Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experimental Analysis on Partial Replacement of Cement by Glass Powder and Using of Steel Fiber

Authors: R. Karthick, N. Gokulnath, Silambarasan G

DOI Link: https://doi.org/10.22214/ijraset.2024.58809

Certificate: View Certificate

Abstract

Concrete consists of fine aggregate, coarse aggregate, water, and optional admixtures, such as Portland cement or another hydraulic cement. Because of its massive resource consumption, the concrete industry poses a serious danger to the sector\'s long-term viability. The concrete industry is struggling in part because of concerns about the environment and the economy. Many studies are currently being conducted on the utilisation of waste materials like Pulverised Fly Ash (PFA) and Ground Granulated Blast Furnace Slag (GGBS) as supplemental cementitious materials. Similar to PFA and GGBS, waste glass powder can be used to partially substitute cement during the hydration reaction. To some extent, waste glass can substitute cement in concrete and contribute to strength development if it is ground to a very fine powder and demonstrates pozzolanic properties due to its high SiO2 content. This research examined the Compressive, Tensile, and Flexural strengths of concrete that had been aged for up to 60 days with concrete that had been partially replaced with Glass Powder at percentages ranging from 0% to 40%. The aggregate test findings suggest that Waste Glass Powder could be used as a suitable cement replacement in construction projects. Fibre reinforced concrete (FRC) is a composite building material made from small, discontinuous fibres that are randomly distributed throughout the concrete part. Steel, glass, and polymer fibres, as well as fibres originating from natural sources, are the most common types of fibre used in cement-based composites. The tendency of fibres to be more closely spaced than traditional reinforcing steel bars makes them more effective at preventing cracking. It\'s important to note that fibre is not a suitable replacement for steel bars when reinforcing concrete.

Introduction

I. INTRODUCTION

Concrete is a global construction staple. In terms of global consumption, it is second only to water. Concrete with a standard blend of fine and coarse aggregate is the cement used. However, there are inevitable ecological concerns connected to its application that should not be ignored. Large-scale production typically includes massive quantities of standard asset characteristics. When concrete is made, a large amount of carbon-dioxide gas is released into the atmosphere, contributing significantly to the hazardous atmospheric deviation and nursery impact. The production of one tonne of concrete releases one tonne of carbon dioxide into the atmosphere, accounting for around 7 percent of the world's total annual output of CO2 (Meyer, 2004). In India, concrete is a common building material, and its production has a comparable effect on the environment.

Glass is a nonliving material that may be used repeatedly without degrading or altering its chemical composition. Waste glass powder, crushed to a precise size, can be used in place of concrete in a number of contexts apart from the production of new glass. Glass, a silica-based substance with an open structure, has potential uses in the concrete industry. This study presents preliminary research findings on the use of glass powder as a concrete replacement. Waste glass powder's successful implementation in substantial will boost the use of such irregular materials, which are often of regional or local origin.

Fibre reinforced concrete (FRC) is a composite building material made from small, discontinuous fibres that are randomly distributed throughout the concrete part. Cement-based composites typically employ fibres sourced from steel, glass, polymer, or natural resources. The tendency of fibres to be more closely spaced than traditional reinforcing steel bars makes them more effective at preventing cracking. It's important to note that fibre is not a suitable replacement for steel bars in reinforcing concrete.

Concrete is the backbone of the worldwide building industry and the second most used substance on Earth after water [1]. Its significance, however, is accompanied with environmental worries due to the substantial use of resources and the release of carbon dioxide during its manufacturing [1]. Because of the negative effects on the environment, scientists have been looking at greener options. Partial cement replacement with waste materials like glass powder has been investigated as a means to improve concrete's durability and strength [1].[2].

Glass powder's pozzolanic properties could make it a cementitious material [2]. Its core properties remain after recycling and construction [2]. Fibre reinforcement, which includes steel fibres, has also improved concrete's mechanical qualities, improving fracture control and lifespan [1][3].

Building materials research is ongoing. Er Manoj Kumar Meena et al. (2018) used glass powder instead of cement and examined how it affects concrete strength and properties [1]. Yajurved Reddy et al. (2016) investigated utilising synthetic sand in concrete instead of natural sand [2]. Pereira de Oliveira et al. (2008) investigated how waste glass particles and fly ash improve concrete strength [3]. These studies demonstrate how seriously individuals take using less material and building better [1][2][3]. Environmental responsibility and construction excellence shape research.

A. Need for Study

- Waste glass powder increases compressive, ductile, and flexural strength.

- This technique can also reduce construction costs because glass powder is cheaper than concrete.

- This concrete substitution material can also reduce the problem of non-degradable waste.

- A better understanding of the display of a non-standard concrete substitution material like glass powder could increase its use, increasing supportability.

- Fibres and continuous reinforcing steel bars have various roles in innovative concrete technology, and both should be used in numerous applications.

B. Scope

- Concrete production requires massive asset depletion and high costs.

- To reduce concrete use since it releases CO2, causing abnormal weather change. Substituting materials for practical concrete is great.

- This study uses discarded glass powder to determine compressive strength, rigidity, flexural strength, and cost.

- ?Most concrete reinforcing uses steel fibre (SF). SFs first inhibit concrete plastic and drying shrinkage. SFs in concrete increase its flexural toughness, energy absorption capacity, ductile behaviour before failure, reduced cracking, and durability.

C. Objective

- At 7, 14, 21, and 28 days of curing, concrete mixes with and without glass powder were tested for compressive strength, flexural strength, split tensile strength, and alkalinity.

- Halfway substitution of concrete with glass powder (10%,20%,30%, and 40%) and apparent cement (0%).

- To test steel fiber's concrete property enhancement.

II. MATERIALS AND METHODS

A. Cement

Cement has sticky and cohesive qualities due to its hardened state. It is a powdered building ingredient consisting of calcined limestone and clay, and it is combined with water and sand or gravel to create mortar and concrete. When water is added to cement, it hardens. There is a one-to-one relationship between cement and strength standards. Walls, bricks, R.C.C. work, plastering, etc. all benefit from using cement.

Conclusion

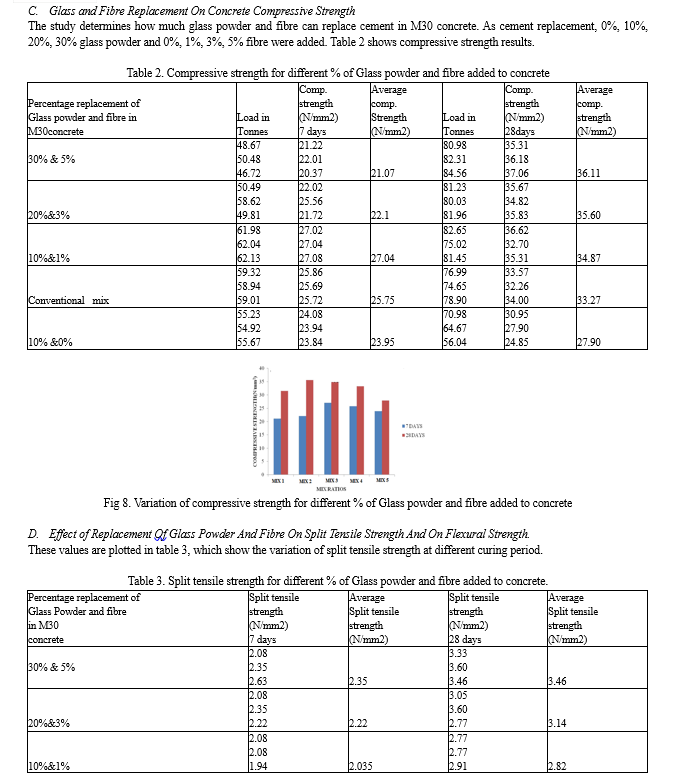

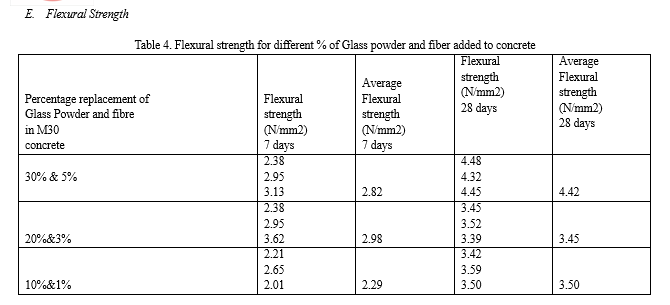

Glass powder and steel fibres alter cement and concrete characteristics. Coarser aggregates require less water because fineness modulus increases. Compression and tensile strength were tested 7, 14, and 28 days after casting. Steel fibres improve concrete properties. Compression strength was 36.62 N/mm2 and tensile strength 2.21 N/mm2. Fineness modulus lowers cement mortar drying shrinkage. Admixture increases compressive and binding strength of mortar. Due to lower water cement ratio. Plastering Sand with a superior particle size distribution, maximum particle size of 2.36 mm, and Fineness Modulus between 1.8 and 3.8 makes better plaster mortar. This project tests the flexural strength of steel fibre concrete beams with glass powder in a loading frame. Testing yields the ultimate load, deflection, and flexural strength, which are summarised and the following conclusions drawn. This project\'s experimental results lead to these conclusions. Concrete mixtures with and without glass powder were tested for compressive, flexural, split tensile, and alkalinity at 7, 14, 21, 28, and 60 days. Glass powder added concrete with 5%, 10%, 15%, 20%, and 25% GLP for M30 grade as a partial cement replacement was tested for strength. Concrete with 15% GLP has the maximum compressive and flexural strength. The graph and table below demonstrate compressive strength, flexural, split, and alkalinity test results for M30 concrete with 0%, 5%, 10%, 15%, 20%, and 25% glass powder replacement. Increased alkalinity minimises reinforcement corrosion and increases above strengths. 1) Waste glass powder\'s finer particle size increases cement activity and concrete mix compressive strength. 2) 150-?m glass powder starts alkali aggregate reaction. 3) The study reveals that superior glass powder can replace cement in concrete. 4) Glass powder reduces concrete workability. Experimental concrete slumps 80–100 mm. 5) At 15%, 10%, and 5% glass powder replacement, compressive, tensile, and flexural strengths were highest. 6) Sample pH averaged 12.59. Alkaline samples resist corrosion and rust. 7) More glass powder reduces water absorption and bulk dry density. 8) Waste glass is cheap and abundant, making it a good material for waste glass disposal. 9) The foregoing result shows that 15% cement substitution by glass powder is optimum. 10) Plasticizers can be used to improve workability, strength, and durability for long-term glass powder replacement studies

References

[1] J.A.Larbi, J.M.J.M.Bijen, et al (2010) ,\"influence of polypropylene fibres on the performance of nanosio2- incorporated mortar\" iranian journal of science & technology, transaction b: engineering, vol. 34, no. B4, pp 385-395 printed in the islamic republic of iran, 2010 © shiraz university. [2] B.K.Raghuprasad, H.Ananthan, et al(2011). \"Mechanical Properties of Synthetic Fibres Reinforced Mortars\" International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April 2011 ISSN 2229-5518 [3] K.H.Khayat, M.Vachon, et al (2010), Fibre reinforced cementitious composites.vol. 34, no. B4, pp 385-395. [4] A.Saccani and A.Motori,, Fibre reinforced cementitious composites? Elsevier applied science London and Newyork 1990. [5] J.Mirza, M.S.Mirza, et al(2012)., ASTM C1018 – 89, Standard Test Method for Flexural Toughness and First Crack Strength of Fibre Reinforced Concrete (Using Beam with Third – Point Loading), 1991 Book of ASTM Standards, Part 04.02, American Society for Testing and Materials, Philadelphia, pp.507 – 513. [6] S.K.Park and D.S.Yang.,(2015) C.D. “Definition and measurement of flexural toughness parameters for fiber reinforced concrete” Cem. Concr. Agg. 1982. [7] Alessandra E.F.de.S.Almeida, Eduvaido P. Sichieri, (2015), “Steel fibrous shotcrete”. A summary of the State – of – the art concrete Int.: Design and construction 1981. [8] Alessandra E.F.de S. Almeida, et al.,(2016), “Fiber reinforced cements and concretes” Advances in concrete technology volume3 – Gordon and Breach Science publishes -2001. [9] J.M.Gao, C.X.Qian,et al., “Steel fiber reinforced concrete” Current paper CP 69/74 Building research establishment Garston Watford 1974. 9. C.D. Johnston, “Steel fiber reinforced mortar and concrete”, A review of mechanical properties. In fiber reinforced concrete ACI – SP 44 – Detroit 1974. [10] JCI Standards for Test Methods of Fibre Reinforced Concrete, Method of Test for Flexural Strength and Flexural Toughness of Fibre Reinforced Concrete (Standard SF4), Japan Concrete Institute, 1983, pp. 45 – 51. [11] M. Zhu and D.D.L. Chung, (1997) \"Improving Brick-To-Mortar Bond Strength By The Addition Of Carbon Fibres To The Mortar\" Cement and Concrete Research. Vol. 27, No. 12, pp. 1829-1839. 1997. [12] Mohammed Ezziane, Laurent Molez Raoul Jauberthie Damien Rangeard, (2011), \"Heat Exposure Tests On Various Types of Fibre Mortar\" EJECE. Volume 15 – No. 5/2011, pages 715 to 726 [13] P. Rathish Kumar and K. Srikanth a Department of Civil Engineering, NIT Warangal, India, (2008), \"Mechanical Characteristics Of Fibre Reinforced Self Compacting Mortars\" Asian journal of civil engineering (building and housing) vol. 9, no. 6 (2008) pages 647-657 [14] Perumalsamy N. Balaguru, Sarendra P. Shah, Fiber reinforced cement composites?? , Mc Graw Hill International Editions 1992. [15] R.J. Craig, “Structural applications of reinforced steel fibrous concrete”. Concrete Int. Design and Construction 1984. Colin D. Johnston, “Fiber reinforced cements and concretes” Advances in concrete technology volume 3 – Gordon and Breach Science publishes – 2001. [16] Prafull Vijay, Sandeep Singh “Physical and Mechanical Properties of Steel Fiber Reinforced Lightweight Aggregate Concrete Using Fly Ash” [17] Aoude, H., Belghiti, M., Cook, W. D., & Mitchell, D. (2012). Response of Steel Fiber-Reinforced Concrete Beams with and without Stirrups. ACI Structural Journal, 109(3), May-June 2012, pp. 359-368. [18] Ashou, S. A., Hasanain, G. S., &Wafa, F. F. (1992). Shear Behavior of High-Strength Fiber Reinforced Concrete Beams. ACI Structural Journal, 89(2), March-April 1992, pp. 176-184. [19] ACI committee, “State - of - the art report in fibre reinforced concrete?? ACI 554 IR – 82 Detroit Mechigan 1982. [20] Khaloo, A. R., & Kim, N. (1997). Influence of Concrete and Fiber Characteristics on Behavior of Steel Fiber-Reinforced Concrete under Direct Shear. ACI Materials Journal, 94(6), November- December 1997, pp. 592-600. [21] Lee, S. C., Cho, J. Y., & Vecchio, F. J. (2011). Diverse Embedment Model for Steel Fiber-Reinforced Concrete in Tension: Model Verification. ACI Materials Journal, 108(5), September-October 2011, pp. 526-525. [22] Naaman, A. E. (1987). High Performance Fiber Reinforced Cement Composites. International Association for Bridge and Structural Engineering (IABSE) Symposium on Concrete Structures for the Future, Paris - Versailles, pp. 371-376. [23] Japan Concrete Institute (1983) JCI Standards for Test Methods of Fiber Reinforced Concrete. Method of Test for Flexural Strength and Flexural Toughness of Fiber Reinforced Concrete (Standard SF4), 45-51. [24] Craig, R.J. (1984) Structural Applications of Reinforced Steel Fibrous Concrete. Concrete Int. Design and Construction. [25] Uses for steel-fiber-reinforced concrete in Australia”. An article of “The Aberdeen Group” which is based on the Australian paper “The Diversifying Applications of Steel Fiber Reinforced Concrete in Australia” by “Winston A. Marsden”, Technical Development Manager of AWI Fiber steel, Australia.IS-383 (1970) Specification for Coarse and Fine Aggregates from Natural Sources for Concrete. 2nd Revision, Bureau of Indians Standards, New Delhi. [26] IS-10262 (2009) Recommended Guidelines for Concrete Mix Design. Bureau of Indian Standards, New Delhi. [27] IS-456 (2000) Indian Standard Code of Practice for Plain and Reinforced Concrete. Bureau of Indian Standards, New Delhi. [28] IS-800 (2007) Indian Standard Code of Practice for Steel. 3rd Revision, Bureau of Indian Standards, New Delhi [29] Chand, N.V. Steel Fiber Reinforced Concrete. Vietnam Joint Seminar. [30] Sinha, D.A. Characteristics Properties of Steel Fiber Reinforced Concrete with Varying Percentages of Fiber.

Copyright

Copyright © 2024 R. Karthick, N. Gokulnath, Silambarasan G. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET58809

Publish Date : 2024-03-06

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online