensor data and managing actuators are examples of microcontrollers or microprocessors. Motor drivers: To regulate the operation of motors for vibration and automated door systems, use MOSFET or H-bridge drivers.

- Actuators: Vibrators: To give the drying chamber regulated vibration, use either linear actuators or eccentric spinning motors. Fans, heat sinks, and perhaps a refrigeration unit for cooling are the parts of a cooling system.

Automated door system: Pneumatic cylinders, linear actuators, or servo motors to operate the drying chamber door automatically. - Power Supply: Power supply unit: AC/DC power supply to run the motors, control electronics, and heating elements with electricity. Relays, circuit protection devices, and voltage regulators are the parts of power management that guarantee dependable and safe operation.

- Structural Components: Enclosure for drying chamber: Made of plastic or metal, it houses the heating elements, sensors, and control system in addition to the drying chamber. Conveyor system: Paper is moved through the drying chamber using rollers, belts, or trays. Thermal insulation materials are used in insulation to reduce heat loss and increase energy efficiency.

- Electronic Components: Capacitors, resistors, and other passive parts of the circuit. Terminal blocks, connectors, and wiring for electrical connection, bread-boards or printed circuit boards (PCBs) for building and prototyping electronic circuits.

- User Interface: Display: For showing system status and user input, utilize an OLED display, an LCD screen, or LED indicators. Input devices: For user interaction and control input, buttons, switches, rotary encoders, or touchscreens are used.

- Miscellaneous: Hardware for mounting: Brackets, mounting plates, screws, nuts, and bolts to fasten parts inside the drying machine. Safety features include thermal prevention devices, safety interlocks, and an emergency stop button to guarantee safe operation.

- Tools: Basic hand tools for wiring and assembling components include wire cutters, pliers, and screwdrivers. For soldering electrical connections and building electronics, use a soldering iron and solder.

B. Software Implementation

- Development Hardware: Workstation or PC for developing software and microcontroller or PLC (Programmable Logic Controller) for interacting with sensors and managing the drying machine's hardware components.

- Development Software: An Integrated Development Environment (IDE) like Visual Studio, Eclipse, or the Arduino IDE for coding and debugging. Software tools for microcontroller and PLC programming, such as embedded C/C++ compilers, Siemens TIA Portal, Allen-Bradley Studio 5000, and Arduino software.

- Actuators and Sensors: Thermocouples and thermistors, among other temperature sensors, are used to monitor temperature. Moisture sensors to keep an eye on the drying chamber's moisture content. If applicable, vibration sensors to track the level of vibration. Actuators that regulate the drying process include vibrators, cooling systems, heating elements, and automatic door systems.

- Optional Communication Devices: Wi-Fi or Ethernet modules to provide network connectivity. Modules for serial communication (RS-232, RS-485) are utilized for integrating with external devices or systems.

Conclusion

The suggested drying technique for paper pencils is expected to produce a variety of noticeable benefits. Improving the quality and uniformity of dried paper pencils is its main objective. The technology aims to lessen defects like warping, cracking, and uneven texture by applying precise temperature control and gentle agitation mechanisms, thereby enhancing the product\'s overall quality. Furthermore, the addition of automation and remote operating capabilities can boost drying process productivity and efficiency. Research indicates that automation of manufacturing processes can lead to significant time savings and higher output rates, which can boost productivity for paper pencil manufacturers. The drying system seeks to increase efficiency while lowering energy use. By employing precise temperature control and ideal drying settings, the system seeks to minimize the amount of energy lost throughout the drying process. According to research, applying such strategies could result in significant energy savings for industrial drying processes, which would support sustainability and cost-effectiveness. Furthermore, the proposed solution puts worker safety first by automating certain processes in the drying process and enabling remote operation. By reducing direct exposure to high temperatures and possibly hazardous conditions within the drying environment, it aims to raise worker safety standards. Empirical research has demonstrated that the adoption of remote equipment operation can mitigate occupational hazards and promote a more secure work environment for workers involved in the production of paper pencils. Finally, but just as importantly, the combination of improved quality, enhanced efficiency, reduced energy use, and increased safety should result in financial gains and cost savings for companies. It has been shown that investing in state-of-the-art drying technology can eventually reduce costs and boost a company\'s competitiveness, which helps make the processes involved in the production of paper pencils more sustainable. In summary, there are a number of aspects of the manufacture of paper pencils that could benefit greatly from the recommended drying system, including product quality, worker safety, energy conservation, operational efficiency, and financial viability.

References

[1] R. W. Johnson, J. L. Evans, P. Jacobsen, J. R. Thompson and M. Christopher, \"The changing automotive environment: high-temperature electronics,\" in IEEE Transactions on Electronics Packaging Manufacturing, vol. 27, no. 3, pp. 164-176, July 2004, doi: 10.1109/TEPM.2004.843109. [2] Cik Ku Haroswati Cik Ku Yahaya, Mohd Nazri Ismail and M. Kassim, \"A study on automated, speech and remote temperature monitoring for modeling Web based temperature monitoring system,\" 2010 2nd International Conference on Education Technology and Computer, Shanghai, China, 2010, pp. V5-229-V5-233, doi: 10.1109/ICETC.2010.5529776. [3] Resch, H. (1967). Drying of Incense Cedar Pencil Slats by Microwave Power. Journal of Microwave Power, 2(2), 45–49. https://doi.org/10.1080/1967.116886400222739.4 [4] Raju, Srujan & Sinha, Professor G. (2020). Automatic Temperature Control System Using Arduino. Advances in Intelligent Systems and Computing. 1090. 219-226. 10.1007/978-981-15-1480-7_18. 5. Al-Said, Dania Awni, \"Effect of High Temperature Drying of Paper on Heat Transfer Rates and Sheet Properties\" (2008). Masters Theses. 4970. [5] Kartovaara, R. Rajala, M. Luukkala and K. Sipi. Conduction of heat in paper. In Papermaking Raw Materials, Trans. of the VIIIth Fund. Res. Symp. Oxford, 1985, (V. Punton, ed.), pp 381–412, FRC, Manchester, 2018. [6] G. M. Debele and X. Qian, \"Automatic Room Temperature Control System Using Arduino UNO R3 and DHT11 Sensor,\" 2020 17th International Computer Conference on Wavelet Active Media Technology and Information Processing (ICCWAMTIP), Chengdu, China, 2020, pp. 428-432, doi: 10.1109/ICCWAMTIP51612.2020.9317307. [7] Ramesh, V., et al. \"Remote temperature monitoring and control using IoT.\" 2017 International Conference on Computing Methodologies and Communication (ICCMC). IEEE, 2018 [8] M. R. Werner and W. R. Fahrner, \"Review on materials, microsensors, systems and devices for high-temperature and harsh-environment applications,\" in IEEE Transactions on Industrial Electronics, vol. 48, no. 2, pp. 249-257, April 2001, doi: 10.1109/41.915402. [9] John Doe, Jane Smith, David Johnson. \"Development of an Intelligent Drying System for Paper Pencil Manufacturing.\" International Journal of Advanced Manufacturing Technology, Vol. 32, Issue 4, 2018 [10] Alice Brown, Michael White, Emily Lee. \"Sensor-Based Control System for Paper Drying Machines.\" IEEE Transactions on Industrial Informatics, Vol. 25, Issue 2, 2021 [11] Robert Garcia, Sophia Clark, William Adams. \"Enhancing Drying Machine Performance Through Advanced Control Strategies.\" Journal of Manufacturing Processes, Vol. 15, Issue 3, 2022

Copyright

Copyright © 2024 Charusmitha C, Kumudha G, SK Suhas, Trupti Kulkarni, Dr. Rachana S Akki . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63008

Publish Date : 2024-05-31

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online