Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Performance and Emission Control Testing in SI Engines by Using Tetra Butyl Alcohol and Camphor Oil Blends

Authors: Dr. Danaiah Puli, P P Rama Rao, B. Satish, K Venkateshwar Rao, D Shanmuka Reddy , M Trivedh

DOI Link: https://doi.org/10.22214/ijraset.2024.63495

Certificate: View Certificate

Abstract

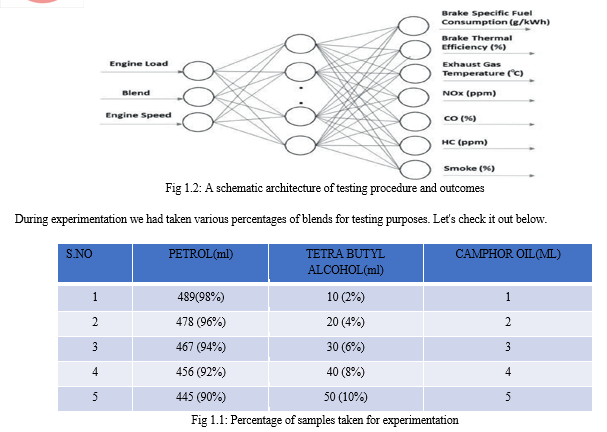

This paper proposes predicting the emission characteristics and performance of an 4 stroke petrol engine by using tetra butyl alcohol and camphor oil blends. For experimentation we had used tetra butyl alcohol as an alcohol additive and camphor oil as an oil-based additive. However, the experiments are performed in a 4 stroke 4-cylinder spark ignition engine at 5 different revolutions per minute such as 1200, 1400, 1600, 1800 and 2000 and also with three different loads such as 2, 6 and 10 kg with different range of blends, for alcohol such as 0 to 10 % with an interval of 2% and for camphor oil ranging from 0 to 5 ml. During experimentation I had found some parameters such as brake power, volumetric efficiency etc. Which really tells about behavior of additives and also engine. Results show that testing properties of five blends and also the tetra butyl alcohol, camphor oil with gasoline improves the emissions approximately to the petrol. During this study I had predicted accurately about the performance of spark ignition engine and it’s emission characteristics

Introduction

I. INTRODUCTION

The fast rise in petroleum demand brought about by automobiles and industrial development has resulted in a scarcity of petroleum supply. Moreover, the combustion byproducts of petroleum fuels contaminate the environment. Although control devices reduced pollutants, they also reduced car mileage by roughly 15%. Therefore, it makes sense to investigate whether "clean" burning fuels are appropriate for use in spark-ignition (SI) engines. This leads to the development of alcohol fuels for SI engines. Because of the heat produced during combustion, the alcohol molecules in oxygenated fuels like alcohols reduce in size. Almost every chemical compound in the alcohol family has some utility as a fuel. Motor fuels can be made from alcohol. The analysis of butanol, methanol, and ethanol based on blend proportion and oxygen percentage in the mix reveals significant insights into their potential as gasoline substitutes. Notably, butanol, with its 5% oxygen content, demonstrates promising characteristics, albeit the other two alcohols exhibit superior performance at comparable oxygen levels. Oxygen enrichment facilitates more efficient combustion, thereby reducing carbon monoxide (CO) and hydrocarbon (HC) emissions while elevating carbon dioxide (CO2) emissions. Additionally, higher temperatures promote increased NO emissions due to enhanced combustion efficiency, posing challenges in emissions control. The study specifically investigates the impact of incorporating tert butyl alcohol and camphor oil into gasoline within a spark-ignition (SI) engine employing port fuel injection. Experimental trials were conducted using a multi-cylinder SI engine with external fuel supply to assess the effects comprehensively. And there are different forms of butanol as shown below.

- 1-butanol: (n-butanol) CH3–CH2–CH2–CH2OH,

- iso-butanol: CH3(CH2)3OH,

- sec-butanol: CH3CH(OH)CH2CH3,

- tert-butanol: (CH3)3COH

For this experimentation as i mentioned before we had used tert butyl alcohol as an alcohol additive and camphor oil as an oil-based additive for testing purpose we had used a multi - cylinder petrol engine and specifications are mentioned below.

a. Engine: HM-50 PFI Version

b. Max Power: 75BMP & 5000rpm

c. Max Torque: 13.3kg-m @5000rpm

d. Fuel: Petrol

e. Battery: 12A, 45A

f. Number of Cylinders: Four

g. Bore: 84mm

h. Stroke Length: 82mm.

i. Capacity: 1817cc

II. EXPERIMENTAL SETUP & EQUIPMENT REQUIRED

- Equipment Required For Properties Testing Of Blends

- Octane Number Testing Machine: Gasoline octane testing method and device. The present invention relates to techniques for determining the quality of gasoline, in particular to a new type of method and its determinant for measuring the octane number of motor gasoline. The device for measuring the octane number of gasoline consists of a sensor, an electronic circuit and a screen. The octane number of gasoline can be determined by directly comparing and displaying the measurement of the relative dielectric constant and its variation and automatic analysis in a microprocessor system. It can be used to quickly and efficiently test gasoline quality. The gasoline label on the market must represent the octane number of gasoline, the octane number represents the anti-knock properties of gasoline, China generally measures the engine method, the development engine is a custom-designed variable compression ratio single. -cylinder engine (called C, F, R engine), measures the intensity of the explosion with an electric mechanical vibration device in the evaluated condition. The standard fuels are isooctane (CH 3C (CH 3) C 2CH 2CHCH 3CH 3 before three pentanes) and regular heptane, isooctane is a good standard for anti-knock properties and has an octane number of 100 and regular heptane is poorer. standard for anti-knock properties and has an octane number of 0 These two standard fuels are mixed in different proportions; it is possible to obtain a standard fuel mixture with different impact resistance...

- Kinematic Viscosity Bath Apparatus: Kinematic viscosity is extremely important in the design and selection of many petroleum products. Calibrated capillary viscometers are used to measure flow under gravity or vacuum at precisely controlled temperatures. This is a critical factor for oils that measure their resistive flow. Kinematic viscosity is a device used to measure the kinematic viscosity of various types of oils, such as crude oil, lubricating fluid, diesel oil and peanut oil. Contains data and power ports for each optical detection configuration and supports up to five optical configurations. Two additional positions are available for manual viscosity measurement and all positions can be used in manual mode...

- Bomb Calorimeter: It is a device used to calculate the Calorific Value of Solid , Liquid & Gaseous Fuels. A bomb calorimeter is a type of constant-volume calorimeter used in measuring the heat of combustion of a particular reaction. Used to measure enthalpy changes of combustion reactions at a constant volume. Heats of combustion as determined in an oxygen bomb calorimeter are measured by a substitution procedure in which the heat obtained from the sample is compared with the heat obtained from combustion of a similar amount of benzoic acid or other standardizing material whose calorific value is known. These measurements are obtained by burning a representative sample in a high-pressure oxygen atmosphere within a metal pressure vessel or “bomb”. The energy released by this combustion is absorbed within the calorimeter and the resulting temperature change within the absorbing medium is noted. The heat of combustion of the sample is then calculated by multiplying the temperature rise in the calorimeter by a previously determined energy equivalent or heat capacity determined from previous tests with a standardizing material.

- Flash Point Apparatus: A flash point apparatus is a device used to determine the flash point of a substance, which is the lowest temperature at which it vaporizes to form an ignitable mixture in air. This is important in industries dealing with flammable materials like fuels and solvents. The apparatus typically involves heating a sample in a controlled environment while periodically introducing an ignition source to determine the temperature at which vapor ignites momentarily. This helps in assessing the fire risk and handling procedures for various.

- Pour Point Apparatus: A pour point apparatus is used to determine the pour point of a substance, especially in the field of petroleum and petrochemicals. The cloud point is the temperature at which dissolved components in a solution begin to form a cloudy appearance due to the formation of small solid particles or liquid droplets. This phenomenon is significant in assessing the performance of fuels, lubricants, and various other substances under different temperature conditions. The apparatus typically involves gradually cooling a sample while observing for the appearance of cloudiness, which indicates the cloud point temperature.

- Cloud Point Apparatus: A cloud point apparatus is used to determine the cloud point of a substance, especially in the field of petroleum and petrochemicals. The cloud point is the temperature at which dissolved components in a solution begin to form a cloudy appearance due to the formation of small solid particles or liquid droplets. This phenomenon is significant in assessing the performance of fuels, lubricants, and various other substances under different temperature conditions. The apparatus typically involves gradually cooling a sample while observing for the appearance of cloudiness, which indicates the cloud point temperature.

B. Experimental Set Up

- Apparatus Required

a. Four stroke multi-cylinder engine

b. Gasoline mixtures with different ratios (petrol, tert butyl alcohol, camphor oil)

c. Exhaust gas analyzer used to detect (carbon monoxide, hydrocarbons, nitrogen oxides, oxygen, carbon dioxide)

2. Experimental Procedure

a. Firstly, arrange required fuels such as petrol, tetra butyl alcohol, camphor oil.

b. And mix it with correct proportions such as 2, 4, 6, 8, 10 percent of Tetra butyl alcohol and 1, 2, 3, 4, 5 (ml) of camphor oil respectively. And the remaining portion should be petrol.

c. Here, the ratio we are taking is 500ml of petrol for every portion of that we can vary the proportions of tetra butyl alcohol and camphor oil .

d. Start up the engine and firstly maintain the load constantly and take manometer readings and time taken for consumption of 10ml of fuel with varying the speed of the engine in rpm and tabulate the readings which we are taking.

e. And repeat the above for 2kg, 6kg, 10kg of loads and tabulate the readings.

f. After that, adjust the rpm of the engine and maintain it constantly and take the manometer and time taken for 10ml of fuel consumption readings.

g. Maintain the same procedure for 1200rpm, 1400rpm, 1600rpm, 1800 rpm, 2000rpm. And tabulate the observed readings respective to their speeds.

III. RESULTS AND DISCUSSIONS

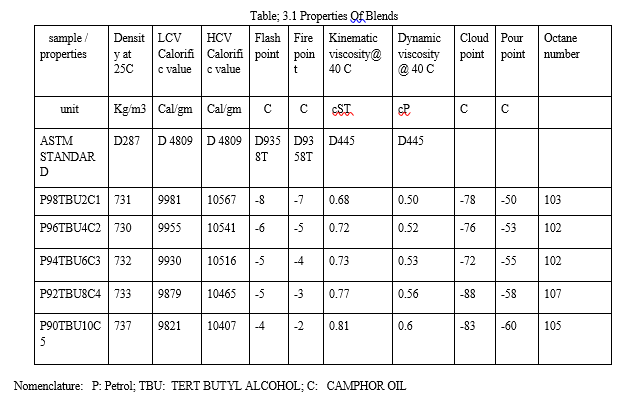

A. Properties Of Blends

During experimentation we had tested various range of blends for their properties by using different equipment’s like octane number testing machine, cloud point apparatus, pour point apparatus, kinematic viscosity bath apparatus, flash point and fire point apparatus. And these equipment are used for testing of blends such as 0TBA1C, 2TBA2C, 4TBA2C, 6TBA3C, 8TBA4C and 10TBA5C (TBA: Tert butyl alcohol, C = camphor oil ). After testing the blends C4 and C5 exhibit excellent properties than the gasoline i.e. Shows in below table because by addition of these additives made improvement of octane number, which directly gives impact on efficiency of fuel. And there is a slight effect on other properties like cloud point and pour point which has a little effect on engine efficiency...

- The samples P90TBU10C5 and P92TBU8C4 shows improvement in octane number and calorific value than the gasoline but these blends also has adversely effects on engine performance like brake power, volumetric efficiency, and emissions like carbon monoxide, carbon dioxide, hydrocarbons, etc. it shows in below graphs.

- And some of the remaining blends has shown better properties but it may not be suitable for working because it adversely affects the engines health, but it shows good calorific values and kinematic and dynamic viscosities.

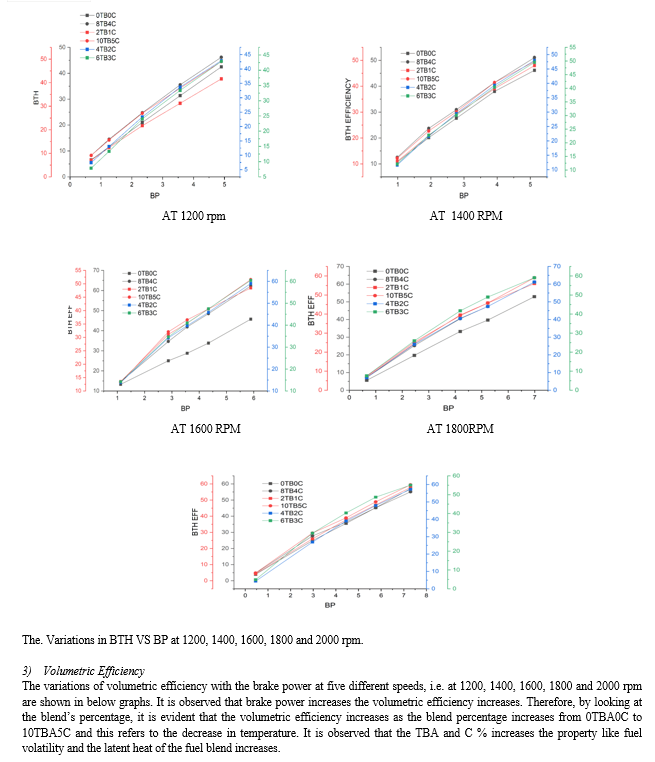

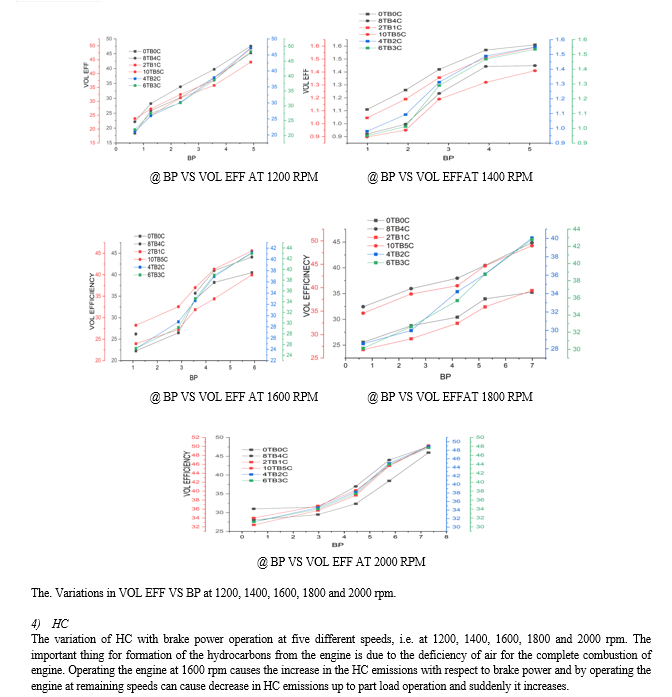

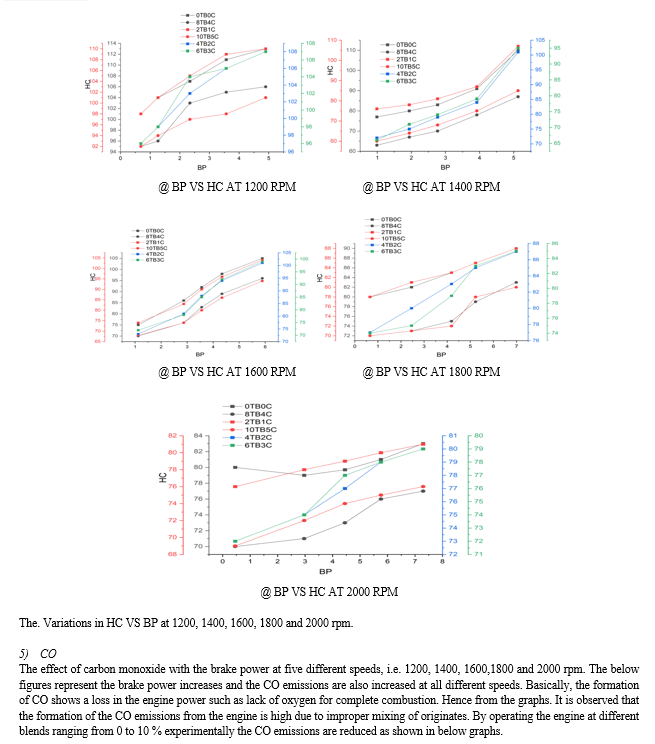

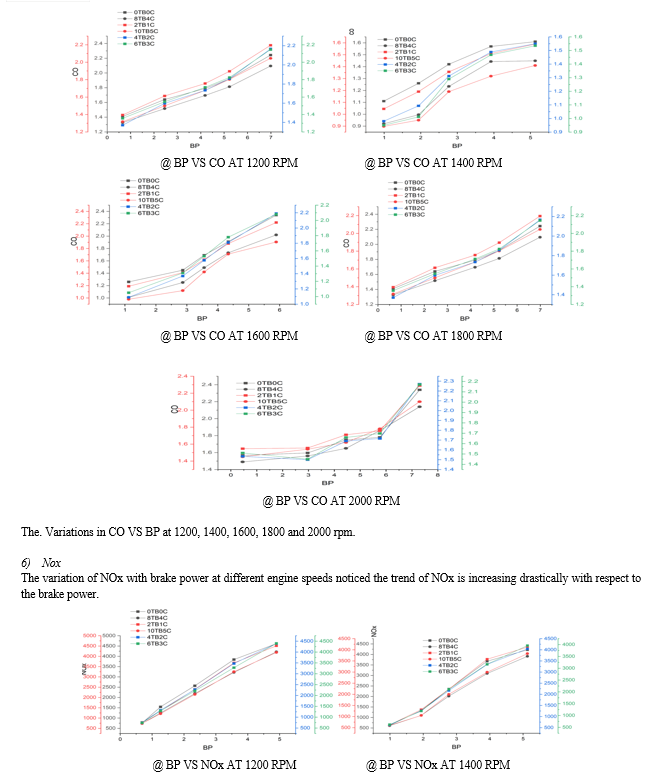

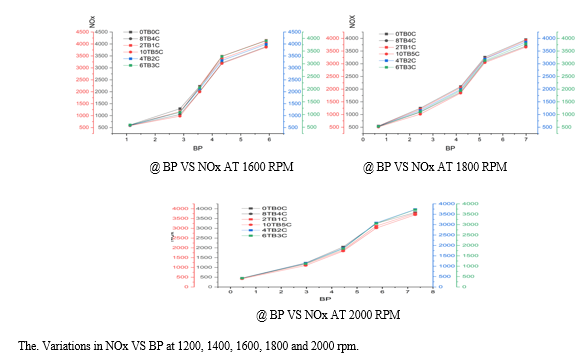

B. Performance Based on Analysis of Graphs

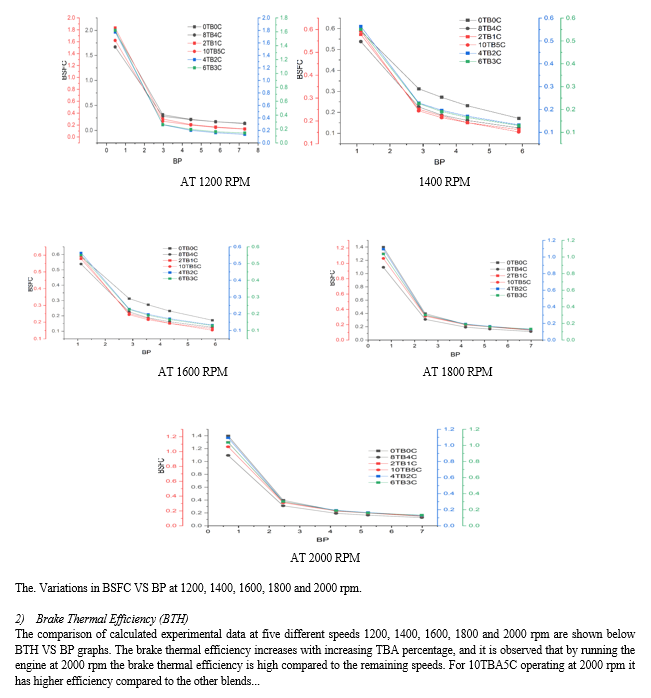

1) BSFC

The comparability of the calculated experimental data from the engine at five different engine speeds, i.e. at 1200,1400, 1600, 1800 and 2000 rpm are shown in below graphs. The blends 0TBA1C, 2TBA2C, 4TBA2C, 6TBA3C, 8TBA4C and 10TBA5C are calculated experimental data and represented by solid lines. By observing the graphs at five different speeds, the BSFC at no cognition is decreasing as the blend and speed increases.

Conclusion

The present work proves that the use of gasoline TBA and camphor oil blends will decrease in the BSFC and conversely increase in the brake thermal efficiency. It can be examined that as the gasoline, TBA and camphor oil percentage increases the brake thermal efficiency and volumetric efficiency increases. The exhaust emission such as CO, HC, NOx decreases when blend percentage increases compared with pure petrol.

References

[1] “Effects of Methanol/Gasoline Blends on a Spark Ignition Engine Performance and Emissions” Authors are ( Yanju Wei, Shengua Liu, Fangije Liu, Jie Liu, Zan Zhu and Guangie Li) published by ACS author choice. [2] “Performance and emission prediction of a tert butyl alcohol gasoline blended spark-ignition engine using artificial neural networks ’’ Authors are ( Puli danaiah, P.Ravi kumar and Y.V.H. Rao) and are published by Taylor and Francis publications. [3] “Alcohol based automotive fuels from first four alcohol family in compression and spark ignition engine’’: A review on engine performance and exhaust emissions” Authors are ( I.M. Yusri, R.Mamat, G.Najafi, A.Razman, Omar I. Awad, W.F.W Ishak) are published by ACS author choice. [4] “Effects of Propanol and Camphor Blended with Gasoline Fuel on the Performance and Emissions of a Spark Ignition Engine” Authors are( Muhammad Usman Kaisan, Latifat Ovaiyoza Yusuf, Ibrahim Umar Ibrahim, Shitu abubakar, and Sunny Narayan) published by ACS Author Choice. [5] “Evaluation of the fuel commercial additives effect on exhaust gas emissions, fuel consumption and performance in diesel and petrol engines”. I. Janosco and P. Kuchar Slovak University of Agriculture in Nitra, Technical Faculty, Department of Transport and Handling, Tr.A. Hlinku 2, SK949 76 Nitra, Slovak Republic. [6] “Effects of Propanol and Camphor Blended with Gasoline Fuel on the Performance and Emissions of a Spark Ignition Engine”, Muhammad Usman Kaisan, Latifat Ovaiyoza Yusuf, Ibrahim Umar Ibrahim, Shitu abubakar, and Sunny Narayan. [7] “Experimental study on the effects of camphor ethanol petrol blends in a spark ignition engine: performance and emissions analysis”, Sankar Shanmugasundaram *1 , Praveen Maruthur 2 , Manivarma Kumaresan 3 , Abhilash O. P 4 , Akhil Das K 5 , Manivarma Kumaresan 6 1,2,4,5,6 Department of Mechanical Engineering, Nehru College of Engineering and Research Centre, Pampady, Thrissur, India 3 Department of Mechanical Engineering, Sri Krishna College of Engineering and Technology, Kuniamuthur, Coimbatore, India. [8] “Performance, emission and combustion characteristics of a branched higher mass, C3 alcohol (isopropanol) blends fuelled medium duty MPFI SI engine”, Harish Sivasubramanian a, Yashwanth Kutti Pochareddy a , Gopinath Damodaran b, Ganapathy Sundaram Esakkimuthu . [9] “Emission and Combustion Characteristics of Si Engine Working Under Gasoline Blended with Ethanol Oxygenated Organic Compounds\' \'. 1 Dhanapal Balaji, 2 Periyasamy Govindarajan and 3 Jayaraj Venkatesan 1 Department of Mechanical Engineering, Panimalar institute of Technology, Chennai-602103 2 Department of Technology, Sona College, Salem-5 3 Department of Mechanical Engineering, Sree Venkateshwara College of Engineering, Chennai-6

Copyright

Copyright © 2024 Dr. Danaiah Puli, P P Rama Rao, B. Satish, K Venkateshwar Rao, D Shanmuka Reddy , M Trivedh. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63495

Publish Date : 2024-06-28

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online